无机材料学报 ›› 2023, Vol. 38 ›› Issue (6): 634-646.DOI: 10.15541/jim20220640 CSTR: 32189.14.10.15541/jim20220640

所属专题: 【结构材料】高导热陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

收稿日期:2022-10-31

修回日期:2023-01-18

出版日期:2023-01-31

网络出版日期:2023-01-31

通讯作者:

白书欣, 教授. E-mail: shuxinde2021@163.com;作者简介:陈强(1992-),男,博士研究生. E-mail: 13548774386@163.com

CHEN Qiang( ), BAI Shuxin(

), BAI Shuxin( ), YE Yicong(

), YE Yicong( )

)

Received:2022-10-31

Revised:2023-01-18

Published:2023-01-31

Online:2023-01-31

Contact:

BAI Shuxin, professor. E-mail: shuxinde2021@163.com;About author:CHEN Qiang (1992-), male, PhD candidate. E-mail: 13548774386@163.com

摘要:

碳化硅陶瓷基复合材料以其高比强度、高比模量、高导热、良好的耐烧蚀性能、高温抗氧化性、抗热震性能等特性, 广泛应用于航空航天、摩擦制动、核聚变等领域, 成为先进的高温结构及功能材料。本文综述了高导热碳化硅陶瓷基复合材料制备及性能等方面的最新研究进展。引入高导热相, 如金刚石粉、中间相沥青基碳纤维等用以增强热输运能力; 优化热解炭炭与碳化硅基体界面用以降低界面热阻; 热处理用以获得结晶度更高、导热性能更好的碳化硅基体; 设计预制体结构用以建立连续导热通路等方法, 提高碳化硅陶瓷基复合材料的热导率。此外, 本文展望了高导热碳化硅陶瓷基复合材料后续研究方向, 即综合考虑影响碳化硅陶瓷基复合材料性能要素, 优化探索高效、低成本的制备工艺; 深入分析高导热碳化硅陶瓷基复合材料导热机理, 灵活运用复合材料结构与性能的构效关系, 以期制备尺寸稳定、具有优异热物理性能的各向同性高导热碳化硅陶瓷基复合材料。

中图分类号:

陈强, 白书欣, 叶益聪. 热管理用高导热碳化硅陶瓷基复合材料研究进展[J]. 无机材料学报, 2023, 38(6): 634-646.

CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review[J]. Journal of Inorganic Materials, 2023, 38(6): 634-646.

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) |

|---|---|---|---|---|---|---|

| Nicalon | NL202 | 220 | 3000 | 2.55 | 14 | 2.97 |

| Hi-Nicalon | 270 | 2800 | 2.74 | 12 | 7.77 | |

| Hi-Nicalon-S | 420 | 2600 | 3.05 | 12 | 18.4 | |

| Tyranno | Lox M | 187 | 3300 | 2.48 | 11 | 1.4 |

| ZMI | 200 | 3400 | 2.48 | 11 | 2.5 | |

| SA | 380 | 2800 | 3.10 | 10/7.5 | 65 | |

| Sylramic | Sylramic | 400 | 2800 | 3.05 | 10 | 40-45 |

| Sylramic-iBN | 400 | 3200 | 3.10 | 10 | >46 | |

| KD[ | KD-A | 170 | 2100 | 2.43 | 12.3 | - |

| KD-B | 300 | 3000 | 2.76 | 11.2 | ||

| KD-C | 320 | 2800 | 2.87 | 11.1 |

表1 碳化硅陶瓷纤维性能及产品[21]

Table 1 Properties and products of silicon carbide based fibers[21]

