无机材料学报 ›› 2025, Vol. 40 ›› Issue (9): 957-963.DOI: 10.15541/jim20240515 CSTR: 32189.14.jim20240515

收稿日期:2024-12-12

修回日期:2025-03-21

出版日期:2025-09-20

网络出版日期:2025-03-25

通讯作者:

苏兴华, 教授. E-mail: suxinghua@chd.edu.cn作者简介:李汶金(2000-), 女, 硕士研究生. E-mail: 1691993742@qq.com

基金资助:

LI Wenjin( ), LOU Chengguang, ZHANG Shuai, SU Xinghua(

), LOU Chengguang, ZHANG Shuai, SU Xinghua( )

)

Received:2024-12-12

Revised:2025-03-21

Published:2025-09-20

Online:2025-03-25

Contact:

SU Xinghua, professor. E-mail: suxinghua@chd.edu.cnAbout author:LI Wenjin (2000-), female, Master candidate. E-mail: 1691993742@qq.com

Supported by:摘要:

陶瓷与金属的连接能满足工程领域对高性能结构部件的需求。然而, 金属和陶瓷热膨胀系数的显著差异, 以及金属对陶瓷表面的润湿性较差, 使得陶瓷与金属的连接面临诸多挑战。本研究采用“闪连”技术, 在电场/电流的辅助作用下和相对低的温度下实现了金属Cu和5YSZ(5%氧化钇稳定氧化锆, 摩尔分数)陶瓷的快速连接。研究了电场强度、电流密度和连接时间对金属Cu和5YSZ“闪连”行为和连接程度的影响, 分析讨论了金属Cu和5YSZ的“闪连”机理。结果表明, 在温度为753 ℃、电流密度为10 A/cm2、连接时间为3 min的条件下, 金属Cu和5YSZ的连接界面最致密。进一步提高温度、增大电流或延长“闪连”时间, 连接接头开始恶化, 甚至发生断裂。当“闪连”发生时, 样品中会发生电化学反应, 并产生氧空位缺陷。物相分析和微观结构分析表明, 在电化学反应作用下, 原子扩散促进了Cu和5YSZ的连接, 其中Cu原子扩散进入5YSZ晶格中, 被还原的Zr原子扩散进入Cu晶格中。此外, 电场方向对Cu和5YSZ的连接有极大影响。当电场方向从5YSZ到Cu时, 可实现良好连接; 当电场方向从Cu到5YSZ时, 二者无法实现连接。

中图分类号:

李汶金, 娄程广, 张帅, 苏兴华. 金属Cu和5YSZ陶瓷的“闪连”研究[J]. 无机材料学报, 2025, 40(9): 957-963.

LI Wenjin, LOU Chengguang, ZHANG Shuai, SU Xinghua. Flash Joining of Metal Cu with 5YSZ Ceramics[J]. Journal of Inorganic Materials, 2025, 40(9): 957-963.

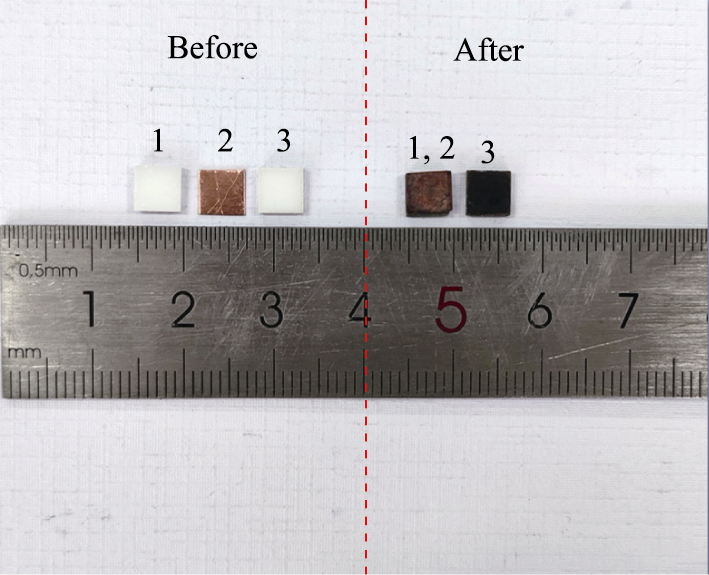

图5 “闪连”前(左: 1-5YSZ; 2-Cu; 3-5YSZ)后(右: 1, 2-Cu-5YSZ; 3-5YSZ)样品的照片

Fig. 5 Photographs of the samples before (left: 1-5YSZ; 2-Cu; 3-5YSZ) and after flash joining (right: 1, 2-Cu-5YSZ joined sample; 3-5YSZ)

