无机材料学报 ›› 2024, Vol. 39 ›› Issue (4): 409-415.DOI: 10.15541/jim20230479 CSTR: 32189.14.10.15541/jim20230479

张婷婷( ), 王方园, 刘长友(

), 王方园, 刘长友( ), 张国荣, 吕佳辉, 宋宇晨, 介万奇

), 张国荣, 吕佳辉, 宋宇晨, 介万奇

收稿日期:2023-10-17

修回日期:2023-11-21

出版日期:2024-04-20

网络出版日期:2023-12-04

通讯作者:

刘长友, 副教授. E-mail: lcy@nwpu.edu.cn作者简介:张婷婷(2000-), 女, 硕士研究生. E-mail: zhangtt@mail.nwpu.edu.cn

基金资助:

ZHANG Tingting( ), WANG Fangyuan, LIU Changyou(

), WANG Fangyuan, LIU Changyou( ), ZHANG Guorong, LÜ Jiahui, SONG Yuchen, JIE Wanqi

), ZHANG Guorong, LÜ Jiahui, SONG Yuchen, JIE Wanqi

Received:2023-10-17

Revised:2023-11-21

Published:2024-04-20

Online:2023-12-04

Contact:

LIU Changyou, associated professor. E-mail: lcy@nwpu.edu.cnAbout author:ZHANG Tingting(2000-), female, Master candidate. E-mail: zhangtt@mail.nwpu.edu.cn

Supported by:摘要:

Cr2+掺杂ZnSe纳米晶是一种重要的中红外材料, 核壳结构的ZnSe基半导体纳米晶表现出优异的光学、电学与催化性能。纳米晶的缺陷可以影响其性能, 如具有孪晶结构的纳米晶拥有更高的强度和硬度。为了提高掺杂纳米晶的综合性能, 本工作以可溶性Zn盐为Zn源, 以新制NaHSe溶液为Se源, 以Cr(AC)2为掺杂源, 通过两次水热过程制备了核壳结构Cr2+:ZnSe/ZnSe, 在氩气保护或高真空下分别于400和800 ℃烧结获得了室温下化学性质稳定的纳米晶。结构和形貌表征结果显示, 纳米晶尺寸主要集中在20~30 nm之间, 壳体厚度约为2.6 nm, 纳米晶具有层错缺陷, 并由此发展成为孪晶。分析可知孪晶面为(111), 相邻两晶面夹角为70.02°, 误差在±0.5°以内。随着样品结晶度提高, 孪晶密度增大, 表明释放晶格畸变能为层错和孪晶的形成提供驱动力, 孪晶的形核与长大符合位错诱导机制。XPS分析表明, Cr元素以+2价存在于纳米晶中; 反射光谱测试结果分析发现, 烧结的纳米晶在1775 nm附近存在吸收带, 表明所制纳米孪晶具有潜在的中红外发光性能。

中图分类号:

张婷婷, 王方园, 刘长友, 张国荣, 吕佳辉, 宋宇晨, 介万奇. 水热-烧结法制备Cr2+:ZnSe/ZnSe核壳结构纳米孪晶[J]. 无机材料学报, 2024, 39(4): 409-415.

ZHANG Tingting, WANG Fangyuan, LIU Changyou, ZHANG Guorong, LÜ Jiahui, SONG Yuchen, JIE Wanqi. Hydrothermal-sintering Preparation of Cr2+:ZnSe/ZnSe Nanotwins with Core-shell Structure[J]. Journal of Inorganic Materials, 2024, 39(4): 409-415.

图1 纳米晶样品的XRD图谱

Fig. 1 XRD patterns of nanocrystalline samples (a) XRD patterns of different samples after sintering; (b) Local magnification of (111) crystal plane diffraction

| Sample | T/℃ | 2θ/(°) | d/nm | FWHM/rad | D/nm |

|---|---|---|---|---|---|

| ZnSe | 200 | 27.455 | 0.3246 | 0.761 | 10.8 |

| ZnSe/ZnSe | 400 | 27.472 | 0.3244 | 0.613 | 13.5 |

| 0.3%Cr2+:ZnSe/ZnSe | 400 | 27.465 | 0.3245 | 0.557 | 14.9 |

| 0.5%Cr2+:ZnSe/ZnSe | 400 | 27.451 | 0.3246 | 0.540 | 15.4 |

| 1.5%Cr2+:ZnSe | 800 | 27.207 | 0.3275 | 0.537 | 15.5 |

表1 不同温度烧结样品的(111)晶面参数

Table 1 Parameters of (111) crystal planes of samples sintered at different temperatures