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) |

|---|---|---|---|---|---|---|

| Nicalon | NL202 | 220 | 3000 | 2.55 | 14 | 2.97 |

| Hi-Nicalon | 270 | 2800 | 2.74 | 12 | 7.77 | |

| Hi-Nicalon-S | 420 | 2600 | 3.05 | 12 | 18.4 | |

| Tyranno | Lox M | 187 | 3300 | 2.48 | 11 | 1.4 |

| ZMI | 200 | 3400 | 2.48 | 11 | 2.5 | |

| SA | 380 | 2800 | 3.10 | 10/7.5 | 65 | |

| Sylramic | Sylramic | 400 | 2800 | 3.05 | 10 | 40-45 |

| Sylramic-iBN | 400 | 3200 | 3.10 | 10 | >46 | |

| KD[ | KD-A | 170 | 2100 | 2.43 | 12.3 | - |

| KD-B | 300 | 3000 | 2.76 | 11.2 | ||

| KD-C | 320 | 2800 | 2.87 | 11.1 |

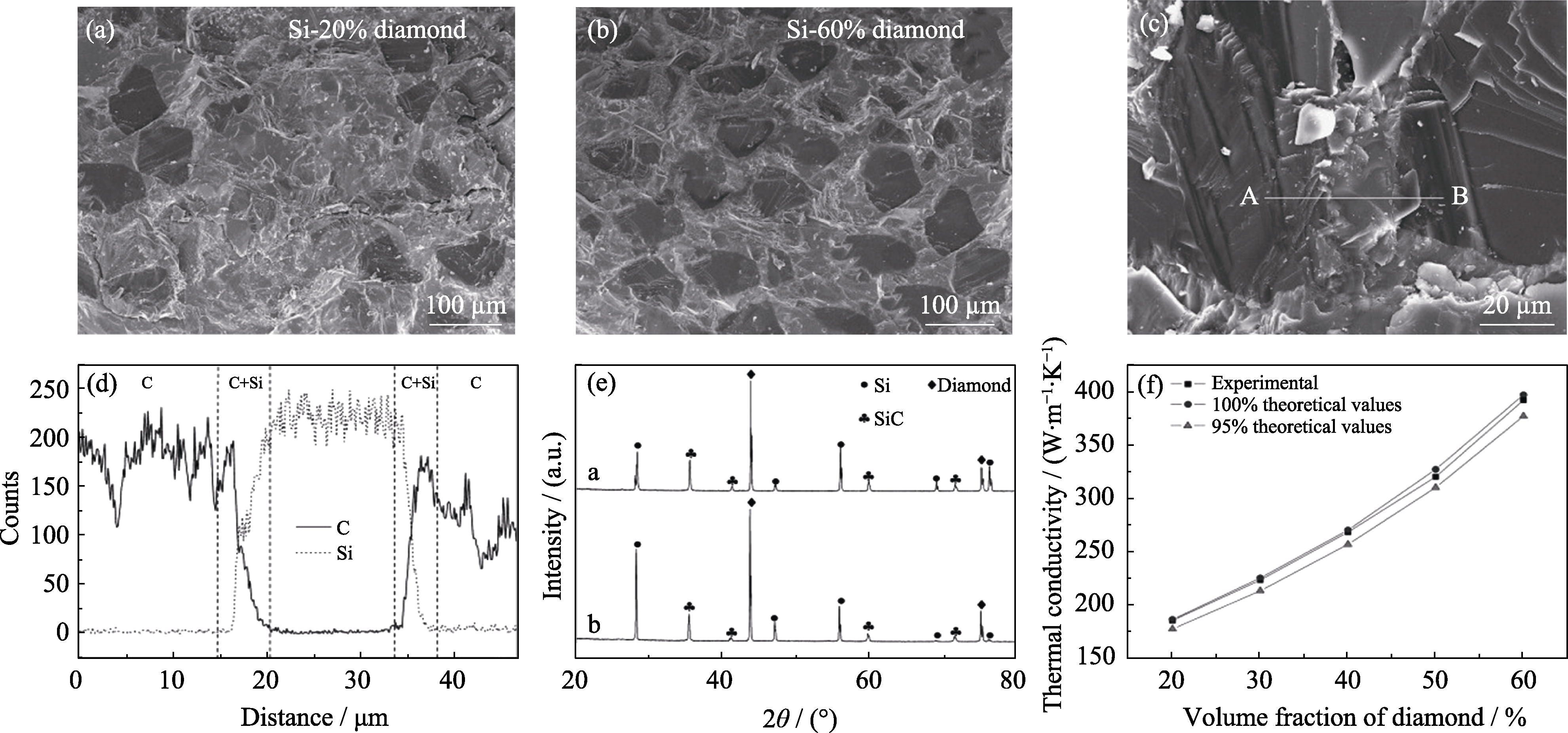

图1 不同金刚石的硅-金刚石-碳化硅复合材料显微组织及热导率[31]

Fig. 1 Microstructures and thermal conductivities of Si-diamond-SiC composites with different diamond volume contents[31] (a) Si-20% diamond (sintered at 1523 K); (b) Si-60% diamond (sintered at 1643 K); (c) Fracture surface of (b); (d) EDX of(c); (e) XRD patterns of (a, b); (f) Experimental and theoretical thermal conductivity of Si-diamond-SiC composites

图2 不同体积分数的金刚石-碳化硅复合材料显微组织及热导率[32]

