无机材料学报 ›› 2018, Vol. 33 ›› Issue (6): 617-622.DOI: 10.15541/jim20170260 CSTR: 32189.14.10.15541/jim20170260

王景平1, 成方媛1, 杜显锋2, 徐友龙2

收稿日期:2017-05-25

修回日期:2017-11-15

出版日期:2018-06-20

网络出版日期:2018-05-24

作者简介:王景平(1973-), 男, 副教授. E-mail: wangjingping@sust.edu.cn

基金资助:WANG Jing-Ping1, CHENG Fang-Yuan1, DU Xian-Feng2, XU You-Long2

Received:2017-05-25

Revised:2017-11-15

Published:2018-06-20

Online:2018-05-24

About author:WANG Jing-Ping. E-mail: wangjingping@sust.edu.cn

Supported by:摘要:

通过提高工作介质氧化膜的介电常数来增加电容器的比容量, 是解决铝电解电容器小型化、轻量化常用的方法之一。本研究采用表面自组装法, 在铝箔表面引入磺酸基团使铝箔表面的荷电性质发生改变, 铝箔与二氧化钛前驱体胶粒间的静电斥力转变为静电引力, 从而增加了二氧化钛在铝箔表面的沉积量。经过热处理与阳极氧化后, 在铝箔表面形成了高介电常数Al2O3/TiO2复合膜。相对未涂覆TiO2的阳极铝箔, 采用表面自组装法制备的复合膜表面的钛含量增加了30倍, 其比容量在400 V耐压下提高了44.26%。本方法制备的大比容量阳极氧化铝箔在铝电解电容器行业有巨大的应用潜力。

中图分类号:

王景平, 成方媛, 杜显锋, 徐友龙. 表面自组装法制备高比容Al2O3/TiO2复合膜[J]. 无机材料学报, 2018, 33(6): 617-622.

WANG Jing-Ping, CHENG Fang-Yuan, DU Xian-Feng, XU You-Long. Preparation of Al2O3/TiO2 Composite film with High Specific Capacitance by Surface Self-assembly Method[J]. Journal of Inorganic Materials, 2018, 33(6): 617-622.

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Contact angle | 9.33° | 125.53° | 5.65° | 42.92° | 21.92° |

表1 不同处理阶段的铝箔接触角照片

Table 1 Contact angle photos of different processing stages of aluminum foil

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Contact angle | 9.33° | 125.53° | 5.65° | 42.92° | 21.92° |

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Zeta potential/mV | +75.25 | +97.97 | -55.91 | +37.24 | +2.68 |

表2 不同处理阶段铝箔表面Zeta电位

Table 2 Zeta potentials of aluminum foil surfaces on different processing stages

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Zeta potential/mV | +75.25 | +97.97 | -55.91 | +37.24 | +2.68 |

