无机材料学报 ›› 2018, Vol. 33 ›› Issue (3): 259-265.DOI: 10.15541/jim20170180 CSTR: 32189.14.10.15541/jim20170180

杨景锋1, 2, 王齐华1, 王廷梅1

收稿日期:2017-04-17

修回日期:2017-06-04

出版日期:2018-03-20

网络出版日期:2018-03-12

作者简介:杨景锋(1978-), 男, 博士. E-mail: jfyang@licp.cas.cn

基金资助:YANG Jing-Feng1, 2, WANG Qi-Hua1, WANG Ting-Mei1

Received:2017-04-17

Revised:2017-06-04

Published:2018-03-20

Online:2018-03-12

About author:YANG Jing-Feng. E-mail: jfyang@licp.cas.cn

Supported by:摘要:

氧化铝气凝胶具有大比表面积、高孔隙率以及比氧化硅气凝胶更优异的热稳定性, 在高温隔热和催化领域有广阔的应用前景, 但其复杂的合成工艺和较低的强度限制了其应用。本文首先介绍氧化铝气凝胶合成工艺, 指出溶胶-凝胶过程中存在的问题, 不同干燥方式的特点以及最新发展的干燥工艺; 然后介绍了近年来氧化铝气凝胶在比表面积、热稳定性、强度、导热系数等性能改善方面所取得的代表性研究成果; 最后介绍了氧化铝气凝胶在高温催化、隔热领域的应用, 并展望了未来氧化铝气凝胶的发展方向以及应关注的问题。

中图分类号:

杨景锋, 王齐华, 王廷梅. 氧化铝气凝胶的合成与性能[J]. 无机材料学报, 2018, 33(3): 259-265.

YANG Jing-Feng, WANG Qi-Hua, WANG Ting-Mei. Synthesis and Property of Alumina Aerogel[J]. Journal of Inorganic Materials, 2018, 33(3): 259-265.

| Drying method | Characteristics | |

|---|---|---|

| Drying process | Alumina aerogel | |

| Supercritical drying | Short drying period, high synthesis cost | Low density, high porosity and specific surface area, low volume shrinkage[ |

| Ambient pressure drying | Long drying period, inexpensive synthesis cost, complicated drying process | High volume shrinkage, large pore size, high density and low specific surface area [ |

| Freeze drying | Long drying period, inexpensive synthesis cost | High volume shrinkage, large pore size, high density and low specific surface area |

表1 几种干燥方式的特点

Table 1 Characteristics of several drying methods

| Drying method | Characteristics | |

|---|---|---|

| Drying process | Alumina aerogel | |

| Supercritical drying | Short drying period, high synthesis cost | Low density, high porosity and specific surface area, low volume shrinkage[ |

| Ambient pressure drying | Long drying period, inexpensive synthesis cost, complicated drying process | High volume shrinkage, large pore size, high density and low specific surface area [ |

| Freeze drying | Long drying period, inexpensive synthesis cost | High volume shrinkage, large pore size, high density and low specific surface area |

