无机材料学报 ›› 2023, Vol. 38 ›› Issue (2): 155-162.DOI: 10.15541/jim20220326 CSTR: 32189.14.10.15541/jim20220326

所属专题: 【信息功能】电介质储能材料(202506); 【信息功能】介电、铁电、压电材料(202506); 【信息功能】柔性材料(202506)

收稿日期:2022-06-11

修回日期:2022-08-08

出版日期:2023-02-20

网络出版日期:2022-09-15

通讯作者:

胡海龙, 副教授. E-mail: hailonghu@csu.edu.cn作者简介:陈雷(1999-), 男, 硕士研究生. E-mail: sccl@mail.ustc.edu.cn

基金资助:Received:2022-06-11

Revised:2022-08-08

Published:2023-02-20

Online:2022-09-15

Contact:

HU Hailong, associate professor. E-mail: hailonghu@csu.edu.cnAbout author:CHEN Lei (1999-), male, Master candidate. E-mail: sccl@mail.ustc.edu.cn

Supported by:摘要:

与其它储能设备相比, 由介电复合材料制得的介质电容器在快速充放电能力与高功率密度方面极具优势, 如何提高介电复合材料能量密度与优化其击穿性能已成为当前研究热点之一。为进一步调控并兼顾介电常数与击穿性能, 本工作基于DBM(Dielectric Breakdown Model, 介电击穿模型), 采用有限元数值模拟, 研究了无机填料的分布对柔性聚二甲硅氧烷(PDMS)基介电复合材料体系的电场与发生介电击穿时击穿损伤形貌演变的具体影响。研究结果表明: 填料与基体边界处存在较大的介电差异, 可以使用较大介电常数的聚合物基体或较小介电常数的无机填料来减小其界面处的高电场区域, 继而提高复合材料的耐击穿能力;同时发现当无机填料分散更均匀时, 其树状损伤通道更容易产生分支, 此种情况将使介电击穿的树状损伤通道的损伤位点增多, 延缓其损伤速度, 继而提高复合材料的耐击穿性能。该研究结果将为开发高储能密度且具有优异击穿性能的有机-无机复合电介质材料提供坚实的理论依据。

中图分类号:

陈雷, 胡海龙. 柔性PDMS基介电复合材料的电场及击穿损伤形貌演变规律研究[J]. 无机材料学报, 2023, 38(2): 155-162.

CHEN Lei, HU Hailong. Evolution of Electric Field and Breakdown Damage Morphology for Flexible PDMS Based Dielectric Composites[J]. Journal of Inorganic Materials, 2023, 38(2): 155-162.

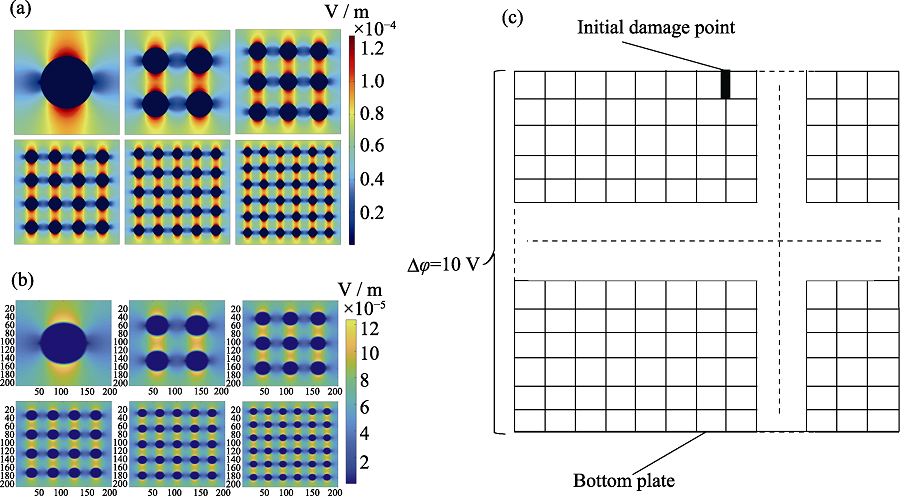

图3 DBM模型的计算方法

Fig. 3 Calculation method of DBM model (a) Electric field distribution determined by finite element analysis; (b) Electric field distribution determined by MATLAB; (c) Two-dimensional array model consisting of 200×200 grid points Colorful figures are available on website

