无机材料学报 ›› 2014, Vol. 29 ›› Issue (3): 225-236.DOI: 10.3724/SP.J.1077.2014.13170 CSTR: 32189.14.SP.J.1077.2014.13170

• • 下一篇

李建林1, 陈彬彬1, 章 文1, 王连军2, 江 莞2

收稿日期:2013-03-25

修回日期:2013-06-30

出版日期:2014-03-20

网络出版日期:2014-02-18

基金资助:LI Jian-Lin1, CHEN Bin-Bin1, ZHANG Wen1, WANG Lian-Jun2, JIANG Wan2

Received:2013-03-25

Revised:2013-06-30

Published:2014-03-20

Online:2014-02-18

Supported by:摘要:

石墨烯是2004年首次成功制备的新型二维碳纳米材料。由于其独特的二维结构和优异的性能, 近年来已成为国内外材料领域的研究热点。本文结合本课题组的相关工作, 综述了石墨烯应用于陶瓷块体复合材料的新近研究成果,包括碳纳米管、SiOC、Al2O3以及Si3N4等为基体的石墨烯块体复合材料,重点介绍了陶瓷/石墨烯块体复合材料的制备方法、增韧机制以及优异的物化性能, 并探讨了陶瓷/石墨烯块体复合材料的研究发展方向和应用前景。

中图分类号:

李建林, 陈彬彬, 章 文, 王连军, 江 莞. 陶瓷/石墨烯块体复合材料的研究进展[J]. 无机材料学报, 2014, 29(3): 225-236.

LI Jian-Lin, CHEN Bin-Bin, ZHANG Wen, WANG Lian-Jun, JIANG Wan. Recent Progress in Ceramic/Graphene Bulk Composites[J]. Journal of Inorganic Materials, 2014, 29(3): 225-236.

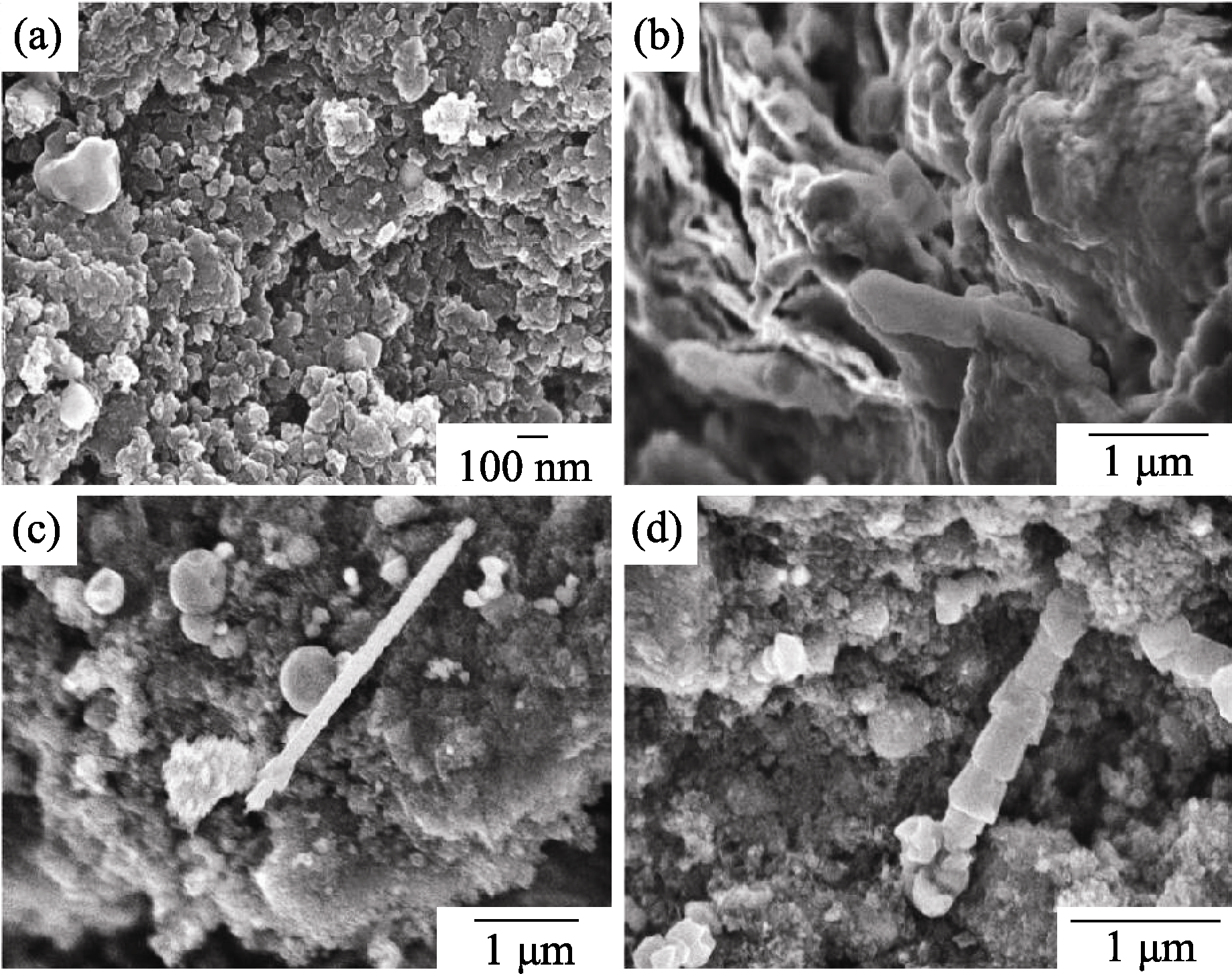

图2 球磨后的粉体FESEM照片

Fig. 2 FESEM micrographs of high energy ball milled graphite powder (a) As-milled graphite powder; (b) Graphite layers with a thickness of 20-50 nm that were highly distorted due to heavy impact of milling balls; (c) and (d) Carbon tubes with a diameter of 80-300 nm and a length of several microns produced during the milling[15]

图3 TiC/C复合材料断面的FESEM照片, 展示了纳米尺寸的石墨烯片和碳管, 约15%的孔隙率, 且平均孔径为3 μm[15]

Fig. 3 FESEM micrographs showing nanosized graphene sheets and carbon tubes on fractured surface of TiC/C composite and pores of an average size of about 3 μm with a porosity of about 15%[15]