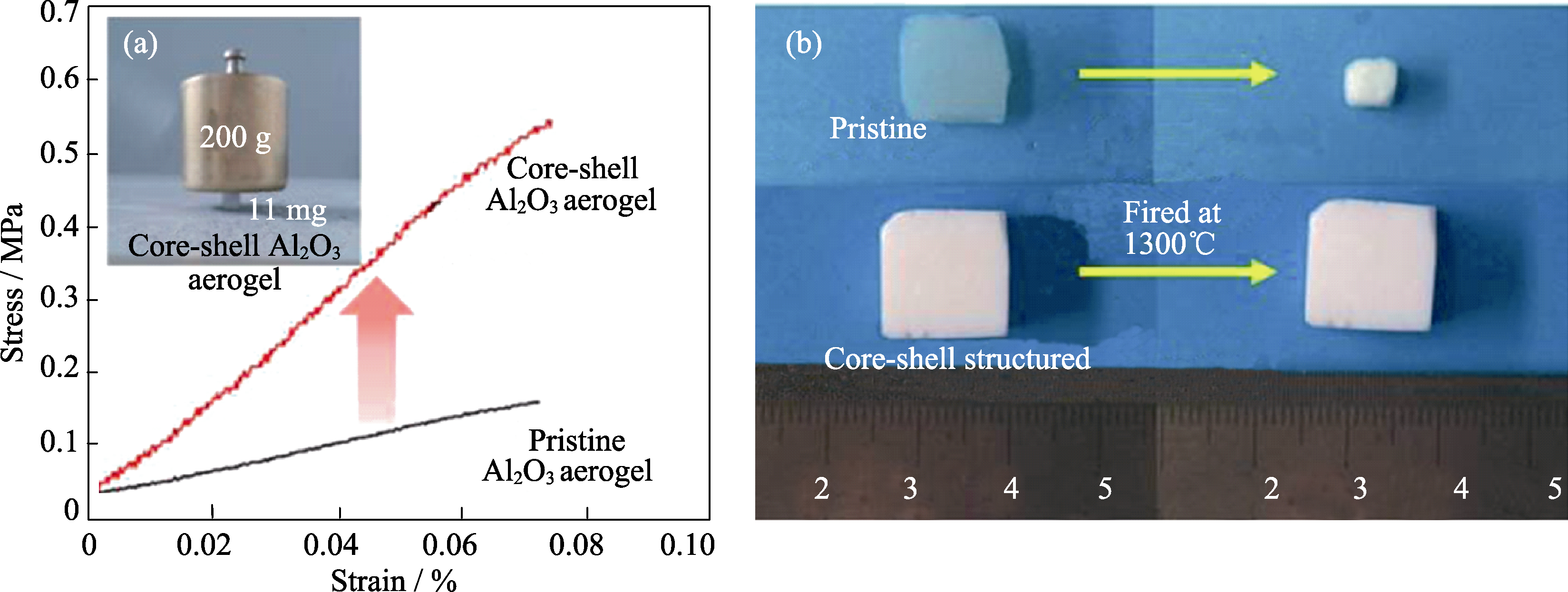

图5 Al2O3气凝胶的应力应变曲线(a)和高温热处理前后Al2O3气凝胶(b)[48]

Fig. 5 Stress-strain curves of Al2O3 aerogels (a) and Al2O3 aerogels before and after heat treatment at high temperature (b)[48]