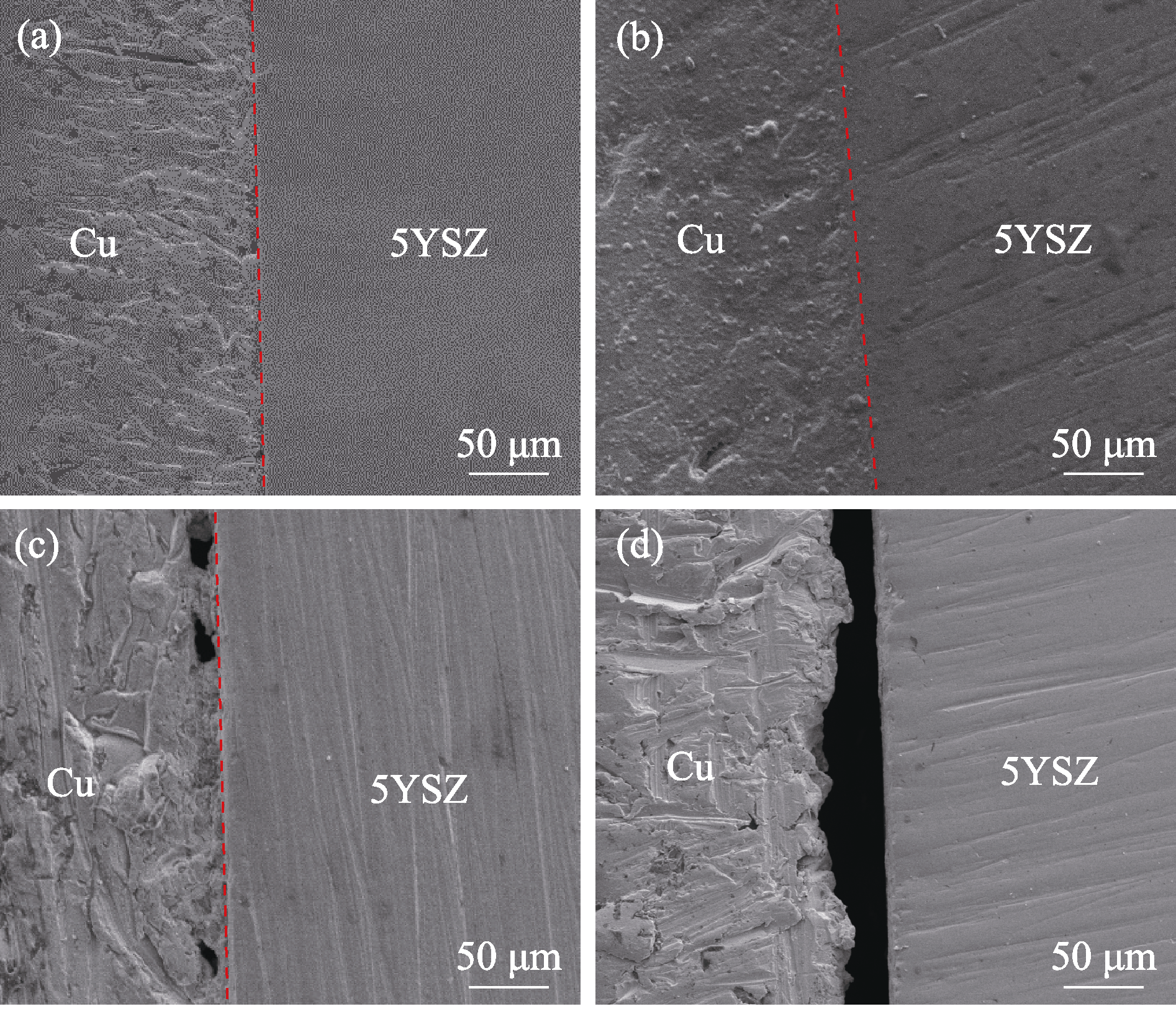

图6 不同“闪连”时间所得接头的SEM照片

Fig. 6 SEM images of the joints with different flash joining times (a) 2 min; (b) 3 min; (c) 5 min; (d) 7 min. Preparation condition: 80 V/cm, 10 A/cm2, 753 ℃

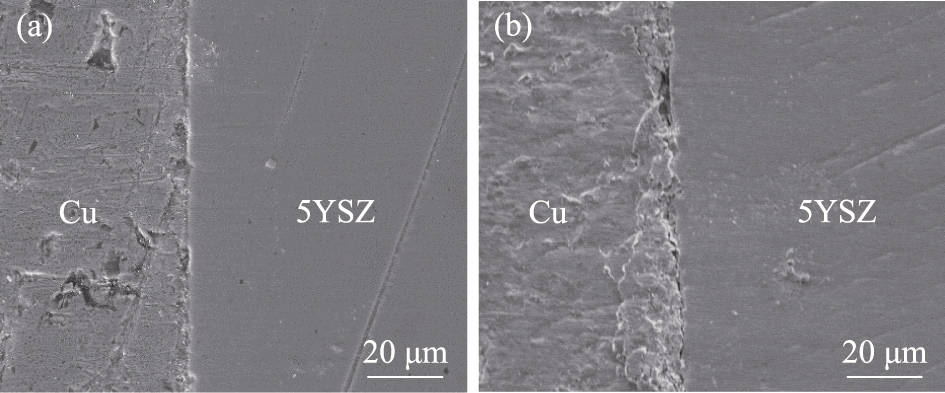

图8 不同“闪连”温度所得接头的SEM照片

Fig. 8 SEM images of the joints flash-jointed at different flash joining temperatures (a) 641 ℃; (b) 780 ℃. Preparation condition: 10 A/cm2, 3 min