Fig. 2 Microstructures and thermal conductivities of diamond/SiC composites with different diamond volume contents[32] (a) RBSD1; (b) RBSD2; (c) RBSD3; (d) RBSD4; (e) Diamond/SiC interface; (f) Graphite interlayer in diamond/SiC interfacial region; (g) TEM image of diamond/SiC interfacial region in post-annealing RBSD; (h) Thermal conductivities of RBSDs before and after high temperature annealing

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) | |

|---|---|---|---|---|---|---|---|

| UCC | P75 | 517 | 2100 | 2.00 | 10 | 185 | |

| P100 | 759 | 2410 | 2.15 | 10 | 520 | ||

| P-120 | 828 | 2410 | 2.18 | 10 | 640 | ||

| Mitsubishi | K-1100 | 931 | 3100 | 2.2 | 10 | 1000 | |

| K13D2U | 935 | 3700 | 2.21 | 10 | 800 | ||

| K13C2U | 900 | 3800 | 2.2 | 10 | 620 | ||

| K63B12 | 860 | 2600 | 2.15 | 10 | 400 | ||

| Nippon | Granoc | 920 | 3530 | 2.19 | 7 | 600 | |

| YS-95A | |||||||

| Granoc | 880 | 3530 | 2.18 | 7 | 500 | ||

| YS-90A | |||||||

| NOCVARB | NM6030-15 | ≥550 | ≥1500 | ≥2.1 | - | ≥250 | |

| NM9050-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥450 | ||

| NM9080-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥750 | ||

| NMA080-25 | ≥950 | ≥2500 | ≥2.15 | - | ≥750 | ||

| TIANCE-TECH | TC-HC-600-S | 750 | 2300 | 2.20 | 13 | 600 | |

| ECO | - | 500-900 | 2500-3500 | 2.2 | 8-12 | 500-800 | |

| TOYI-CARBEN | TYG-1 | 800 | 2300 | 2.2 | 12 | 600 | |

| TYG-2 | 900 | 2500 | 2.2 | 12 | 800 | ||

表2 沥青基碳纤维性能及产品[42-43]

Table 2 Properties and products of pitch based carbon fibers[42-43]