| Sample | T/℃ | 2θ/(°) | d/nm | FWHM/rad | D/nm |

|---|---|---|---|---|---|

| ZnSe | 200 | 27.455 | 0.3246 | 0.761 | 10.8 |

| ZnSe/ZnSe | 400 | 27.472 | 0.3244 | 0.613 | 13.5 |

| 0.3%Cr2+:ZnSe/ZnSe | 400 | 27.465 | 0.3245 | 0.557 | 14.9 |

| 0.5%Cr2+:ZnSe/ZnSe | 400 | 27.451 | 0.3246 | 0.540 | 15.4 |

| 1.5%Cr2+:ZnSe | 800 | 27.207 | 0.3275 | 0.537 | 15.5 |

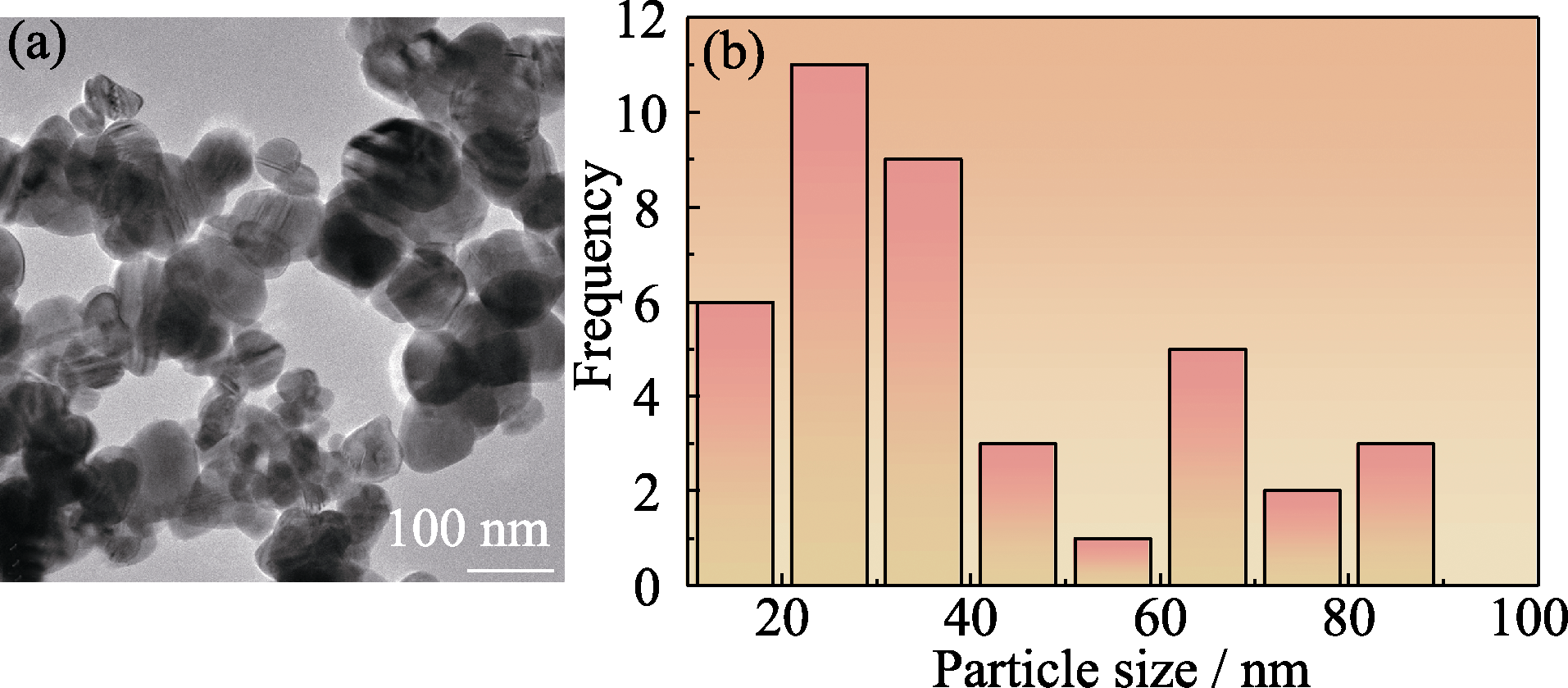

图2 400 ℃烧结0.5%Cr2+:ZnSe/ZnSe的微观形貌(a)和晶粒尺寸分布图(b)

