无机材料学报 ›› 2024, Vol. 39 ›› Issue (3): 291-298.DOI: 10.15541/jim20230488 CSTR: 32189.14.10.15541/jim20230488

所属专题: 【信息功能】电介质储能材料(202506); 【信息功能】介电、铁电、压电材料(202506); 【信息功能】纪念殷之文先生诞辰105周年虚拟学术专辑

收稿日期:2023-10-20

修回日期:2023-11-20

出版日期:2024-03-20

网络出版日期:2023-12-19

通讯作者:

罗进, 副教授. E-mail: jluuky2014@njtech.edu.cn;作者简介:刘松(1999-), 男, 硕士研究生. E-mail: 202161203172@njtech.edu.cn

基金资助:

LIU Song1,2( ), ZHANG Faqiang2, LUO Jin1(

), ZHANG Faqiang2, LUO Jin1( ), LIU Zhifu2(

), LIU Zhifu2( )

)

Received:2023-10-20

Revised:2023-11-20

Published:2024-03-20

Online:2023-12-19

Contact:

LUO Jin, associate professor. E-mail: jluuky2014@njtech.edu.cn;About author:LIU Song (1999-), male, Master candidate. E-mail: 202161203172@njtech.edu.cn

Supported by:摘要:

电介质薄膜是通过介质极化方式存储静电能的一种材料, 以其高功率密度和高充放电效率, 在电子器件领域得到广泛应用。目前, 储能密度较低和温度稳定性差仍是电介质储能薄膜的缺陷。本研究采用溶胶-凝胶法在Pt/Ti/SiO2/Si衬底上制备了0.9BaTiO3-0.1Bi(Ti1/2Mg1/2)O3(0.9BT-0.1BMT)薄膜, 通过引入BMT期望获得高储能密度及宽温度稳定性, 并研究了退火温度对薄膜的相组成和微观形貌的影响。研究结果表明, 退火温度过高会导致薄膜的致密性明显降低并伴随晶粒尺寸增大, 750 ℃是最佳的退火温度。综合性能研究发现, 1 kHz下, 薄膜的室温介电常数为399, 介电损耗为5.8%。薄膜在各测试频率下的介电温度稳定性满足X9R标准, ∆C/C25 ℃≤±13.9%。通过Currie-Weiss关系计算得到薄膜的弛豫系数(Relaxor value)γ值为≈1.96, 说明其具有明显的弛豫特性。储能特性研究显示, 薄膜的室温储能密度Wrec达51.9 J/cm3, 室温~200 ℃的宽温度范围内, 储能密度Wrec>20 J/cm3, 可释放能量效率η>65%(1600 kV/cm)。在脉冲放电测试中, 薄膜的脉冲放电时间τ0.9保持在15 μs以内, 且具有优异的频率、温度和循环可靠性。本研究所制备的0.9BT-0.1BMT铁电薄膜具有出色的储能特性和宽温度稳定性, 具备在高温环境中应用的潜力。

中图分类号:

刘松, 张发强, 罗进, 刘志甫. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3铁电薄膜制备及储能特性[J]. 无机材料学报, 2024, 39(3): 291-298.

LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage[J]. Journal of Inorganic Materials, 2024, 39(3): 291-298.