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) | |

|---|---|---|---|---|---|---|---|

| UCC | P75 | 517 | 2100 | 2.00 | 10 | 185 | |

| P100 | 759 | 2410 | 2.15 | 10 | 520 | ||

| P-120 | 828 | 2410 | 2.18 | 10 | 640 | ||

| Mitsubishi | K-1100 | 931 | 3100 | 2.2 | 10 | 1000 | |

| K13D2U | 935 | 3700 | 2.21 | 10 | 800 | ||

| K13C2U | 900 | 3800 | 2.2 | 10 | 620 | ||

| K63B12 | 860 | 2600 | 2.15 | 10 | 400 | ||

| Nippon | Granoc | 920 | 3530 | 2.19 | 7 | 600 | |

| YS-95A | |||||||

| Granoc | 880 | 3530 | 2.18 | 7 | 500 | ||

| YS-90A | |||||||

| NOCVARB | NM6030-15 | ≥550 | ≥1500 | ≥2.1 | - | ≥250 | |

| NM9050-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥450 | ||

| NM9080-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥750 | ||

| NMA080-25 | ≥950 | ≥2500 | ≥2.15 | - | ≥750 | ||

| TIANCE-TECH | TC-HC-600-S | 750 | 2300 | 2.20 | 13 | 600 | |

| ECO | - | 500-900 | 2500-3500 | 2.2 | 8-12 | 500-800 | |

| TOYI-CARBEN | TYG-1 | 800 | 2300 | 2.2 | 12 | 600 | |

| TYG-2 | 900 | 2500 | 2.2 | 12 | 800 | ||

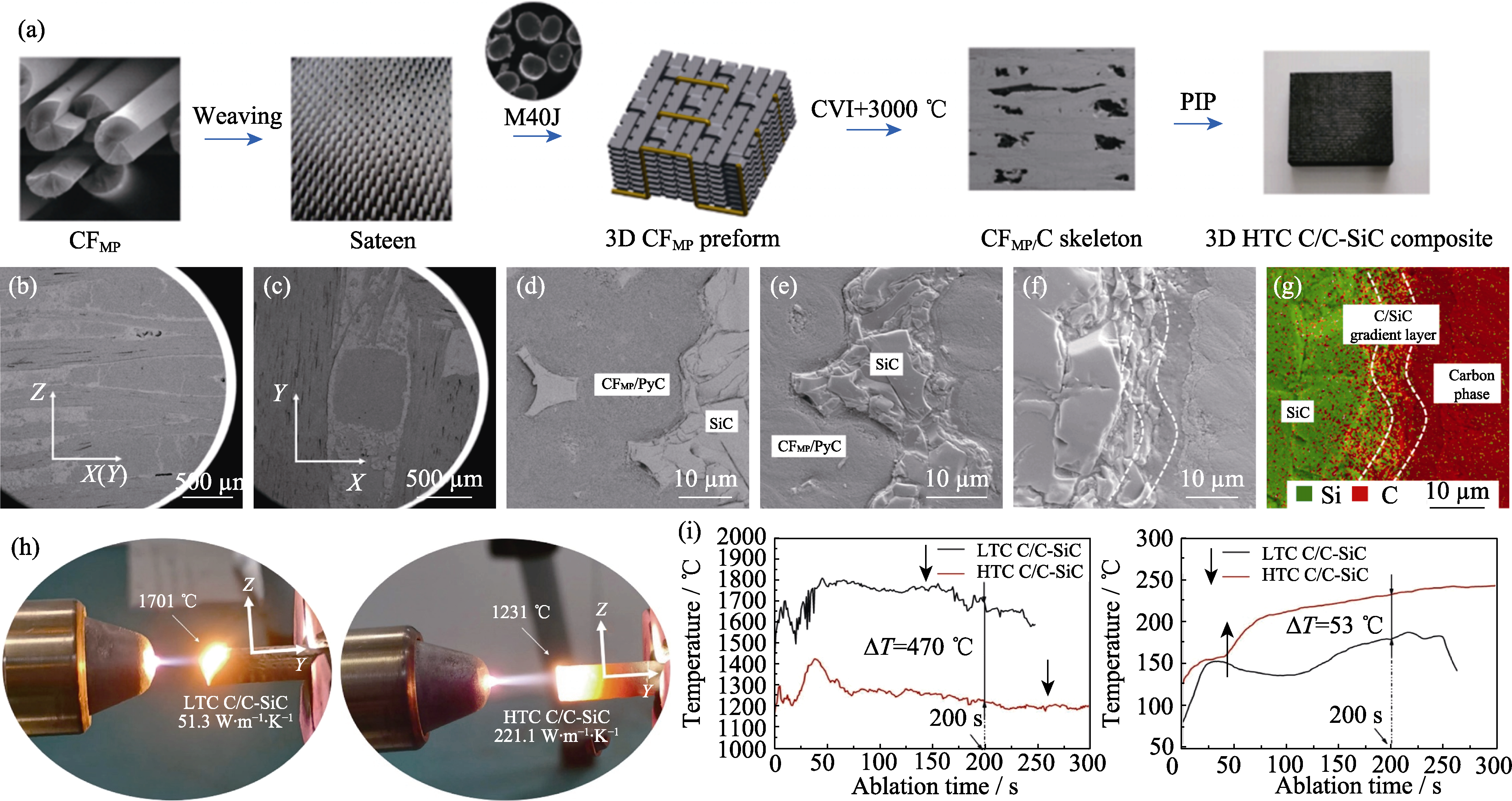

图3 3D HTC C/C-SiC制备工艺及微观组织[25]

Fig. 3 Diagram of fabrication and microstructure of the 3D HTC C/C-SiC composite[25] (a) Fabrication process of 3D HTC C/C-SiC; (b-f) Microstructures of the 3D HTC C/C-SiC composite; (g) Interface energy spectrum diagram of the 3D HTC C/C-SiC; (h) Ablation tests and (i) temperature curves of the C/C-SiC

图4 烧蚀后的碳纤维增强碳化硅陶瓷基复合材料表面形貌[47]

Fig. 4 Surface topographies of the as-ablated C/C-SiC[47] (a) Image of the as-ablated C/C-SiC; (b-d) Magnification images of (b) middle region, (c) area “A” and (d) naked fibers in the center region of (a)

图6 碳化硅纤维表面电泳沉积碳纳米管微观组织及复合材料热物理性能[57]

Fig. 6 Microstructures of SiC fiber with electrodeposited CNTs and thermophysical properties of SiCf/SiC compersites[57] (a) Surface of SiC fibers with CNTs; (b) Surface of SiC fibers without CNTs; (c) Interface between CNTs and PyC; (d) TEM image of PyC deposited on CNTs; (e, f) HRTEM images of PyC deposited on (e) SiC fibers and (f) CNTs; (g) Bending strength and (h) thermal conductivity of SiC/SiC composites with different interfaces