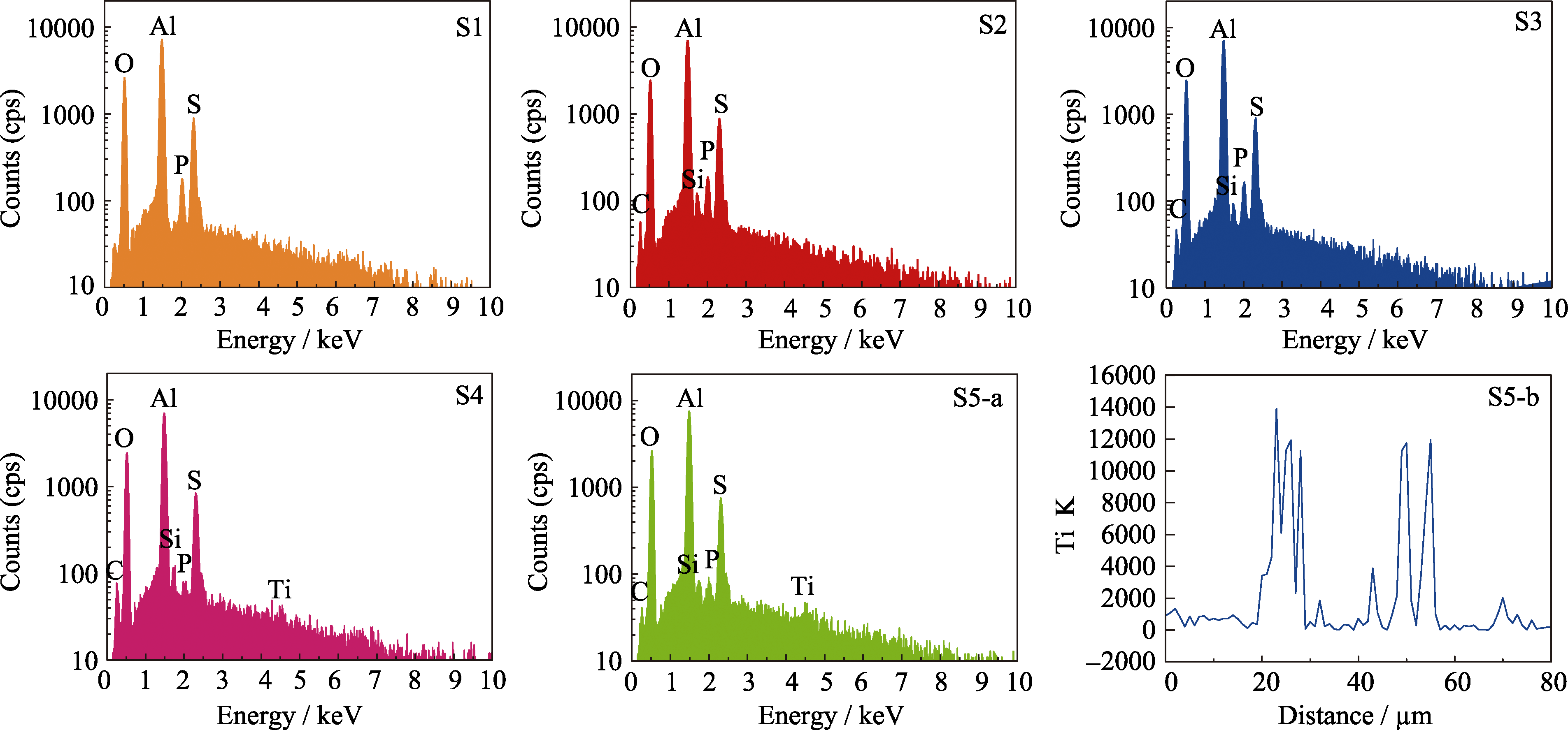

图3 不同处理条件下的铝箔EDAX图谱

Fig. 3 EDAX patterns of different processing stages of aluminum foilS1, S2, S3, S4, S5, and S5-a are the surface EDAX results while S5-b is S5 cross section results

| Specimens | C/ (nF•cm-2) | V/V | CV/ (nF•V•cm-2) | ΔC/% | ΔCV/% |

|---|---|---|---|---|---|

| S0 | 29.46 | 408 | 12019.68 | - | - |

| S6 | 32.85 | 402 | 13205.70 | 11.51 | 9.87 |

| S5 | 42.50 | 405 | 17212.50 | 44.26 | 43.20 |

表3 铝箔的电容器特征参数

Table 3 Capacitor characteristic parameters of anodic aluminum foils coated with or without TiO2

| Specimens | C/ (nF•cm-2) | V/V | CV/ (nF•V•cm-2) | ΔC/% | ΔCV/% |

|---|---|---|---|---|---|

| S0 | 29.46 | 408 | 12019.68 | - | - |

| S6 | 32.85 | 402 | 13205.70 | 11.51 | 9.87 |

| S5 | 42.50 | 405 | 17212.50 | 44.26 | 43.20 |

| [1] | DU XIAN-FENG, LIN BAI-GE, LI BING, et al. Surface modification of Al foils for aluminum electrolytic capacitor. Advanced Functional Materials, 2017, 27(11): 1-5. |

| [2] | DU XIAN-FENG, XU YOU-LONG.Formation of Al2O3-BaTiO3 composite thin film to increase the specific capacitance of aluminum electrolytic capacitor.Thin Solid Films, 2008, 516(23): 8436-8440. |

| [3] | Du XIAN-FENG, Xu YOU-LONG.Preparation and electrical properties of an anodized Al2O3-BaTiO3 composite film. Journal of the American Ceramic Society, 2008, 91(7): 2360-2363. |