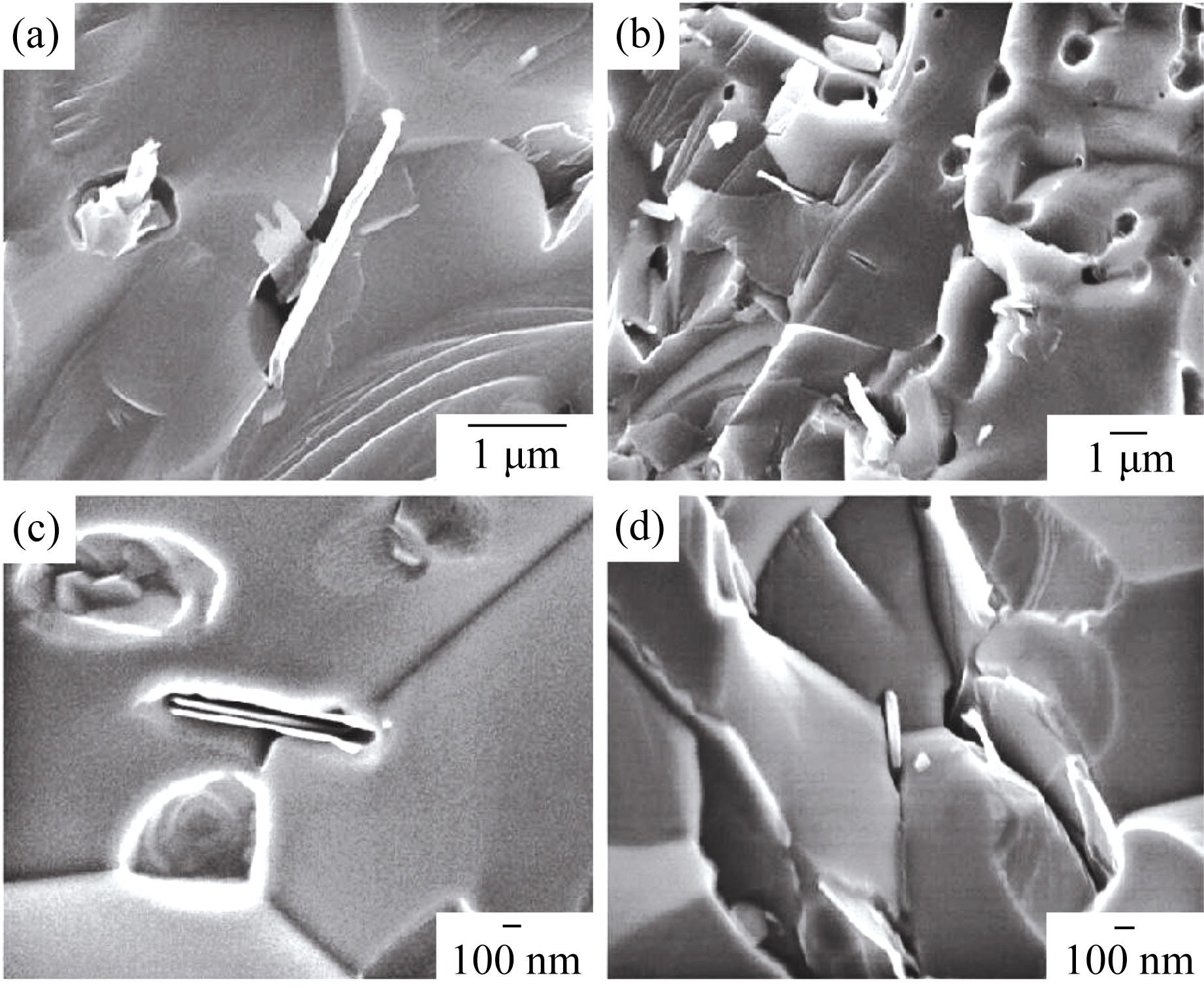

图4 FESEM照片: (a)未经处理的作为起始原料的多壁碳纳米管; (b)和(c)摩擦抛光后的多壁碳纳米管表面((b)一个由高密度聚集的碳纳米管构成的有光泽表面, (c)从密集到疏松过渡的碳纳米管); (d)摩擦抛光后的块体材料表面, 在表面的多壁碳纳米管结构已经发生改变, 外凸的石墨烯壁从碳管上脱落[16]

Fig. 4 FESEM micrographs showing: (a) the raw MWCNTs used as the starting material; (b-c) polished surface with a scratch of MWCNTs ((b) a shiny surface comprised of high- density aggregation CNTs; (c) transition from the dense to the loose CNTs); (d) polished surface with a scratch on it, MWCNTs in the surface have changed their structure and the outer graphene walls have come off the tubes[16]

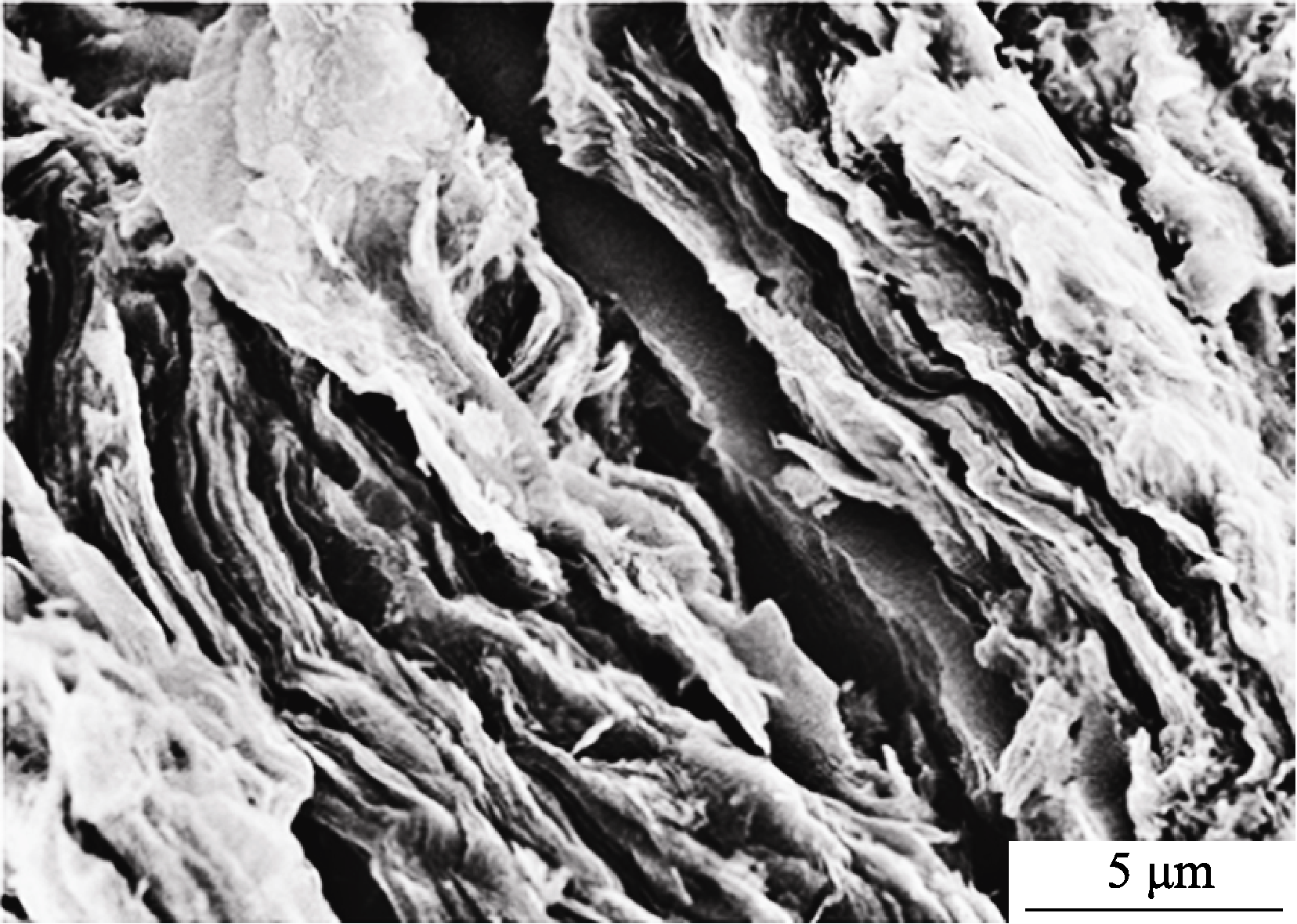

图5 SiOC/GNS 断面SEM照片, 石墨烯在陶瓷中形成片层状结构, 呈一定取向分布[20]

