无机材料学报 ›› 2021, Vol. 36 ›› Issue (3): 299-305.DOI: 10.15541/jim20200253 CSTR: 32189.14.10.15541/jim20200253

所属专题: 能源材料论文精选(2021)

朱勇1( ), 顾军1,2(

), 顾军1,2( ), 于涛1,3, 何海佟1, 姚睿1

), 于涛1,3, 何海佟1, 姚睿1

收稿日期:2020-05-12

修回日期:2020-07-06

出版日期:2021-03-20

网络出版日期:2020-08-01

通讯作者:

顾 军, 副教授. E-mail: junguca@nju.edu.cn

作者简介:朱 勇(1994-), 男, 硕士研究生. E-mail: Zyong_mail@yeah.net

基金资助:

ZHU Yong1( ), GU Jun1,2(

), GU Jun1,2( ), YU Tao1,3, HE Haitong1, YAO Rui1

), YU Tao1,3, HE Haitong1, YAO Rui1

Received:2020-05-12

Revised:2020-07-06

Published:2021-03-20

Online:2020-08-01

Contact:

GU Jun, associate professor. E-mail: junguca@nju.edu.cn

About author:ZHU Yong(1994-), male, Master candidate. E-mail: Zyong_mail@yeah.net

Supported by:摘要:

研制高活性的电催化剂是实现质子交换膜燃料电池的商业化应用必须解决的关键技术之一。本研究以三乙胺为碱性络合剂、硼氢化钠为还原剂, 采用液相合成法制备PtCo纳米合金电催化剂, 再通过高温热处理实现最佳电化学性能。采用各种表征方法对催化剂的微观结构及电化学性能进行测定, 探究硼氢化钠、三乙胺的添加量及高温热处理对催化剂电化学性能的影响。结果显示, 适量的硼氢化钠可提升催化剂的电化学活性面积, 三乙胺可以改变催化剂的质量活性, 高温热处理能有效提升催化剂的质量活性, 极大提升催化剂的氧还原反应(ORR)能力; 在同一测试体系下, 添加100 mg硼氢化钠及100 μL三乙胺在500 ℃高温热处理条件下制备的PtCo纳米合金电催化剂的质量活性达到133 mA/mgPt, 是田中贵金属工业株式会社(TKK)商用PtCo合金催化剂的3倍。

中图分类号:

朱勇, 顾军, 于涛, 何海佟, 姚睿. 铂钴合金纳米电催化剂的制备及性能研究[J]. 无机材料学报, 2021, 36(3): 299-305.

ZHU Yong, GU Jun, YU Tao, HE Haitong, YAO Rui. Synthesis and Property of Platinum-cobalt Alloy Nano Catalyst[J]. Journal of Inorganic Materials, 2021, 36(3): 299-305.