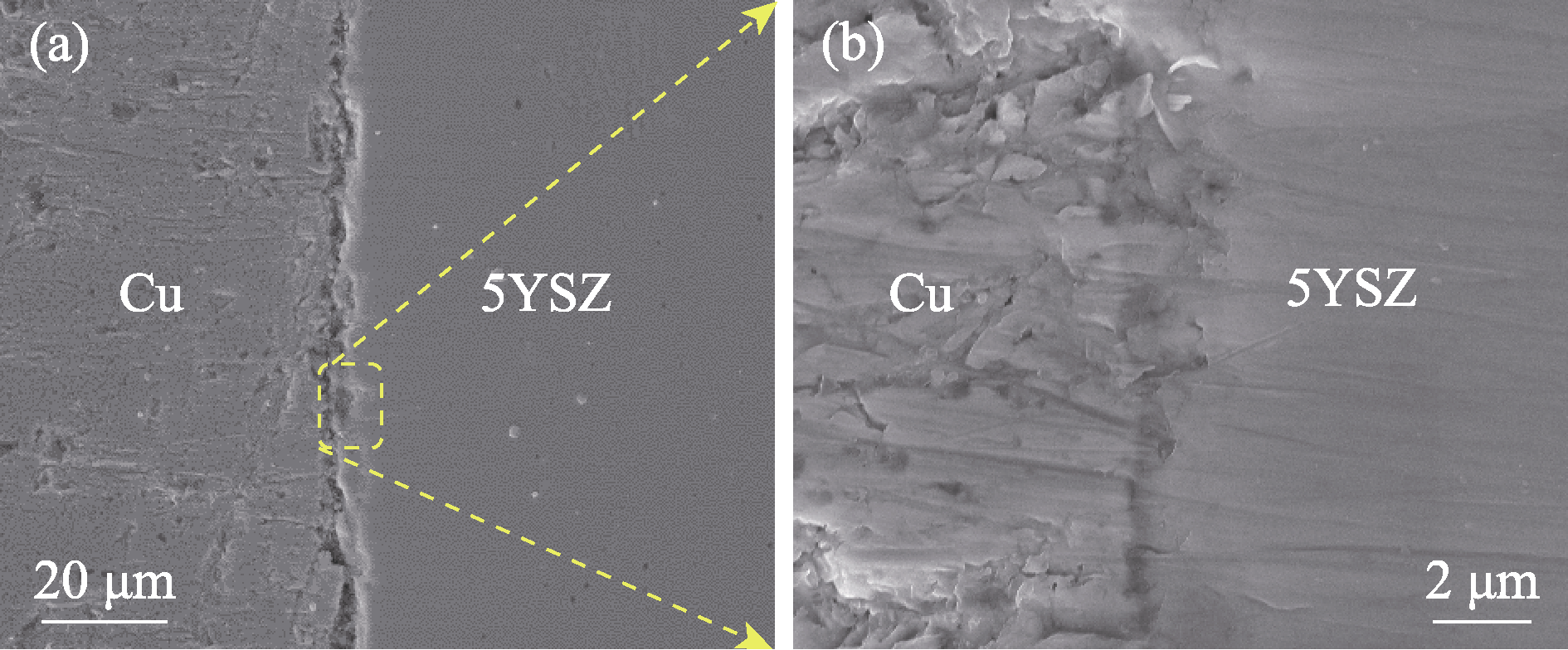

图9 电流密度12 A/cm2、“闪连”温度753 ℃、“闪连”时间3 min条件下所得接头的SEM照片

Fig. 9 SEM images of the joint flash-jointed at a current density of 12 A/cm2, a flash joining temperature of 753 ℃, and a flash joining time of 3 min (b) Local area magnification of Fig. (a)

