无机材料学报 ›› 2023, Vol. 38 ›› Issue (5): 561-568.DOI: 10.15541/jim20220555 CSTR: 32189.14.10.15541/jim20220555

所属专题: 【结构材料】陶瓷基复合材料(202506)

收稿日期:2022-09-22

修回日期:2022-11-21

出版日期:2022-12-09

网络出版日期:2022-12-09

通讯作者:

付前刚, 教授. E-mail: fuqiangang@nwpu.edu.cn作者简介:张 硕(1994-), 女, 博士研究生. E-mail: shuozhang@mail.nwpu.edu.cn

基金资助:

ZHANG Shuo( ), FU Qiangang(

), FU Qiangang( ), ZHANG Pei, FEI Jie, LI Wei

), ZHANG Pei, FEI Jie, LI Wei

Received:2022-09-22

Revised:2022-11-21

Published:2022-12-09

Online:2022-12-09

Contact:

FU Qiangang, professor. E-mail: fuqiangang@nwpu.edu.cnAbout author:ZHANG Shuo (1994-), female, PhD candidate. E-mail: shuozhang@mail.nwpu.edu.cn

Supported by:摘要:

低密度C/C多孔体的结构与性能调控是制备具有优异摩擦磨损性能的C/C-SiC复合材料的关键。本研究采用化学气相渗积法制备了C/C多孔体, 并对其进行2100 ℃高温热处理, 再通过反应熔渗法制备了C/C-SiC复合材料, 研究了C/C多孔体高温热处理对C/C-SiC复合材料微观结构、导热性能和摩擦磨损性能的影响。结果表明, 经2100 ℃热处理的C/C多孔体孔隙率和石墨化程度增加, 用其制备的C/C-SiC复合材料比C/C多孔体未经热处理的密度更大(2.22 g/cm3), 孔隙率由5.1%降低至3.4%, SiC陶瓷相含量比热处理前提高11.9%。石墨化程度越高,声子的平均自由程越大, 因此其室温的导热率提升到3.1倍, 1200 ℃导热率提升到1.2倍。经过热处理的热解炭更软, 摩擦面易形成连续且稳定的摩擦膜, 因此摩擦系数更稳定, 并且在测试载荷为3、6和9 N下磨损率均显著降低, 下降幅度达到47.8%、41.9%和11.7%, 平均摩擦系数分别为0.47、0.38和0.39。综上所述, 对C/C多孔体进行高温热处理可使C/C-SiC复合材料的导热性能提升, 更耐磨并且表现出更稳定的摩擦系数。

中图分类号:

张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568.

ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites[J]. Journal of Inorganic Materials, 2023, 38(5): 561-568.