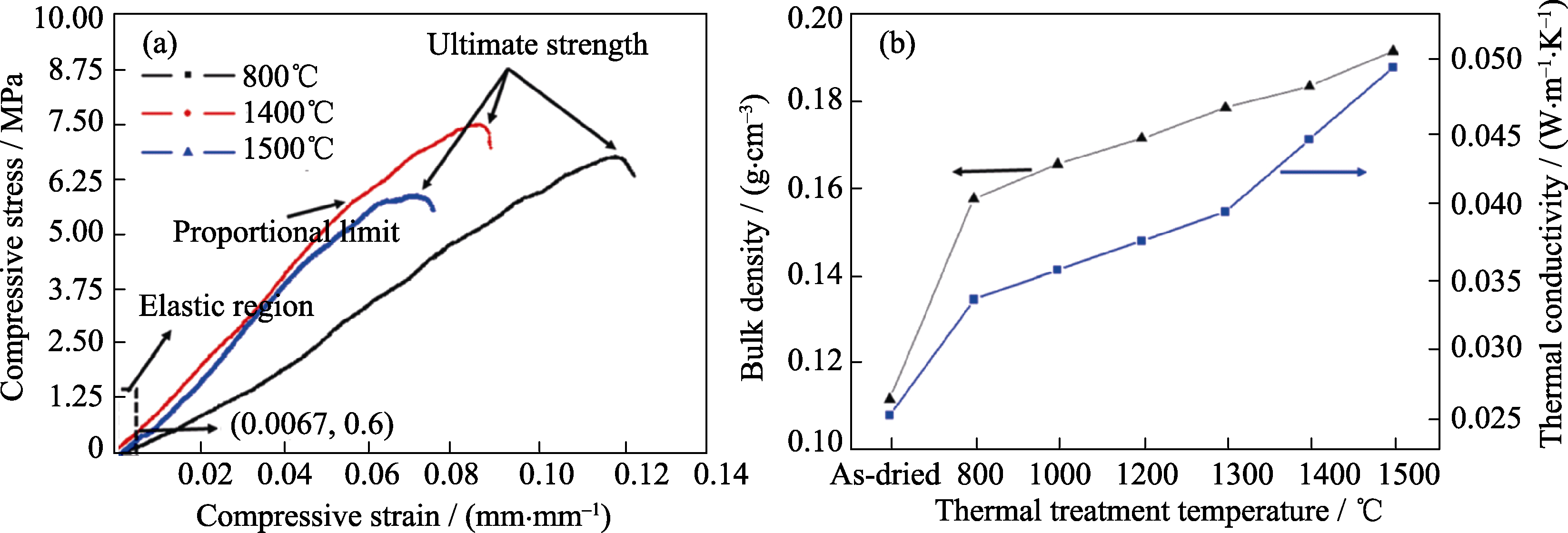

图6 C/Al2O3气凝胶不同温度热处理后的应力-应变曲线(a)和密度、导热系数变化(b)[50]

Fig. 6 Compressive stress-strain curves (a) and bulk densities and thermal conductivities (b) of C/Al2O3 aerogels heat treated at different temperatures[50]