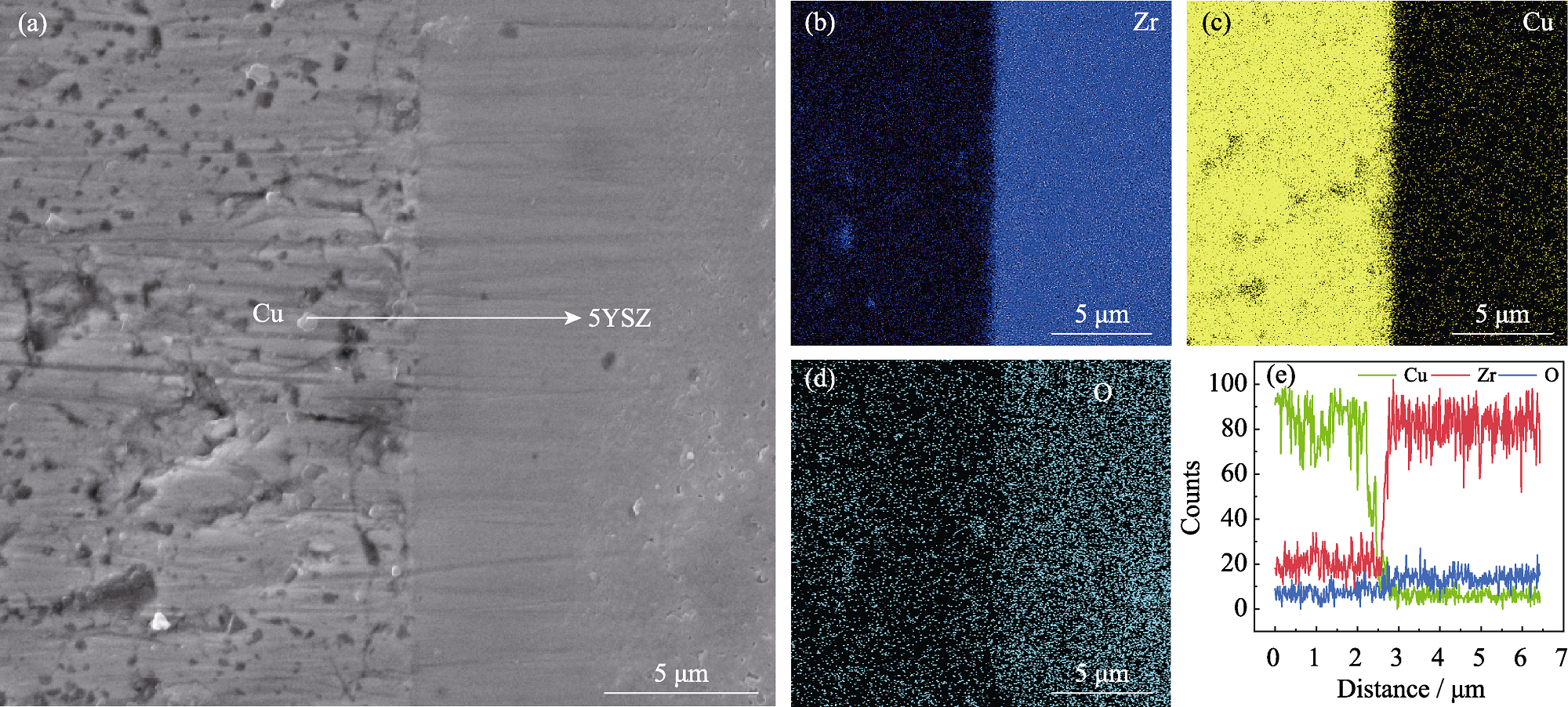

图10 电流密度10 A/cm2、“闪连”温度753 ℃、“闪连”时间3 min条件下所得接头的(a) SEM照片及(b~e)元素分布图

Fig. 10 (a) SEM image and (b-e) element distributions of the joint flash-jointed at a current density of 10 A/cm2, a flash joining temperature of 753 ℃, and a flash joining time of 3 min Colorful figures are available on website

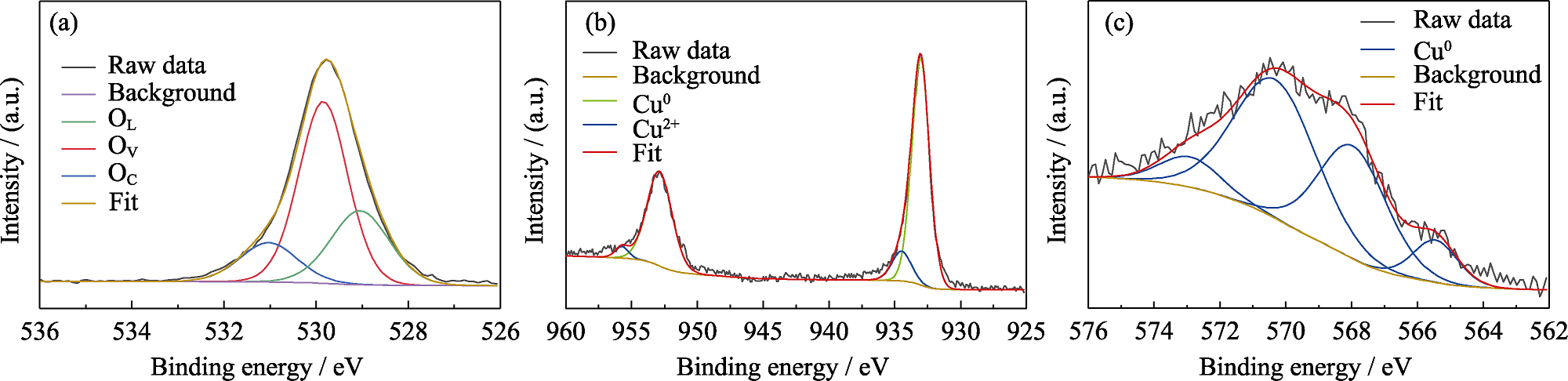

图11 “闪连”后样品的(a) O1s、(b) Cu2p和(c) CuKLL的XPS谱图

Fig. 11 XPS spectra of (a) O1s, (b) Cu2p and (c) CuKLL of the samples after flash joining Colorful figures are available on website

| [1] | HUANG J, DU K F, WANG P L, et al. Electrochemical preparation and homogenization of face-centered FeCoNiCu medium entropy alloy electrodes enabling oxygen evolution reactions. Electrochimica Acta, 2021, 378: 138142. |