| [4] | DU XIAN-FENG, MEN KAI, XU YOU-LONG,et al. Enhanced capacitance performance of Al2O3-TiO2 composite thin film via Sol-Gel using double chelators. Journal of Colloid Interface Science, 2015, 443: 170-176. |

| [5] | 杨邦朝, 冯哲圣, 陈金菊.纳米复合高介电常数铝氧化膜生长技术. 中国.C23C 18/00. CN1502719. 2004.6.19. |

| [6] | GU DE-EN, CHEN JIN-JU, FENG ZHE-SHENG,et al. Aluminum foil composite surface anodic oxidation film studies. Functional materials, 2004, 35(5): 600-602. |

| [7] | CHEN JIN-JU, FENG ZHE-SHENG, JIANG MEI-LIAN,et al. The effect of anodizing voltage on the electrical properties of Al-Ti composite oxide film on aluminum. Journal of Electroanalytical Chemistry, 2006, 590(1): 26-31. |

| [8] | CHEN JIN-JU, FENG ZHE-SHENG, GUO HONG-LEI,et al. Preparation of high dielectric constant composite oxide films for aluminum electrolytic capacitors. Materials Engineering, 2006 (2): 56-60. |

| [9] | CHEN JIN-JU, JIANG MEI-LIAN, FENG ZHE-SHENG,et al. Effects of technologycal parameters on specific capacitance of Al-Ti composite oxide films. Electronic Components and Materials, 2005, (8): 8-10. |

| [10] | CHEN JIN-JU, YANG BANG-CHAO, JIANG MEI-LIAN,et al. The effect of anodizing temperature on the structure and electrical properties of Al-Ti composite oxide film. Science in China Series E-Engineering & Materials Science, 2005, 48(6): 612-621. |

| [11] | CHEN JIN-JU, GU DE-EN, FENG ZHE-SHENG,et al. Formation of Al-Ti composite oxide films on aluminum by hydrolysis precipitation and anodizing. Journal of Functional Materials, 2005, 36(3): 399-401. |

| [12] | CHEN JIN-JU, FENG ZHE-SHENG, JIANG MEI-LIAN,et al. The effect of anodizing voltage on the electrical properities of Al-Ti composite oxide films on aluminum. Journal of Electronalytical Chemistry, 2006, 590: 26-31. |

| [13] | XU YOU-LONG.Al2O3-(Ba0.5Sr0.5)TiO3 composite oxide films on etched aluminum foil by Sol-Gel coating and anodizing.Ceramics International, 2004, 30(7): 1741-1743. |

| [14] | DUXIAN-FENG, XU YOU-LONG.Formation of Al2O3-Bi4Ti3O12 nanocomposite oxide films on low-voltage etched aluminum foil by Sol-Gel processing.Surface and Coatings Technology, 2008, 202(10): 1923-1927. |

| [15] | DU XIAN-FENG, XU YOU-LONG.Formation of Al2O3-BaTiO3 nanocomposite oxide films on etched aluminum foil by Sol-Gel coating and anodizing. Journal of Sol-Gel Science and Technology, 2008, 45(1): 57-61. |

| [1] | 王晓波, 朱于良, 薛稳超, 史汝川, 骆柏锋, 罗骋韬. PT含量变化对PMN-PT单晶的大功率性能影响[J]. 无机材料学报, 2025, 40(7): 840-846. |

| [2] | 汤新丽, 丁自友, 陈俊锐, 赵刚, 韩颖超. 基于稀土铕离子荧光标记的磷酸钙纳米材料体内分布与代谢研究[J]. 无机材料学报, 2025, 40(7): 754-764. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789. |

| [5] | 孙晶, 李翔, 毛小建, 章健, 王士维. 月桂酸改性剂对氮化铝粉体抗水解性能的影响[J]. 无机材料学报, 2025, 40(7): 826-832. |

| [6] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [7] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [8] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [9] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [10] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [11] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [12] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [13] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [14] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| [15] | 安然, 林锶, 郭世刚, 张冲, 祝顺, 韩颖超. 铁掺杂纳米羟基磷灰石的制备及紫外吸收性能研究[J]. 无机材料学报, 2025, 40(5): 457-465. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||