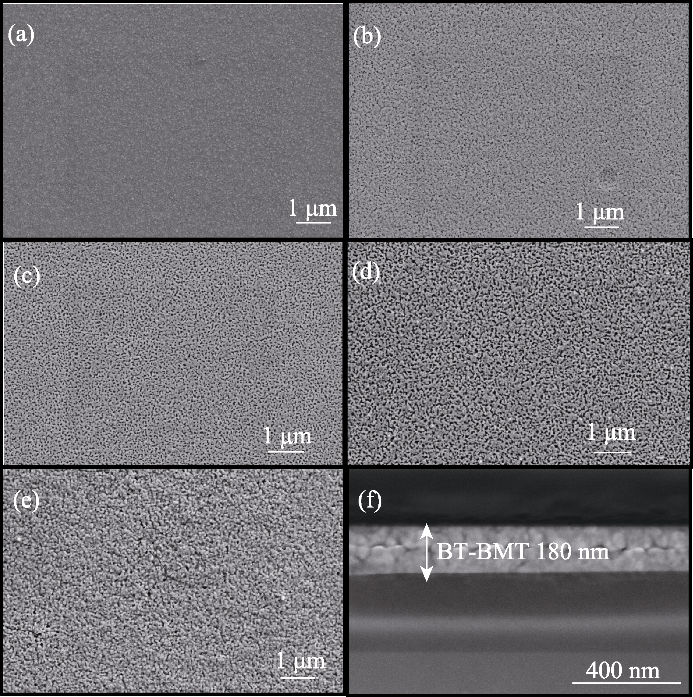

图2 不同温度退火制备的0.9BT-0.1BMT薄膜的SEM照片

Fig. 2 SEM images of thin films annealed at different temperatures (a) 700 ℃; (b) 750 ℃; (c) 800 ℃; (d) 850 ℃; (e) 900 ℃; (f) Cross-section structure of thin films annealed at 750 ℃