| [2] | CAO Y, XU G C, SHEN P. Flash joining of 3YSZ and 430 SS using Ag-CuO filler. Ceramics International, 2022, 48(3): 4005. |

| [3] | LIU Y H, HU J D, ZHANG Y P, et al. Joining of zirconia and Ti-6Al-4V using a Ti-based amorphous filler. Journal of Materials Science & Technology, 2011, 27(7): 653. |

| [4] | HANSON W B, IRONSIDE K I, FERNIE J A. Active metal brazing of zirconia. Acta Materialia, 2000, 48(18/19): 4673. |

| [5] | CAI Q S, LIU W S, MA Y Z, et al. Diffusion brazing of tungsten and steel using Ti-Ni liquid phase forming interlayer. Fusion Engineering and Design, 2015, 91: 67. |

| [6] | POLANCO R, MIRANZO P, OSENDI M I. Fabrication and microstructure of a ZrO2-Ni functionally graded bonding interlayer using the airbrush spraying method. Acta Materialia, 2006, 54(8): 2215. |

| [7] | POLANCO R, MIRANZO P, OSENDI M I. ZrO2-Ni functionally graded joining interlayers: microstructure and properties. Advanced Engineering Materials, 2007, 9(11): 1005. |

| [8] | COLOGNA M, RASHKOVA B, RAJ R. Flash sintering of nanograin zirconia in <5 s at 850 ℃. Journal of the American Ceramic Society, 2010, 93(11): 3556. |

| [9] | STEIL M C, MARINHA D, AMAN Y, et al. From conventional AC flash-sintering of YSZ to hyper-flash and double flash. Journal of the European Ceramic Society, 2013, 33(11): 2093. |

| [10] | DOWNS J A, SGLAVO V M. Electric field assisted sintering of cubic zirconia at 390 ℃. Journal of the American Ceramic Society, 2013, 96(5): 1342. |

| [11] | XIA J B, REN K, WANG Y G. One-second flash joining of zirconia ceramic by an electric field at low temperatures. Scripta Materialia, 2019, 165: 34. |

| [12] | MUNDRA R, GUPTA P, EQBAL A, et al. Flash joining of metal-ceramic multi-layered sandwich structure. Journal of the European Ceramic Society, 2024, 44(1): 353. |

| [13] | XIA J B, REN K, WANG Y G, et al. Reversible flash-bonding of zirconia and nickel alloys. Scripta Materialia, 2018, 153: 31. |

| [14] | YANG B, SHEN P, YU L T, et al. Electrochemically-driven direct joining of Ni and ZrO2. Scripta Materialia, 2017, 141: 41. |

| [15] | XIA J B, REN K, LIU W, et al. Ultrafast joining of zirconia ceramics using electric field at low temperatures. Journal of the European Ceramic Society, 2019, 39(10): 3173. |

| [16] | ZHOU L, LI C, SI X Q, et al. Flash joining of SiC at ultra-low temperature. Journal of the European Ceramic Society, 2023, 43(6): 2713. |

| [17] | XIA J B, REN K, WANG Y G. Flash joining of alumina ceramics under a small current density. Journal of the European Ceramic Society, 2021, 41(4): 2782. |

| [18] | XIA J B, REN K, WANG Y G. Rapid joining of heterogeneous ceramics with a composite interlayer under the action of an electric field. Journal of the European Ceramic Society, 2021, 41(14): 7164. |

| [19] | LIU G W, QIAO G J, WANG H J, et al. Pressureless brazing of zirconia to stainless steel with Ag-Cu filler metal and TiH2 powder. Journal of the European Ceramic Society, 2008, 28(14): 2701. |

| [20] | GAMBARO S, VALENZA F, PASSERONE A, et al. Brazing transparent YAG to Ti6Al4V: reactivity and characterization. Journal of the European Ceramic Society, 2016, 36(16): 4185. |

| [21] | XIA J B, REN W. Flash joining of BaTiO3 ceramic to NiCrFe medium-entropy alloy by using an electric field. Ceramics International, 2023, 49(24): 40924. |

