无机材料学报 ›› 2026, Vol. 41 ›› Issue (2): 137-149.DOI: 10.15541/jim20250124 CSTR: 32189.14.jim20250124

• 综述 • 下一篇

任先培1( ), 李超1, 胡启威1, 向晖1(

), 李超1, 胡启威1, 向晖1( ), 彭跃红2(

), 彭跃红2( )

)

收稿日期:2025-03-25

修回日期:2025-06-12

出版日期:2025-07-16

网络出版日期:2025-07-16

通讯作者:

向 晖, 副教授. E-mail: hxiang0717@163.com;作者简介:任先培(1982-), 男, 副教授. E-mail: renxianpei@163.com

基金资助:

REN Xianpei1( ), LI Chao1, HU Qiwei1, XIANG Hui1(

), LI Chao1, HU Qiwei1, XIANG Hui1( ), PENG Yuehong2(

), PENG Yuehong2( )

)

Received:2025-03-25

Revised:2025-06-12

Published:2025-07-16

Online:2025-07-16

Contact:

XIANG Hui, associate professor. E-mail: hxiang0717@163.com;About author:REN Xianpei (1982-), male, associate professor. E-mail: renxianpei@163.com

Supported by:摘要:

氢能作为一种理想的能源载体, 对推动能源结构转型具有重要意义。电解水制氢技术是实现制氢规模化的重要手段, 而催化剂的析氢活性、稳定性和成本则是该技术发展的核心要素。过渡金属化合物(TMCs)凭借其成本低、资源丰富以及电子结构可调等优点, 已成为替代贵金属催化剂的热门候选材料。构建半导体与金属之间的莫特-肖特基(Mott-Schottky, M-S)结是一种有效提升催化活性的策略。本文系统综述了金属/TMCs M-S结催化剂的研究进展, 包括其分类(如金属/氧化物、硫化物、硒化物、磷化物、氮化物)、构建策略(如水热法、原位还原、磷化处理等)及析氢增强机制。研究表明, M-S结通过界面电荷重排和形成内建电场, 优化电子结构和氢吸附自由能, 促进电荷分离和传输, 从而显著提升析氢活性。此外, 本文还探讨了M-S结催化剂需深入探索和厘清的关键问题, 并对未来研究方向和发展趋势进行了展望。本文旨在为设计高效、廉价析氢电催化剂提供理论指导, 推动氢能技术的可持续发展。

中图分类号:

任先培, 李超, 胡启威, 向晖, 彭跃红. 金属/过渡金属化合物莫特-肖特基析氢催化剂研究进展[J]. 无机材料学报, 2026, 41(2): 137-149.

REN Xianpei, LI Chao, HU Qiwei, XIANG Hui, PENG Yuehong. Research Progress on Mott-Schottky Hydrogen Evolution Catalysts Based on Metal/Transition Metal Compounds[J]. Journal of Inorganic Materials, 2026, 41(2): 137-149.

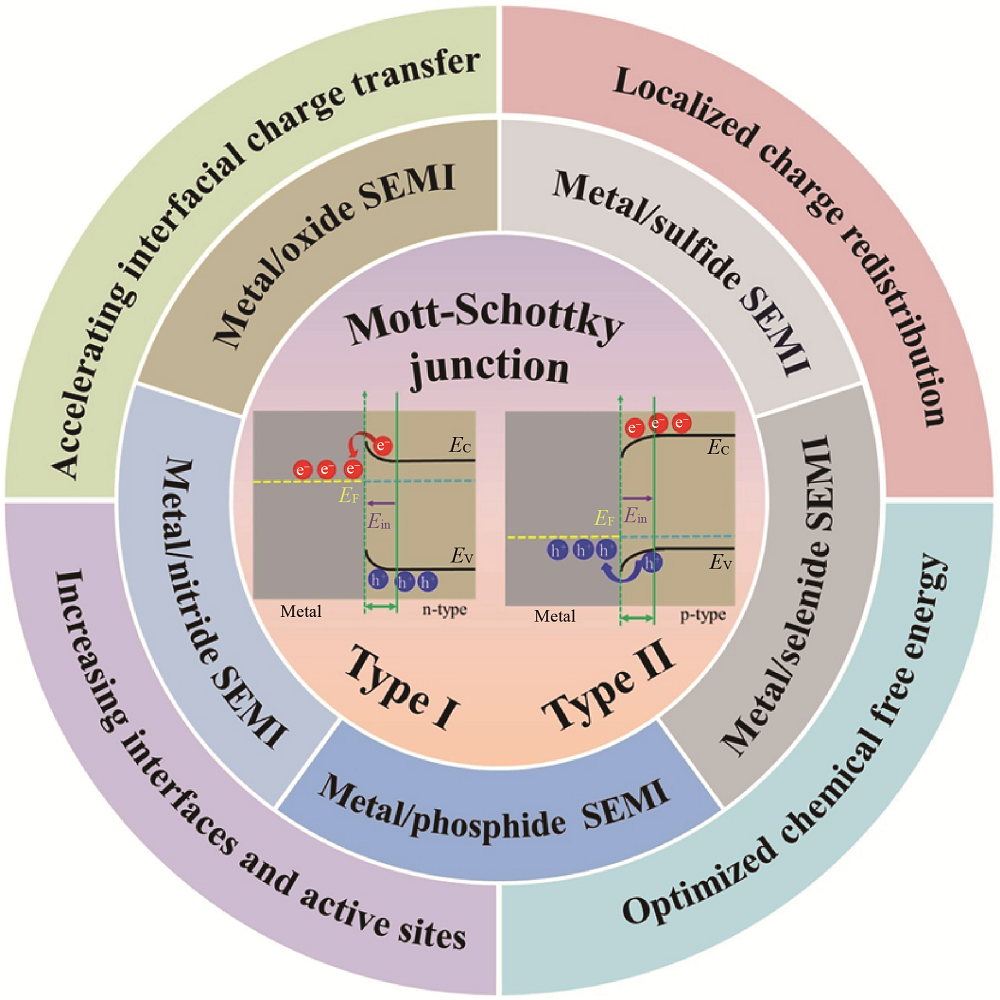

图1 金属/TMCs半导体M-S结催化剂的结构、类型以及增强析氢机制

Fig. 1 Structures, types and enhanced hydrogen evolution mechanisms of metal/TMCs semiconductor M-S junction catalysts SEMI: semiconductor