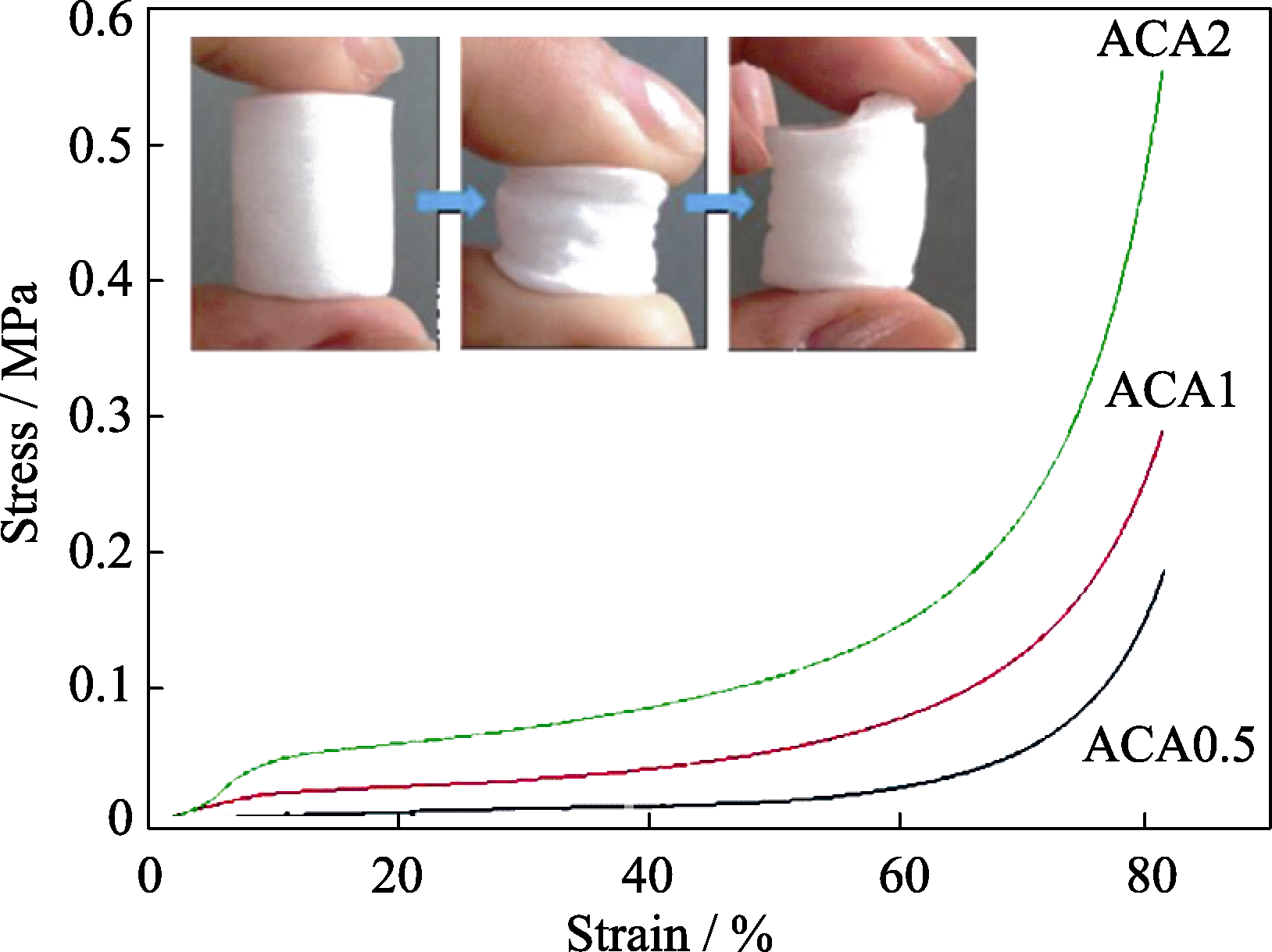

图7 不同纤维素含量ACA的应力应变曲线(ACA0.5, ACA1, ACA2分别为纤维素含量0.5%, 1%, 2%)[51]

Fig. 7 Stress-strain curves of ACAs with different contents of cellulose (ACA0.5, ACA1 and ACA2 corresponding to the cellulose content of 0.5wt%, 1wt% and 2wt%, respectively)[51]