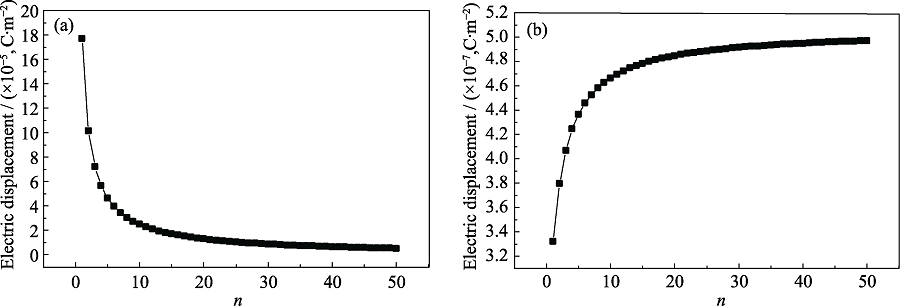

图4 改变填料与基体介电常数之比时, 介电复合材料电位移的变化

Fig. 4 Electrical displacement evolution of dielectric composite material with varied ratio n between fillers and matrix dielectric constant (a)When the dielectric composite filler is selected to be BaTiO3; (b) When the dielectric composite matrix is selected to be PDMS

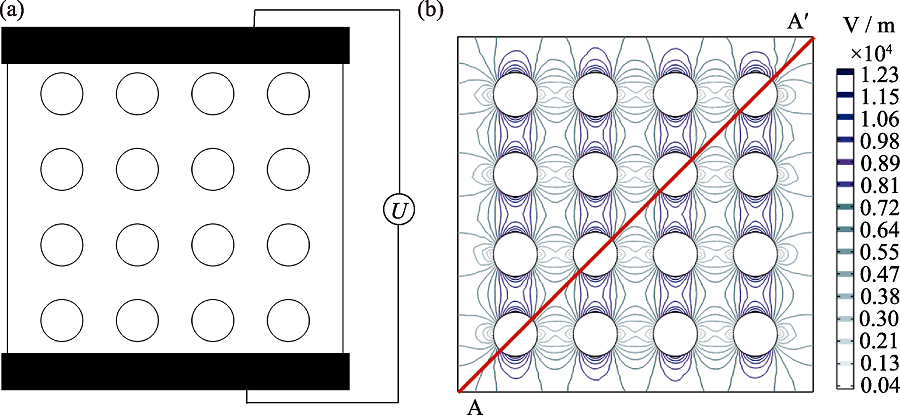

图7 电场分布分析

Fig. 7 Analysis of electric field distribution (a) Dielectric composites composed of filler particles and matrix; (b) Internal electric field distribution in dielectric composites Colorful figures are available on website

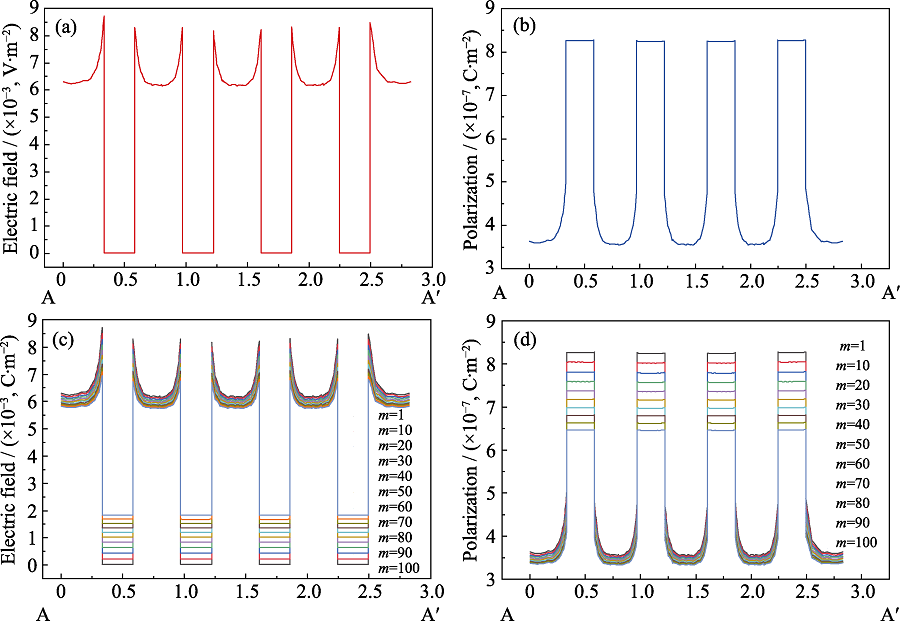

图8 不同介电常数时的电场及电位移场分布

Fig. 8 Electric field and displacement field distribution with different dielectric constant (a) Electric field distribution along AA' transversal; (b) Electric displacement field distribution along AA' transversal; (c) Electric field distribution along AA' transversal with dielectric constant of filler particles reduced by m times; (d) Electric displacement field distribution along AA' transversal with dielectric constant of filler particles reduced by m times Colorful figures are available on website