Fig.5 SEM image of the fracture surface of SiOC/GNS composite, with graphene forming a lamellar structure of a certain aligned distribution in the ceramic matrix[20]

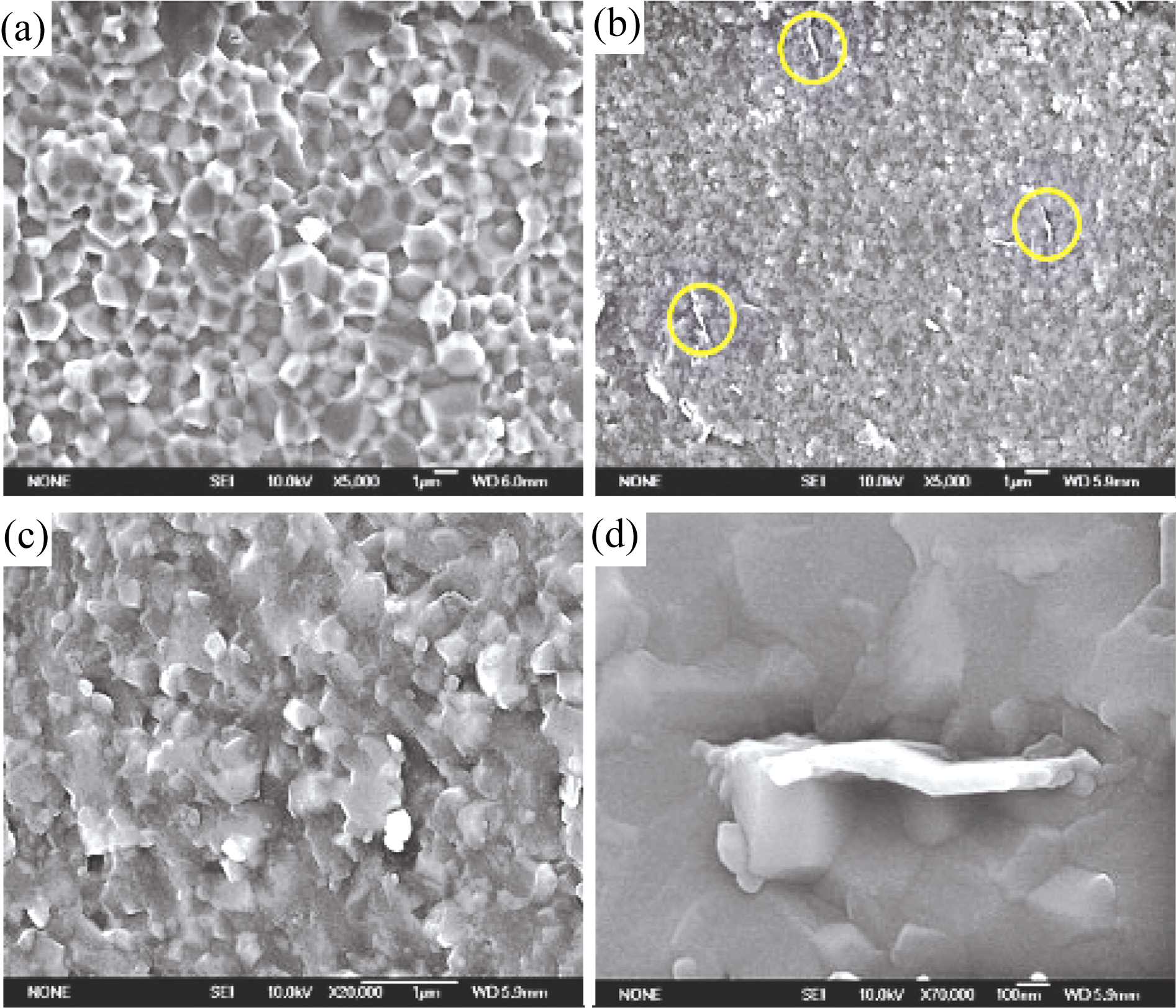

图 7 纯氧化铝陶瓷(a)及GNSs含量为 1vol%的GNS/ Al2O3复合材料(b~d)的断面SEM照片[22]

Fig. 7 SEM images of fractured surfaces of a pure Al2O3 ceramic (a) and a GNS/Al2O3 composite containing 1vol% GNSs (b-d) (c) and (d) are magnified parts of (b)[22]