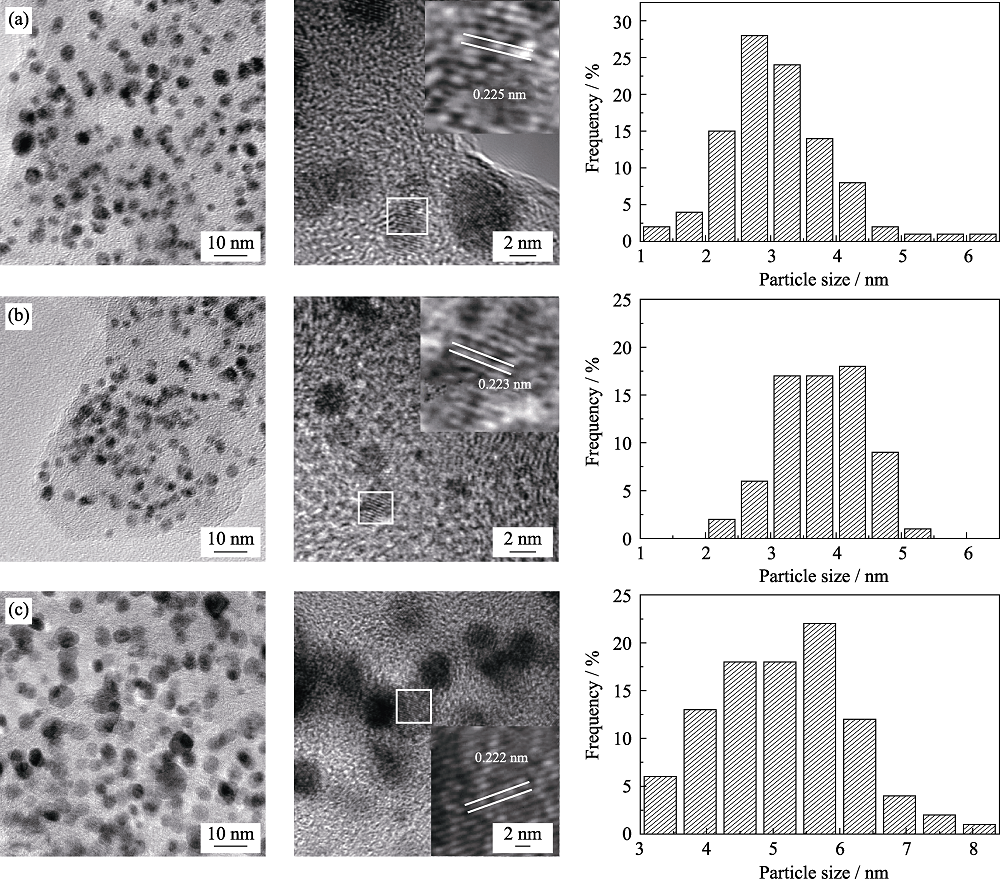

图2 Pt2.8Co/C(a)、Pt2.8Co/C-500(b)和TKK-PtCo/C(c)的TEM照片及粒径分布图

Fig. 2 TEM images and particle size distributions of Pt2.8Co/C(a), Pt2.8Co/C-500(b) and TKK-PtCo/C(c)

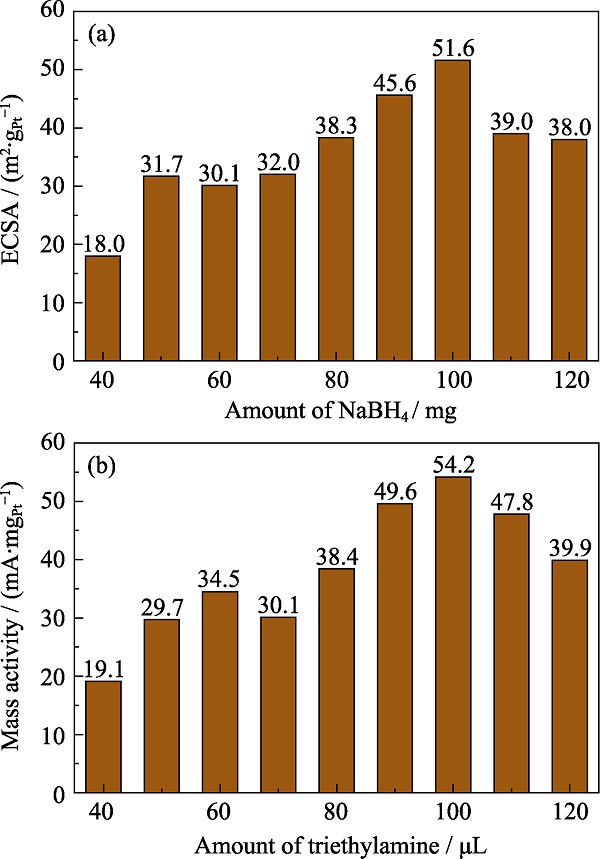

图4 不同NaBH4添加量所制备的DN-Pt2.8Co/C的ECSA直方图(a); 不同三乙胺添加量所制备DTL-Pt2.8Co/C的MA直方图(b)

Fig. 4 ECSA histogram for DN-Pt2.8Co/C with different amounts of NaBH4 (a); MA histogram for DTL-Pt2.8Co/C with different amounts of triethylamine (b)