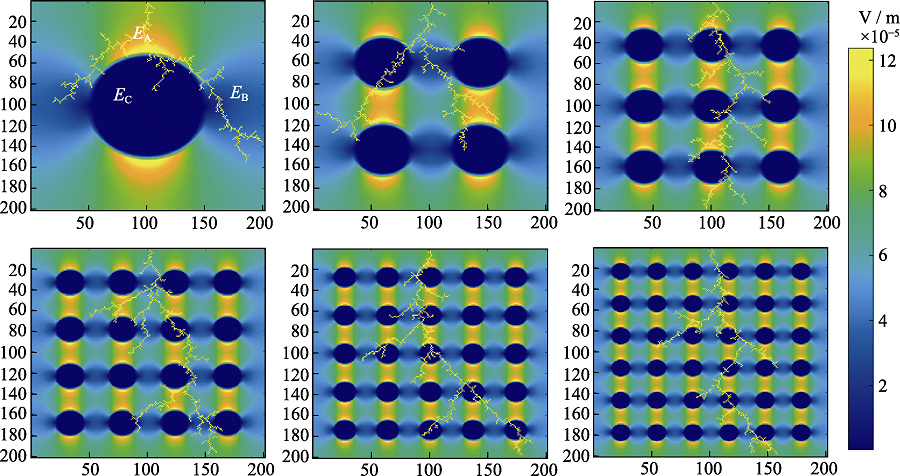

图9 添加不同无机填料含量的介电复合材料的击穿损伤形貌

Fig. 9 Breakdown damage morphologies of dielectric composites with different contents of inorganic fillers Colorful figures are available on website

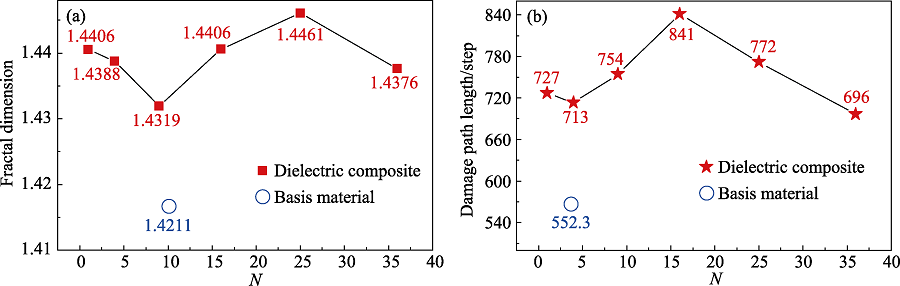

图10 不同含量无机填料的介电复合材料与纯聚合物基体的损伤形貌量化对比分析

Fig. 10 Quantitative analysis of breakdown damage morphology between dielectric composite with different contents of filler particles and pure polymer matrix (a) Fractal dimension; (b) Damage path length

| [1] |

LI D, ZENG X, LI Z, et al. Progress and perspectives in dielectric energy storage ceramics. Journal of Advanced Ceramics, 2021, 10(4): 675.

DOI URL |

| [2] |

CHU B, XIN Z, REN K, et al. A dielectric polymer with high electric energy density and fast discharge speed. Science, 2006, 313(5785): 334.

PMID |

| [3] |

HU H, ZHANG F, LUO S, et al. Recent advances in rational design of polymer nanocomposite dielectrics for energy storage. Nano Energy, 2020, 74: 104844.

DOI URL |

| [4] |

HU H, ZHANG F, LUO S, et al. Electrocaloric effect in relaxor ferroelectric polymer nanocomposites for solid-state cooling. Journal of Materials Chemistry A, 2020, 8(33): 16814.

DOI URL |

| [5] |

WANG L, GAO F, XU J, et al. Enhanced dielectric tunability and energy storage properties of plate-like Ba0.6Sr0.4TiO3/poly(vinylidene fluoride) composites through texture arrangement. Composites Science and Technology, 2018, 158: 112.