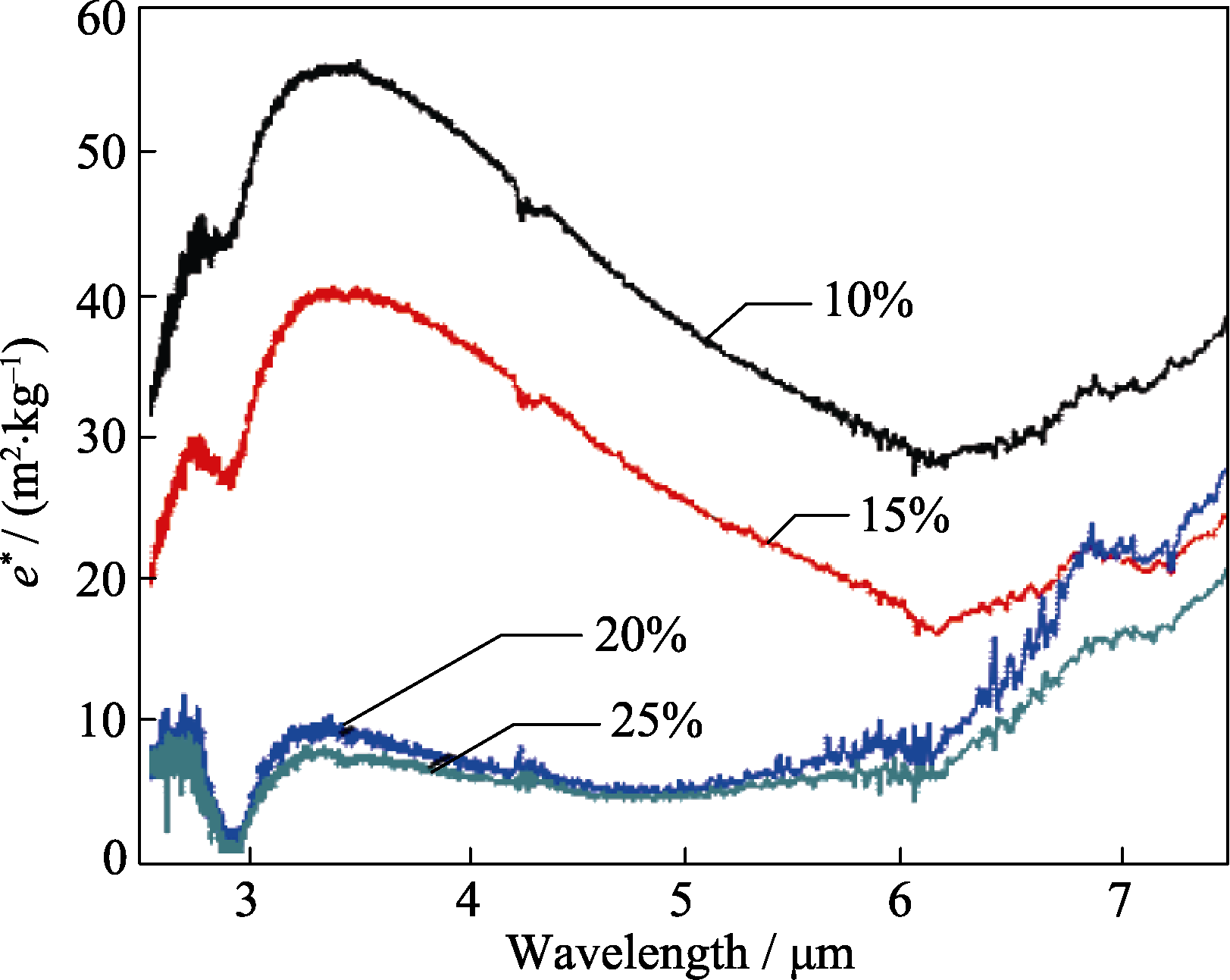

图8 不同前驱物浓度得到的SiC涂层的莫来石纤维/Al2O3- SiO2气凝胶的有效比消光系数[52]

Fig. 8 Effective specific extinction coefficient of Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers prepared with different concentration of precursor[52]

| [1] | AMEEN K B, RAJASEKAR K, RAJASEKHARAN T, et al.The effect of heat-treatment on the physico-chemical properties of silica aerogel prepared by sub-critical drying technique. Journal of Sol-Gel Science and Technology, 2008, 45(1): 9-15. |

| [2] | HURWITZ F I, GUO H, ROGERS R B, et al.Influence of Ti addition on boehmite-derived aluminum silicate aerogels: structure and properties. Journal of Sol-Gel Science and Technology, 2012, 64(2): 367-374. |

| [3] | JUHL S J, DUNN N J H, CARROLL M K, et al. Epoxide-assisted alumina aerogels by rapid supercritical extraction. Journal of Non-Crystalline Solids, 2015, 426: 141-149. |

| [4] | SMITH S J, HUANG B, BARTHOLOMEW C H, et al.La-dopant location in La-doped γ-Al2O3 nanoparticles synthesized using a novel one-pot process. The Journal of Physical Chemistry C, 2015, 119(44): 25053-25062. |

| [5] | WEI Q, CHEN Z X, WANG Z H, et al.Effect of La, Ce, Y and B addition on thermal stability of unsupported alumina membranes. Journal of alloys and compounds, 2005, 387(1): 292-296. |

| [6] | JR. M S B, ANDERSON A M, CARROLL M K. Alumina aerogels prepared via rapid supercritical extraction .[J]. Sol-Gel Sci. Technol., 2010, 53(2010): 216-226. |

| [7] | AL-YASSIR N, LE VAN MAO R. Thermal stability of alumina aerogel doped with yttrium oxide, used as a catalyst support for the thermocatalytic cracking (TCC) process: an investigation of its textural and structural properties. Applied Catalysis A: General, 2007, 317(2): 275-283. |

| [8] | OZAWA M. Thermal stabilization of catalytic compositions for automobile exhaust treatment through rare earth modification of alumina nanoparticle support. Journal of Alloys and Compounds, 2006, 408-412: 1090-1095. |

| [9] | CHEN X, LIU Y, NIU G, et al.High temperature thermal stabilization of alumina modified by lanthanum species. Applied Catalysis A: General, 2001, 205(1): 159-172. |