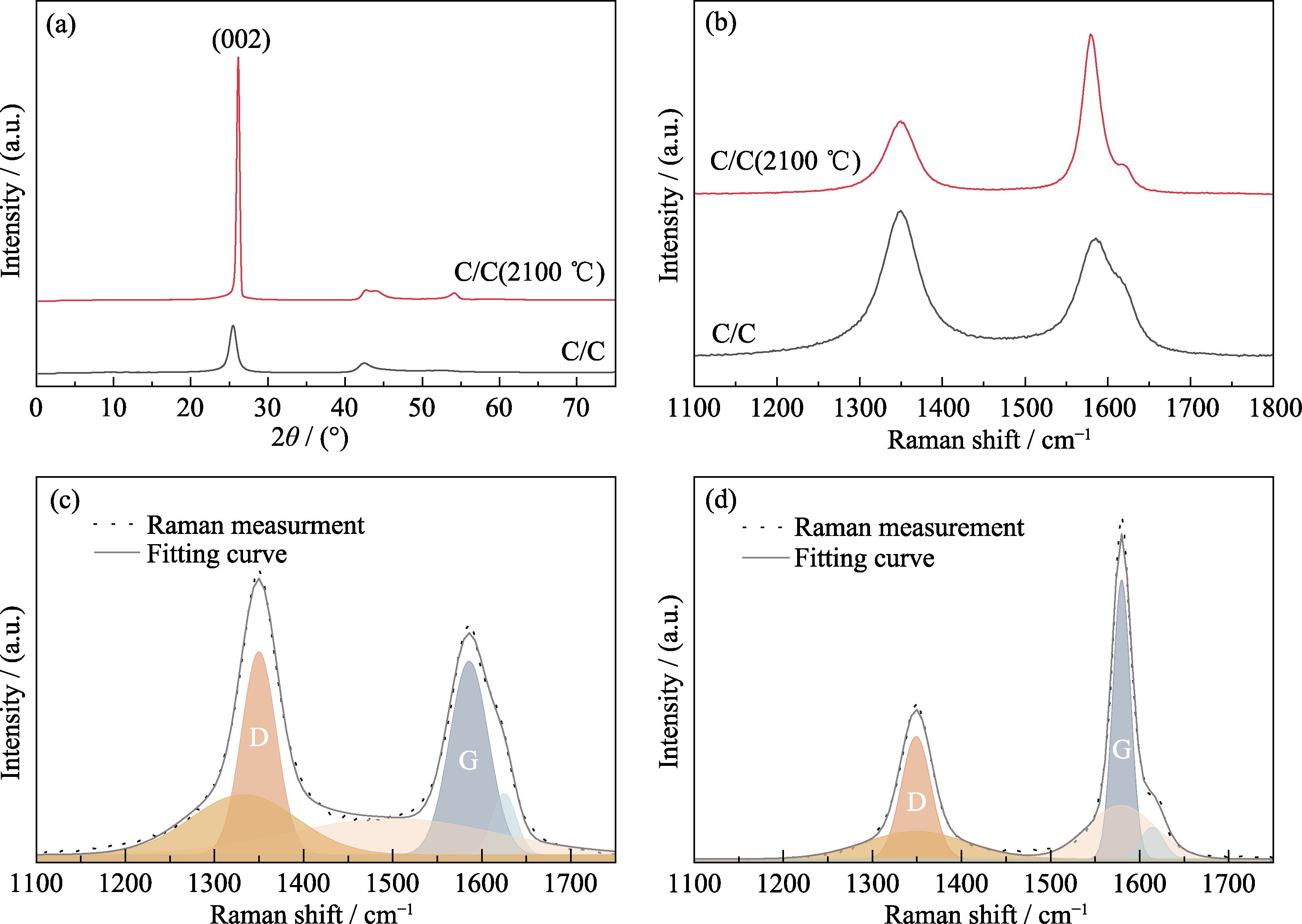

图2 C/C多孔体PyC晶体分析

Fig. 2 Analysis of PyC crystal in porous C/C preform (a) XRD patterns; (b) Raman spectra; (c, d) Raman fitting spectra of (c) sample C/C and (d) sample C/C (2100 ℃)

| Sample | 2θC(002)/(°) | g/% | ID/IG | AG/AT |

|---|---|---|---|---|

| C/C | 25.501 | -60.93 | 1.19 | 0.20 |

| C/C(2100 ℃) | 26.162 | 41.74 | 0.44 | 0.31 |

表1 C/C多孔体的XRD衍射峰位、石墨化度和拉曼光谱拟合结果

Table 1 XRD diffraction peaks, graphitization degrees, and Raman spectral fitting results of porous C/C preform