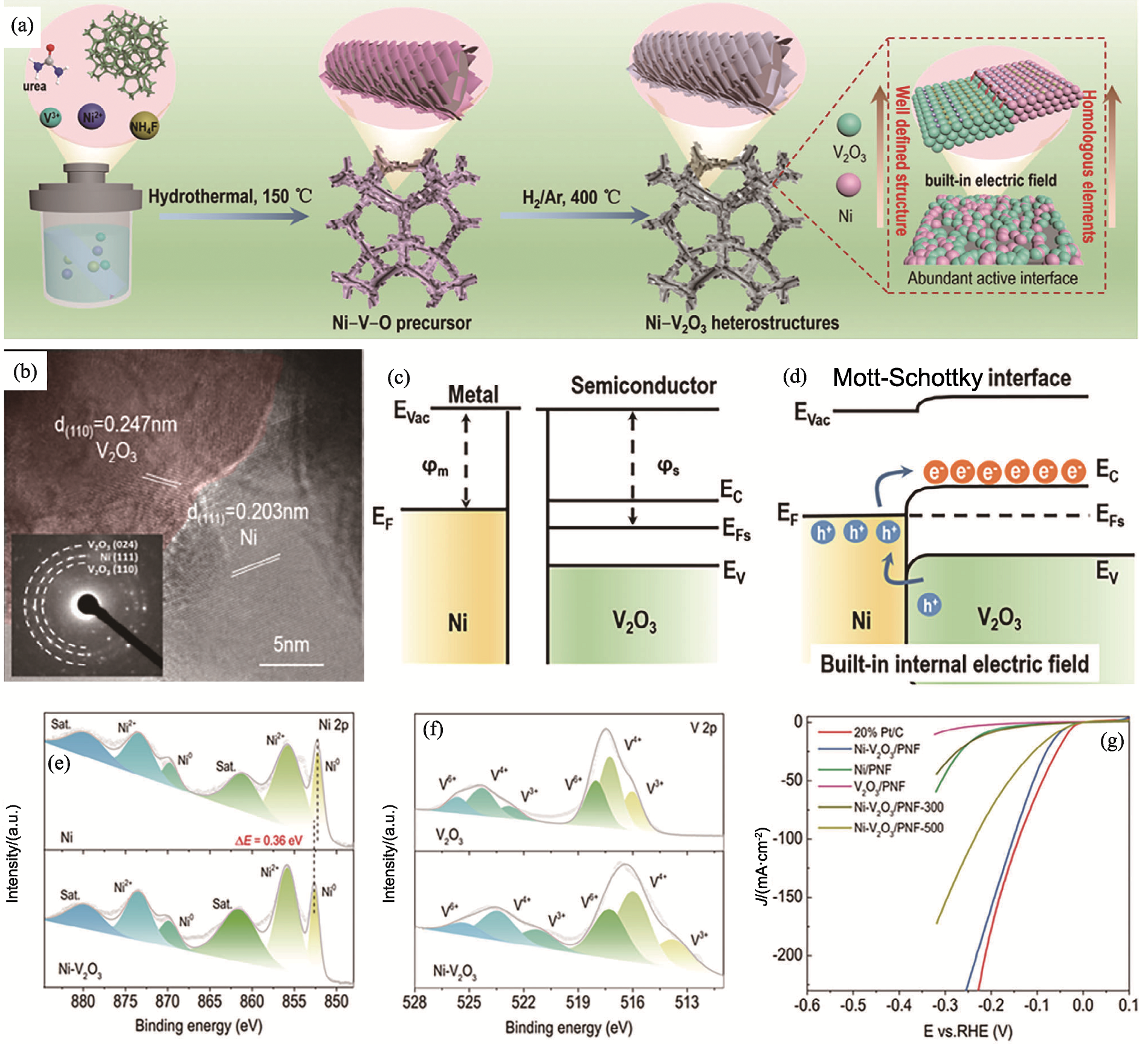

图2 Ni-V2O3/PNF的制备、表征与析氢性能[37]

Fig. 2 Preparation, characterization and hydrogen evolution performance of Ni-V2O3/PNF[37] (a) Schematic diagram of synthesis process for Ni-V2O3/PNF; (b) HRTEM image of Ni-V2O3/PNF; (c) Energy band diagram of Ni and V2O3;(d) Schematic diagram of band structures; (e, f) High-resolution XPS spectra of Ni2p (e) and V2p (f);(g) Linear sweep voltammetry (LSV) curves of 20% Pt/C, Ni-V2O3/PNF, Ni/PNF, V2O3/PNF, and Ni-V2O3/PNF-300/500, where 300 and 500 represent the thermal reduction temperatures in unit ℃, while 400 ℃ for Ni-V2O3/PNF

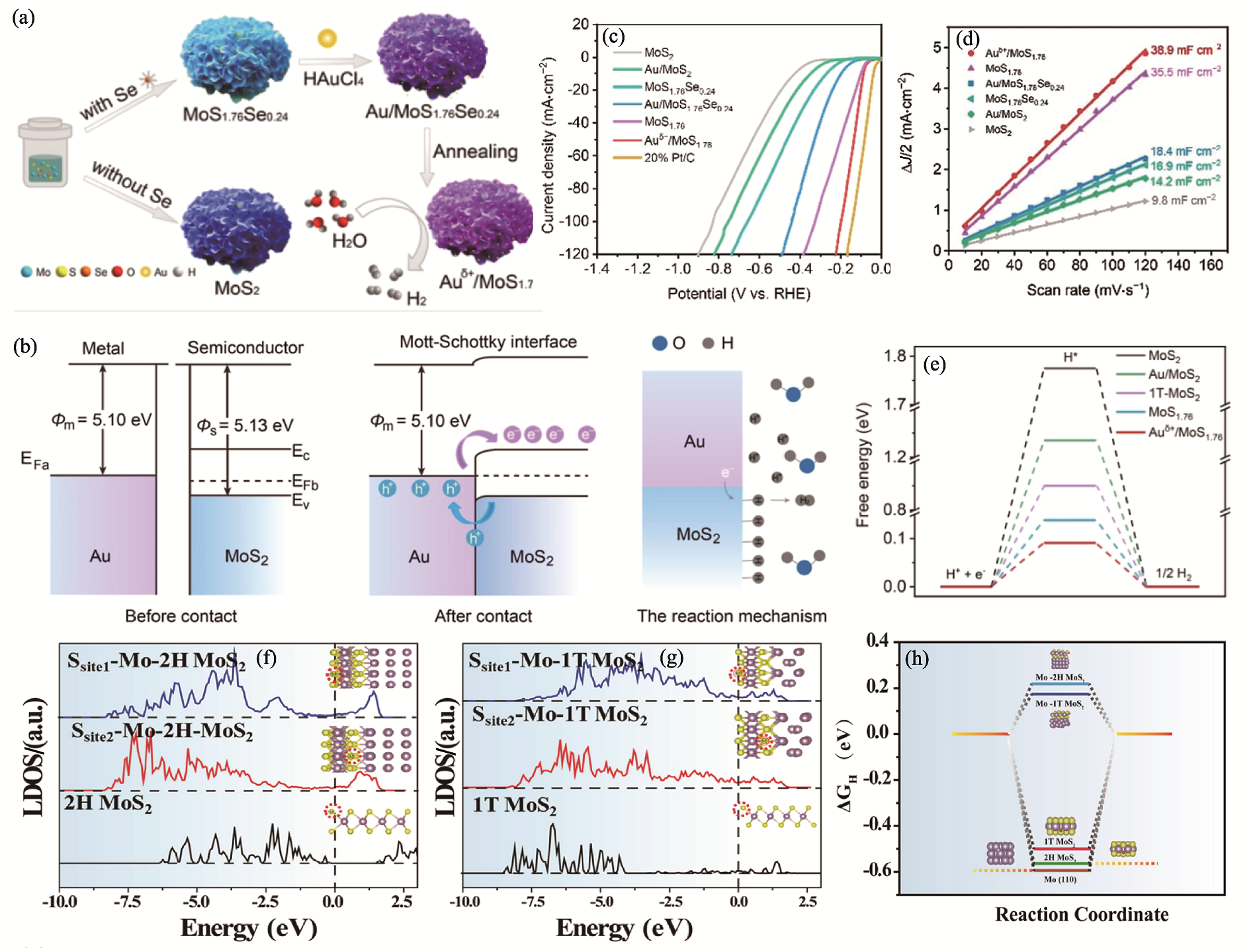

图3 Auδ+/1T-MoS1.76与Mo-MoS2 M-S结催化剂的制备、理论计算与析氢性能[44-45]