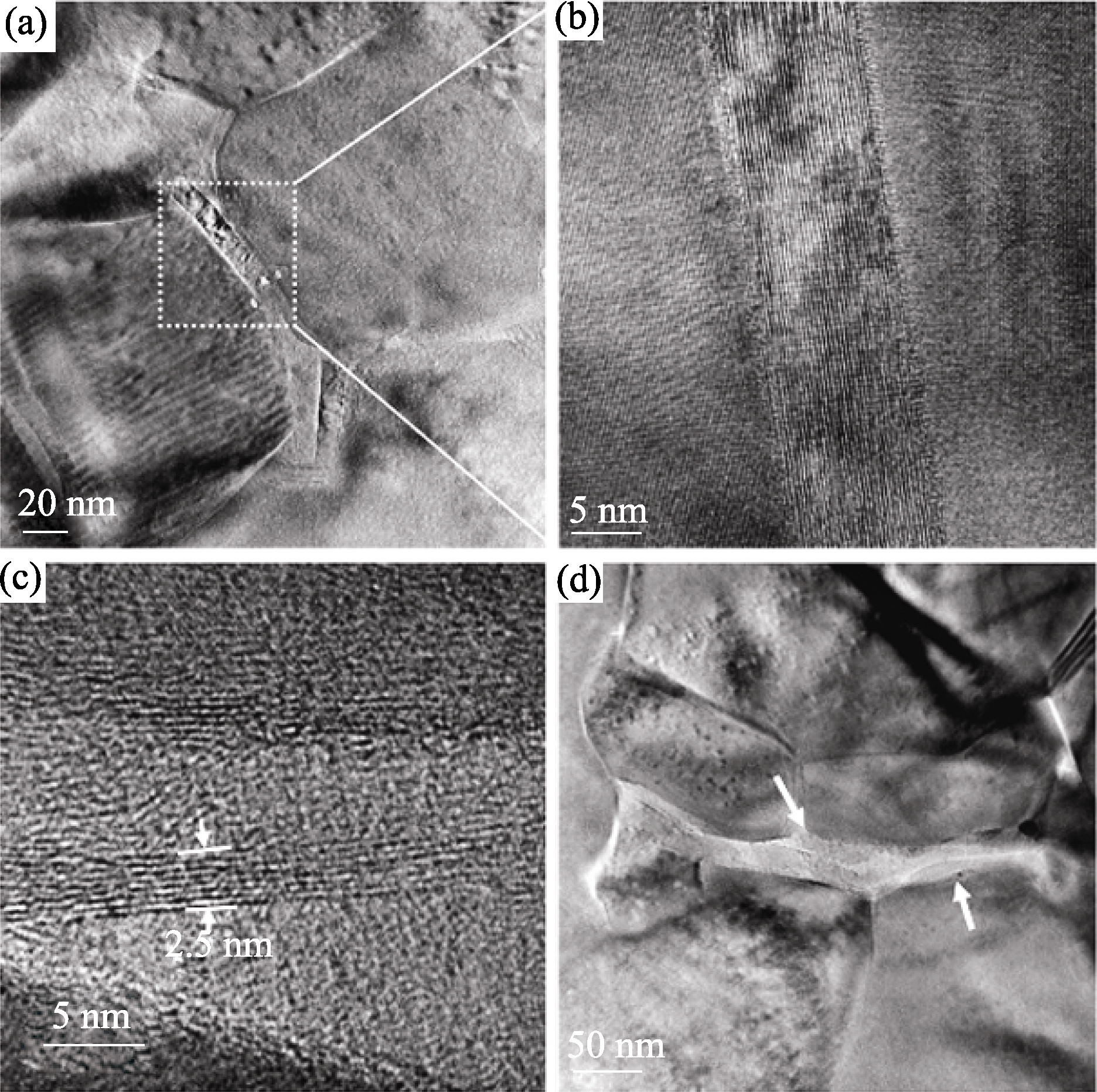

图 8 GNSs含量为 5vol%的GNS/Al2O3 复合材料的TEM和HRTEM照片

Fig. 8 TEM and HRTEM images of a GNS/Al2O3composite containing 5vol% GNSs (a) GNSs surrounding Al2O3 nanoparticles; (b) A magnified image of GNSs with a thickness of about 10 nm in (a); (c) GNSs with a thickness of 2.5 nm; (d) Overlap of GNSs between Al2O3 nano-particles[22]

| Starting powders / wt% | Additives / wt% | Type of GPL additive | Hardness HV/GPa | Fracture toughness KIC/(MPa•m1/2) | ||

|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | Y2O3 | C | |||

| 90 | 4 | 6 | 1 | Multilayer graphene | 16.38 ± 0.48 | 9.92 ± 0.38 |

| 90 | 4 | 6 | 1 | Nanographene platelets:Angstron Noo6-010-P | 14.59 ± 0.43 | 8.89 ± 0.37 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-25 | 15.05 ± 0.31 | 8.62 ± 0.17 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-5 | 14.59 ± 0.25 | 7.84 ± 0.43 |

| 90 | 4 | 6 | 0 | - | 15.38 ± 0.48 | 6.89 ± 0.39 |

表1 不同Si3N4/石墨烯复合材料的力学性能[34]

Table 1 Mechanical properties of different Si3N4/graphene composites [34]

| Starting powders / wt% | Additives / wt% | Type of GPL additive | Hardness HV/GPa | Fracture toughness KIC/(MPa•m1/2) | ||

|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | Y2O3 | C | |||

| 90 | 4 | 6 | 1 | Multilayer graphene | 16.38 ± 0.48 | 9.92 ± 0.38 |

| 90 | 4 | 6 | 1 | Nanographene platelets:Angstron Noo6-010-P | 14.59 ± 0.43 | 8.89 ± 0.37 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-25 | 15.05 ± 0.31 | 8.62 ± 0.17 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-5 | 14.59 ± 0.25 | 7.84 ± 0.43 |

| 90 | 4 | 6 | 0 | - | 15.38 ± 0.48 | 6.89 ± 0.39 |

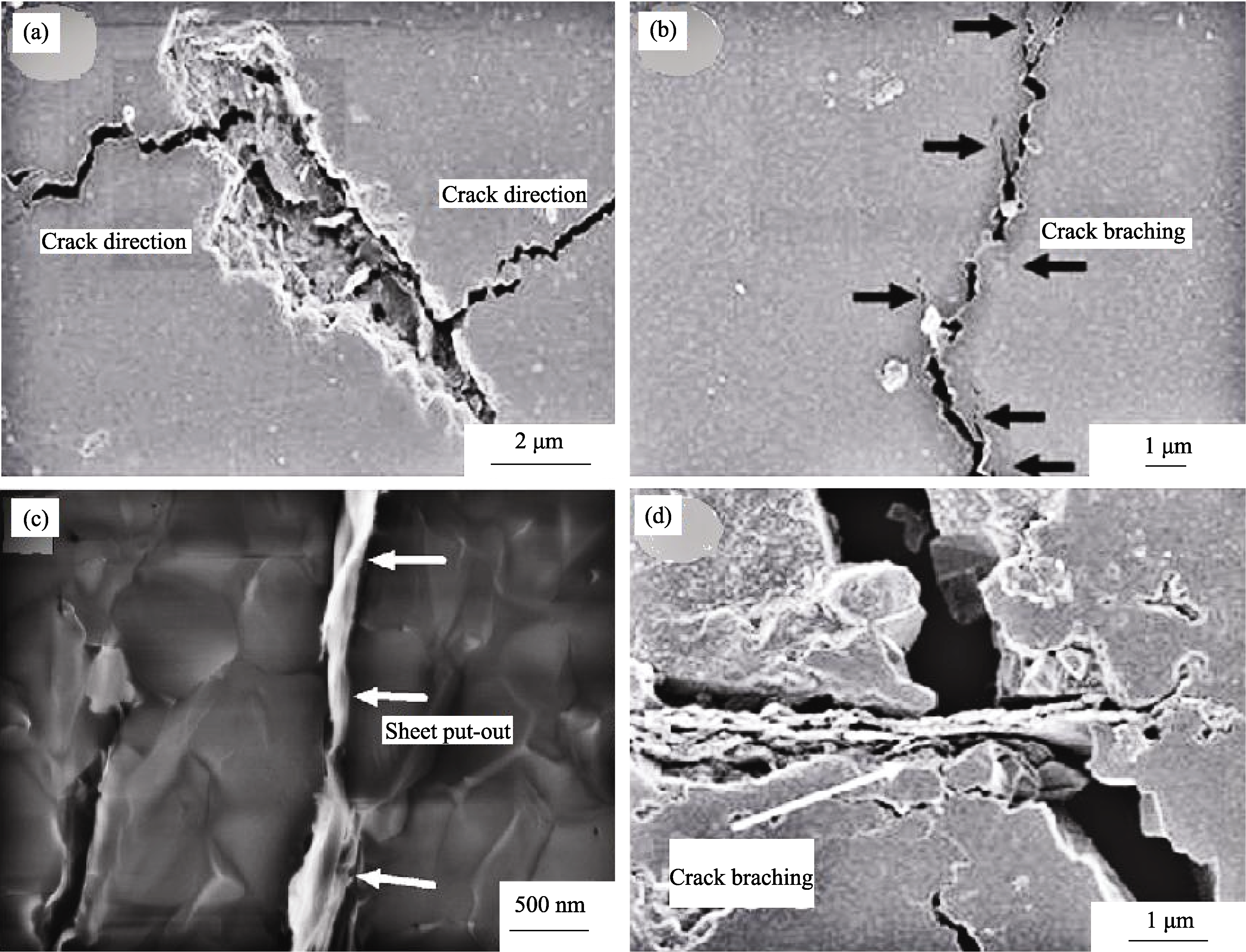

图 10 复合材料的增韧机制

Fig. 10 Toughening mechanisms of composites (a) Crack deflection on a plane with larger size and crack plane orientation almost parallel (fracture line)[29]; (b) Crack branching during crack propagation in the nanographene platelet-reinforced composite (fracture line)[34]; (c) Sheet put-out with a GPL on the fracture surface, with the plane of the sheet perpendicular to the plane of the fracture surface[28]; (d) Crack bridging by GPLs on the fracture line with the plane orientated of sheet nearly perpendicular to the plane of the polished surface[34]