| [22] | WANG L, YU H, HAO Z D, et al. Investigating the effect of solid loading on microstructure, mechanical properties, and translucency of highly translucent zirconia ceramics prepared via stereolithography- based additive manufacturing. Journal of the Mechanical Behavior of Biomedical Materials, 2023, 144: 105952. |

| [23] | LIU C, ZHENG J J, LIU X F, et al. Facile laser-based process of superwetting zirconia ceramic with adjustable adhesion for self-cleaning and lossless droplet transfer. Applied Surface Science, 2023, 638: 158069. |

| [24] | GHAEMI M H, REICHERT S, KRUPA A, et al. Zirconia ceramics with additions of alumina for advanced tribological and biomedical applications. Ceramics International, 2017, 43(13): 9746. |

| [25] | LIU D G, FAN J Y, ZHAO K, et al. Preparation of super-strong ZrO2 ceramics using dynamic hot forging. Journal of the European Ceramic Society, 2023, 43(2): 733. |

| [26] | BICALHO L A, BAPTISTA C A R P, SOUZA R C, et al. Fatigue and subcritical crack growth in ZrO2-bioglass ceramics. Ceramics International, 2013, 39(3): 2405. |

| [27] | YANG H Y, MA Z C, LEI C H, et al. High strength and high conductivity Cu alloys: a review. Science China Technological Sciences, 2020, 63(12): 2505. |

| [28] | LI X W, ZHANG D T, QIU C, et al. Microstructure and mechanical properties of dissimilar pure copper/1350 aluminum alloy butt joints by friction stir welding. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1298. |

| [29] | MUHAMMAD N A, WU C S. Ultrasonic vibration assisted friction stir welding of aluminium alloy and pure copper. Journal of Manufacturing Processes, 2019, 39: 114. |

| [30] | YOSHIDA H, HAYASAKA H, SOGA K, et al. Doping effect on the flash sintering of Y2O3: promotion of densification and optical translucency. Journal of the European Ceramic Society, 2020, 40(15): 6053. |

| [31] | YANG J X, FU M Y, TIAN Q, et al. Preparation of Gd2Zr2O7 nanoceramics by flash sintering and two-step flash sintering. Ceramics International, 2023, 49(11): 16594. |

| [32] |

JIA Y J, SU X H, WU Y J, et al. Flash sintering of 3YSZ/Al2O3-platelet composites. Journal of the American Ceramic Society, 2020, 103(4): 2351.

DOI |

| [33] | JHA S K, TERAUDS K, LEBRUN J M, et al. Beyond flash sintering in 3 mol% yttria stabilized zirconia. Journal of the Ceramic Society of Japan, 2016, 124(4): 283. |

| [34] | BIESUZ M, PINTER L, SAUNDERS T, et al. Investigation of electrochemical, optical and thermal effects during flash sintering of 8YSZ. Materials, 2018, 11(7): 1214. |

| [35] | DASHTBOZORG B, SHI F Z, TAGLIAFERRO A, et al. Plasma defect-engineering of bulk oxygen-deficient zirconia. Acta Materialia, 2024, 262: 119457. |

| [36] | SU X H, LI W J, CHEN D, et al. Rapid fabrication of oxygen-deficient zirconia by flash sintering treatment. Journal of Advanced Ceramics, 2024, 13(11): 1881. |

| [37] | ZHANG J J, GAO Y F, JIA X R, et al. Oxygen vacancy-rich mesoporous ZrO2 with remarkably enhanced visible-light photocatalytic performance. Solar Energy Materials and Solar Cells, 2018, 182: 113. |

| [38] | LV H F, ZHOU Y J, ZHANG X M, et al. Infiltration of Ce0.8Gd0.2O1.9 nanoparticles on Sr2Fe1.5Mo0.5O6-δ cathode for CO2 electroreduction in solid oxide electrolysis cell. Journal of Energy Chemistry, 2019, 35: 71. |

| [39] | LIU P, HENSEN E J M. Highly efficient and robust Au/MgCuCr2O4 catalyst for gas-phase oxidation of ethanol to acetaldehyde. Journal of the American Chemical Society, 2013, 135(38): 14032. |

