无机材料学报 ›› 2024, Vol. 39 ›› Issue (12): 1384-1390.DOI: 10.15541/jim20240241 CSTR: 32189.14.10.15541/jim20240241

李宪珂( ), 张超逸, 黄林, 孙鹏, 刘波, 徐军, 唐慧丽(

), 张超逸, 黄林, 孙鹏, 刘波, 徐军, 唐慧丽( )

)

收稿日期:2024-05-13

修回日期:2024-05-29

出版日期:2024-06-24

网络出版日期:2024-06-24

通讯作者:

唐慧丽, 教授. E-mail: tanghl@tongji.edu.cn作者简介:李宪珂(1999-), 男, 硕士研究生. E-mail: va142857@163.com

基金资助:

LI Xianke( ), ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili(

), ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili( )

)

Received:2024-05-13

Revised:2024-05-29

Published:2024-06-24

Online:2024-06-24

Contact:

TANG Huili, professor. E-mail: tanghl@tongji.edu.cnAbout author:LI Xianke (1999-), male, Master candidate. E-mail: va142857@163.com

Supported by:摘要:

β-Ga2O3是一种新型超宽带隙半导体材料, 性能出色, 在高功率电子器件和日盲深紫外探测器等领域有着巨大的应用前景。通过掺入In3+离子, 可以调节β-Ga2O3的带隙宽度和光学性质, 从而进一步拓展其应用范围。本研究以高纯度Ga2O3、In2O3为原料, 采用光学浮区法制备了β-Ga2O3:9%In、β-Ga2O3:15%In单晶。生长速度为5 mm/h时, 晶体出现失透现象, 在光学显微镜下观察, 发现晶体中含有大量气泡缺陷, 这些缺陷主要呈条状和球状, 其中条状气泡的长度在50~200 μm范围内, 沿[010]晶体生长方向延伸。通过扫描电子显微镜观察缺陷形貌和元素分布, 发现气泡周围的元素分布均匀, 无杂质元素聚集。结果表明, 缺陷的形成与In2O3高温分解有关, 产生的气体未及时排出, 随熔体结晶进入晶体内部形成气泡。优化晶体生长工艺解决了气泡缺陷引起的晶体失透问题, 得到的透明β-Ga2O3:9%In单晶摇摆曲线半峰宽可达44 arcsec, 晶体的结晶质量显著提升。本研究为生长高质量β-Ga2O3:In体块单晶提供了解决方案, 为深入了解其光电性能奠定了基础。

中图分类号:

李宪珂, 张超逸, 黄林, 孙鹏, 刘波, 徐军, 唐慧丽. 高质量铟掺杂氧化镓单晶浮区法生长研究[J]. 无机材料学报, 2024, 39(12): 1384-1390.

LI Xianke, ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili. High-quality Indium-doped Gallium Oxide Single Crystal Growth by Floating Zone Method[J]. Journal of Inorganic Materials, 2024, 39(12): 1384-1390.

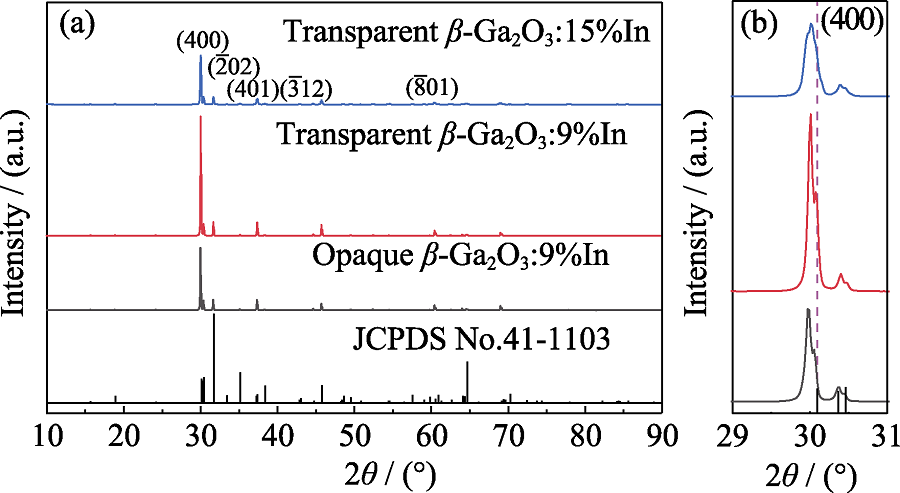

图2 β-Ga2O3: In晶体粉末的XRD图谱

Fig. 2 XRD patterns of β-Ga2O3:In crystal powders (a) XRD patterns in the range of 2θ=10°-90°; (b) XRD diffraction peak of (400) crystal surface at 2θ=30.095°