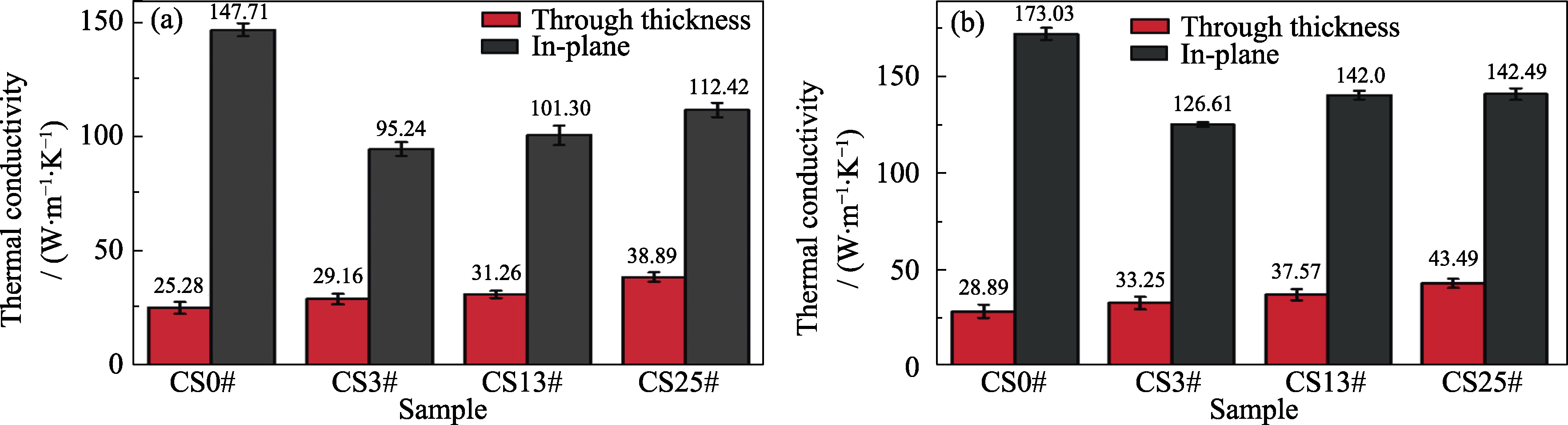

图7 Cpf/SiC复合材料(1600 ℃-2 h)热处理(a)前(b)后的热导率[48]

Fig. 7 Thermal conductivities of Cpf/SiC composites (a) before and (b) after heat-treatment(1600 ℃-2 h)[48]

图8 金刚石/SiC复合材料界面区域表征[58]

Fig. 8 Characterization of diamond/SiC interfacial zone[58] (a) TEM image of diamond and SiC separated by a layer of graphite with lighter contrast; (b) HRTEM image of the rectangular region in (a) showing the graphite (G) and diamond (D) zones; (c-e) TEM and HRTEM images of (c, d) graphite layer and (e) reaction formed nano-crystalline SiC with stacking faults; (f) TEM image of Al4C3 formed adjacent to the interface; (g) HRTEM image from the rectangular region in (f); (h) ADF STEM of diamond/SiC interfacial area in (f)

图9 不同温度热处理的SiCf/SiC复合材料微观组织及热导率[59]

Fig. 9 Microstructures and thermal conductivities of SiCf/SiC composites with different heat-treatment[59] (a) SiC matrix without heat-treatment; (b) SiC matrix with 1700 ℃-2 h heat-treatment; (c) SiC matrix with 1900 ℃-2 h heat-treatment; (d-f) TEM images of SiC matrix corresponding to (a-c); (g) Thermal conductivity of 2D SiCf/SiC after different heat-treatments; (h) Full width at half maximum of (111) diffraction crystal plane after different heat-treatments

图12 生长30 min的 (a, b) ECNT-CF和(c, d) VACNT-CF不同放大倍率的微观组织[52]

Fig. 12 Low and high magnification SEM images of (a, b) ECNT-CF and (c, d) VACNT-CF fabrics with a growth duration of 30 min[52]

| [1] |

PARTHASARATHY T A, PETRY M D, CINIBULK M K, et al. Thermal and oxidation response of UHTC leading edge samples exposed to simulated hypersonic flight conditions. Journal of the American Ceramic Society, 2013, 96(3):907.

DOI URL |

| [2] |

UYANNA O, NAJAFI H. Thermal protection systems for space vehicles: a review on technology development, current challenges and future prospects. Acta Astronautica, 2020, 176: 341.

DOI URL |

| [3] |

NOZAWA T, HINOKI T, HASEGAWA A, et al. Recent advances and issues in development of silicon carbide composites for fusion applications. Journal of Nuclear Materials, 2009, 386-388: 622.