Fig. 3 Preparation, theoretical calculations and hydrogen evolution performance of Auδ+/1T-MoS1.76 and Mo-MoS2 M-S junction catalysts[44-45] (a) Schematic diagram of synthesis process for Auδ+/1T-MoS1.76[44]; (b) Schematic illustration of the energy band structure for Auδ+/1T-MoS1.76 heterostructure and the proposed charge-transfer mechanism[44]; (c) LSV curves and (d) linear fits of half capacitive current vs. scan rate for the extraction of Cdl for different samples[44]; (e) Free-energy diagram for HER[44]; (f) LDOS for different S sites of 2H MoS2 and Mo-2H MoS2[45]; (g) LDOS for different S sites of 1T MoS2 and Mo-1T MoS2[45]; (h) Optimal ΔGH* for HER[45]

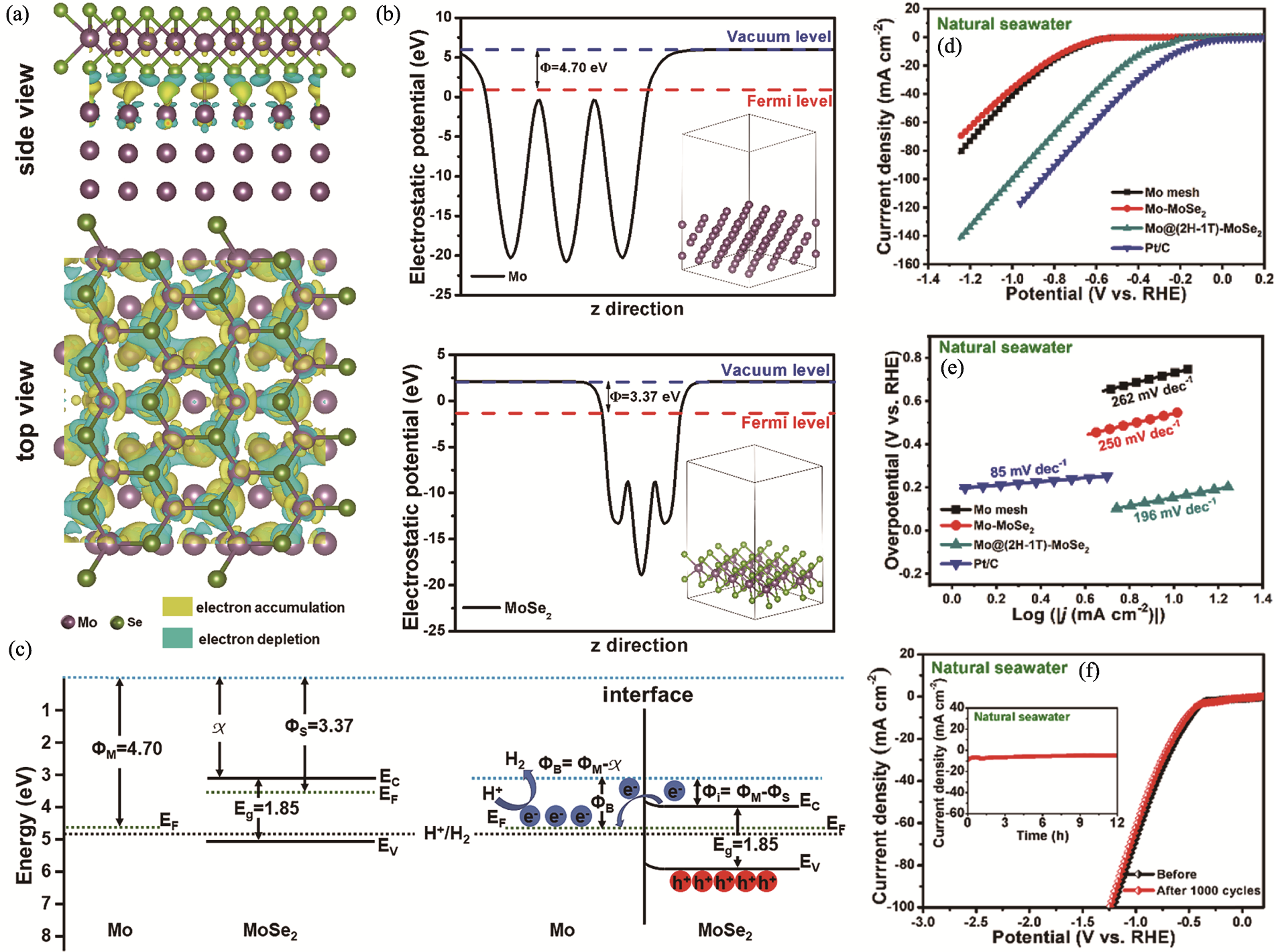

图4 Mo@(2H-1T)-MoSe2 M-S结催化剂的理论计算、能带结构与析氢性能[48]

Fig. 4 Theoretical calculations, band structure and hydrogen evolution performance of Mo@(2H-1T)-MoSe2 M-S junction catalyst[48] (a) Charge density distribution at interface of the Mo@(2H-1T)-MoSe2 heterostructure; (b) Electrostatic potential calculations of Mo metal (top) and MoSe2 (bottom); (c) Energy levels of the two components in Mo@(2H-1T)-MoSe2 before and after contact; (d) LSV curves and (e) corresponding Tafel slopes for the electrodes Mo mesh, Mo-MoSe2, Mo@(2H-1T)-MoSe2 and Pt/C in natural seawater; (f) LSV curves for Mo@(2H-1T)-MoSe2 before and after 1000 CV cycles