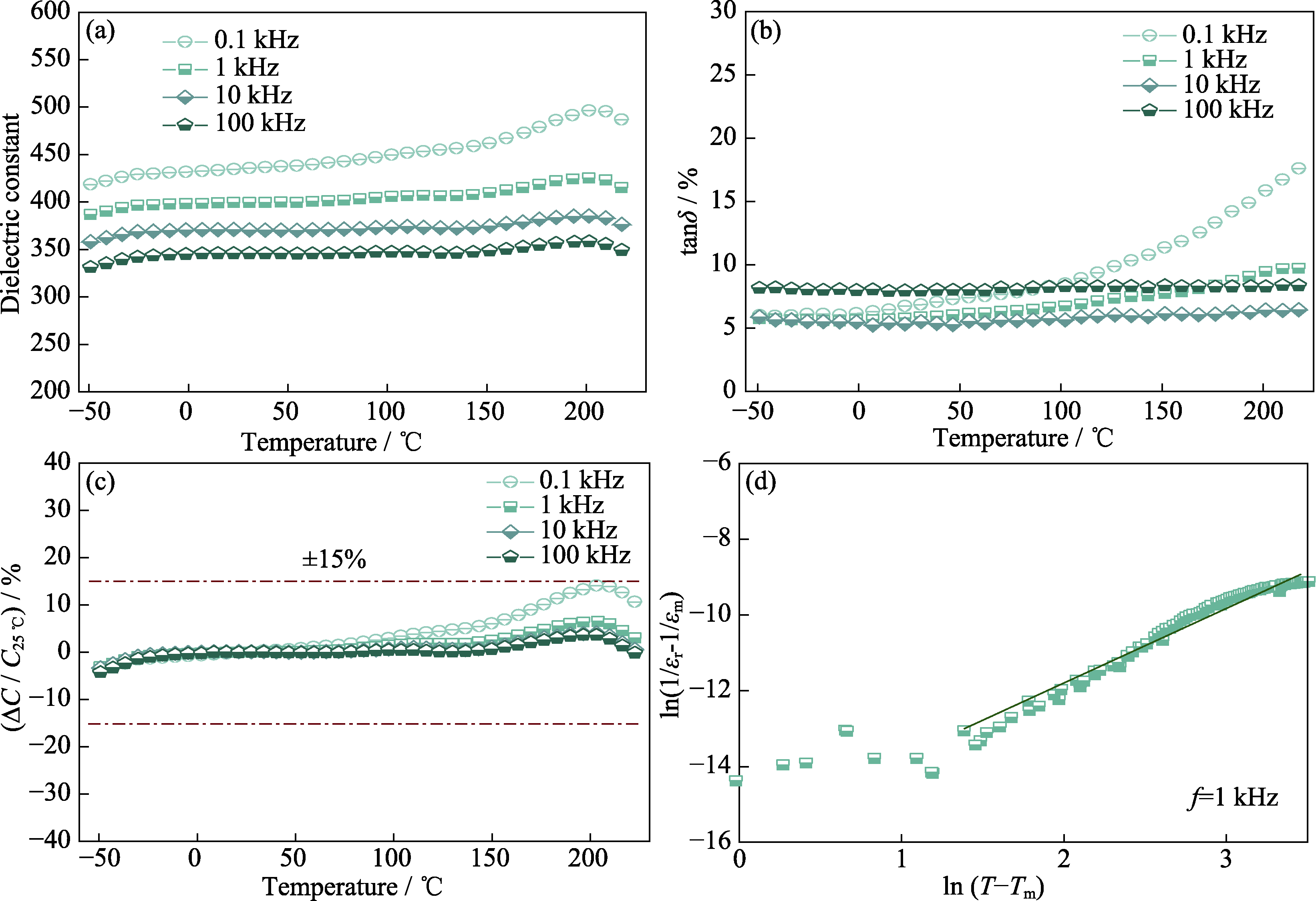

图3 750 ℃退火制备的0.9BT-0.1BMT薄膜在不同测试频率下的介电特性

Fig. 3 Dielectric properties of 0.9BT-0.1BMT thin films annealed at 750 ℃ and tested at different frequencies (a-c) Temperature-dependent (a) dielectric constant, (b) loss tangent and (c) capacitance of 0.9BT-0.1BMT thin films annealed at 750 ℃; (d) Function of ln(1/εr−1/εm) versus ln(T−Tm) measured under 1 kHz with symbols standing for experiment data and solid line indicating fitting to the modified Curie-Weiss law