DOI URL |

| [4] |

YAO X M, WANG X J, LIU X J, et al. Friction-wear properties and mechanism of hard facing pairs of SiC and WC. Journal of Inorganic Materials, 2019, 34(6):673.

DOI URL |

| [5] | 肖鹏, 熊翔, 张红波, 等. C/C-SiC陶瓷制动材料的研究现状与应用. 中国有色金属学报, 2005, 15(5):667. |

| [6] |

KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2005, 412(1/2):177.

DOI URL |

| [7] |

LUO L, WANG Y G, LIU L P, et al. Carbon fiber reinforced silicon carbide composite-based sharp leading edges in high enthalpy plasma flows. Composites Part B-Engineering, 2018, 135: 35.

DOI URL |

| [8] |

WANG X, GAO X, ZHANG Z, et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. Journal of the European Ceramic Society, 2021, 41(9):4671.

DOI URL |

| [9] |

SLACK G A. Thermal conductivity of pure and impure silicon, silicon carbide, and diamond. Journal of Applied Physics, 1964, 35(12):3460.

DOI URL |

| [10] |

ZHOU Y, HIRAO K, WATARI K, et al. Thermal conductivity of silicon carbide densified with rare-earth oxide additives. Journal of the European Ceramic Society, 2004, 24(2):265.

DOI URL |

| [11] |

AN Q L, CHEN J, MING W W, et al. Machining of SiC ceramic matrix composites: a review. Chinese Journal of Aeronautics, 2021, 34(4):540.

DOI URL |

| [12] |

EOM J H, KIM Y W, SONG I H. Effects of the initial α-SiC content on the microstructure, mechanical properties, and permeability of macroporous silicon carbide ceramics. Journal of the European Ceramic Society, 2012, 32(6):1283.

DOI URL |

| [13] | 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展. 航空制造技术, 2003(1): 24. |

| [14] |

YUAN Q, SONG Y C. Research and development of continuous SiC fibers and SiCf/SiC composities. Journal of Inorganic Materials, 2016, 31(11):1157.

DOI |

| [15] |

LIU G, ZHANG X, YANG J, et al. Recent advances in joining of SiC-based materials (monolithic SiC and SiCf/SiC composites): joining processes, joint strength, and interfacial behavior. Journal of Advanced Ceramics, 2019, 8(1):19.

DOI |

| [16] |

KATOH Y, OZAWA K, SHIH C, et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. Journal of Nuclear Materials, 2014, 448(1/2/3):448.

DOI URL |

| [17] | XU Y D, CHENG L F, ZHANG L T. Three dimensional textile SiC/SiC composites by chemical vapor infiltration. Journal of Inorganic Materials, 2001, 16(2):344. |

| [18] |

LIU W, WEI Y, DENG J. Carbon-fiber-reinforced C-SiC binary matrix composites. Carbon, 1995, 33(4):441.

DOI URL |

| [19] |

HU C L, HONG W H, XU X J, et al. Sandwich-structured C/C-SiC composites fabricated by electromagnetic-coupling chemical vapor infiltration. Scientific Reports, 2017, 7: 13120.

DOI PMID |

| [20] |

STALIN M, RAJAGURU K, RANGARAJ L. Processing of Cf/SiC composites by hot pressing using polymer binders followed by polymer impregnation and pyrolysis. Journal of the European Ceramic Society, 2020, 40(2):290.

DOI URL |

| [21] |

OKAMURA K, SHIMOO T, SUZUYA K, et al. SiC-based ceramic fibers prepared via organic-to-inorganic conversion process-a review. Journal of the Ceramic Society of Japan, 2006, 114(6):445.

DOI URL |

| [22] | 张建可.树脂基碳纤维复合材料的热物理性能之一——导热系数. 中国空间科学技术, 1987, (3):55. |

| [23] |

MARADUDIN A A. The lattice thermal conductivity of an isotopically isordered crystal. Journal of the American Chemical Society, 1964, 86(17):3405.

DOI URL |

| [24] |

NI Y, XIONG S, VOLZ S, et al. Thermal transport along the dislocation line in silicon carbide. Physical Review Letters, 2014, 113(12):124301.

DOI URL |

| [25] |

HUANG D, TAN R X, LIU L, et al. Preparation and properties of the three-dimensional highly thermal conductive carbon/carbon- silicon carbide composite using the mesophase-pitch-based carbon fibers and pyrocarbon as thermal diffusion channels. Journal of the European Ceramic Society, 2021, 41(8):4438.