| [40] | GAO B H, TAN B M, LIU Y L, et al. A study of FTIR and XPS analysis of alkaline-based cleaning agent for removing Cu-BTA residue on Cu wafer. Surface and Interface Analysis, 2019, 51(5): 566. |

| [41] | FINŠGAR M, KOVAČ J, MILOŠEV I. Surface analysis of 1-hydroxybenzotriazole and benzotriazole adsorbed on Cu by X-ray photoelectron spectroscopy. Journal of the Electrochemical Society, 2010, 157(2): C52. |

| [42] |

XIA J B, REN K, WANG Y G. Reversible joining of zirconia to titanium alloy. Ceramics International, 2019, 45(2): 2509.

DOI |

| [43] | JANEK J, KORTE C. Electrochemical blackening of yttria-stabilized zirconia-morphological instability of the moving reaction front. Solid State Ionics, 1999, 116(3/4): 181. |

| [44] | XIA J B, DING T, REN W, et al. Ceramics/metals joining under the influence of electric field: a review. Journal of the European Ceramic Society, 2023, 43(12): 5061. |

| [45] | ZHANG K Y, LI T Y, ZHAO Z Y, et al. Flash joining of Y2O3 transparent ceramic to titanium alloy. Journal of the European Ceramic Society, 2024, 44(1): 408. |

| [46] | XIA J B, REN W, ZHANG Y X, et al. Fast joining of 8YSZ to NiCrFe medium-entropy alloy by using an electric field. Journal of the European Ceramic Society, 2023, 43(10): 4431. |

| [1] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [2] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [3] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [4] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [5] | 孙雨萱, 王政, 时雪, 史颖, 杜文通, 满振勇, 郑嘹赢, 李国荣. 缺陷偶极子热稳定性对Fe掺杂PZT陶瓷机电性能影响研究[J]. 无机材料学报, 2025, 40(5): 545-551. |

| [6] | 范小暄, 郑永炅, 徐丽荣, 姚子敏, 曹硕, 王可心, 王绩伟. 基于富氧空位LiYScGeO4: Bi3+长余辉光催化剂的自激活余辉驱动有机污染物芬顿降解[J]. 无机材料学报, 2025, 40(5): 481-488. |

| [7] | 唐阳, 刘立敏, 周晓亮, 张搏, 蒋星洲, 贾浩义, 罗延麟庆. 质子陶瓷膜反应器的制备及低温氨分解性能研究[J]. 无机材料学报, 2025, 40(11): 1277-1284. |

| [8] | 江强, 施立志, 陈政燃, 周志勇, 梁瑞虹. 高于居里温度极化的硬性PZT压电陶瓷的制备及叠层驱动器性能研究[J]. 无机材料学报, 2024, 39(10): 1091-1099. |

| [9] | 彭萍, 谭礼涛. CuO掺杂(Ba,Ca)(Ti,Sn)O3陶瓷的结构与压电性能[J]. 无机材料学报, 2024, 39(10): 1100-1106. |

| [10] | 柯鑫, 谢炳卿, 王忠, 张敬国, 王建伟, 李占荣, 贺会军, 汪礼敏. 第三代半导体互连材料与低温烧结纳米铜材的研究进展[J]. 无机材料学报, 2024, 39(1): 17-31. |

| [11] | 王润, 相恒阳, 曾海波. 钙钛矿多色级联发光二极管中多中心载流子均衡分布调控研究[J]. 无机材料学报, 2023, 38(9): 1062-1068. |

| [12] | 罗淑文, 马名生, 刘峰, 刘志甫. Ca-B-Si体系LTCC材料腐蚀行为及腐蚀机理[J]. 无机材料学报, 2023, 38(5): 553-560. |

| [13] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [14] | 张万文, 罗建强, 刘淑娟, 马建国, 张小平, 杨松旺. 氧化锆间隔层的低温喷涂制备及其三层结构钙钛矿太阳能电池应用性能[J]. 无机材料学报, 2023, 38(2): 213-218. |

| [15] | 陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||