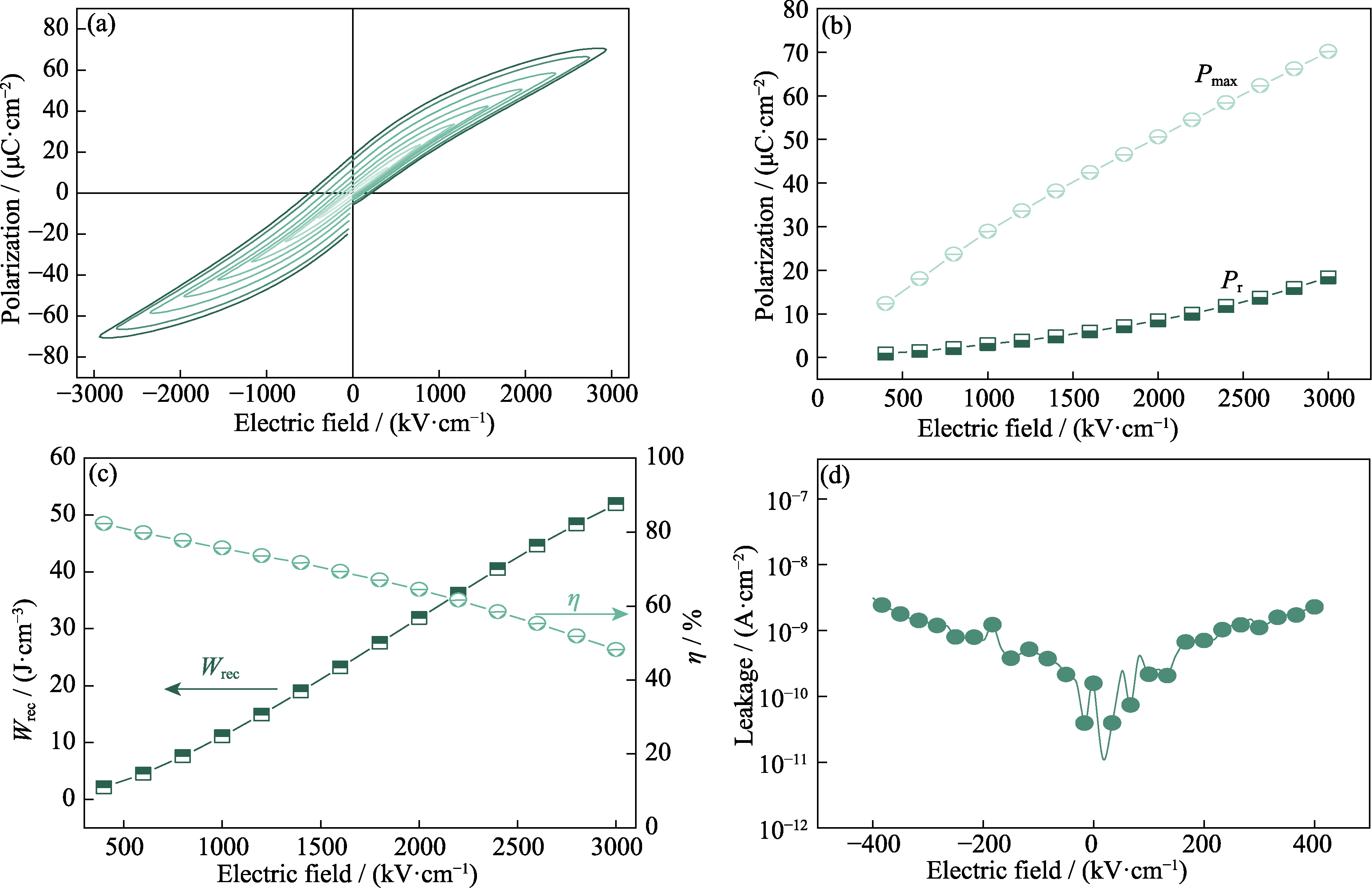

图4 室温下测试的0.9BT-0.1BMT薄膜的电学性能

Fig. 4 Electrical performance of 0.9BT-0.1BMT thin films tested at room temperature (a) P-E loops; (b) Pmax and Pr measured at different electric fields; (c) Wrec and η measured at different electric fields; (d) Leakage current of thin films at 400 kV/cm

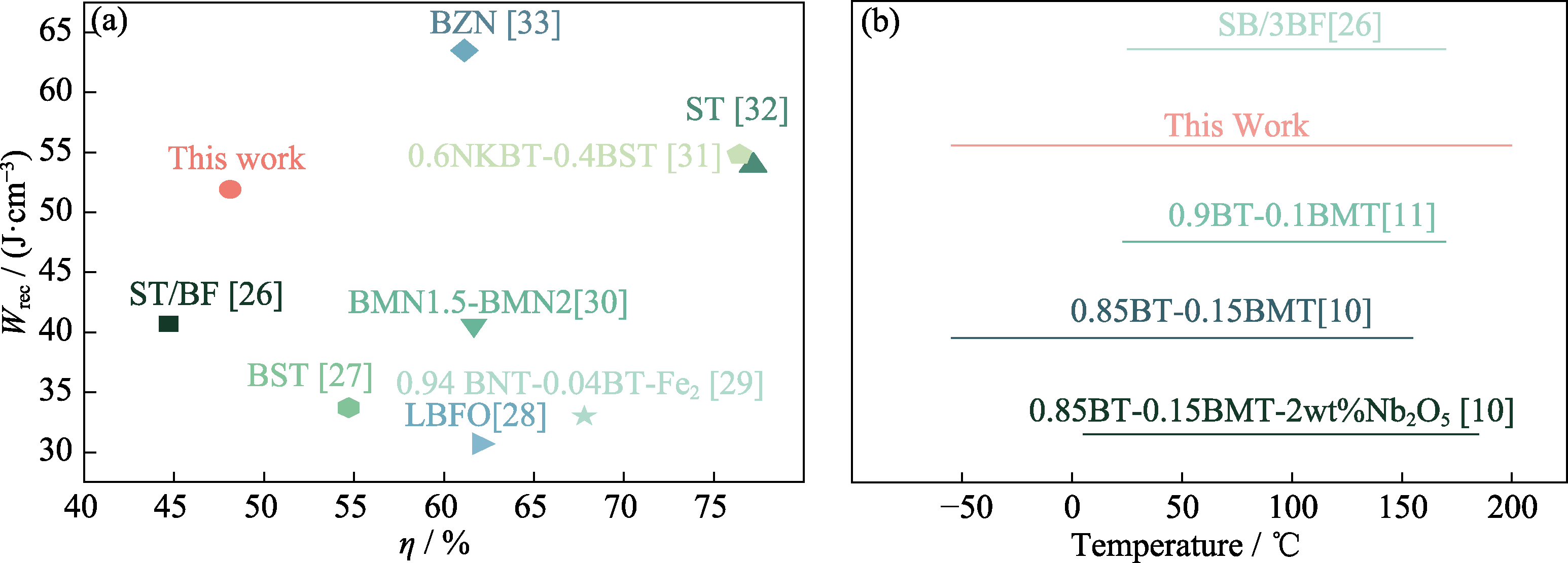

图5 本研究制备的材料与其他材料的性能对比

Fig. 5 Property comparison for materials prepared in this work with other materials (a) Energy storage performance [26⇓⇓⇓⇓⇓⇓-33]; (b) Meet ∆C/C25℃≤±15% temperature range[10-11,26]