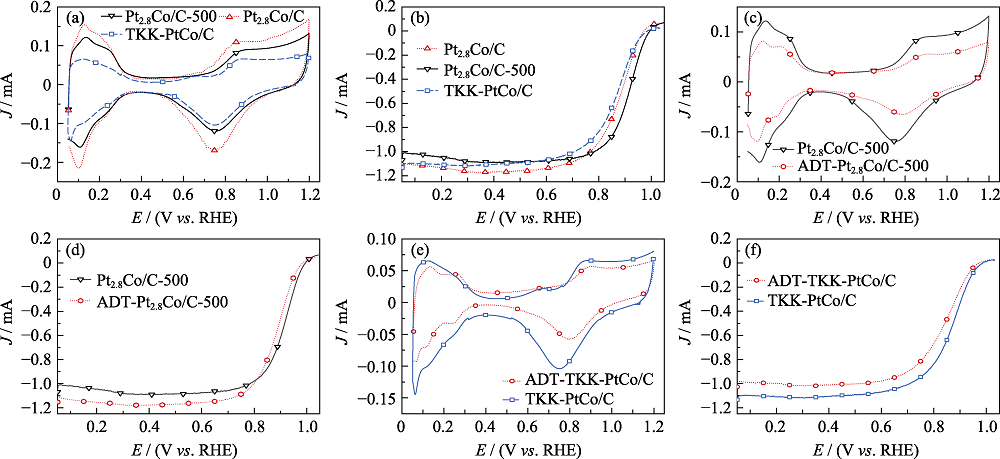

图5 Pt2.8Co/C、Pt2.8Co/C-500、TKK-PtCo/C的CV (a)和LSV曲线(b); 加速稳定性测试(ADT)前后Pt2.8Co/C-500(c, d), TKK-PtCo/C(e, f)的CV(c, e)和LSV(d, f)曲线

Fig. 5 CV(a) and LSV (b) curves for Pt2.8Co/C, Pt2.8Co/C-500 and TKK-PtCo/C; CV(c, e) and LSV(d, f) curves of Pt2.8Co/C-500 (c, d) and TKK-PtCo/C (e, f) before and after durability tests

| Sample | ECSA/(m2∙gPt-1) | MA/(mA∙mgPt-1) |

|---|---|---|

| Pt2.8Co/C | 51.6 | 54.2 |

| Pt2.8Co/C-500 | 43.5 | 133.0 |

| TKK-PtCo/C | 28.1 | 44.3 |

| ADT-Pt2.8Co/C-500 | 24.6 | 71.0 |

| ADT-TKK-PtCo/C | 15.7 | 27.2 |

表1 PtCo合金电催化剂的ECSA和MA数据

Table 1 ECSA and MA parameters of platinum-cobalt alloy nano catalysts

| Sample | ECSA/(m2∙gPt-1) | MA/(mA∙mgPt-1) |

|---|---|---|

| Pt2.8Co/C | 51.6 | 54.2 |

| Pt2.8Co/C-500 | 43.5 | 133.0 |

| TKK-PtCo/C | 28.1 | 44.3 |

| ADT-Pt2.8Co/C-500 | 24.6 | 71.0 |

| ADT-TKK-PtCo/C | 15.7 | 27.2 |

| [1] | 毛宗强 . 燃料电池. 化学工业出版社, 2005. |

| [2] | 孙世刚 等. 电催化. 北京: 化学工业出版社, 2013: 663. |

| [3] | SUI S, WANG X, ZHOU X, et al. A comprehensive review of Pt electrocatalysts for the oxygen reduction reaction: nanostructure, activity, mechanism and carbon support in PEM fuel cells. J. Mater. Chem. A, 2017,5(5):1808-1825. |

| [4] | ZHAO L, WANG Q, ZHANG X, et al. Combined electron and structure manipulation on Fe-containing N-doped carbon nanotubes to boost bifunctional oxygen electrocatalysis. ACS Appl. Mater. Int., 2018,10(42):35888-35895. |

| [5] | GAN J, ZHANG J, ZHANG B, et al. Active sites engineering of Pt/CNT oxygen reduction catalysts by atomic layer deposition. J. Energy Chem., 2020,45:59-66. |

| [6] | JUNG W S. Study on durability of Pt supported on graphitized carbon under simulated start-up/shut-down conditions for polymer electrolyte membrane fuel cells. J. Energy Chem., 2018,27(1):326-334. |