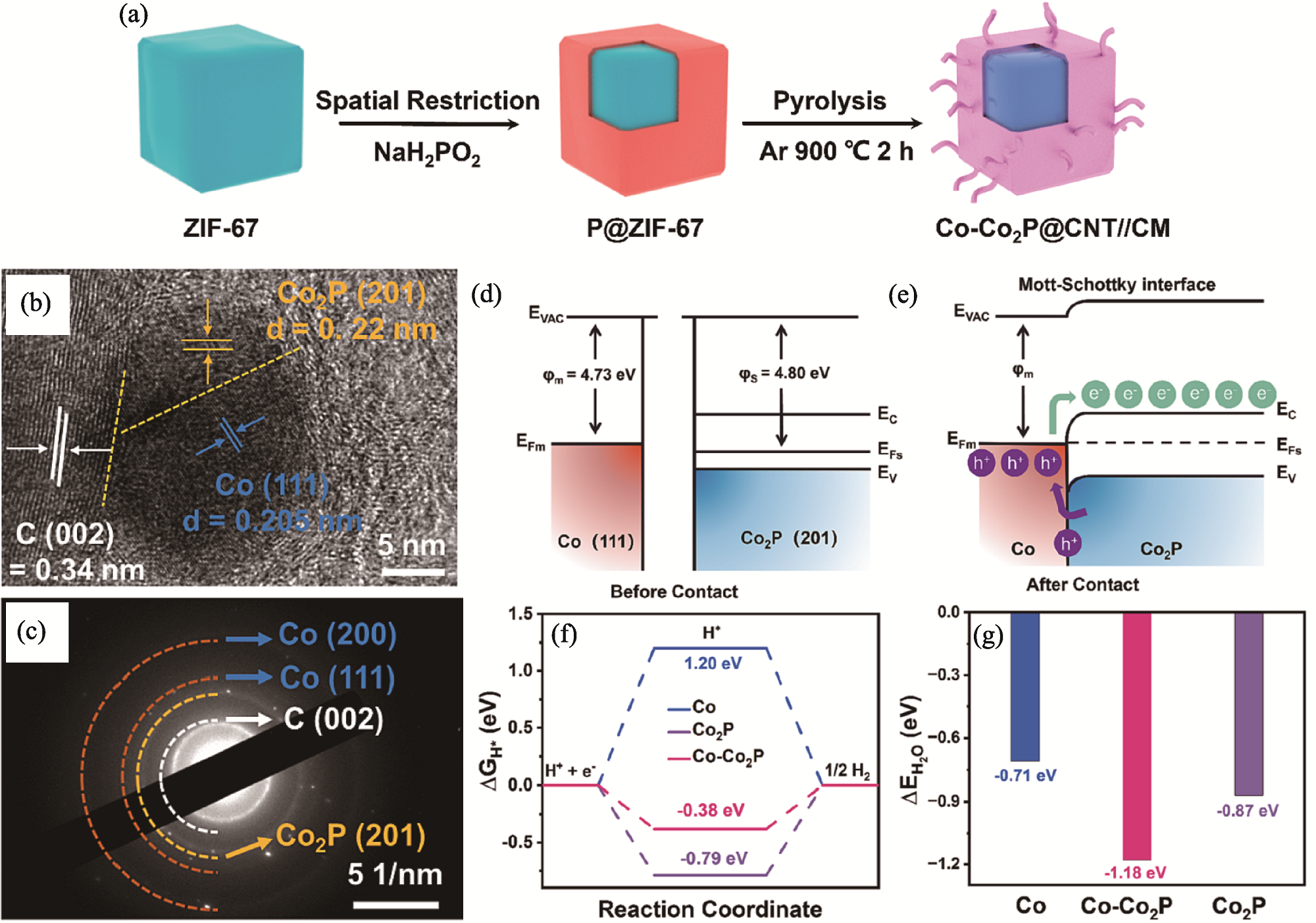

图5 M-S型Co-Co2P@CNT//CM异质结的制备、结构、能带与自由能[53]

Fig. 5 Preparation, structure, band alignment and free energy of M-S type Co-Co2P@CNT//CM heterojunction[53] (a) Schematic diagram of synthesis process for M-S type Co-Co2P@CNT//CM heterojunction; (b) HRTEM and (c) SAED images of Co-Co2P@CNT//CM; (d, e) Energy diagrams for Co and Co2P before and after Schottky contact; (f) Calculated ΔGH* and (g) ΔEH2O of Co, Co2P and Co-Co2P

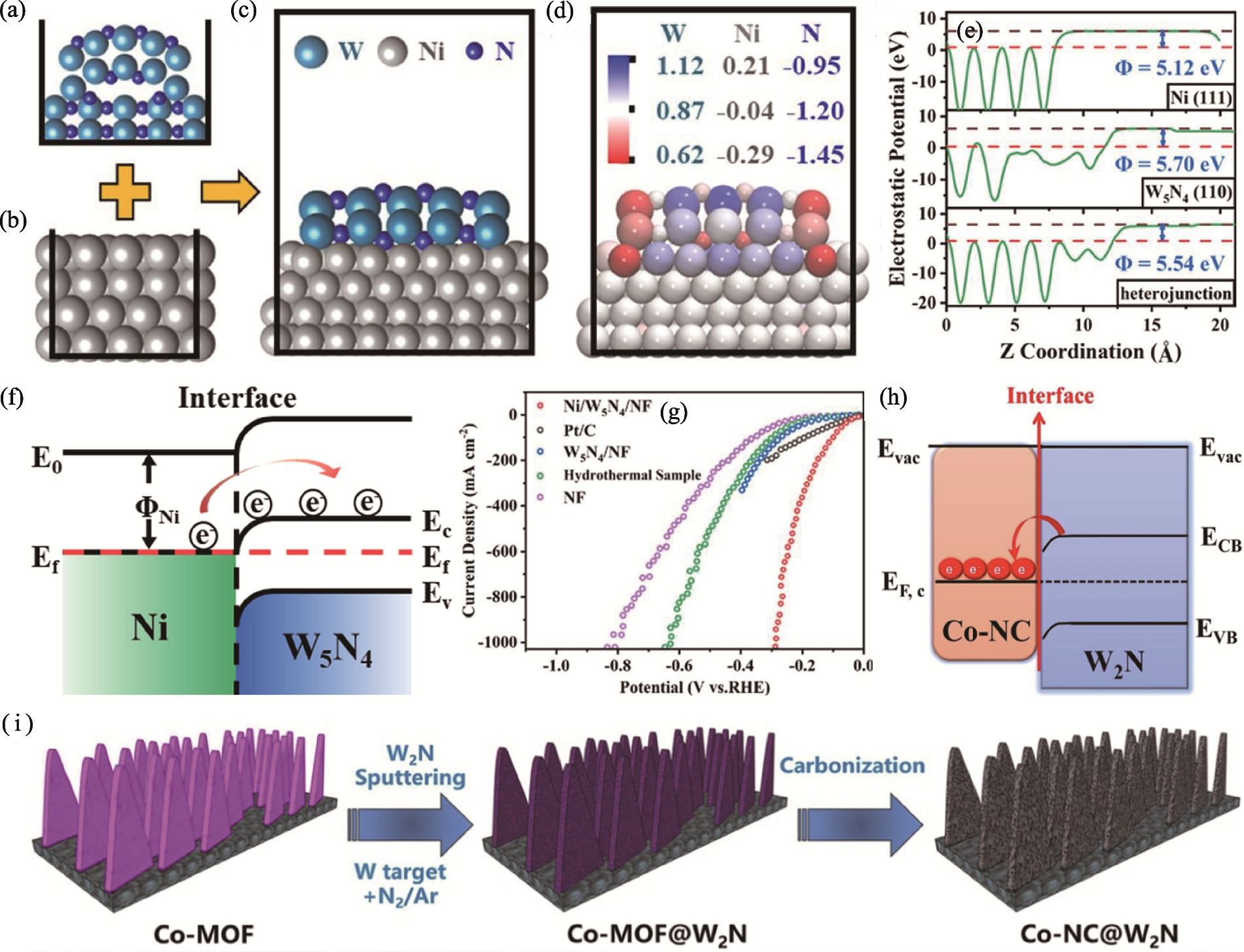

图6 Ni/W5N4与Co-NC@W2N M-S结催化剂的结构模型、能带结构与制备示意图[59-60]

Fig. 6 Structural models, band structures and preparation schematic diagrams of Ni/W5N4 and Co-NC@W2N M-S junction catalysts[59-60] (a-c) Calculated geometries of (a) W5N4 (100), (b) Ni (111) and (c) M-S heterojunction[59]; (d) Structure diagram of atomic Bader charge coloring for the M-S heterojunction[59]; (e) Electrostatic potential for the corresponding geometries[59]; (f) Energy band diagram of metallic Ni and W5N4 with M-S interface after Schottky contact[59]; (g) HER polarization curves of the series of catalysts[59]; (h) Schematic illustration of Co-NC@W2N M-S junction after contacting[60]; (i) Schematic diagram of synthesis process for Co-NC@W2N[60]