| Sample | 2θC(002)/(°) | g/% | ID/IG | AG/AT |

|---|---|---|---|---|

| C/C | 25.501 | -60.93 | 1.19 | 0.20 |

| C/C(2100 ℃) | 26.162 | 41.74 | 0.44 | 0.31 |

| Sample | Density/(g·cm-3) | Porosity /% |

|---|---|---|

| C/C | 1.45 | 18.9 |

| C/C(2100 ℃) | 1.41 | 21.9 |

| C/C-SiC | 2.13 | 5.1 |

| C/C(2100 ℃)-SiC | 2.22 | 3.4 |

表2 C/C多孔体及C/C-SiC复合材料的密度与孔隙率

Table 2 Densities and porosities of the C/C and C/C-SiC composites

| Sample | Density/(g·cm-3) | Porosity /% |

|---|---|---|

| C/C | 1.45 | 18.9 |

| C/C(2100 ℃) | 1.41 | 21.9 |

| C/C-SiC | 2.13 | 5.1 |

| C/C(2100 ℃)-SiC | 2.22 | 3.4 |

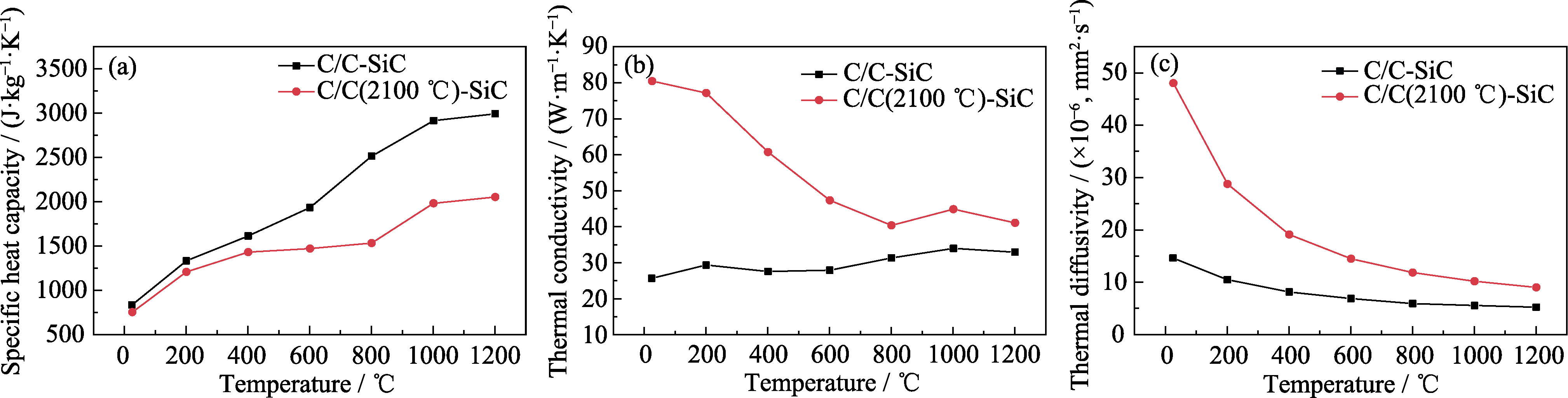

图5 C/C-SiC复合材料Z向热学性能随温度的变化

Fig. 5 Relations of thermal properties to temperature of C/C-SiC composites on Z direction (a) Specific heat capacity; (b) Thermal conductivity; (c) Thermal diffusivity

图7 不同载荷下C/C-SiC复合材料磨痕SEM照片

Fig. 7 SEM images of C/C-SiC composites grinding defect under different loads (a-c) Sample C/C-SiC under (a) 3 N, (b) 6 N, (c) 9 N loads; (d-f) Sample C/C(2100 ℃)-SiC under (d) 3 N, (e) 6 N, (f) 9 N loads