| [7] | PENG H, MO Z, LIAO S, et al. High performance Fe- and N- doped carbon catalyst with graphene structure for oxygen reduction. Sci. Rep.-UK, 2013,3(1):1765. |

| [8] | LUO Y, FENG J Z, FENG J, et al. Research progress on advanced carbon materials as Pt support for proton exchange membrane fuel cells. J. Inorg. Mater., 2020,35(4):407-415. |

| [9] | LIU J, HE T, WANG Q, et al. Confining ultrasmall bimetal alloys in porous N-carbon as scalable and sustainable electrocatalysts for rechargeable Zn-air batteries. J. Mater. Chem. A, 2019,7:12451. |

| [10] | LOUISIA S, THOMAS Y R J, LECANTE P, et al. Alloyed Pt3 M (M=Co, Ni) nanoparticles supported on S- and N-doped carbon nanotubes for the oxygen reduction reaction. Beilstein J. Nanotech., 2019,10(1):1251-1269. |

| [11] | XU W, LYU F, BAI Y, et al. Porous cobalt oxide nanoplates enriched with oxygen vacancies for oxygen evolution reaction. Nano Energy, 2018,43:110-116. |

| [12] | CHEN Z, WANG Q, ZHANG X, et al. N-doped defective carbon with trace Co for efficient rechargeable liquid electrolyte-/all-solid-state Zn-air batteries. Science Bulletin, 2018,63(9):548-555. |

| [13] | BEARD B C. The structure and activity of Pt-Co alloys as oxygen reduction electrocatalysts. J. Electrochem. Soc., 1990,137(11):3368. |

| [14] | LI S L, YUAN X X, KONG H C, et al. Fe-PPy-TsOH/C as cathode catalyst for proton exchange membrane fuel cells. J. Inorg. Mater., 2017,32(4):393. |

| [15] | BAI P, TIAN F, WANG H, et al. Electrocatalytic enhancement of 0D/1D/2D multidimensional PtCo alloy@cobalt benzoate/graphene composite catalyst for alcohol electro-oxidation. Advanced Materials Interfaces, 2019,6(19):1900946. |

| [16] | 杨德隆, 顾军, 刘晓梦 , 等. 铂基催化剂氧还原测试技术的研究进展. 电源技术, 2019,43(12):2040-2043. |

| [17] |

WANG G, HILGERT J, RICHTER F H, et al. Platinum-cobalt bimetallic nanoparticles in hollow carbon nanospheres for hydrogenolysis of 5-hydroxymethylfurfural. Nat. Mater., 2014,13(3):293-300.

DOI URL PMID |

| [18] |

ZHANG L, HAN L, LIU H, et al. Potential-cycling synthesis of single platinum atoms for efficient hydrogen evolution in neutral media. Angewandte Chemie International Edition, 2017,56(44):13694-13698.

DOI URL PMID |

| [19] |

LIN L, ZHOU W, GAO R, et al. Low-temperature hydrogen production from water and methanol using Pt/alpha-MoC catalysts. Nature, 2017,544(7648):80-83.

DOI URL PMID |

| [20] |

HUANG H, LI K, CHEN Z, et al. Achieving remarkable activity and durability toward oxygen reduction reaction based on ultrathin Rh-doped Pt nanowires. J. Am. Chem. Soc., 2017,139(24):8152-8159.

DOI URL PMID |

| [21] |

STRASSER P, KOH S, ANNIYEV T, et al. Lattice-strain control of the activity in dealloyed core-shell fuel cell catalysts. Nat. Chem., 2010,2(6):454-460.

DOI URL PMID |

| [22] | YANG D, GU J, LIU X, et al. Monodispersed Pt3Ni nanoparticles as a highly efficient electrocatalyst for PEMFCs. Catalysts, 2019,9(7):588. |

| [23] | PAQUETTE. Encyclopedia of Reagents for Organic Synthesis. Chichester: Wiley, 1995: 8. |

| [24] | YAO S, FENG L, ZHAO X, et al. Pt/C catalysts with narrow size distribution prepared by colloidal-precipitation method for methanol electrooxidation. J. Power Sources, 2012,217:280-286. |

| [25] | ANTOLINI E. Structural parameters of supported fuel cell catalysts: the effect of particle size, inter-particle distance and metal loading on catalytic activity and fuel cell performance. Applied Catalysis B: Environmental, 2016,181:298-313. |