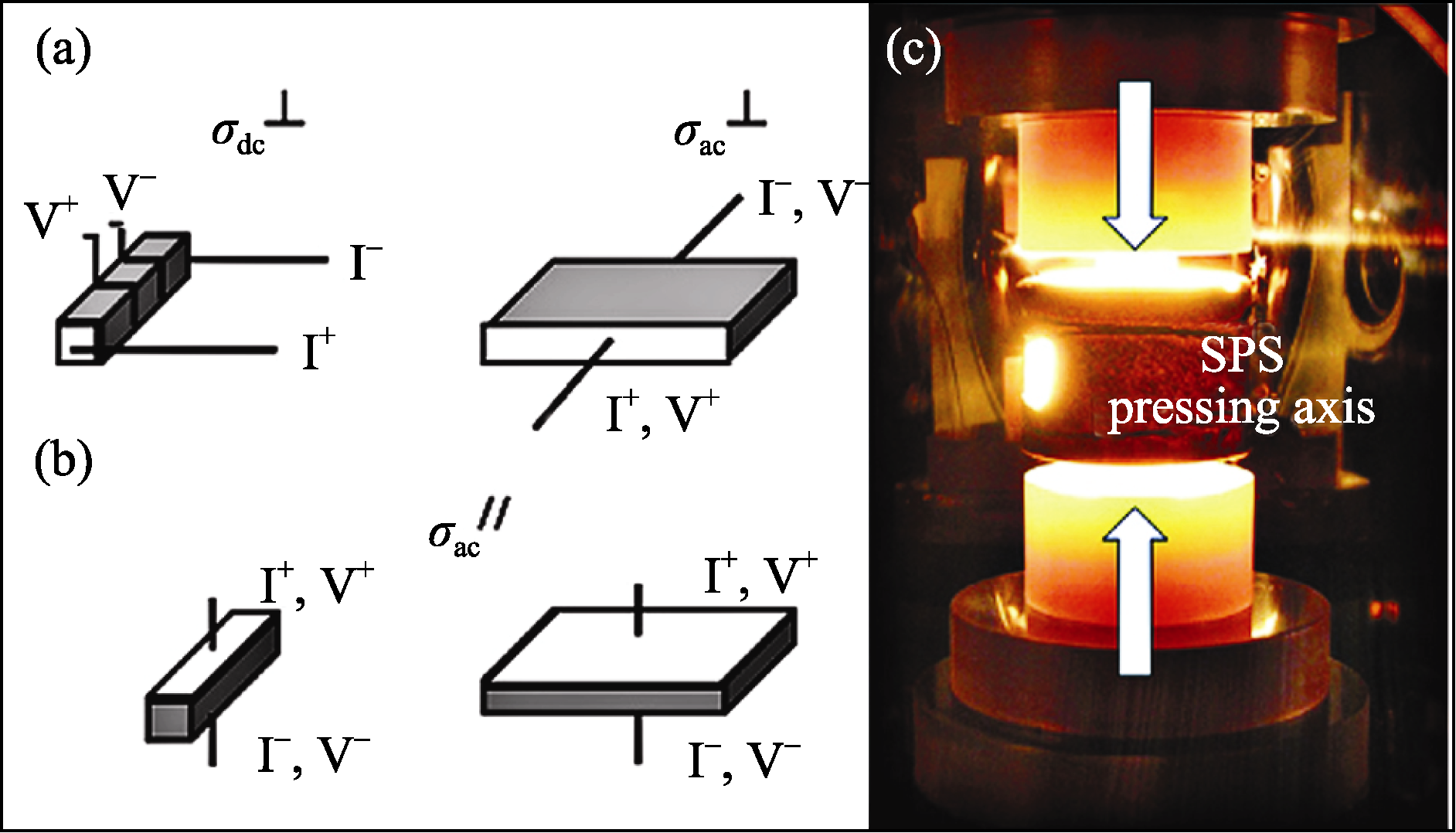

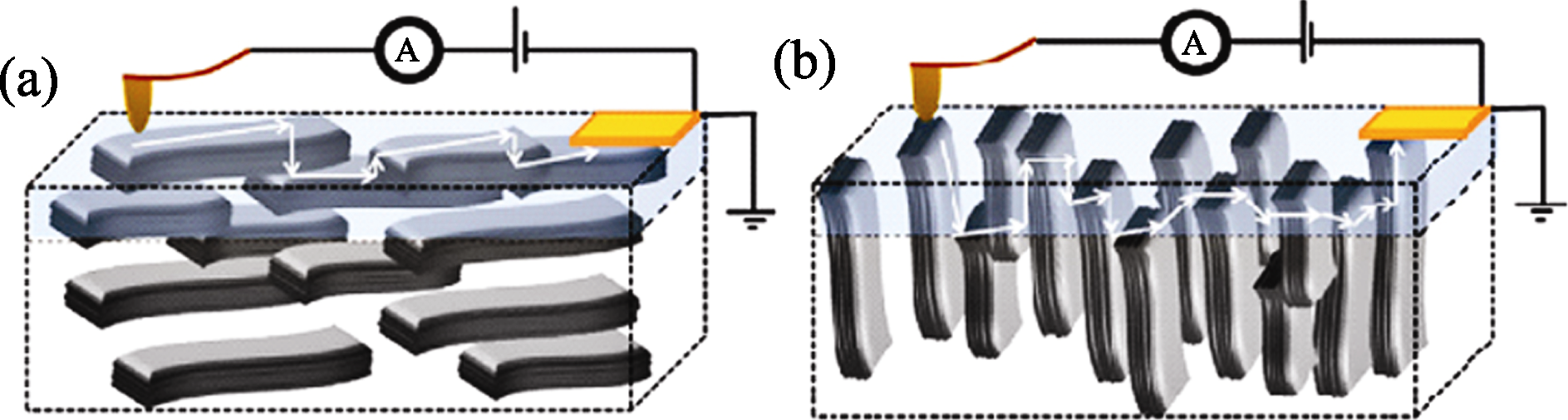

图11 沿着2个方向测量直流和交流电导率的实验装置示意图

Fig. 11 Diagram of experimental setup of dc and ac electrical conductivity (σdc ,σac) measurements along different directions[35] (a) perpendicular (defined by superscript┴) and (b) parallel (superscript″) to the SPS pressing axis; (c) sample and graphite die in the SPS furnace