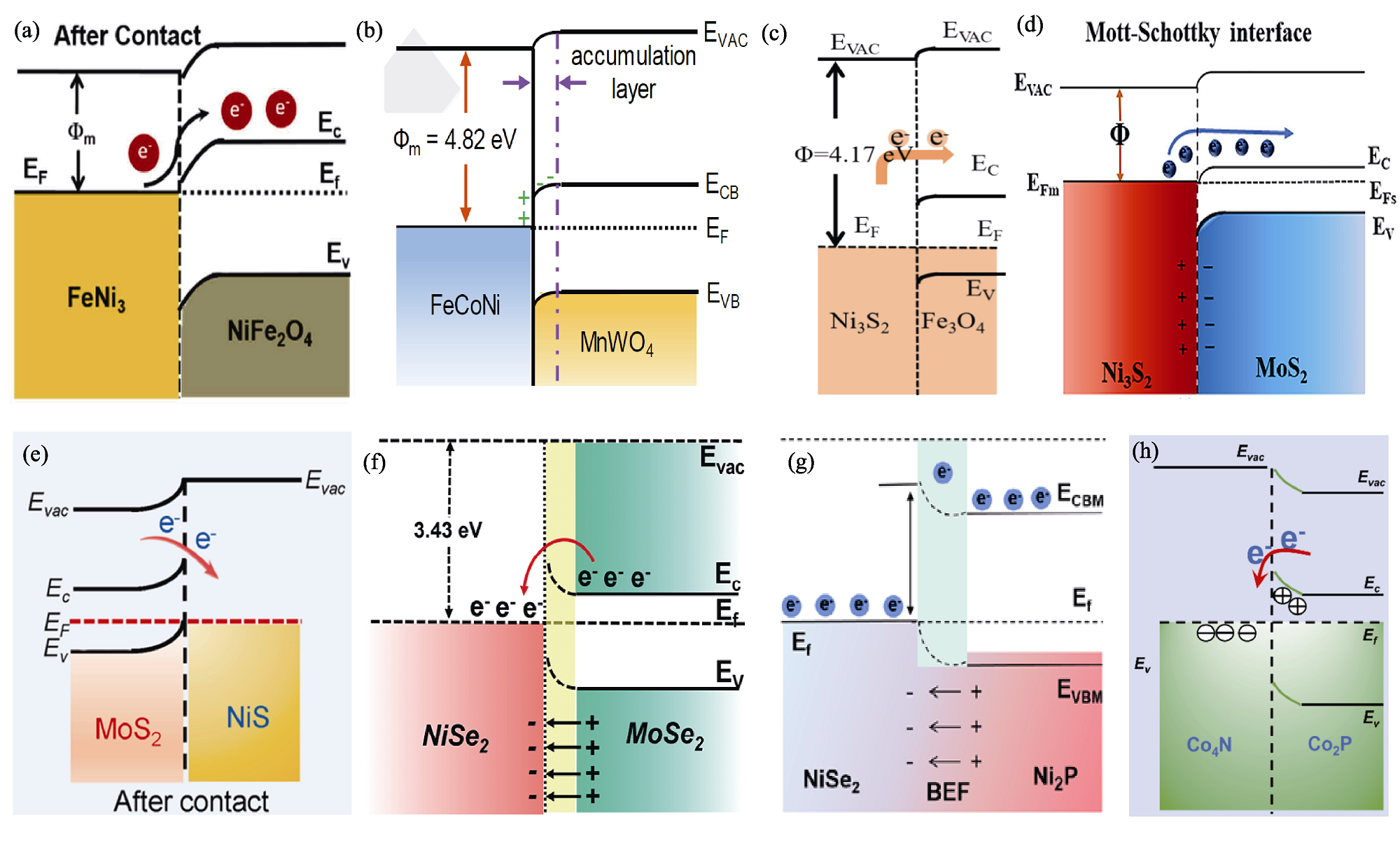

图7 金属性质的化合物与TMCs半导体形成的M-S结[62-69]

Fig. 7 M-S junction formed between metallic compounds and TMCs semiconductors[62-69] (a) FeNi3/NiFe2O4[62]; (b) FeCoNi/MnWO4[63]; (c) Ni3S2/Fe3O4[64]; (d) Ni3S2/MoS2[65]; (e) NiS/MoS2[66]; (f) NiSe2/MoSe2[67]; (g) NiSe2/Ni2P[68]; (h) Co4N/Co2P[69]

| No. | Mott-Schottky catalyst | Metal | Semiconductor | Electron transfer | Ref. |

|---|---|---|---|---|---|

| 1 | V2O3/Ni | Ni | V2O3 | Metal to semiconductor | [ |

| 2 | Ni@NiO | Ni | NiO | Metal to semiconductor | [ |

| 3 | Co/a-WOx | Co | a-WOx | Metal to semiconductor | [ |

| 4 | Ni/NiFeO | Ni | NiFeO | Metal to semiconductor | [ |

| 5 | Au/MoS2 | Au | MoS2 | Metal to semiconductor | [ |

| 6 | Mo-MoS2 | Mo | MoS2 | Metal to semiconductor | [ |

| 7 | Co-Co2P | Co | Co2P | Metal to semiconductor | [ |

| 8 | NiCoP-Co | Co | NiCoP | Metal to semiconductor | [ |

| 9 | Ni/W5N4 | Ni | W5N4 | Metal to semiconductor | [ |

| 10 | Ni/Ni3N | Ni | Ni3N | Metal to semiconductor | [ |

| 11 | FeNi3/NiFe2O4 | FeNi3 | NiFe2O4 | Metal to semiconductor | [ |

| 12 | FeCoNi/MnWO4 | FeCoNi | MnWO4 | Metal to semiconductor | [ |

| 13 | Ni3S2/Fe3O4 | Ni3S2 | Fe3O4 | Metal to semiconductor | [ |

| 14 | Ni3S2/MoS2 | Ni3S2 | MoS2 | Metal to semiconductor | [ |

| 15 | Ru-WO2.72 | Ru | WO2.72 | Semiconductor to metal | [ |

| 16 | Mo@(2H-1T)-MoSe2 | Mo | MoSe2 | Semiconductor to metal | [ |

| 17 | Co/Co0.85Se | Co | Co0.85Se | Semiconductor to metal | [ |

| 18 | Co/MoSe2 | Co | MoSe2 | Semiconductor to metal | [ |

| 19 | Ru/Ru, Fe-CoP | Ru | Ru, Fe-CoP | Semiconductor to metal | [ |

| 20 | Co/CoP | Co | CoP | Semiconductor to metal | [ |

| 21 | Co-NC@W2N | Co | W2N | Semiconductor to metal | [ |

| 22 | NiS/MoS2 | NiS | MoS2 | Semiconductor to metal | [ |

| 23 | NiSe2/MoSe2 | NiSe2 | MoSe2 | Semiconductor to metal | [ |

| 24 | NiSe2/Ni2P | NiSe2 | Ni2P | Semiconductor to metal | [ |

| 25 | Co4N/Co2P | Co4N | Co2P | Semiconductor to metal | [ |

表1 M-S结催化剂中电子传输方向汇总

Table 1 Summary of the direction of electron transfer in M-S junction catalysts

| No. | Mott-Schottky catalyst | Metal | Semiconductor | Electron transfer | Ref. |