Fig. 2 Microscopic morphology (a) and grain size distribution (b) of 0.5%Cr2+:ZnSe/ZnSe sintered at 400 ℃

图3 400 ℃烧结ZnSe/ZnSe的HRTEM照片

Fig. 3 HRTEM images of ZnSe/ZnSe sintered at 400 ℃ (a) High resolution TEM image; (b) Local grain enlargement image Colorful figure is available on website

图4 400 ℃烧结0.3%Cr2+:ZnSe/ZnSe 的HRTEM照片

Fig. 4 HRTEM images of 0.3%Cr2+:ZnSe/ZnSe sintered at 400 ℃ (a) High resolution TEM image; (b) Local enlarged grain image Colorful figure is available on website

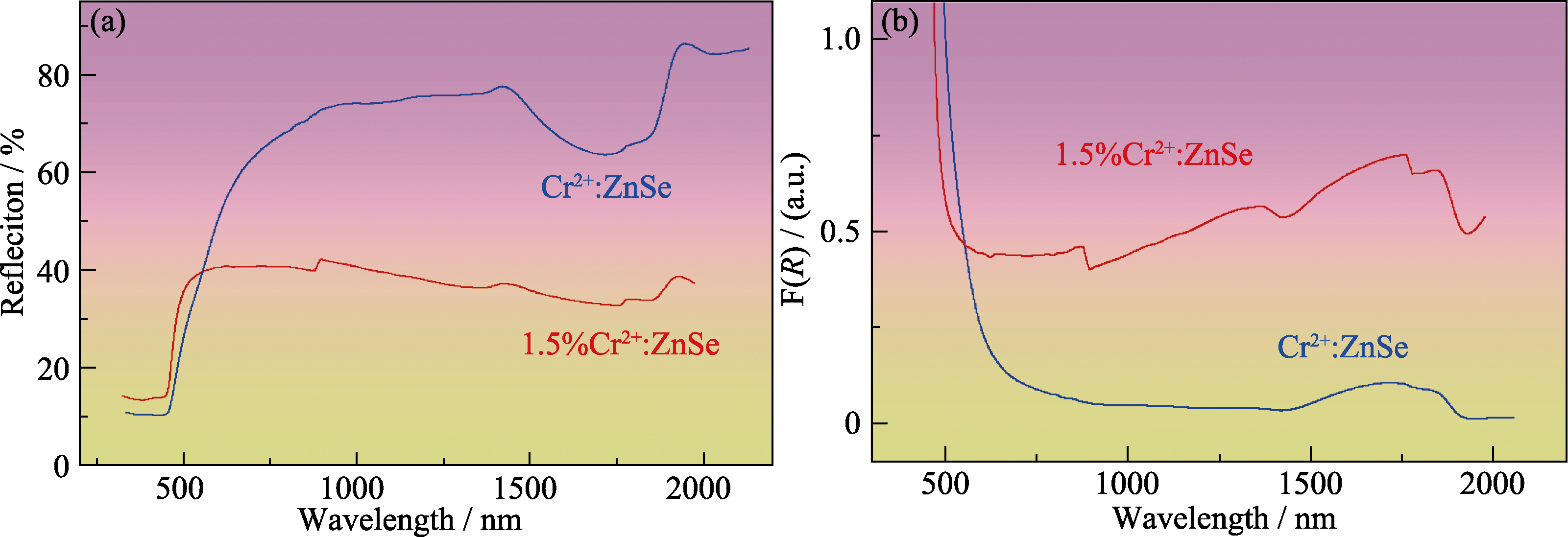

图8 1.5%Cr2+:ZnSe纳米孪晶和Cr2+:ZnSe多晶粉末的反射谱图

Fig. 8 Reflection spectra of 1.5%Cr2+:ZnSe nanotwins and Cr2+:ZnSe polycrystalline powders (a) Ultraviolet-visible-near infrared band reflection spectra; (b) Kublka-Munk function transformation graphs

| [1] |

SHARMA J, SINGH H, SINGH T, et al. Structural, optical and photo-electrical properties of nanocrystalline ZnSe thin films. Journal of Materials Science: Materials in Electronics, 2018, 29: 5688.