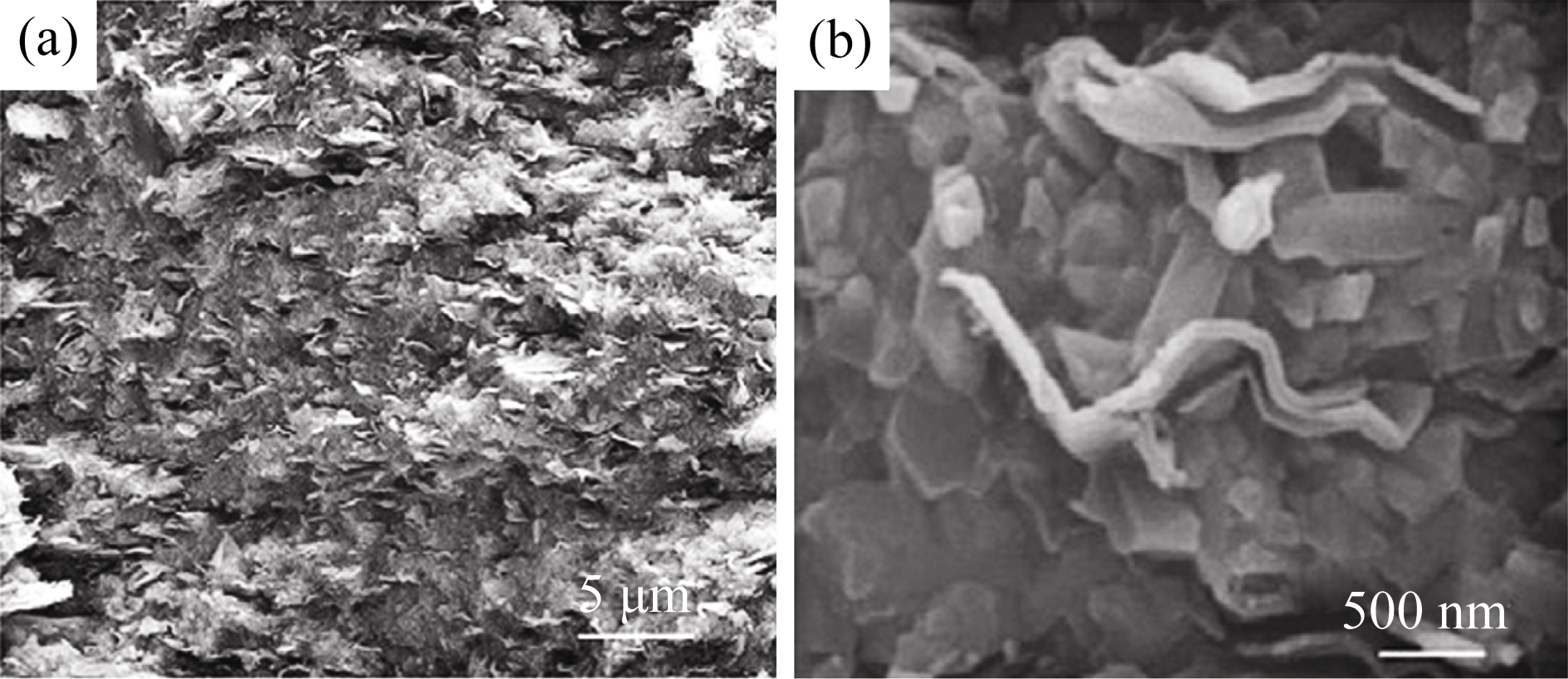

图12 Si3N4/GNP块体复合材料的断面FESEM照片(a)和高倍率图像显示纳米片沿着基体晶界Z字形弯曲(b)[36]

Fig. 12 FESEM micrographs of the fracture surface of the Si3N4/GNP composite where nanoplatelets protrude from the surface (a) and high magnification image showing the zigzag bending of nanoplatelets along the matrix grain boundaries (b)[36]

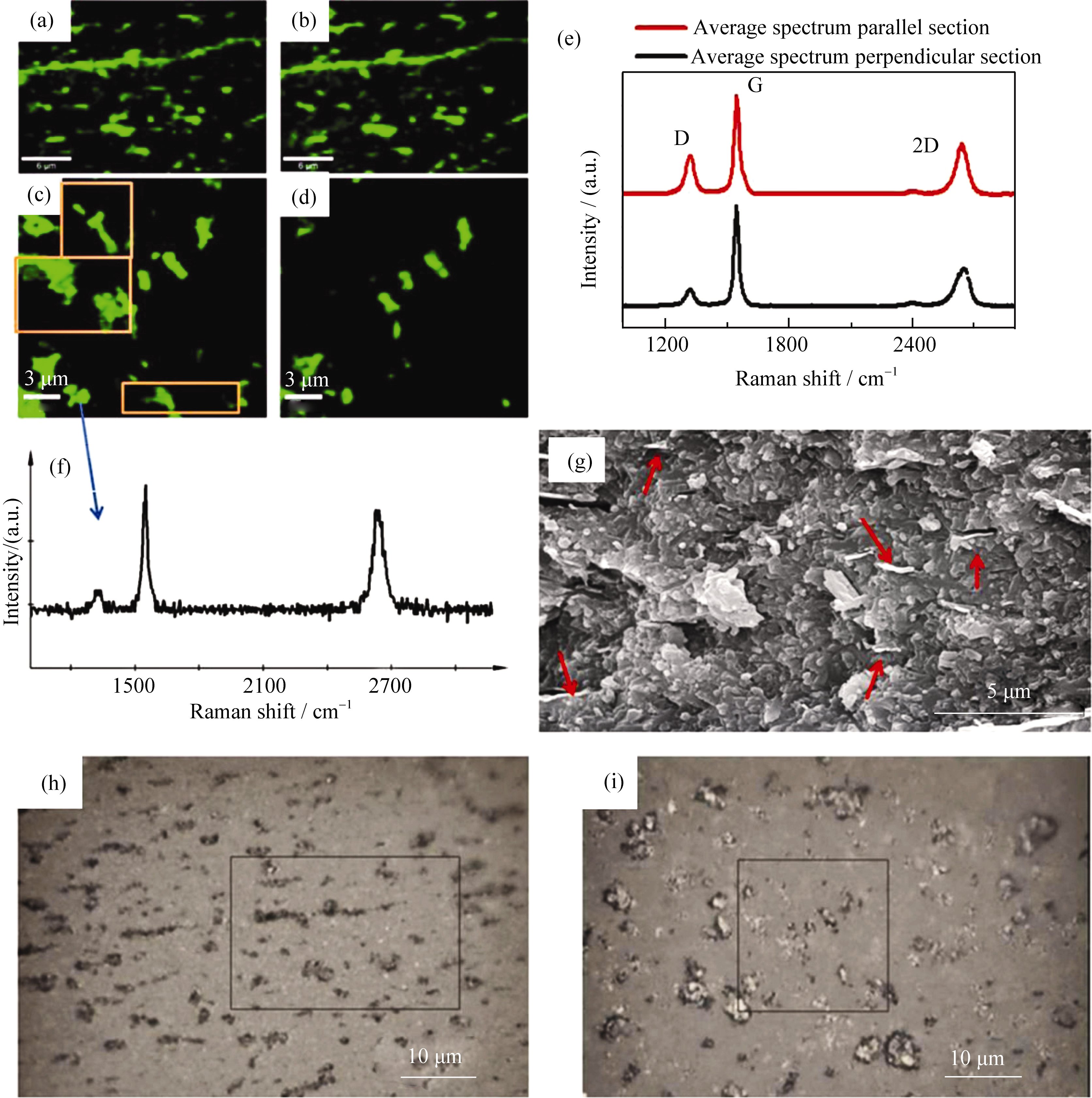

图13 对于复合材料的两个取向: 平行(a和b)和垂直(c和d)于SPS压轴线, 由G(a和c)和D(b和d)峰强度建立的拉曼图像; (e)为两个扫描区域的平均光谱图; (f)为具有2D峰强度的多层石墨烯单一频谱图, 该单一频谱是从集合的(c)图中提取的; (g)为断面(平行取向)SEM照片, 显示了GNPs的(箭头所指)择优取向; (h和i)为平行(左)和垂直(右)于SPS压轴的两个样品取向的扫描区域(轮廓)的光学图像[38]