图3 光学显微镜下失透β-Ga2O3:9%In气泡缺陷形貌

Fig. 3 Optical microscope morphologies of bubble defects in opaque β-Ga2O3:9%In (a) Long strip bubble; (b) Short strip bubble; (c) Spherical bubble; (d) Short strip bubble

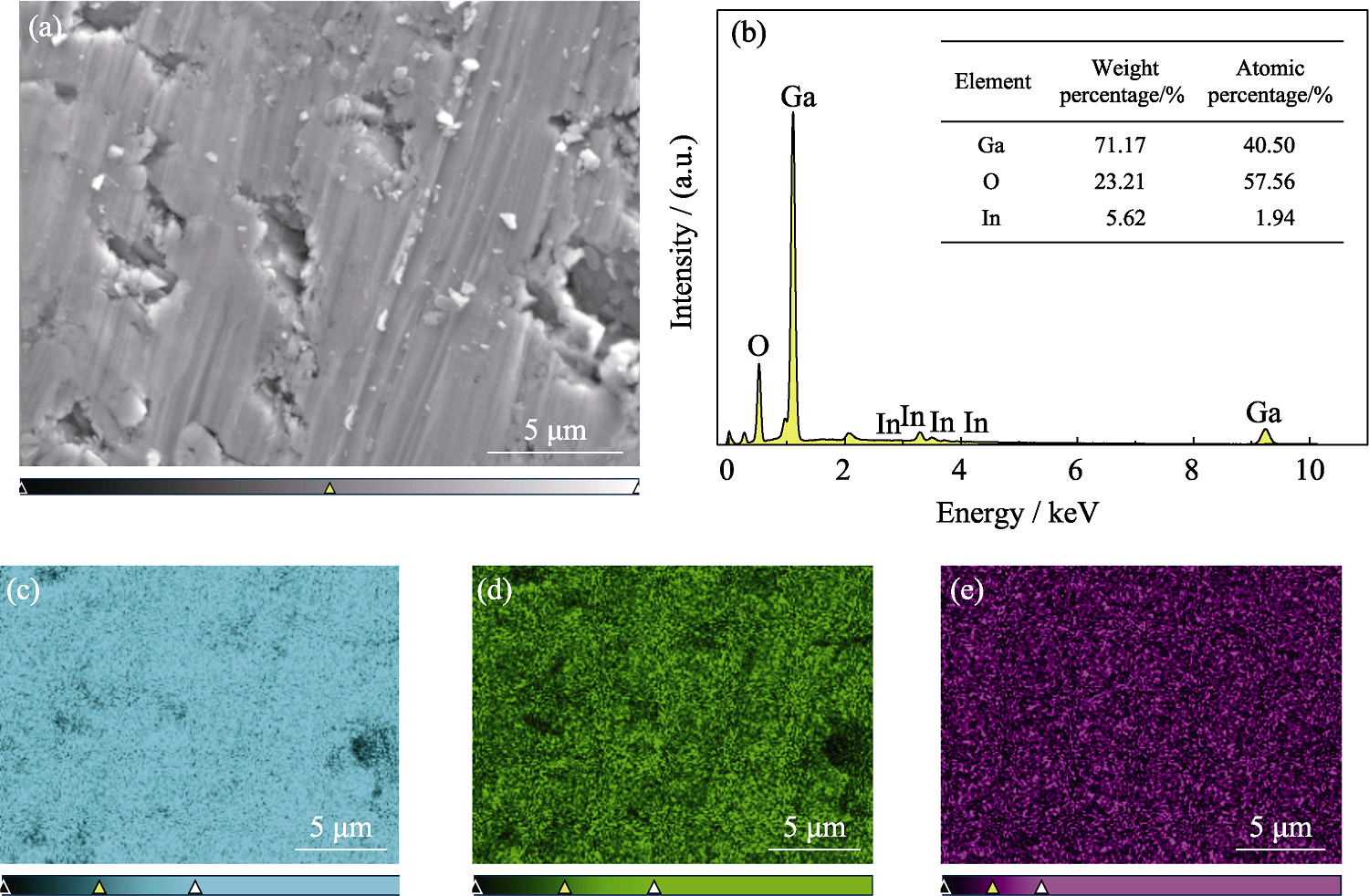

图4 失透β-Ga2O3:9%In晶体SEM照片、EDS能谱和对应的元素分布

Fig. 4 SEM image, EDS pattern and corresponding elemental mappings of the opaque β-Ga2O3:9%In crystal (a) SEM image; (b) EDS pattern and elemental contents; (c-e) Elemental mappings of (c) Ga, (d) O and (e) In