|---|---|---|---|---|---|

| 1 | V2O3/Ni | Ni | V2O3 | Metal to semiconductor | [ |

| 2 | Ni@NiO | Ni | NiO | Metal to semiconductor | [ |

| 3 | Co/a-WOx | Co | a-WOx | Metal to semiconductor | [ |

| 4 | Ni/NiFeO | Ni | NiFeO | Metal to semiconductor | [ |

| 5 | Au/MoS2 | Au | MoS2 | Metal to semiconductor | [ |

| 6 | Mo-MoS2 | Mo | MoS2 | Metal to semiconductor | [ |

| 7 | Co-Co2P | Co | Co2P | Metal to semiconductor | [ |

| 8 | NiCoP-Co | Co | NiCoP | Metal to semiconductor | [ |

| 9 | Ni/W5N4 | Ni | W5N4 | Metal to semiconductor | [ |

| 10 | Ni/Ni3N | Ni | Ni3N | Metal to semiconductor | [ |

| 11 | FeNi3/NiFe2O4 | FeNi3 | NiFe2O4 | Metal to semiconductor | [ |

| 12 | FeCoNi/MnWO4 | FeCoNi | MnWO4 | Metal to semiconductor | [ |

| 13 | Ni3S2/Fe3O4 | Ni3S2 | Fe3O4 | Metal to semiconductor | [ |

| 14 | Ni3S2/MoS2 | Ni3S2 | MoS2 | Metal to semiconductor | [ |

| 15 | Ru-WO2.72 | Ru | WO2.72 | Semiconductor to metal | [ |

| 16 | Mo@(2H-1T)-MoSe2 | Mo | MoSe2 | Semiconductor to metal | [ |

| 17 | Co/Co0.85Se | Co | Co0.85Se | Semiconductor to metal | [ |

| 18 | Co/MoSe2 | Co | MoSe2 | Semiconductor to metal | [ |

| 19 | Ru/Ru, Fe-CoP | Ru | Ru, Fe-CoP | Semiconductor to metal | [ |

| 20 | Co/CoP | Co | CoP | Semiconductor to metal | [ |

| 21 | Co-NC@W2N | Co | W2N | Semiconductor to metal | [ |

| 22 | NiS/MoS2 | NiS | MoS2 | Semiconductor to metal | [ |

| 23 | NiSe2/MoSe2 | NiSe2 | MoSe2 | Semiconductor to metal | [ |

| 24 | NiSe2/Ni2P | NiSe2 | Ni2P | Semiconductor to metal | [ |

| 25 | Co4N/Co2P | Co4N | Co2P | Semiconductor to metal | [ |

| [57] | 秦睿, 王鹏彦, 林灿, 等. 过渡金属氮化物的活性起源、合成方法及电催化应用. 物理化学学报, 2021, 37(7): 41. |

| [58] |

TANG S, ZHANG Z, XIANG J, et al. Recent advances in transition metal nitrides for hydrogen electrocatalysis in alkaline media: from catalyst design to application. Frontiers in Chemistry, 2022, 10: 1073175.

DOI URL |

| [59] |

ZHOU Y M, CHU B X, SUN Z J, et al. Surface reconstruction and charge distribution enabling Ni/W5N4 Mott-Schottky heterojunction bifunctional electrocatalyst for efficient urea-assisted water electrolysis. Applied Catalysis B: Environmental, 2023, 323: 122168.

DOI URL |

| [60] |

HONG Z Z, XU Z L, WU Z T, et al. Construction of core-shell Co-NC@W2N Schottky heterojunctions for high-efficiency hydrogen evolution reaction. Applied Surface Science, 2023, 608: 155159.

DOI URL |

| [61] |

RUI D, LI J, DU X, et al. VFe@Ni/Ni3N Mott-Schottky heterojunction induced electronic modulation for efficient alkaline water splitting. Journal of Electroanalytical Chemistry, 2023, 947: 117763.

DOI URL |

| [62] |

SAKILA K, PAL S, ROY P, et al. Surface oxygen vacancy engineering of Cr-doped FeNi3/NiFe2O4Mott-Schottky heterojunction as efficient electrocatalyst for high current density water oxidation. Journal of Alloys and Compounds, 2024, 977: 173393.

DOI URL |

| [63] |

JIANG M M, XU J, CHEN Y J, et al. High-efficiency photo- assisted large current-density water splitting with Mott-Schottky heterojunctions. Angewandte Chemie International Edition, 2024, 64(3): e202415492.

DOI URL |

| [64] |

HUANG Z, CHEN L, ZHANG H, et al. Manipulating interfacial charge redistribution in Mott-Schottky electrocatalyst for high-performance water-seawater splitting. Chemical Engineering Journal, 2024, 501: 157628.

DOI URL |

| [65] |

REN Y, WANG C, DUAN W, et al. MoS2/Ni3S2Schottky heterojunction regulating local charge distribution for efficient urea oxidation and hydrogen evolution. Journal of Colloid and Interface Science, 2022, 628: 446.

DOI URL |

| [66] |

GU C, ZHOU G Y, YANG J, et al. NiS/MoS2 Mott-Schottky heterojunction-induced local charge redistribution for high- efficiency urea-assisted energy-saving hydrogen production. Chemical Engineering Journal, 2022, 443: 136321.

DOI URL |

| [1] |

XU Y, WANG C, HUANG Y, et al. Recent advances in electrocatalysts for neutral and large-current-density water electrolysis. Nano Energy, 2021, 80: 105545.

DOI URL |

| [2] |

XU Z, WU Z S. Scalable production of high-performance electrocatalysts for electrochemical water splitting at large current densities. eScience, 2025, 5(4): 100334.

DOI URL |

| [3] |

李宇明, 徐砚文, 刘红宇, 等. 镍基磷化物的合成及其在电解水制氢中的应用. 化工学报, 2024, 75(12): 4385.

DOI |

| [4] |

陈心悦, 陈彬剑, 毛煜东, 等. 碱性电解水析氢催化剂的研究进展及展望. 化工进展, 2025, 44(11): 6334.

DOI |

| [5] |

HU C, LV C, ZENG N, et al. Recent advances in Ni-based electrocatalysts for hydrogen evolution reaction. Energy Technology, 2023, 11(1): 2201048.

DOI URL |

| [6] |

HE H, MAI J H, HU K S, et al. Recent advances in electrocatalysts for efficient hydrogen evolution reaction. Rare Metals, 2025, 44: 2208.

DOI URL |

| [7] | 王红霞, 徐婉怡, 张早校. 可再生电力电解制绿色氢能的发展现状与建议. 化工进展, 2022, 41(S1): 118. |

| [8] | 张正, 宋凌珺. 电解水制氢技术: 进展、挑战与未来展望. 工程科学学报, 2025, 47(2): 282. |

| [9] |

DOU S, WANG X, WANG S Y, et al. Rational design of transition metal-based materials for highly efficient electrocatalysis. Small Methods, 2019, 3(1): 1800211.

DOI URL |

| [10] | 张博轩, 崔金星, 李智芳, 等. 非贵金属析氢电催化剂的结构调控研究进展. 化学通报, 2023, 86(7): 784. |

| [11] |

DO H H, TRAN N T, VAN TRAN V. Recent advancements and perspectives in MoO2-based heterostructures for electrochemical hydrogen evolution reaction. International Journal of Hydrogen Energy, 2025, 105: 234.