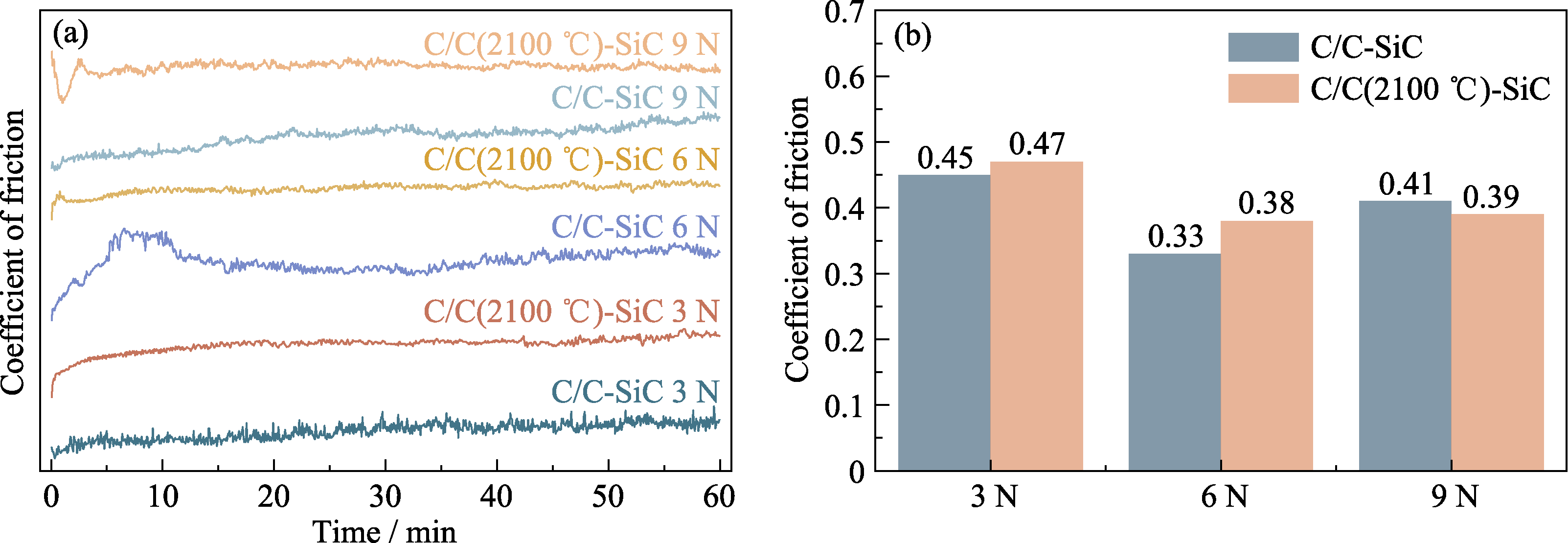

图6 C/C-SiC复合材料摩擦系数

Fig. 6 Friction coefficient of C/C-SiC composites (a) Variation of friction coefficient with time under different loads; (b) Average coefficient of friction under different loads