DOI URL |

| [26] | SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling. Journal of Nuclear Materials, 2007, 371(1/2/3):329. |

| [27] | GRAEBNER J E. Thermal Conductivity of Diamond. In: PAN L S, KANIA D R. Boston, Diamond:Electronic Properties and Applications. MA: Springer US, 1995: 285. |

| [28] |

YE C, WU H, ZHU S P, et al. Microstructure of high thermal conductivity mesophase pitch-based carbon fibers. New Carbon Materials, 2021, 36(5):980.

DOI URL |

| [29] | 高晓晴, 郭全贵, 刘朗, 等. 高导热炭材料的研究进展. 功能材料, 2006(2): 173. |

| [30] | DONALD T M, GLEN A S. Conductivity of single crystals. In SHINDE S L, GOELA J S. High thermal conductivity materials. New York: Springer, 2006: 21. |

| [31] |

ZHU C X, LANG J, MA N G. Preparation of Si-diamond-SiC composites by in-situ reactive sintering and their thermal properties. Ceramics International, 2012, 38(8):6131.

DOI URL |

| [32] |

ZHANG Y Y, WANG T S, HSU C Y, et al. Thermal transport characteristics in diamond/SiC composites via molten Si infiltration. Ceramics International, 2021, 47(12):17084.

DOI URL |

| [33] | 李亮.碳化硅纤维高温氧化行为研究. 长沙: 国防科学技术大学硕士学位论文, 2016. |

| [34] | EKSTROM T, ZHENG J, KLOUB K, et al. Heat conductive material. United States, Grant, 6914025. 2005.07.05. |

| [35] |

YANG Z L, HE X B, WU M, et al. Fabrication of diamond/SiC composites by Si-vapor vacuum reactive infiltration. Ceramics International, 2013, 39(3):3399.

DOI URL |

| [36] | ZHENG W, HE X B, WU M, et al. Preparation and thermal conductivities of diamond/SiC composites. Applied Physics A-Materials Science & Processing, 2018, 124(12):804. |

| [37] |

YANG Z L, HE X B, WU M, et al. Infiltration mechanism of diamond/SiC composites fabricated by Si-vapor vacuum reactive infiltration process. Journal of the European Ceramic Society, 2013, 33(4):869.

DOI URL |

| [38] |

MATTHEY B, KUNZE S, HORNER M, et al. SiC-bonded diamond materials produced by pressureless silicon infiltration. Journal of Materials Research, 2017, 32(17):3362.

DOI URL |

| [39] |

SHIMONO M, KUME S. HIP-sintered composites of C (Diamond)/ SiC. Journal of the American Ceramic Society, 2004, 87(4):752.

DOI URL |

| [40] | 李子晗. 中间相沥青基碳纤维复合材料研究进展及发展前景. 新型工业化, 2022, 12(8):174. |

| [41] | 宁亮.中间相沥青基碳纤维的制备及其表面处理的研究. 北京: 北京化工大学硕士学位论文, 2009. |

| [42] | 毛德君. 沥青基碳纤维的生产及应用. 炼油与化工, 2002, 13(4):3. |

| [43] | 徐兵.高导热沥青基炭纤维的制备及其在三维炭/炭复合材料中的应用研究. 武汉: 武汉科技大学博士学位论文, 2018. |

| [44] |

CALEBRESE C, EISMAN G A, LEWIS D J, et al. Swelling and related mechanical and physical properties of carbon nanofiber filled mesophase pitch for use as a bipolar plate material. Carbon, 2010, 48(13):3939.

DOI URL |

| [45] |

EDIE D D, FOX N K, BARNETT B C, et al. Melt-spun non-circular carbon fibers. Carbon, 1986, 24(4):477.

DOI URL |

| [46] |

YOON S H, KORAI Y, MOCHIA I, et al. Axial nano-scale microstructures in graphitized fibers inherited from liquid crystal mesophase pitch. Carbon, 1996, 34(1):83.

DOI URL |

| [47] |

FANG D, CHEN Z, SONG Y, et al. Morphology and microstructure of 2.5 dimension C/SiC composites ablated by oxyacetylene torch. Ceramics International, 2009, 35: 1249.

DOI URL |

| [48] |

CAO L Y, WANG J, LIU Y S, et al. Effect of heat transfer channels on thermal conductivity of silicon carbide composites reinforced with pitch-based carbon fibers. Journal of the European Ceramic Society, 2022, 42(2):420.

DOI URL |

| [49] |

CAO L Y, LIU Y S, ZHANG Y H, et al. Thermal conductivity and bending strength of SiC composites reinforced by pitch-based carbon fibers. Journal of Advanced Ceramics, 2022, 11(2):247.