DOI URL |

| [12] |

XIONG W, YIN H, WU T, et al. Challenges and opportunities of transition metal oxides as electrocatalysts. Chemistry-A European Journal, 2023, 29(5): e202202872.

DOI URL |

| [13] | ZHU Y L, LIN Q, ZHONG Y J, et al. Metal oxide-based materials as an emerging family of hydrogen evolution electrocatalysts. Energy & Environmental Science, 2020, 13: 3361. |

| [14] |

SHIRAZ H G, CRISPIN X, BERGGREN M. Transition metal sulfides for electrochemical hydrogen evolution. International Journal of Hydrogen Energy, 2021, 46(47): 24060.

DOI URL |

| [15] |

GUO Y, PARK T, YI J W, et al. Nanoarchitectonics for transition- metal-sulfide-based electrocatalysts for water splitting. Advanced Materials, 2019, 31(17): 1807134.

DOI URL |

| [16] | 万凯, 向志朋, 刘文博, 等. 过渡金属硫化物电解水析氢/析氧反应电催化剂研究进展. 科学通报, 2022, 67(19): 2126. |

| [17] |

WANG Z Y, LIU S L, DUAN W, et al. Transition metal selenides as catalysts for electrochemical water splitting. International Journal of Hydrogen Energy, 2024, 60: 1414.

DOI URL |

| [18] |

LI Y, WANG C, ABDUKAYUM A, et al. Advances in green hydrogen generation based on MoSe2 hybrid catalysts. Electrochimica Acta, 2024, 503: 144891.

DOI URL |

| [19] |

白苗苗, 刘江英, 韩婕, 等. 硒化镍基电催化水裂解催化剂的研究进展. 功能材料, 2023, 54(11): 11050.

DOI |

| [20] |

DU M, LI D, LIU S F, et al. Transition metal phosphides: a wonder catalyst for electrocatalytic hydrogen production. Chinese Chemical Letters, 2023, 34(9): 108156.

DOI |

| [21] |

DENG R, GUO M, WANG C, et al. Recent advances in cobalt phosphide-based materials for electrocatalytic water splitting: from catalytic mechanism and synthesis method to optimization design. Nano Materials Science, 2024, 6(2): 139.

DOI URL |

| [22] |

ZHANG W Y, GUO R H, YUE Q X, et al. High-entropy phosphide bifunctional catalyst: preparation and performance of efficient water splitting. Journal of Inorganic Materials, 2024, 39(11): 1265.

DOI URL |

| [23] | PENG X, PI C, ZHANG X, et al. Recent progress of transition metal nitrides for efficient electrocatalytic water splitting. Sustainable Energy & Fuels, 2019, 3(2): 366. |

| [67] |

YUN S, GAO Z, YANG T, et al. Constructing NiSe2/MoSe2 Mott- Schottky heterojunctions onto N-doped brain coral-carbon spheres by phase separation strategies for advanced energy conversion applications. Advanced Functional Materials, 2023, 34(17): 2314226.

DOI URL |

| [68] |

SUN Y, CAO W, GE X, et al. Built-in electric field induced interfacial charge distributions of Ni2P/NiSe2 heterojunction for urea-assisted hydrogen evolution reaction. Inorganic Chemistry Frontiers, 2023, 10: 6674.

DOI URL |

| [69] | QIN M, CHEN L, ZHANG H, et al. Achieving highly efficient pH-universal hydrogen evolution by Mott-Schottky heterojunction of Co2P/Co4N. Chemical Engineering Journal, 2023, 454: 14023. |

| [24] |

蒋博龙, 崔艳艳, 史顺杰, 等. 双金属氮化物NiMoN析氢催化剂制备及其电解海水析氢性能的研究. 化学学报, 2022, 80(10): 1394.

DOI |

| [25] |

JIANG J, QIU Y, DONG H, et al. Enhancing hydrogen evolution by heterointerface engineering of Ni/MoN catalysts. Journal of Colloid and Interface Science, 2025, 686: 681.

DOI PMID |

| [26] |

XU C, HONG Y, LI Z, et al. Transition metal-based heterojunctions for alkaline electrocatalytic water splitting. Coordination Chemistry Reviews, 2025, 523: 216287.

DOI URL |

| [27] | LONG X, MENG J, GU J, et al. Interfacial engineering of NiFeP/ NiFe-LDH heterojunction for efficient overall water splitting. Chinese Journal of Structural Chemistry, 2022, 41(4): 2204046. |

| [28] |

ZHAO G, JIANG Y, DOU S X, et al. Interface engineering of heterostructured electrocatalysts towards efficient alkaline hydrogen electrocatalysis. Science Bulletin, 2021, 66(1): 85.

DOI PMID |

| [29] |

REN X P, LI Q, LING F, et al. Construction of MoO2/MoS2 heterojunction on carbon nanotubes as high-efficiency electrocatalysts for H2 production. CrystEngComm, 2023, 25: 5238.

DOI URL |

| [30] |

XU D, ZHANG S N, LI X H, et al. Design of the synergistic rectifying interfaces in Mott-Schottky catalysts. Chemical Reviews, 2023, 123(1): 1.

DOI URL |

| [31] |

ZHANG H M, LI R, MUHAMMAD H, et al. Recent progress in Mott-Schottky junction electrocatalysts for the pH-universal hydrogen evolution reaction. Materials Chemistry Frontiers, 2024, 8(12): 2811.

DOI URL |

| [32] |

TONG Y X, LIU W, LI C M, et al. A metal/semiconductor contact induced Mott-Schottky junction for enhancing the electrocatalytic activity of water-splitting catalysts. Sustainable Energy Fuels, 2023, 7(1): 12.

DOI URL |

| [33] |

QIAO D, YUN S, SUN M, et al. 1D/3D trepang-like N-modified carbon confined bimetal carbides and metal cobalt: boosting electron transfer via dual Mott-Schottky heterojunctions triggered built-in electric fields for efficient hydrogen evolution and tri-iodide reduction. Applied Catalysis B: Environmental, 2023, 334: 122830.

DOI URL |

| [34] | 刘恩科, 朱秉升, 罗晋生. 半导体物理学. 北京: 电子工业出版社, 2017. |

| [35] |

张伶, 陈红梅, 魏子栋. 过渡金属氧化物催化析氧反应研究进展. 化工学报, 2020, 71(9): 3876.

DOI |

| [36] |

SAHOO S, WICKRAMATHILAKA K Y, NJERI E, et al. A review on transition metal oxides in catalysis. Frontiers in Chemistry, 2024, 12: 1374878.

DOI URL |

| [37] |

CHEN L, WANG H, TIAN W W, et al. Enabling internal electric field in heterogeneous nanosheets to significantly accelerate alkaline hydrogen electrocatalysis. Small, 2024, 20(18): 2307252.

DOI URL |

| [38] |

LI R, PU Z, ZHOU R, et al. In situ controllable construction of Ni@NiO Schottky heterojunctions for electrocatalytic hydrogen evolution. Journal of Materials Chemistry C, 2024, 12(46): 18849.

DOI URL |

| [39] |

CHEN J, ZHENG J, HE W, et al. Self-standing hollow porous Co/a-WOx nanowire with maximum Mott-Schottky effect for boosting alkaline hydrogen evolution reaction. Nano Research, 2023, 16(4): 4603.