图6 (a~c)频率、(d~f)温度和(g~i)循环次数对0.9BT-0.1BMT薄膜的P-E曲线、Pmax、Pr和储能特性的影响

Fig. 6 Effects of (a-c) frequency, (d-f) temperature and (g-i) switching cycles on P-E loops, Pmax, Pr, and energy storage performance of 0.9BT-0.1BMT thin films

图7 0.9BT-0.1BMT薄膜电容器的放电特性

Fig. 7 Discharge characteristics of 0.9BT-0.1BMT film capacitors (a) Curves of overdamped discharge current; (b) Time dependence of Wdis at various electric fields; (c) Values of Wdis and τ0.9 at different electric fields; (d) Overdamped discharge current curves at 1388 kV/cm with different temperatures; (e) Time dependence of Wdis at different temperatures; (f) Values of Wdis and τ0.9 at different temperatures; Colorful figures are available on website

| [1] | DU JINHUA, LI YONG, SUN NINGNING, et al. Energy storage behavior of inorganic dielectric materials. Journal of Silicate, 2022, 50(3): 608. |

| [2] | YANG MINZHENG, JIANG JIANYONG, SHEN YANG. Recent progress in dielectric energy storage materials with high energy density. Journal of Silicate, 2021, 49(7): 14. |

| [3] |

HONG K, LEE T H, SUH J M, et al. Perspectives and challenges in multilayer ceramic capacitors for next generation electronics. Journal of Materials Chemistry C, 2019, 7(32): 9782.

DOI URL |

| [4] |

DUNN B, KAMATH H, TARASCON J M. Electrical energy storage for the grid: a battery of choices. Science, 2011, 334(6058): 928.

DOI PMID |

| [5] |

DANG Z M, YUAN J K, YAO S H, et al. Flexible nanodielectric materials with high permittivity for power energy storage. Advanced Materials, 2013, 25(44): 6334.

DOI URL |

| [6] |

BEUERLEIN M A, KUMAR N, USHER T M, et al. Current understanding of structure-processing-property relationships in BaTiO3-Bi(M)O3 dielectrics. Journal of the American Ceramic Society, 2016, 99(9): 2849.

DOI URL |

| [7] | MOKI S, KIMURA J, KANEKO N, et al. Structural and dielectric properties of BaTiO3-Bi(Mg1/2Ti1/2)O3 thin films fabricated by chemical solution deposition. Japanese Journal of Applied Physics, 2014, 53(9S): 9PA11.1. |

| [8] |

HU Q, JIN L, WANG T, et al. Dielectric and temperature stable energy storage properties of 0.88BaTiO3-0.12Bi(Mg1/2Ti1/2)O3 bulk ceramics. Journal of Alloys and Compounds, 2015, 640: 416.

DOI URL |

| [9] |

XIE J, YAO Z, HAO H, et al. A novel lead-free bismuth magnesium titanate thin films for energy storage applications. Journal of the American Ceramic Society, 2019, 102(7): 3819.

DOI URL |

| [10] |

XIONG B, HAO H, ZHANG S, et al. Structure, dielectric properties and temperature stability of BaTiO3-Bi(Mg1/2Ti1/2)O3perovskite solid solutions. Journal of the American Ceramic Society, 2011, 94(10): 3412.

DOI URL |

| [11] |

ZHANG Q, LI Z, LI F, et al. Structural and dielectric properties of Bi(Mg1/2Ti1/2)O3-BaTiO3lead-free ceramics. Journal of the American Ceramic Society, 2011, 94(12): 4335.

DOI URL |

| [12] |

ZHANG L L, TAN G Q, CHENG M, et al. Effects of annealing temperature on morphology and dielectric property of BiFeO3films. Key Engineering Materials, 2012, 512-515: 1736.

DOI URL |

| [13] |

SUN X H, HOU S, LUO Z M, et al. Enhanced the dielectric and tunable properties of BZNT thin films through adjusting annealing process. Applied Mechanics and Materials, 2012, 252: 211.