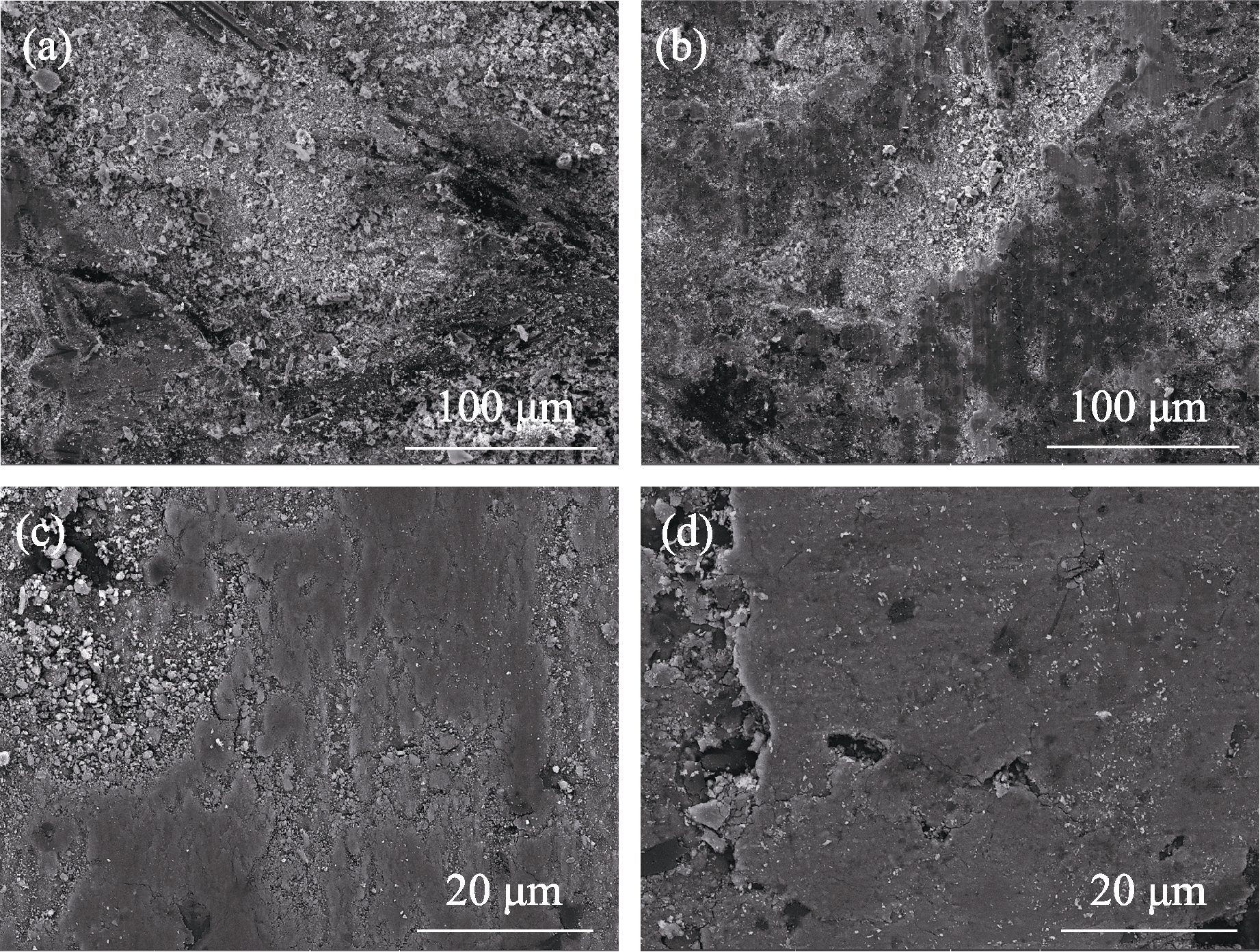

图9 不同载荷下C/C-SiC复合材料磨痕高倍SEM照片

Fig. 9 SEM images of C/C-SiC composites grinding defect under different loads (a, b) Sample C/C-SiC under (a) 3 N, (b) 9 N loads; (c, d) Sample C/C(2100 ℃)-SiC under (c) 3 N, (d) 9 N loads

| [1] |

DUAN J, ZHANG M, CHEN P, et al. Tribological behavior and applications of carbon fiber reinforced ceramic composites as high-performance frictional materials. Ceramics International, 2021, 47(14): 19271.

DOI URL |

| [2] |

WANG Z, HAN J, DOMBLESKY J P, et al. Crack propagation and microstructural transformation on the friction surface of a high-speed railway brake disc. Wear, 2019, 428-429: 45.

DOI URL |

| [3] |

LI Z, XIAO P, ZHANG B G, et al. Preparation and tribological properties of C/C-SiC brake composites modified by in situ grown carbon nanofibers. Ceramics International, 2015, 41(9): 11733.

DOI URL |

| [4] |

XU J, GUO L, WANG H, et al. Influence of graphitization temperature on microstructure and mechanical property of C/C-SiC composites with highly textured pyrolytic carbon. Journal of the European Ceramic Society, 2022, 42(5): 1893.