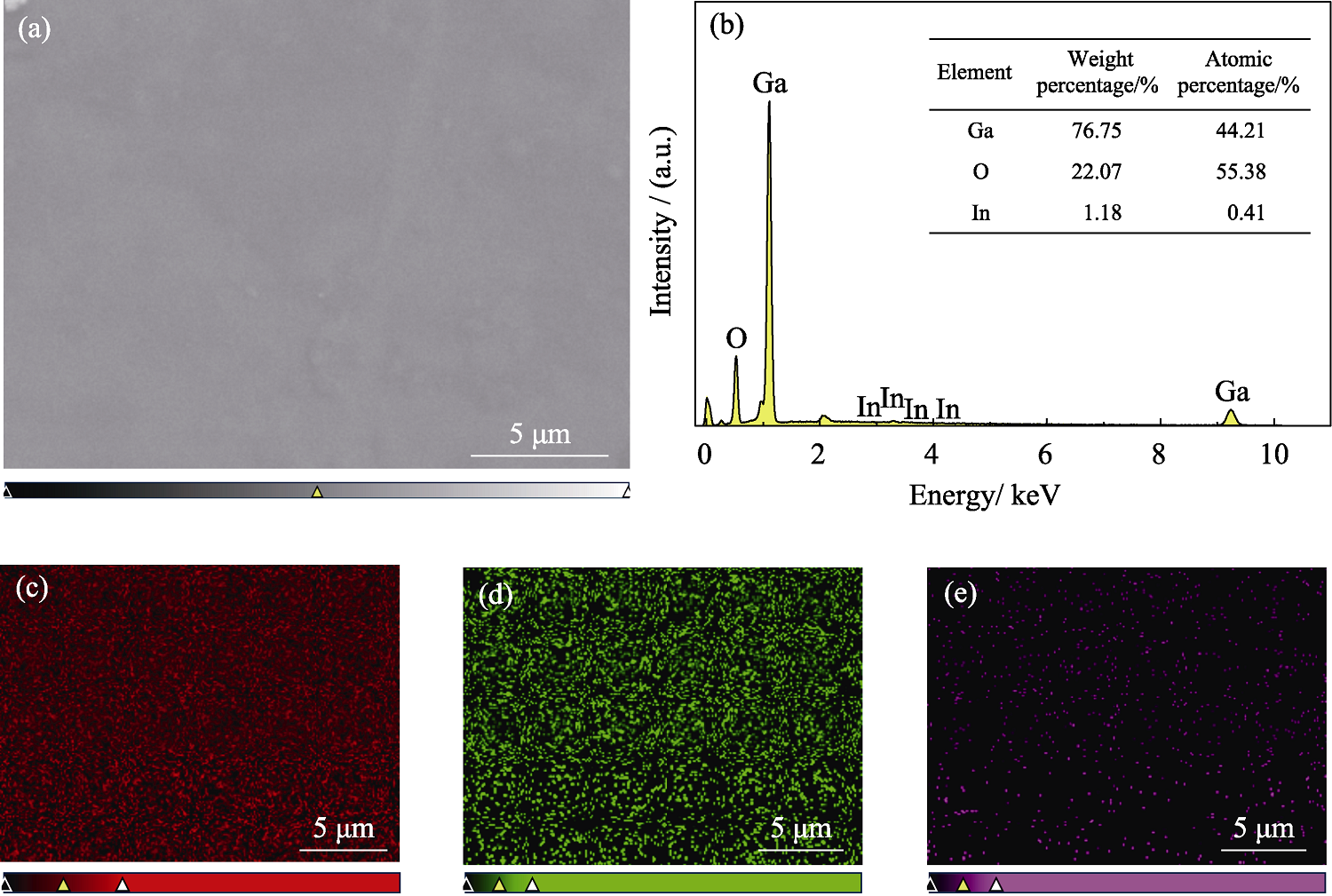

图6 透明β-Ga2O3:9%In晶体SEM照片、EDS能谱和对应的元素分布

Fig. 6 SEM image, EDS pattern and corresponding elemental mappings of transparent β-Ga2O3:9%In crystal (a) SEM image; (b) EDS pattern and elemental contents; (c-e) Elemental mappings of (c) Ga, (d) O and (e) In

| Element | β-Ga2O3:9%In | β-Ga2O3:15%In |

|---|---|---|

| In | 1.76 | 1.87 |

| Si | 0.01 | 0.03 |

| Al | 0.01 | 0.01 |

| Fe | 0.01 | 0 |

| Mg | 0.02 | 0.02 |

表1 透明β-Ga2O3:9%In、β-Ga2O3:15%In晶体的ICP-AES测试结果(%, in mass)

Table 1 ICP-AES testing of transparent β-Ga2O3:9%In and β-Ga2O3:15%In crystals (%, in mass)

| Element | β-Ga2O3:9%In | β-Ga2O3:15%In |

|---|---|---|

| In | 1.76 | 1.87 |

| Si | 0.01 | 0.03 |

| Al | 0.01 | 0.01 |

| Fe | 0.01 | 0 |

| Mg | 0.02 | 0.02 |

图7 UID β-Ga2O3和β-Ga2O3:In晶体的吸收光谱和光学带隙

Fig. 7 Absorption spectra and optical bandgaps of UID β-Ga2O3 and β-Ga2O3:In crystals (a) Absorption spectra of UID β-Ga2O3, opaque β-Ga2O3:9%In, transparent β-Ga2O3:9%In and transparent β-Ga2O3:15%In crystals; (b) Optical bandgap fitting of UID β-Ga2O3, transparent β-Ga2O3:9%In and transparent β-Ga2O3:15%In crystals

| [1] | ZHANG J, LI B, XIA C, et al. Growth and spectral characterization of β-Ga2O3 single crystals. Journal of Physics and Chemistry of Solids, 2006, 67(12): 2448. |