| [10] | GUIDOTTI R A, REED S T, ASHLEY C S, et al.Evaluation of Aerogel Materials for High-Temperature Batteries. SAE International, 1999. |

| [11] | AEGERTER M A, LEVENTIS N, KOEBEL M M.Aerogels handbook. Springer Science & Business Media, 2011. |

| [12] | JONES S M.Aerogel: Space exploration applications. Journal of Sol-Gel Science and Technology, 2006, 40(2/3): 351-357. |

| [13] | HURWITZ F I. Thermal Protection Systems (TPSs). In book: Richard Blockley, Wei Shyy, Encyclopedia of Aerospace Engineering. John Wiley & Sons, Ltd. 2010: 1-13. |

| [14] | YANG X, WEI J, SHI D, et al.Comparative investigation of creep behavior of ceramic fiber-reinforced alumina and silica aerogel. Materials Science and Engineering: A, 2014, 609: 125-130. |

| [15] | YANG J, LI S, LUO Y, et al.Compressive properties and fracture behavior of ceramic fiber-reinforced carbon aerogel under quasi-static and dynamic loading. Carbon, 2011, 49(5): 1542-1549. |

| [16] | ZU G, SHEN J, WEI X, et al.Preparation and characterization of monolithic alumina aerogels. Journal of, 2011, 357(15): 2903-2906. |

| [17] | BAUMANN T F, GASH A E, CHINN S C, et al.Synthesis of high-surface-area alumina aerogels without the use of alkoxide precursors. Chemistry of Materials, 2005, 17(2): 395-401. |

| [18] | JI L, LIN J, TAN K, et al.Synthesis of high-surface-area alumina using aluminum tri-sec-butoxide-2, 4-pentanedione-2-propanolnitric acid precursors. Chemistry of Materials, 2000, 12(4): 931-939. |

| [19] | POCO J, SATCHER J, HRUBESH L.Synthesis of high porosity, monolithic alumina aerogels. Journal of Non-Crystalline Solids, 2001, 285(1): 57-63. |

| [20] | PIERRE A, BEGAG R, PAJONK G.Structure and texture of alumina aerogel monoliths made by complexation with ethyl acetoacetate. Journal of Materials Science, 1999, 34(20): 4937-4944. |

| [21] | PIERRE A C, PAJONK G M.Chemistry of aerogels and their applications. Chemical Reviews, 2002, 102(11): 4243-4266. |

| [22] | GAO Q F, ZHANG C R, FENG J, et al.Preparation of low density, monolithic alumina aerogels. Chinese Journal of Inorganic Chemistry, 2008, 9: 19-25. |

| [23] | ZU G, SHEN J, ZOU L, et al.Nanoengineering super heat-resistant, strong alumina aerogels. Chemistry of Materials, 2013, 25(23): 4757-4764. |

| [24] | JANOSOVITS U, ZIEGLER G, SCHARF U, et al.Structural characterization of intermediate species during synthesis of Al2O3- aerogels. Journal of Non-crystalline Solids, 1997, 210(1): 1-13. |

| [25] | HORIUCHI T, CHEN L, OSAKI T, et al.A novel alumina catalyst support with high thermal stability derived from silica-modified alumina aerogel. Catalysis Letters, 1999, 58(2/3): 89-92. |

| [26] | OSAKI T, NAGASHIMA K, WATARI K, et al.Silica-doped alumina cryogels with high thermal stability. Journal of Non-crystalline Solids, 2007, 353(24): 2436-2442. |

| [27] | HE FEI, HE XIAO-DONG, LI YAO.Al2O3 Xerogels synthesized by inorganic salt and organic alkoxide. Journal of the Chinese Ceramic Society, 2006, 34(9): 1093-1097. |

| [28] | HAO Z, LIU H, GUO B, et al.Sol-Gel synthesis of alumina using inorganic salt precursor. Acta Physico-Chimica Sinica, 2007, 23(3): 289-294. |

| [29] | GASH A E, TILLOTSON T M, SATCHER J H, et al.Use of epoxides in the Sol-Gel synthesis of porous iron (III) oxide monoliths from Fe (III) salts. Chemistry of Materials, 2001, 13(3): 999-1007. |