Fig. 13 Raman images built from G (a and c) and D peak intensities (b and d) for both composite orientations: parallel (a and b) and perpendicular (c and d) to the SPS pressing axis. Average spectra of both scanned regions (e). Example of a single spectrum extracted from the collection of image (c) with the intense 2D peak of few layer graphene (f). SEM micrograph of the fracture surface (parallel orientation) (g), showing the preferential orientation of projected GNPs (pointed by arrows). (h and i) Optical images of the scanned zones (outlined) for both specimen orientations parallel (left) and perpendicular (right) to the SPS axis[38]

图14 几何形状测量电流的简化原理图(在样品表面边缘的对电极), (a)垂直于SPS加压轴线的导电路径; (b)平行于SPS加压轴线的导电路径[36]

Fig. 14 Simplified schematics of the measuring geometry (counter-electrode at the sample surface edge) to illustrate the conducting paths for the orientations perpendicular (a) and parallel (b) respect to the SPS pressing axis[36]

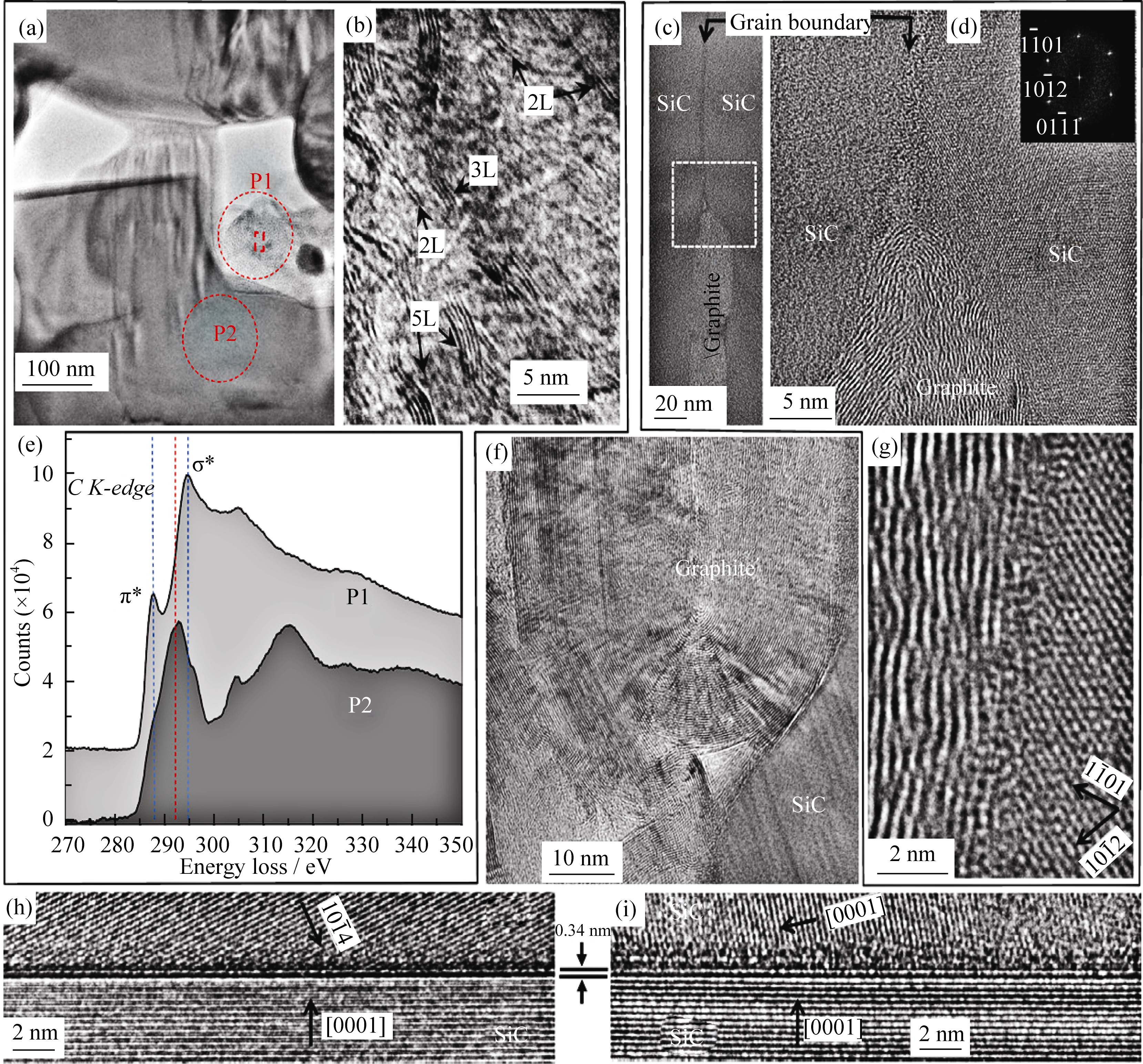

图15 α-SiC复合材料样品的TEM照片, 显示了不同石墨烯层数的几个区域。1区: (a)研究区域的低倍率TEM照片, (b)是富含SP2杂化区的P1区域(突出显示的矩形区域)的高倍率图像, 显示了少层石墨烯片(2L、3L和5L)的不同截面; 暗线条线之间的间距与石墨烯之间一致。(e)是分别在P1和P2位置碳K边界的电子能量损失谱(去除多重散射背景后)。2区: (c)具有形成石墨岛屿晶界的低倍率TEM照片, (d,g)是同一区域的高分辨率TEM照片, 插图是右侧SiC颗粒的电子衍射图。3区:(f)几十纳米的石墨形成区。4区: (h和i)代表双层石墨烯的两个不同晶界[40]

Fig. 15 TEM images of the α-SiC composite sample, showing several regions with different number of graphene layers. Region 1: (a) low magnification TEM image of the region of interest. (b) is a higher magnification image of the P1 region (inside the highlighted rectangular region) which is rich in sp2 carbon, showing different cross-section views of few-layers graphene flakes (2L, 3L and 5L); the spacing between dark contrast lines is consistent with the spacing between graphene sheets. (e) are electron energy loss spectroscopy spectra (after multiple-scattering background removal) of the carbon K edge at positions P1 and P2, respectively. Region 2: (c) low magnification TEM image of a grain boundary with formation of a graphite island, (d, g) high-resolution TEM images of the same region, the inset is SEAD of the right side SiC grain. Region 3: (f) graphitic formation of several tens of nanometers. Region 4: (h and i) two different grain boundaries presenting bi-layer graphene[40]

| [1] | GEIM A K, NOVOSELOV K S. The rize of graphene. Nature Materials, 2007, 6(3): 183-191. |

| [2] | NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films. Science, 2004, 306(5696): 666-669. |

| [3] | WEITZ R T, YACOBY A. Nanomaterials: graphene rests easy. Nat. Nanotechnol., 2010, 5(10): 699-700. |

| [4] | LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer grapheme. Science, 2008, 321(5887): 385-388. |

| [5] | GEIM A K. Graphene: status and prospects. Science, 2009, 324(5934): 1530-1534. |

| [6] | VAN B J. Graphene: from strength to strength. Nat. Nanotechnol., 2007, 2(4): 199-201. |

| [7] | NAIR R, BLAKE P, GRIGORENKO A, et al. Fine structure constant defines visual transparency of grapheme. Science, 2008, 320(5881): 1308. |

| [8] | NOVOSELOV K S, JIANG Z, ZHANG Y, et al. Room-temperature quantum hall effect in grapheme. Science, 2007, 315(5817): 1379. |

| [9] | KATSNELSON M I, NOVOSELOV K S, GEIM A K. Chiral tunnelling and the Klein paradox in graphene. Nat. Phys., 2006, 2(9): 620-625. |