DOI URL |

| [5] |

FU Q G, ZHNAG P, ZHUANG L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science and Technology, 2021, 96: 31.

DOI URL |

| [6] |

KRENKEL W, HEIDENREICH B, RENZ R. C/C-SiC composites for advanced friction systems. Advanced Engineering Materials, 2009, 4(7): 427.

DOI URL |

| [7] |

ZHOU H J, DONG S M, HE P, et al. Tribological behaviors and anti-wear mechanisms of carbon/carbon-silicon carbide composites. Journal of Inorganic Materials, 2013, 28(10): 1057.

DOI URL |

| [8] |

BERNDT W K. C/C-SiC composites for space applications and advanced friction systems. Materials Science and Engineering: A, 2005, 412: 177.

DOI URL |

| [9] |

KUMAR P, SRIVASTAVA V K. Tribological behaviour of C/C-SiC composites-a review. Journal of Advanced Ceramics, 2016, 5(1): 1.

DOI URL |

| [10] |

ALMEIDA R, LI Y, BSESER B, et al. Damage analysis of 2.5D C/C-SiC composites subjected to fatigue loadings. Journal of the European Ceramic Society, 2019, 39(7): 2244.

DOI |

| [11] |

REN J J, LI K Z, ZHANG S Y, et al. Preparation of carbon/carbon composite by pyrolysis of ethanol and methane. Materials and Design, 2015, 65: 174.

DOI URL |

| [12] | 李贺军, 史小红, 沈庆凉, 等. 国内C/C复合材料研究进展. 中国有色金属学报, 2019, 29(9): 13. |

| [13] | SUN J J, LI H J, HAN L Y, et al. Enhancing both strength and toughness of carbon/carbon composites by heat-treated interface modification. Journal of Materials Science & Technology, 2019, 35(3): 383. |

| [14] | 王静. 近零膨胀C/C-SiC复合材料的反应烧结法制备及性能研究. 长沙: 国防科学技术大学硕士学位论文, 2013. |

| [15] |

LI W, LI H J, WANG J, et al. Preparation and mechanical properties of carbon/carbon composites with high textured pyrolytic carbon matrix. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 2129.

DOI URL |

| [16] | 虎琳, 李崇俊, 张永辉. C/C多孔体热处理温度对C/C-SiC复合材料微观结构和热学性能的影响. 炭素, 2018(1): 18. |

| [17] |

周蕊, 韩文静, 施伟伟. 高温热处理对C/C复合刹车材料摩擦磨损性能影响的研究. 复合材料科学与工程, 2021(3): 112.

DOI |

| [18] |

WANG T, LI H, ZHANG S, et al. The effect of microstructural evolution on micromechanical behavior of pyrolytic carbon after heat treatment. Diamond and Related Materials, 2020, 103: 107729.

DOI URL |

| [19] |

DENG P, LI P, XIAO P, et al. Oxidation behaviour of C/C-SiC brake discs tested on full-scale bench rig. Ceramics International, 2021, 47(24): 34783.

DOI URL |

| [20] |

PIAO Y, TONDARE V N, DAVIS C S, et al. Comparative study of multiwall carbon nanotube nanocomposites by Raman, SEM, and XPS measurement techniques. Composites Science and Technology, 2021, 208(80): 108753.

DOI URL |

| [21] | RONG X A, ZW A, ZZ A, et al. Anisotropic tribological behavior of LSI based 2.5D needle-punched carbon fiber reinforced Cf/C-SiC composites. Ceramics International, 2022, 48(15): 21324. |

| [22] | 曾志伟. C/C-SiC复合材料的制备及摩擦性能研究. 长沙: 中南大学硕士学位论文, 2013. |

| [23] |

ZHANG Y H, XIAO Z C, WANG J P, et al. Effect of pyrocarbon content on thermal and frictional properties in C/C preforms of C/C-SiC composites. Wear, 2010, 269(1): 132.