| [30] | GASH A E, TILLOTSON T M, SATCHER JR J H, et al. New Sol-Gel synthetic route to transition and main-group metal oxide aerogels using inorganic salt precursors. Journal of, 2001, 285(1): 22-28. |

| [31] | XU ZI-JIE, GAN LI-HUA, PANG YING-CONG, et al.Preparation of Al2O3 bulk aerogels by non-supercritical fluid drying technology. Acta Phys.-Chim.Sin., 2005, 21(2): 221-224. |

| [32] | WU X, SHAO G, SHEN X, et al.Novel Al2O3-SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method. RSC Adv, 2016, 6(7): 5611-5620. |

| [33] | JUHL S J, DUNN N J H, CARROLL M K, et al. Epoxide-assisted alumina aerogels by rapid supercritical extraction. Journal of, 2015, 426: 141-149. |

| [34] | SHEWALE P M, RAO A V, RAO A P.Effect of different trimethyl silylating agents on the hydrophobic and physical properties of silica aerogels. Applied Surface Science, 2008, 254(21): 6902-6907. |

| [35] | HILONGA A, KIM J K, SARAWADE P B, et al.Low-density TEOS-based silica aerogels prepared at ambient pressure using isopropanol as the preparative solvent. Journal of Alloys and Compounds, 2009, 487(1): 744-750. |

| [36] | WU L, HUANG Y, WANG Z, et al.Fabrication of hydrophobic alumina aerogel monoliths by surface modification and ambient pressure drying. Applied Surface Science, 2010, 256(20): 5973-5977. |

| [37] | TALEBI MAZRAEH-SHAHI Z, MOUSAVI SHOUSHTARI A, BAHRAMIAN A R, et al. Synthesis, pore structure and properties of polyurethane/silica hybrid aerogels dried at ambient pressure. Journal of Industrial and Engineering Chemistry, 2015, 21: 797-804. |

| [38] | YANG J, WANG Q, WANG T, et al.Facile one-step precursor- to-aerogel synthesis of silica-doped alumina aerogels with high specific surface area at elevated temperatures. Journal of Porous Materials, 2017, 24(4): 889-897. |

| [39] | REN L, CUI S, CAO F, et al.An easy way to prepare monolithic inorganic oxide aerogels. Angew Chem. Int. Ed. Engl., 2014, 53(38): 10147-10149. |

| [40] | ZHONG X, ZHAO H, LIU C, et al.Improvement in thermal shock resistance of gadolinium zirconate coating by addition of nanostructured yttria partially-stabilized zirconia. Ceramics International, 2015, 41(6): 7318-7324. |

| [41] | TATSURO H, TOSHIHIKO O, TOYOHIKO S, et al.Maintenance of large surface area of alumina aerogel heated at elevated temperature above 1300 by preparing silica-containing aerogel. Journal of, 2001, 291(3): 187-198. |

| [42] | MIZUSHIMA Y, HORI M.Preparation of heat-resistant alumina aerogels. Journal of Materials Research, 1993, 8(11): 2993-2999. |

| [43] | YANG J, WANG Q, WANG T, et al.Rapid preparation process, structure and thermal stability of lanthanum doped alumina aerogels with a high specific surface area. RSC Adv, 2016, 6(31): 26271-26279. |

| [44] | BANG Y, SEO J G, SONG I K.Hydrogen production by steam reforming of liquefied natural gas (LNG) over mesoporous Ni- La-Al2O3 aerogel catalysts: effect of La content. International Journal of Hydrogen Energy, 2011, 36(14): 8307-8315. |

| [45] | ALPHONSE P, FAURE B.Thermal stabilization of alumina modified by lanthanum. Microporous and Mesoporous Materials, 2014, 196: 191-198. |

| [46] | WU X, SHAO G, CUI S, et al.Synthesis of a novel Al2O3-SiO2 composite aerogel with high specific surface area at elevated temperatures using inexpensive inorganic salt of aluminum. Ceramics International, 2016, 42(1): 874-882. |