DOI URL |

| [6] |

WANG SIJING, QU PENG, LI CHENG, et al. Hydrothermal synthesis of dendritic BaTiO3 ceramic powders and its application in BaTiO3/P(VDF-TrFE) composites. International Journal of Applied Ceramic Technology, 2017, 14(5): 969.

DOI URL |

| [7] |

WANG Y, WANG L, YUAN Q, et al. Ultrahigh energy density and greatly enhanced discharged efficiency of sandwich-structured polymer nanocomposites with optimized spatial organization. Nano Energy, 2018, 44: 364.

DOI URL |

| [8] |

HOLLAND I. Fundamentals of the finite element method. Computers & Structures, 1974, 4(1): 3.

DOI URL |

| [9] |

BERGERO P, PERUANI F, SOLOVEY G, et al. Dielectric breakdown model for conductor-loaded and insulator-loaded composite materials. Physical Review E, 2004, 69(1): 016123.

DOI URL |

| [10] |

NIEMEYER L, PIETRONERO L, WIESMANN H J. Fractal dimension of dielectric breakdown. Physical Review Letters, 1984, 52(12): 1033.

DOI URL |

| [11] |

ADILA ISMAIL F, ROZANA A M O, SOBRI IDRIS M, et al. Dielectric and microstructural properties of BaTiO3 and Ba0.9925Er0.0075TiO3 ceramics. EPJ Web of Conferences, 2017, 162: 01051.

DOI URL |

| [12] |

MENG X, ZHANG Z, LIN D, et al. Effects of particle size of dielectric fillers on the output performance of piezoelectric and triboelectric nanogenerators. Journal of Advanced Ceramics, 2021, 10(5): 991.

DOI URL |

| [13] | FENG X J, LIU X L, ZHAO K, et al. Effects of dopamine- modified BaTiO3 on breakdown strength of BaTiO3/PVDF composites. Acta Materiae Compositae Sinica, 2015, 32(3): 699. |

| [14] |

CHEN S S, HU J, GAO L, et al. Enhanced breakdown strength and energy density in PVDF nanocomposites with functionalized MgO nanoparticles. RSC Advances, 2016, 6(40): 33231.

DOI URL |

| [15] | 迟晓红.纳米蒙脱土/聚烯烃复合材料结构形态与电树生长机理研究. 哈尔滨: 哈尔滨理工大学博士学位论文, 2015. |

| [16] | 薛福明.基于WZ模型的电树枝生长仿真分析. 哈尔滨: 哈尔滨理工大学硕士学位论文, 2012. |

| [17] |

IMAI T, SAWA F, OZAKI T, et al. Influence of temperature on mechanical and insulation properties of epoxy-layered silicate nanocomposite. IEEE Transactions on Dielectrics and Electrical Insulation, 2006, 13(2): 445.

DOI URL |

| [18] | ZHOU K, BOGGS S A, RAMPRASAD R, et al. Dielectric response and tunability of a dielectric-paraelectric composite. Applied Physics Letters, 2008, 93(10): 325. |

| [19] |

ZHU L. Exploring strategies for high dielectric constant and low loss polymer dielectrics. Journal of Physical Chemistry Letters, 2014, 5(21): 3677.

DOI PMID |

| [20] |

HUANG X, JIANG P. Core-shell structured high-k polymer nanocomposites for energy storage and dielectric applications. Advanced Materials, 2015, 27(3): 546.

DOI URL |

| [1] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [2] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [3] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [4] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [5] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| [6] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [7] | 杨舒琪, 杨存国, 牛慧祝, 石唯一, 舒珂维. GeP3/科琴黑复合材料作为钠离子电池高性能负极材料[J]. 无机材料学报, 2025, 40(3): 329-336. |

| [8] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [9] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [10] | 王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38. |

| [11] | 全文心, 余艺平, 方冰, 李伟, 王松. 管状C/SiC复合材料高温空气氧化行为与宏细观建模研究[J]. 无机材料学报, 2024, 39(8): 920-928. |

| [12] | 何思哲, 王俊舟, 张勇, 费嘉维, 吴爱民, 陈意峰, 李强, 周晟, 黄昊. 高频低损耗的Fe/亚微米FeNi软磁复合材料[J]. 无机材料学报, 2024, 39(8): 871-878. |

| [13] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [14] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [15] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||