| [10] | HEERSCHE H B, JARILLO-HERRERO P, OOSTINGA J B, et al. Bipolar supercurrent in graphene. Nature, 2007, 446(7131): 56-59. |

| [11] | WANG Y, HUANG Y, SONG Y, et al. Room temperature ferromagnetism of grapheme. Nano Lett., 2009, 9(1): 220-224. |

| [12] | ZHAO Y, HUANG W J. Research progress on preparation and performance of grephene and its composite. Journal of Chongqing University of Technology (Natural Science), 2011, 7(25): 64-70. |

| [13] | XIE P, LU Q, WANG L E, et al. Research progress in preparation and modify of graphene and polymers/graphene nanocomposities. Materials Review, 2010, 11(24): 163-166. |

| [14] | LI Y X, CHEN Y, ZHUANG X D, et al. Chemistry and potential application of graphene. Journal of Shanghai Second Polytechnic University, 2010, 4(27): 259-269. |

| [15] | LI J L, BAI G Z, WANG L J, et al. Microstructure and mechanical properties of in-situ produced TiC/C nanocomposite. Scripta Materialia, 2005, 52(9): 867-871. |

| [16] | LI J L, BAI G Z, WANG L J, et al. Microstructure and mechanical properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon, 2005, 43(13): 2649-2653. |

| [17] | LI J L, WANG L J, JIANG W, et al. Surface graphitization and mechanical properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon, 2007, 45(13): 2636-2642. |

| [18] | CHEN J T, CHEN L Q, ZHANG Z C, et al. Graphene layers produced from carbon nanotubes by friction. Carbon, 2012, 50(5): 1934-1941. |

| [19] | JI F, LI Y L, FENG J M, et al. Electrochemical performance of graphene nanosheets and ceramic composites as anodes for lithium batteries. J. Mater. Chem., 2009, 19(47): 9603-9607. |

| [20] | KANG Y R, JI F, LI Y L, et al. Synthesis of graphite oxides by chemical oxidation method and ceramic composites. Journal of the Chinese Ceramic Society, 2010, 8(38): 1558-1561. |

| [21] | HE T, LI J L, WANG L J, et al. Preparation and consolidation of alumina/graphene composite powders. Materials Transactions, 2009, 50(4): 749-751. |

| [22] | FAN Y C, WANG L J, LI J L, et al. Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Carbon, 2010, 48(6): 1743-1749. |

| [23] | FAN Y C, JIANG W, AKIRA K. Highly conductive few-layer graphene/Al2O3 nanocomposites with tunable charge carrier type. Advanced Functional Materials, 2012, 22(18): 3882-3889. |

| [24] | WANG K, WANG Y F, WEI T, et al. Preparation of graphene nanosheet/alumina composites by spark plasma sintering. Materials Research Bulletin, 2011, 46(2): 315-318. |

| [25] | LIU J, YAN H X, MIKE J R, et al. Toughening of zirconia/alumine composites by the addition of graphene plateles. Journal of the Europen Ceramic Society, 2012, 32(16): 4185-4193. |

| [26] | LIU J, YAN H X, JIANG K. Mechanical properties of graphene platelet-reinforced alumina ceramic composites. Ceramics International, 2013, 39(6): 6215-6221. |

| [27] | WALKER L S, MAROTTO V R, RAFIEE M A, et al. Toughening in graphene ceramic composites. ACS Nano, 2011, 4(5): 3182-3190. |

| [28] | KUN P, TAPASZTÓ O, WÉBER F, et al. Determination of structural and mechanical properties of multilayer graphene added silicon nitride-based composites. Ceramics International, 2012, 38(1): 211-216. |

| [29] | DUSZA J, MORGIEL J, DUSZOVÁ A, et al. Microstructure and fracture toughness of Si3N4+ graphene platelet composites. Journal of the European Ceramic Society, 2012, 32(12): 3389-3397. |

| [30] | KVETKOVÁ L, DUSZOVÁ A, KAŠIAROVÁ M, et al. Influence of processing on fracture toughness of Si3N4 + graphene platelet composites. Journal of the European Ceramic Society, 2013, 33(12): 2299-2304. |

| [31] | TAPASZTÓ O, TAPASZTÓ L, MARKÒ M, et al. Dispersion patterns of graphene and carbon nanotubes in ceramic matrix composites. Chemical Physics Letters, 2011, 511(4/5/6): 340-343. |

| [32] | BELMONTE M, RAM-REZ C, JULIAN J G, et al. The beneficial effect of graphene nanofillers on the tribological performance of ceramics. Carbon, 2013, 61: 431-435. |

| [33] | HVIZDOŠ P, DUSZA J, BALÁZSI C. Tribological properties of Si3N4- graphene nanocomposites. Journal of the European Ceramic Society, 2013, 33(12): 2359-2364. |

| [34] | KVERTKOVÁ L, DUSZOVÁ A, HVIZDOŠ P, et al. Fracture toughness and toughening mechanisms in graphene platelet reinforced Si3N4 composites. Scripta Materialia, 2012, 66(10): 793-796. |

| [35] | RAMIREZ C, FIGUEIREDO F M, MIRANZO P, et al. Graphene nanoplatelet/silicon nitride composites with high electrical conductivity. Carbon, 2012, 50(10): 3607-3615. |

| [36] | RAMIREZ C, GARZÓN L, MIRANZO P, et al. Electrical conductivity maps in graphene nanoplatelet/silicon nitride composites using conducting scanning force microscopy. Carbon, 2011, 49(12): 3873-3880. |

| [37] | RAMÍRZE C, VEGA-DIAZ S M, FIGUEIREDO F M, et al. Synthesis of conducting graphene/Si3N4 composites by spark plasma sintering. Carbon, 3013, 57: 425-432. |

| [38] | RAMIREZ C, OSENDI M I. Characterzation of graphene nanoplateles-Si3N4 composites by Raman spectroscopy. Journal of the European Ceramic Society, 2013, 33(3): 471-477. |

| [39] | MIRANZO P, GARCÍA E, RAMÍREZ C, et al. Anisotropic thermal conductivity of silicon nitride ceramics containing carbon nanostructures. Journal of the European Ceramic Society, 2012, 32(8): 1847-1854. |

| [40] | MIRANZO P, GARCÍA E, RAMÍREZ C, et al. In situ processing of electrically conducting graphene/SiC nanocomposites. Journal of the European Ceramic Society, 2013, 33(10): 1665-1674. |

| [41] | YADHUKULAKRISHNAN G B, KARUMURI S, RAHMAN A, et al. Spark plasma sintering of graphene reinforced zirconium diboride ultra- high temperature ceramic composites. Ceramics International, 2013, 39(6): 6637-6649. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 余艺平, 肖鹏, 赵长浩, 徐梦迪, 姚立冬, 李伟, 王松. 耐高温层状Ta/Ta0.5Hf0.5C金属陶瓷的高频等离子体风洞烧蚀行为研究[J]. 无机材料学报, 2025, 40(7): 790-798. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [5] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [6] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [7] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [8] | 唐莹, 李洁, 相怀成, 方维双, 林慧兴, 杨俊峰, 方亮. Rattling效应: 一种影响微波介质陶瓷谐振频率温度系数的新机制[J]. 无机材料学报, 2025, 40(6): 656-666. |

| [9] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [10] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [11] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [12] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [13] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [14] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [15] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||