| [26] | SAHIN N E, NAPPORN T W, DUBAU L, et al. Temperature- dependence of oxygen reduction activity on Pt/C and PtCr/C electrocatalysts synthesized from microwave-heated diethylene glycol method. Applied Catalysis B: Environmental, 2017,203:72-84. |

| [27] | ARUMUGAM B, TAMAKI T, YAMAGUCHI T. Beneficial role of copper in the enhancement of durability of ordered intermetallic PtFeCu catalyst for electrocatalytic oxygen reduction. ACS Appl. Mater. Int., 2015,7(30):16311-16321. |

| [28] | KUROKI H, TAMAKI T, MATSUMOTO M, et al. Platinum- iron-nickel trimetallic catalyst with superlattice structure for enhanced oxygen reduction activity and durability. Ind. Eng. Chem. Res., 2016,55(44):11458-11466. |

| [1] | 刘磊, 郭瑞华, 王丽, 王艳, 张国芳, 关丽丽. Pt3Co高指数晶面氧还原过程的密度泛函理论研究[J]. 无机材料学报, 2025, 40(1): 39-46. |

| [2] | 张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568. |

| [3] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [4] | 杨代辉, 孙甜, 田合鑫, 史晓斐, 马东伟. 铁氮共掺杂介孔碳材料的简易制备及其氧还原反应催化性能[J]. 无机材料学报, 2023, 38(11): 1309-1315. |

| [5] | 孙炼, 顾全超, 杨雅萍, 王洪磊, 余金山, 周新贵. 二维过渡金属硫属化合物氧还原反应催化剂的研究进展[J]. 无机材料学报, 2022, 37(7): 697-709. |

| [6] | 蒋丽丽, 徐帅帅, 夏宝凯, 陈胜, 朱俊武. 缺陷调控石墨烯复合催化剂在氧还原反应中的作用[J]. 无机材料学报, 2022, 37(2): 215-222. |

| [7] | 刘自若, 刘炜, 郝策, 胡金文, 史彦涛. 蜂窝状碳负载铁基单原子催化剂的制备及ORR催化性能研究[J]. 无机材料学报, 2021, 36(9): 943-949. |

| [8] | 郝策, 刘自若, 刘炜, 史彦涛. 用于氧还原反应的碳基负载金属单原子催化剂研究进展[J]. 无机材料学报, 2021, 36(8): 820-834. |

| [9] | 田建建, 马霞, 王敏, 姚鹤良, 华子乐, 张玲霞. 锡量子点制备及其电催化还原二氧化碳产甲酸性能[J]. 无机材料学报, 2021, 36(12): 1337-1342. |

| [10] | 丁昇, 宁锴, 袁斌霞, 潘卫国, 尹诗斌, 刘建峰. 碱性溶液中不同微观结构的Fe-N/C催化剂氧还原性能的稳定性对比研究[J]. 无机材料学报, 2020, 35(8): 953-958. |

| [11] | 魏玉全,杨勇,刘盟,郦其乐,黄政仁. 高温热处理对SiBCN/HfC复相陶瓷物相组成及微观结构的影响[J]. 无机材料学报, 2020, 35(8): 931-938. |

| [12] | 何王涛, 马汝广, 朱钰方, 杨明杰, 王家成. 氢氧化钾活化制备可再生多孔碳及其电催化氧还原性能研究[J]. 无机材料学报, 2019, 34(10): 1115-1122. |

| [13] | 杨志宾, 岳彤联, 余向南, 吴苗苗. 钴掺杂氧化铈纳米粒子电催化性能研究[J]. 无机材料学报, 2018, 33(8): 845-853. |

| [14] | 崔香枝, 张琳琳, 曾黎明, 张晓华, 陈航榕, 施剑林. 石墨化介孔碳包裹WC纳米粒子的构建及其氧还原性能研究[J]. 无机材料学报, 2018, 33(2): 213-220. |

| [15] | 施 旗, 雷永鹏, 王应德, 王仲民. 氮掺杂石墨烯@碳纳米纤维的原位制备及其电催化氧还原性能[J]. 无机材料学报, 2016, 31(4): 351-357. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||