DOI |

| [2] |

COCO M G, ARO S C, MCDANIEL S A, et al. Continuous wave Fe2+:ZnSe mid-IR optical fiber lasers. Optics Express, 2020, 28(20): 30263.

DOI URL |

| [3] |

SHI H W, CUI X X, XIAO X S, et al. Cobalt and iron co-doped ZnSe nanocrystals: mid-IR luminescence at room temperature. Journal of Luminescence, 2020, 221: 117102.

DOI URL |

| [4] |

WEI Y C, LIU C Y, MA E, et al. The optical spectra characterization of Cr2+:ZnSe polycrystalline synthesized by direct reaction of Zn-Cr alloy and element Se. Ceramics International, 2020, 46(13): 21136.

DOI URL |

| [5] |

YU S Q, CARLONI D, WU Y Q. Microstructure development and optical properties of Fe:ZnSe transparent ceramics sintered by spark plasma sintering. Journal of the American Ceramic Society, 2020, 103(8): 4159.

DOI URL |

| [6] |

CHLIQUE C, CONANEC-MERDRIGNAC O, HAKMEH N, et al. Transparent ZnS ceramics by sintering of high purity monodisperse nanopowders. Journal of the American Ceramic Society, 2013, 96(10): 3070.

DOI URL |

| [7] |

XU J, WANG C R, Wu B H, et al. Twinning effect on photoluminescence spectra of ZnSe nanowires. Journal of Applied Physics, 2014, 116(17): 174303.

DOI URL |

| [8] |

ALGRA R E, VERHEIJEN M A, BORGSTRÖM M T, et al. Twinning superlattices in indium phosphide nanowires. Nature, 2008, 456: 369.

DOI |

| [9] |

YE K C, WANG Z J. Twins enhanced mechanical properties of boron carbide. Ceramics International, 2022, 48(10): 14499.

DOI URL |

| [10] |

SUN C C, GU Y R, WEN W J, et al. ZnSe based semiconductor core-shell structures: from preparation to application. Optical Materials, 2018, 81: 12.

DOI URL |

| [11] |

ZHAO L J, SUN C C, TIAN G, et al. Multiple-shell ZnSe core-shell spheres and their improved photocatalytic activity. Journal of Colloid and Interface Science, 2017, 502: 1.

DOI PMID |

| [12] |

WU P, FANG Z, ZHONG X H, et al. Depositing ZnS shell around ZnSe core nanocrystals in aqueous media via direct thermal treatment. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2011, 375(1/2/3): 109.

DOI URL |

| [13] |

MYOUNG N, PARK J S, MARTINEZ A, et al. Mid-IR spectroscopy of Fe:ZnSe quantum dots. Optical Express, 2016, 24(5): 5366.

DOI URL |

| [14] |

LI C Y, CHEN H H, IVANOV M, et al. Large-scale hydrothermal synthesis and optical properties of Cr2+:ZnS nanocrystals. Ceramics International, 2018, 44(11): 13169.

DOI URL |

| [15] |

LOZOVOY K A, KOROTAEV A G, KOKHANENKO A P, et al. Kinetics of epitaxial formation of nanostructures by Frank-van der Merwe, Volmer-Weber and Stranski-Krastanow growth modes. Surface and Coatings Technology, 2020, 384: 125289.

DOI URL |

| [16] |

PONCHET A, PATRIARCHE G, RODRIGUEZ J B, et al. Interface energy analysis of III-V islands on Si (001) in the Volmer- Weber growth mode. Applied Physics Letters, 2018, 113: 191601.

DOI URL |

| [17] | 曹茂盛. 材料现代设计理论与方法. 哈尔滨: 哈尔滨工业大学出版社, 2017: 5-8. |

| [18] |

TIAN Y J, XU B, YU D L, et al. Ultrahard nanotwinned cubic boron nitride. Nature, 2013, 493: 385.

DOI |

| [19] |

OLEINIK G S. Structural transformations in the HP-HT formation of monophase superhard materials based on carbon and boron nitride dense phases. Journal of Superhard Materials, 2011, 33: 217.