DOI URL |

| [14] |

YAO K, YU S, ENG-HOCK TAY F. Residual stress analysis in ferroelectric Pb(Zr0.52Ti0.48)O3 thin films fabricated by a Sol-Gel process. Applied Physics Letters, 2003, 82(25): 4540.

DOI URL |

| [15] |

GALLEGOS-MELGAR A, ESPINOSA-ARBELAEZ D G, FLORES-RUIZ F J, et al. Ferroelectric properties of manganese doped (Bi1/2Na1/2)TiO3and (Bi1/2Na1/2)TiO3-BaTiO3 epitaxial thin films. Applied Surface Science, 2015, 359: 923.

DOI URL |

| [16] | GENG W, CHEN X, PAN L, et al. Improved crystallization, domain, and ferroelectricity by controlling lead/oxygen vacancies in Mn- doped PZT thin films. Materials Characterization, 2021, 176: 1. |

| [17] |

LI M D, TANG X G, ZENG S M, et al. Giant electrocaloric effect in BaTiO3-Bi(Mg1/2Ti1/2)O3 lead-free ferroelectric ceramics. Journal of Alloys and Compounds, 2018, 747: 1053.

DOI URL |

| [18] | TANG B, ZHANG S, YUAN Y, et al. Latest progress of curie point shift of barium titanate ceramic and its mechanisms. Journal of Vacuum Science and Technology, 2008(2): 6. |

| [19] |

UCHIDA H, SAIKI A, WAKIYA N, et al. Effect of the residual stress induced by external stress application on dielectric properties of epitaxial lead titanate film. Journal of the Ceramic Society of Japan, 2000, 108(1253): 21.

DOI URL |

| [20] | OHNO T, GOTOH Y, SAKAMOTO N, et al. Low temperature processing of alkoxide-derived PMN thin films. IOP Conference Series: Materials Science and Engineering, 2012, 30: 012002. |

| [21] | 胡钰晴. 铁酸铋-钛酸钡铁电薄膜的制备与多功能特性研究. 上海: 上海师范大学硕士学位论文. 2020. |

| [22] | 汤卉. 铁酸铋-钛酸钡基陶瓷的制备、储能特性和电卡效应研究. 广州: 广东工业大学博士学位论文. 2022. |

| [23] |

SHVARTSMAN V V, LUPASCU D C, GREEN D J. Lead-free relaxor ferroelectrics. Journal of the American Ceramic Society, 2012, 95(1): 1.

DOI URL |

| [24] |

VIEHLAND D, JANG S J, CROSS L E, et al. Freezing of the polarization fluctuations in lead magnesium niobate relaxors. Journal of Applied Physics, 1990, 68(6): 2916.

DOI URL |

| [25] |

WANG J, LI Y, SUN N, et al. Bi(Mg0.5Ti0.5)O3 addition induced high recoverable energy-storage density and excellent electrical properties in lead-free Na0.5Bi0.5TiO3-based thick films. Journal of the European Ceramic Society, 2019, 39(2/3): 255.

DOI URL |

| [26] |

DIAO C, LIU H, LOU G, et al. Structure and electric properties of sandwich-structured SrTiO3/BiFeO3 thin films for energy storage applications. Journal of Alloys and Compounds, 2019, 781: 378.

DOI URL |

| [27] |

WANG Y, LIU X, SUN H, et al. Enhanced recoverable energy storage density of barium strontium titanate-based thin films with compositionally graded structure. Journal of Materials Science: Materials in Electronics, 2021, 32(2): 2193.

DOI |

| [28] |

SONG H, SON J Y. Energy storage and multiferroic properties of La-doped epitaxial BiFeO3 thin films according to La doping concentration. Journal of Energy Storage, 2023, 68(15): 107729.

DOI URL |

| [29] |

XIE Y, HAO H, HUANG Z, et al. Large energy-storage density with good dielectric property in bismuth sodium titanate-based thin films. Journal of Alloys and Compounds, 2021, 884: 161031.

DOI URL |

| [30] |

YU S, ZHANG C, WU M, et al. Energy storage and dielectric properties of a novel Bi1.5MgNb1.5O7-Bi2Mg2/3Nb4/3O7 thin film. Ceramics International, 2021, 47(1): 1238.

DOI URL |

| [31] |

DING J, ZHANG Y, ZHAI Y, et al. Optimized energy storage performances in morphotropic phase boundary (Na0.8K0.2)0.5Bi0.5TiO3- based lead-free ferroelectric thin films. Ceramics International, 2022, 48(5): 6062.