DOI |

| [40] |

LIU M, YANG H, ZHOU Z, et al. Homologous heterostructures of Ni/NiFeO Mott-Schottky for alkaline water electrolysis. Journal of Materials Chemistry A, 2024, 12: 22210.

DOI URL |

| [41] |

PENG L, SU L, YU X, et al. Electron redistribution of ruthenium- tungsten oxides Mott-Schottky heterojunction for enhanced hydrogen evolution. Applied Catalysis B: Environmental, 2022, 308: 121229.

DOI URL |

| [42] |

何倩倩, 王哲, 孟令佳, 等. 基于过渡金属二硫族化物析氢催化的研究进展. 高等学校化学学报, 2021, 42(2): 523.

DOI |

| [43] |

SUN J, MENG X. Modulating the electronic properties of MoS2 nanosheets for electrochemical hydrogen production: a review. ACS Applied Nano Materials, 2021, 4(11): 11413.

DOI URL |

| [44] | JIANG L, XIA Y X, LI J J, et al. Engineering Mott-Schottky heterojunction Auδ+/1T-MoS1.76 electrocatalyst for boosting hydrogen evolution reaction. ACS Applied Energy Materials, 2023, 6(6): 3255. |

| [45] |

SUN Z, LIN L, YUAN M W, et al. Mott-Schottky heterostructure induce the interfacial electron redistribution of MoS2 for boosting pH-universal hydrogen evolution with Pt-like activity. Nano Energy, 2022, 101: 107563.

DOI URL |

| [46] |

WAZIR M B, DAUD M, SAFEER S, et al. Review on 2D molybdenum diselenide (MoSe2) and its hybrids for green hydrogen (H2) generation applications. ACS Omega, 2022, 7(20): 16856.

DOI URL |

| [47] |

YANG C M, LI X, LIANG Y C. Recent advances in molybdenum diselenide-based electrocatalysts: preparation and application in the hydrogen evolution reaction. Inorganic Chemistry Frontiers, 2023, 10(19): 5517.

DOI URL |

| [48] |

YANG C, ZHOU L, WANG C, et al. Large-scale synthetic Mo@(2H-1T)-MoSe2 monolithic electrode for efficient hydrogen evolution in all pH scale ranges and seawater. Applied Catalysis B: Environmental, 2022, 304: 120993.

DOI URL |

| [49] |

SONG T, ZHANG Z, ZHAO B, et al. Boosting catalytic performance of hierarchical Co/Co0.85Se microspheres via Mott- Schottky effect toward triiodide reduction and alkaline hydrogen evolution. Journal of Alloys and Compounds, 2022, 918: 165608.

DOI URL |

| [50] |

REN X P, HU Q W, LING F, et al. Mott-Schottky heterojunction formation between Co and MoSe2 on carbon nanotubes towards superior hydrogen evolution. New Carbon Materials, 2023, 38(6): 1059.

DOI URL |

| [51] |

SHI Y M, ZHANG B. Recent advances in transition metal phosphide nanomaterials: synthesis and applications in hydrogen evolution reaction. Chemical Society Reviews, 2016, 45(6): 1529.

DOI PMID |

| [52] |

杨博, 吕功煊, 马建泰, 等. 过渡金属磷化物在催化反应中的稳定性. 化学进展, 2024, 36(7): 998.

DOI |

| [53] |

LIU Z Y, FENG C, YANG S T, et al. 1D/3D dual carbon-supported Mott-Schottky-type Co-Co2P heterojunctions for pH-universal hydrogen evolution. Journal of Colloid and Interface Science, 2024, 657: 559.

DOI URL |

| [54] |

WANG Z, WANG S. Constructing built-in electric field to accelerate the asymmetric local charge distribution for efficient alkaline overall water/seawater splitting. Applied Catalysis B: Environment and Energy, 2024, 352: 124002.

DOI URL |

| [55] |

XUE Z H, SU H, YU Q Y, et al. Janus Co/CoP nanoparticles as efficient Mott-Schottky electrocatalysts for overall water splitting in wide pH range. Advanced Energy Materials, 2017, 7(12): 1602355.

DOI URL |

| [56] |

YAN L, CHEN Y H, XIE J C, et al. Optimizing heterointerface of NiCoP-Co/MXene with regulated charge distribution via built-in electric field for efficient overall water-splitting. Rare Metals, 2025, 44(2): 1067.

DOI URL |

| [1] | 刘占一, 李勉, 欧阳晓平, 柴之芳, 黄庆. 干法后处理熔盐中Sr/Cs去除方法的研究进展[J]. 无机材料学报, 2026, 41(2): 150-158. |

| [2] | 孙炼, 张磊磊, 薛泽旭, 吴坤, 陈晔, 李志远, 王鲁凯, 王尊刚. 面向辐射探测应用的零维金属卤化物闪烁体研究进展[J]. 无机材料学报, 2026, 41(2): 159-176. |

| [3] | 范雨竹, 王媛, 王林燕, 向美玲, 鄢雨婷, 黎本慧, 李敏, 文志东, 王海超, 陈永福, 邱会东, 赵波, 周成裕. 氧化石墨烯基吸附材料去除水体中Pb(II): 制备、性能及机理[J]. 无机材料学报, 2026, 41(1): 12-26. |

| [4] | 邬博宇, 张深根, 张生杨, 刘波, 张柏林. CeO2对MnOx催化剂低温脱硝性能的影响及其机理研究[J]. 无机材料学报, 2026, 41(1): 87-95. |

| [5] | 徐锦涛, 高攀, 何唯一, 蒋圣楠, 潘秀红, 汤美波, 陈锟, 刘学超. 3C-SiC晶体制备研究进展[J]. 无机材料学报, 2026, 41(1): 1-11. |

| [6] | 余升阳, 苏海军, 姜浩, 余明辉, 姚佳彤, 杨培鑫. 激光增材制造超高温氧化物陶瓷孔隙缺陷形成及抑制研究进展[J]. 无机材料学报, 2025, 40(9): 944-956. |

| [7] | 刘江平, 管鑫, 唐振杰, 朱文杰, 罗永明. 含氮挥发性有机化合物催化氧化的研究进展[J]. 无机材料学报, 2025, 40(9): 933-943. |

| [8] | 肖晓琳, 王玉祥, 谷佩洋, 朱圳荣, 孙勇. 二维无机材料调控病损皮肤组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 860-870. |

| [9] | 马景阁, 吴成铁. 无机生物材料用于毛囊和毛发再生的研究[J]. 无机材料学报, 2025, 40(8): 901-910. |

| [10] | 张洪健, 赵梓壹, 吴成铁. 无机生物材料调控神经细胞功能及神经化组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 849-859. |

| [11] | 艾敏慧, 雷波. 微纳米生物活性玻璃: 功能化设计与血管化皮肤再生[J]. 无机材料学报, 2025, 40(8): 921-932. |

| [12] | 王宇彤, 常江, 徐合, 吴成铁. 硅酸盐生物陶瓷/玻璃促创面修复的研究进展:作用、机制和应用方式[J]. 无机材料学报, 2025, 40(8): 911-920. |

| [13] | 马文平, 韩雅卉, 吴成铁, 吕宏旭. 无机活性材料在类器官研究领域的应用[J]. 无机材料学报, 2025, 40(8): 888-900. |

| [14] | 罗晓民, 乔志龙, 刘颍, 杨晨, 常江. 无机生物活性材料调控心肌再生的研究进展[J]. 无机材料学报, 2025, 40(8): 871-887. |

| [15] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||