DOI URL |

| [20] | 曹传宝. Ⅲ-Ⅴ氮化物纳米材料的制备与性能研究. 哈尔滨: 哈尔滨工业大学出版社, 2017: 117. |

| [21] | 颜鑫, 张霞. 半导体纳米线材料与器件. 北京: 北京邮电大学出版社, 2017: 42. |

| [22] | 王恩德, 付建飞, 王丹丽. 结晶学与矿物学教程. 北京: 冶金工业出版社, 2019: 101. |

| [23] | 冯端, 师昌绪, 刘治国. 材料科学导论—融贯的论述. 北京: 化学工业出版社, 2003: 152. |

| [24] |

LU L, SHEN Y F, CHEN X H, et al. Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304(5669): 422.

PMID |

| [25] |

WANG Y Q, PHILIPOSE U, XU T, et al. Twinning modulation in ZnSe nanowires. Semiconductor Science and Technology, 2007, 22(3): 175.

DOI URL |

| [26] |

DURAND G R, HAKMEH N, DORCET V, et al. New insights in structural characterization of transparent ZnS ceramics hot-pressed from nanocrystalline powders synthesized by combustion method. Journal of the European Ceramic Society, 2019, 39(10): 3094.

DOI URL |

| [27] |

DESHPANDE A C, SINGH S B, ABYANEH M K, et al. Low temperature synthesis of ZnSe nanoparticles. Materials Letters, 2008, 62(23): 3803.

DOI URL |

| [28] |

SHENASA M, SAINKAR S, LICHTMAN D. XPS study of some selected selenium compounds. Journal of Electron Spectroscopy and Related Phenomena, 1986, 40(4): 329.

DOI URL |

| [29] |

BIESINGER M C, BROWN C, MYCROFT J R, et al. X-ray photoelectron spectroscopy studies of chromium compounds. Surface and Interface Analysis, 2004, 36(12): 1550.

DOI URL |

| [30] |

WEI Y C, LIU C Y, MA E, et al. Optical properties of mid-infrared Cr2+:ZnSe single crystals grown by chemical vapor transporting with NH4Cl. Optical Materials Express, 2021, 11(3): 664.

DOI URL |

| [1] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [2] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [3] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [4] | 苟燕子, 康伟峰, 王堋人. 烧结条件对制备高结晶近化学计量比SiC纤维的影响[J]. 无机材料学报, 2025, 40(4): 405-414. |

| [5] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [6] | 樊文楷, 杨潇, 李宏华, 李永, 李江涛. 无压烧结制备(Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7高熵陶瓷及其高温抗CMAS腐蚀性能[J]. 无机材料学报, 2025, 40(2): 159-167. |

| [7] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [8] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [9] | 王智祥, 陈莹, 逄清阳, 李鑫, 王根水. 碳酸锰掺杂氧化镁基陶瓷的烧结行为和介电性能[J]. 无机材料学报, 2025, 40(1): 97-103. |

| [10] | 张婧慧, 陆晓彤, 毛海雁, 田亚州, 张山林. 烧结助剂对BaZr0.1Ce0.7Y0.2O3-δ电解质烧结行为及电导率的影响[J]. 无机材料学报, 2025, 40(1): 84-90. |

| [11] | 王康龙, 殷杰, 陈晓, 王力, 刘学建, 黄政仁. 颗粒级配对选区激光烧结打印结合常压固相烧结制备碳化硅陶瓷性能的影响[J]. 无机材料学报, 2024, 39(7): 754-760. |

| [12] | 刘焱, 覃显鹏, 甘霖, 周国红, 章天金, 王士维, 陈鹤拓. 亚微米球形Y2O3粉体及其透明陶瓷的制备[J]. 无机材料学报, 2024, 39(6): 691-696. |

| [13] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [14] | 郑斌, 康凯, 张青, 叶昉, 解静, 贾研, 孙国栋, 成来飞. 前驱体转化陶瓷法制备Ti3SiC2陶瓷及其热稳定性研究[J]. 无机材料学报, 2024, 39(6): 733-740. |

| [15] | 郑雅雯, 张翠萍, 张瑞杰, 夏乾, 茹红强. 硼酸碳热还原-渗硅反应烧结制备碳化硼陶瓷复合材料[J]. 无机材料学报, 2024, 39(6): 707-714. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||