| [2] | TIPPINS H H. Optical absorption and photoconductivity in the band edge of β-Ga2O3. Physical Review, 1965, 140(1A): A316. |

| [3] | MATSUMOTO T, AOKI M, KINOSHITA A, et al. Absorption and reflection of vapor grown single crystal platelets of β-Ga2O3. Japanese Journal of Applied Physics, 1974, 13(10): 1578. |

| [4] | RICCI F, BOSCHI F, BARALDI A, et al. Theoretical and experimental investigation of optical absorption anisotropy in β-Ga2O3. Journal of Physics: Condensed Matter, 2016, 28(22): 224005. |

| [5] | ONUMA T, SAITO S, SASAKI K, et al. Valence band ordering in β-Ga2O3 studied by polarized transmittance and reflectance spectroscopy. Japanese Journal of Applied Physics, 2015, 54(11): 112601. |

| [6] | HE N, TANG H, LIU B, et al. Ultra-fast scintillation properties of β-Ga2O3 single crystals grown by floating zone method. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2018, 888: 9. |

| [7] | GALAZKA Z, GANSCHOW S, SEYIDOV P, et al. Two inch diameter, highly conducting bulk β-Ga2O3 single crystals grown by the Czochralski method. Applied Physics Letters, 2022, 120(15): 152101. |

| [8] | UEDA Y, IGARASHI T, KOSHI K, et al. Two-inch Fe-doped β-Ga2O3 (010) substrates prepared using vertical bridgman method. Japanese Journal of Applied Physics, 2023, 62: SF1006. |