| [47] | WU X, SHAO G, SHEN X, et al.Novel Al2O3-SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method. RSC Adv., 2016, 6(7): 5611-5620. |

| [48] | ZU G, SHEN J, WANG W, et al.Robust, highly thermally stable, core-shell nanostructured metal oxide aerogels as high-temperature thermal superinsulators, adsorbents, and catalysts. Chemistry of Materials, 2014, 26(19): 5761-5772. |

| [49] | CAO F, REN L, LI X.Synthesis of high strength monolithic alumina aerogels at ambient pressure. RSC Adv., 2015, 5(23): 18025-18028. |

| [50] | WU X, ZHONG Y, KONG Y, et al.Preparation and characterization of C/Al2O3 composite aerogel with high compressive strength and low thermal conductivity. Journal of Porous Materials, 2015, 22(5): 1235-1243. |

| [51] | HE F, SUI C, HE X, et al.Facile synthesis of strong alumina- cellulose aerogels by a freeze-drying method. Materials Letters, 2015, 152: 9-12. |

| [52] | XU L, JIANG Y, FENG J, et al.Infrared-opacified Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations. Ceramics International, 2015, 41(1): 437-442. |

| [53] | YOO J, BANG Y, HAN S J, et al.Hydrogen production by steam reforming of liquefied natural gas (LNG) over magnesium-doped nickel-alumina aerogel catalyst. Journal of Nanoscience and Nanotechnology, 2016, 16(10): 10835-10840. |

| [54] | HAO Z, ZHU Q, JIANG Z, et al.Characterization of aerogel Ni/Al2O3 catalysts and investigation on their stability for CH4-CO2 reforming in a fluidized bed. Fuel Processing Technology, 2009, 90(1): 113-121. |

| [55] | CHEN JI-XIANG, WANG RI-JIE, LI YU-MIN, et al.Study of nickel-based aerogel catalyzing CO2 reforming of CH4 to synthesis gas. Journal of Fuel Chemistry and Technology, 2002, 30(1): 45-48. |

| [56] | MI YU-HONG, ZHANG XIAO-BIN, LUO JUN-HANG, et al.Influence of calcining temperature of aerogel catalyst on its catalytic activity for synthesizing SWNTs. Journal of Inorganic Materials, 2007, 22(4): 604-608. |

| [57] | GAO QING-FU, ZHANG CHANG-RUI, FENG JIAN, et al.Preparation and thermal performance of alumina aerogel insulation composites. Journal of National University of Denfense Technology, 2008, 30(4): 39-42. |

| [58] | JIANG YING-YING, ZHANG LIN-PING, XU HONG, et al.Preparation and characterization of thermal protective aluminum hydroxide aerogel/PSA fabric composites. Journal of Sol-Gel Science and, 2017, 82(2): 370-379. |

| [59] | XIE HONG-YAN, YANG WEI, YUEN ANTHONY CHUN YIN, et al. Study on flame retarded flexible polyurethane foam/alumina aerogel composites with improved fire safety. Chemical Engineering Journal, 2017, 311: 310-317. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 陈相杰, 李玲, 雷添福, 王佳佳, 汪尧进. 相界工程和畴工程调控(1-x)(0.8PZT-0.2PZN)-xBZT陶瓷的压电性能[J]. 无机材料学报, 2025, 40(6): 729-734. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [5] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [6] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [7] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [8] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [9] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [10] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [11] | 孙雨萱, 王政, 时雪, 史颖, 杜文通, 满振勇, 郑嘹赢, 李国荣. 缺陷偶极子热稳定性对Fe掺杂PZT陶瓷机电性能影响研究[J]. 无机材料学报, 2025, 40(5): 545-551. |

| [12] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [13] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [14] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| [15] | 万俊池, 杜路路, 张永上, 李琳, 刘建德, 张林森. Na4FexP4O12+x/C钠离子电池正极材料的结构演变及其电化学性能[J]. 无机材料学报, 2025, 40(5): 497-503. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||