DOI URL |

| [24] | 李专, 肖鹏, 熊翔, 等. C/C-SiC复合材料的导热性能及其影响因素. 中南大学学报: 自然科学版, 2013, 44(1): 6. |

| [25] |

KUMAR P, SRIVASTAVA V K. Reciprocating sliding tribology of ceramic fiber composites with variation of laminate orientation and surface conformity. Ceramics International, 2017, 44(5): 5365.

DOI URL |

| [26] |

FOUQUET S, ROLLIN M, PAILLER R, et al. Tribological behaviour of composites made of carbon fibres and ceramic matrix in the Si-C system. Wear, 2008, 264(9/10): 850.

DOI URL |

| [1] | 张睿, 张侃, 袁梦雅, 谷鑫磊, 郑伟涛. 氮空位调控晶格畸变度强化(NbMoTaW)Nx薄膜的力学性质和耐磨损性[J]. 无机材料学报, 2024, 39(6): 715-725. |

| [2] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [3] | 程玮杰, 王明磊, 林国强. 电弧离子镀CrAlN-DLC硬质复合薄膜的成分、结构与性能[J]. 无机材料学报, 2022, 37(7): 764-772. |

| [4] | 陈俊云, 孙磊, 靳田野, 罗坤, 赵智胜, 田永君. 无黏结剂层状BN增韧cBN刀具材料的研究[J]. 无机材料学报, 2022, 37(6): 623-628. |

| [5] | 郭隐犇, 陈子曦, 王宏志, 张青红. 基于无机填料复合薄膜的摩擦纳米发电机研究进展[J]. 无机材料学报, 2021, 36(9): 919-928. |

| [6] | 朱勇, 顾军, 于涛, 何海佟, 姚睿. 铂钴合金纳米电催化剂的制备及性能研究[J]. 无机材料学报, 2021, 36(3): 299-305. |

| [7] | 魏玉全,杨勇,刘盟,郦其乐,黄政仁. 高温热处理对SiBCN/HfC复相陶瓷物相组成及微观结构的影响[J]. 无机材料学报, 2020, 35(8): 931-938. |

| [8] | 韩杰敏, 王梅, 仝召民, 马一飞. 基于石墨烯森林电极的摩擦纳米发电机[J]. 无机材料学报, 2019, 34(8): 839-843. |

| [9] | 姚秀敏, 王晓洁, 刘学建, 陈忠明, 黄政仁. 碳化硅/碳化钨硬面密封摩擦副的摩擦磨损性能和机理研究[J]. 无机材料学报, 2019, 34(6): 673-678. |

| [10] | 刘玉玲, 王瑞莉, 李楠, 刘梅, 张青红. ZnO介晶填料的制备及其齿科复合树脂的性能[J]. 无机材料学报, 2019, 34(10): 1077-1084. |

| [11] | 司晓阳, 陈凡燕, 邓启煌, 都时禹, 黄庆. MXene/铜合金复合材料的制备与性能研究[J]. 无机材料学报, 2018, 33(6): 603-608. |

| [12] | 王学政, 王海滨, 刘雪梅, 杨 涛, 宋晓艳. 抑制剂对WC-Co硬质合金涂层性能的影响[J]. 无机材料学报, 2017, 32(8): 813-818. |

| [13] | 古毓康, 曹 磊, 万 勇, 高建国. 铝合金基底微碳球作为润滑油添加剂的摩擦学性能及其润滑机理[J]. 无机材料学报, 2017, 32(6): 625-630. |

| [14] | 张昌松, 刘 强, 陈 威. hBN含量对Si3N4-hBN复相陶瓷性能和微观结构的影响[J]. 无机材料学报, 2017, 32(5): 509-516. |

| [15] | 罗军明, 吴小红, 徐吉林. 电解液组分对TiCP/Ti6Al4V复合材料微弧氧化膜耐蚀性及耐磨性影响[J]. 无机材料学报, 2017, 32(4): 418-424. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||