| [9] | TANG H, HE N, ZHANG H, et al. Inhibition of volatilization and polycrystalline cracking, and the optical properties of β-Ga2O3 grown by the EFG method. CrystEngComm, 2020, 22(5): 924. |

| [10] | LI Z, CHEN J, TANG H, et al. Band gap engineering in β-Ga2O3 for a high-performance X-ray detector. ACS Applied Electronic Materials, 2021, 3(10): 4630. |

| [11] | ZHANG C, TANG H, LI J, et al. Boltzmann thermometer with broadband emission in Mn4+-doped β-Ga2O3 crystals. Journal of Luminescence, 2024, 267: 120334. |

| [12] | XIAO H, SHAO G, SAI Q, et al. Wide Bandgap engineering of β-(Al, Ga)2O3 mixed crystals. Journal of Inorganic Materials, 2016, 31(11): 1258. |

| [13] | KPKUBUN Y, ABE T, NAKAGOMI S. Sol-Gel prepared (Ga1-xInx)2O3 thin films for solar-blind ultraviolet photodetectors. Physica Status Solidi (a), 2010, 207(7): 1741. |

| [14] | SEACAT S, LYONS J L, PEELAERS H. Properties of orthorhombic Ga2O3 alloyed with In2O3 and Al2O3. Applied Physics Letters, 2021, 119(4): 042104. |

| [15] | SHAIK E B, KAMAL C S, SRINIVASU K, et al. Optical insights of indium-doped β-Ga2O3 nanoparticles and its luminescence mechanism. Journal of Materials Science: Materials in Electronics, 2020, 31(8): 6185. |

| [16] | LIN T, XIE C, YANG S, et al. Investigation on the bandgap- adjustable (Ga1-xInx)2O3 film prepared by magnetron sputtering. ACS Applied Electronic Materials, 2024, 6(3): 1858. |

| [17] | SUN S M, LIU W J, WANG Y P, et al. Band alignment of In2O3/ β-Ga2O3 interface determined by X-ray photoelectron spectroscopy. Applied Physics Letters, 2018, 113(3): 031603. |

| [18] | TANG H, WU Q, LUO P, et al. Growth and property of In:Ga2O3 oxide semiconductor single crystal. Journal of Inorganic Materials, 2017, 32(6): 621. |

| [19] | GALAZKA Z, UECKER R, IRMSCHER K, et al. Melt growth, characterization and properties of bulk In2O3 single crystals. Journal of Crystal Growth, 2013, 362: 349. |

| [20] | OSHIMA T, FUJITA S. Properties of Ga2O3-based (InxGa1-x)2O3 alloy thin films grown by molecular beam epitaxy. Physica Status Solidi (c), 2008, 5(9): 3113. |

| [21] | ZHANG F, SAITO K, TANAKA T, et al. Wide bandgap engineering of (GaIn)2O3 films. Solid State Communications, 2014, 186: 28. |

| [22] | ZHANG F, SUN J, LI H, et al. Band-gap tunable (GaxIn1-x)2O3 layer grown by magnetron sputtering. Frontiers of Information Technology & Electronic Engineering, 2021, 22(10): 1370. |

| [23] | VASYLTSIV V I, RYM Y I, ZAKHARKO Y M. Optical absorption and photoconductivity at the band edge of β-Ga2-xInxO3. Physica Status Solidi (b), 1996, 195(2): 653. |

| [24] | WU Q, TANG H, SU L, et al. Growth and properties of β-Ga2O3:In single crystal by optical floating zone method. Journal of the Chinese Ceramic Society, 2017, 45(4): 548. |

| [25] | LI Z, TANG H, LI Y, et al. Enhanced scintillation performance of β-Ga2O3 single crystals by Al3+ doping and its physical mechanism. Applied Physics Letters, 2022, 121(10): 102102. |

| [26] | TANG H, HE N, ZHU Z, et al. Temperature-dependence of X-ray excited luminescence of β-Ga2O3 single crystals. Applied Physics Letters, 2019, 115(7): 071904. |