DOI URL |

| [32] |

DIAO C, LIU H, LI Z, et al. Simultaneously achieved high energy storage density and efficiency in Sol-Gel-derived amorphous Mn- doped SrTiO3 thin films. Journal of Alloys and Compounds, 2020, 845: 155636.

DOI URL |

| [33] |

WU M, YU S, WANG X, et al. Ultra-high energy storage density and ultra-wide operating temperature range in Bi2Zn2/3Nb4/3O7 thin film as a novel lead-free capacitor. Journal of Power Sources, 2021, 497: 229879.

DOI URL |

| [1] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [2] | 吴鲁康, 傅正钱, 于子怡, 杨俊, 周斌, 陈学锋, 许钫钫. 电子能量损失谱在BaTiO3基多层陶瓷电容器中的应用研究[J]. 无机材料学报, 2025, 40(6): 683-689. |

| [3] | 康文烁, 郭晓杰, 邹凯, 赵祥永, 周志勇, 梁瑞虹. 层状结构第二相增强BiFeO3-BaTiO3陶瓷电阻率研究[J]. 无机材料学报, 2023, 38(12): 1420-1426. |

| [4] | 韦婷婷, 徐华蕊, 朱归胜, 龙神峰, 张秀云, 赵昀云, 江旭鹏, 宋金杰, 郭宁杰, 龚祎鹏. BaTiO3陶瓷的低温冷烧结制备及性能研究[J]. 无机材料学报, 2022, 37(8): 903-910. |

| [5] | 赵玉垚, 欧阳俊. 硅片上集成高介电调谐率的柱状纳米晶BaTiO3铁电薄膜[J]. 无机材料学报, 2022, 37(6): 596-602. |

| [6] | 王艳香, 高培养, 范学运, 李家科, 郭平春, 黄丽群, 孙健. SnO2退火温度对钙钛矿太阳能电池性能的影响[J]. 无机材料学报, 2021, 36(2): 168-174. |

| [7] | 孙丹丹, 张家良, 武燕庆, 张仲秋, 刘大康. 原料预处理对BaTiO3压电陶瓷的物性影响[J]. 无机材料学报, 2017, 32(6): 615-620. |

| [8] | 马 剑, 张波萍, 陈建银. Bi过量以及冷却方式对BiFeO3-BaTiO3陶瓷的相结构及电学性能的影响[J]. 无机材料学报, 2017, 32(10): 1035-1041. |

| [9] | 李佳乐, 向 军, 叶 芹, 刘 敏, 沈湘黔. Ni0.4Co0.2Zn0.4Fe2O4/BaTiO3纳米纤维双层吸波涂层的微波吸收特性研究[J]. 无机材料学报, 2015, 30(5): 479-486. |

| [10] | 刘 颖, 龙西法. 新型铁电晶体铌镥酸铅-钛酸铅的生长与性能[J]. 无机材料学报, 2014, 29(1): 47-51. |

| [11] | 徐 琴, 丁士华, 宋天秀, 彭 勇, 吴小亮. 复合掺杂BCZT陶瓷的介电弛豫行为研究[J]. 无机材料学报, 2013, 28(4): 441-446. |

| [12] | 蒋大洞, 郑学军, 龚跃球, 朱 哲, 彭金峰. 退火温度对Bi3.15(Eu0.7Nd0.15)Ti3O12铁电薄膜力学性能的影响[J]. 无机材料学报, 2013, 28(2): 131-135. |

| [13] | 李红霞, 季振国, 席俊华. 退火温度对TiO2基电阻开关器件性能的影响[J]. 无机材料学报, 2012, 27(10): 1063-1067. |

| [14] | 蒲永平, 许 宁, 王 博, 吴海东, 陈 凯. Cu 含量对 BaTiO3/Cu复相陶瓷材料介电性能的影响[J]. 无机材料学报, 2011, 26(2): 175-179. |

| [15] | 王永霞, 冶银平, 李红轩, 吉利, 陈建敏, 周惠娣. 退火温度对 a-C:H 膜结构及摩擦学性能的影响[J]. 无机材料学报, 2011, 26(2): 209-213. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||