DOI |

| [50] |

GUO S Q. Thermal and electrical properties of hot-pressed short pitch-based carbon fiber-reinforced ZrB2-SiC matrix composites. Ceramics International, 2013, 39(5):5733.

DOI URL |

| [51] |

GUO S Q, NAITO K, KAGAWA Y. Mechanical and physical behaviors of short pitch-based carbon fiber-reinforced HfB2-SiC matrix composites. Ceramics International, 2013, 39(2):1567.

DOI URL |

| [52] |

CHEN S, FENG Y, QIN M, et al. Improving thermal conductivity in the through-thickness direction of carbon fibre/SiC composites by growing vertically aligned carbon nanotubes. Carbon, 2017, 116: 84.

DOI URL |

| [53] |

HU M, YANG Z H. Perspective on multi-scale simulation of thermal transport in solids and interfaces. Physical Chemistry Chemical Physics, 2021, 23(9):5680.

DOI URL |

| [54] |

LI Z X, LI X Q, ZHANG B X, et al. Enhanced thermal and mechanical properties of optimized SiCf/SiC composites with in-situ CNTs on PyC interface. Ceramics International, 2020, 46(11):18071.

DOI URL |

| [55] |

CUI G Y, LUO R Y, WANG L Y, et al. Effect of SiC nanowires on the mechanical properties and thermal conductivity of 3D-SiCf/SiC composites prepared via precursor infiltration pyrolysis. Journal of the European Ceramic Society, 2021, 41(10):5026.

DOI URL |

| [56] |

LI J X, LIU Y S, CHEN C, et al. Effects of phenolic resin contents on microstructures and properties of C/SiC-diamond composites. Journal of the American Ceramic Society, 2021, 104(7):3424.

DOI URL |

| [57] |

FENG W, ZHANG L T, LIU Y S, et al. The improvement in the mechanical and thermal properties of SiC/SiC composites by introducing CNTs into the PyC interface. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2015, 637: 123.

DOI URL |

| [58] |

ZHANG Y Y, HSU C Y, KARANDIKAR P, et al. Interfacial zone surrounding the diamond in reaction bonded diamond/SiC composites: Interphase structure and formation mechanism. Journal of the European Ceramic Society, 2019, 39(16):5190.

DOI URL |

| [59] |

FENG W, ZHANG L T, LIU Y S, et al. Increasing the thermal conductivity of 2D SiC/SiC composites by heat-treatment. Fusion Engineering and Design, 2015, 90: 110.

DOI URL |

| [60] |

HAN S, LIN J T, YAMADA Y, et al. Enhancing the thermal conductivity and compressive modulus of carbon fiber polymer-matrix composites in the through-thickness direction by nanostructuring the interlaminar interface with carbon black. Carbon, 2008, 46(7):1060.

DOI URL |

| [61] |

ZHANG Y H, LIU Y S, CAO Y J, et al. Effect of well-designed graphene heat conductive channel on the thermal conductivity of C/SiC composites. Ceramics International, 2021, 47(13):19115.

DOI URL |

| [62] |

ZHANG Y H, LIU Y S, CAO L Y, et al. Three-dimensional micro-pipelines high thermal conductive C/SiC composites. Ceramics International, 2021, 47(24):34333.

DOI URL |

| [63] |

PAN Y, WANG J, WANG N, et al. Effects of aligned carbon nanotube microcolumns on mechanical and thermal properties of C/SiC composites prepared by LA-CVI methods. Journal of the European Ceramic Society, 2019, 39(16):5463.

DOI URL |

| [64] |

ZHANG Y H, LIU Y S, CAO Y J, et al. Effect of initial density on thermal conductivity of new micro-pipeline heat conduction C/SiC composites. Journal of the American Ceramic Society, 2021, 104(1):645.

DOI URL |

| [65] |

SNEAD L L, SCHWARZ O J. Advanced SiC composites for fusion applications. Journal of Nuclear Materials, 1995, 219: 3.

DOI URL |

| [66] | NASLAIN R. Hybrid ceramic matrix fibrous composites:an overview. IOP Conference Series: Materials Science and Engineering, 2011, 18: 082002. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [9] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [10] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [11] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [12] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [13] | 杨舒琪, 杨存国, 牛慧祝, 石唯一, 舒珂维. GeP3/科琴黑复合材料作为钠离子电池高性能负极材料[J]. 无机材料学报, 2025, 40(3): 329-336. |

| [14] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [15] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||