| [27] | VARLEY J B, WEBER J R, JANOTTI A, et al. Oxygen vacancies and donor impurities in β-Ga2O3. Applied Physics Letters, 2010, 97(14): 142106. |

| [28] | WANG V, XIAO W, KANG L J, et al. Sources of n-type conductivity in GaInO3. Journal of Physics D: Applied Physics, 2015, 48(1): 015101. |

| [29] | VÍLLORA E G, YAMAGA M, INOUE T, et al. Optical spectroscopy study on β-Ga2O3. Japanese Journal of Applied Physics, 2002, 41: L622. |

| [30] | ISLAM M M, RANA D, HERNANDEZ A, et al. Study of trap levels in β-Ga2O3 by thermoluminescence spectroscopy. Journal of Applied Physics, 2019, 125(5): 055701. |

| [1] | 蔡豪, 汪琦航, 邹朝勇. 镁离子调控无定形碳酸钙制备一水碳酸钙结晶过程[J]. 无机材料学报, 2024, 39(11): 1275-1282. |

| [2] | 郝永鑫, 秦娟, 孙军, 杨金凤, 李清连, 黄贵军, 许京军. 坩埚底角形状对提拉法生长同成分铌酸锂晶体的影响[J]. 无机材料学报, 2024, 39(10): 1167-1174. |

| [3] | 秦娟, 梁丹丹, 孙军, 杨金凤, 郝永鑫, 李清连, 张玲, 许京军. 提拉法生长平肩同成分铌酸锂晶体的研究[J]. 无机材料学报, 2023, 38(8): 978-986. |

| [4] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [5] | 杨佳雪, 李雯, 王燕, 朱昭捷, 游振宇, 李坚富, 涂朝阳. Dy3+: Y3Al5O12晶体的光谱与黄色激光性能[J]. 无机材料学报, 2023, 38(3): 350-356. |

| [6] | 吴振, 李慧芳, 张中晗, 张振, 李阳, 蓝江河, 苏良碧, 武安华. 面向磁光应用的CeF3晶体生长与性能表征[J]. 无机材料学报, 2023, 38(3): 296-302. |

| [7] | 齐雪君, 张健, 陈雷, 王绍涵, 李翔, 杜勇, 陈俊锋. 坩埚下降法生长大尺寸Bi12GeO20晶体的宏观缺陷[J]. 无机材料学报, 2023, 38(3): 280-287. |

| [8] | 齐占国, 刘磊, 王守志, 王国栋, 俞娇仙, 王忠新, 段秀兰, 徐现刚, 张雷. GaN单晶的HVPE生长与掺杂进展[J]. 无机材料学报, 2023, 38(3): 243-255. |

| [9] | 张超逸, 唐慧丽, 李宪珂, 王庆国, 罗平, 吴锋, 张晨波, 薛艳艳, 徐军, 韩建峰, 逯占文. 新型GaN与ZnO衬底ScAlMgO4晶体的研究进展[J]. 无机材料学报, 2023, 38(3): 228-242. |

| [10] | 陈昆峰, 胡乾宇, 刘锋, 薛冬峰. 多尺度晶体材料的原位表征技术与计算模拟研究进展[J]. 无机材料学报, 2023, 38(3): 256-269. |

| [11] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [12] | 徐家跃, 李志超, 潘芸芳, 周鼎, 温丰, 马文军. 超化学计量比氧化铀晶体的研究进展[J]. 无机材料学报, 2020, 35(11): 1183-1192. |

| [13] | 李荣辉, 郏义征, 胡楠楠. 三维层级花状活性氧化铝纳米材料的制备及其除砷性能研究[J]. 无机材料学报, 2019, 34(5): 553-559. |

| [14] | 王东海, 薛艳艳, 李纳, 周仕明, 徐晓东, 李东振, 徐军, 王庆国. 导模法生长微孔蓝宝石晶体工艺及性能研究[J]. 无机材料学报, 2019, 34(12): 1290-1294. |

| [15] | 陈巧玲, 罗敏, 林晨升. 新型紫外非线性光学晶体KNa5Ca5(CO3)8的合成、表征及性能的研究[J]. 无机材料学报, 2018, 33(6): 667-672. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||