无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 278-288.DOI: 10.15541/jim20210599 CSTR: 32189.14.10.15541/jim20210599

所属专题: 2022年度中国知网高下载论文

刘凯1,2( ), 孙策2, 史玉升3, 胡佳明2, 张庆庆2, 孙云飞2, 章嵩4, 涂溶4, 闫春泽3, 陈张伟5, 黄尚宇2, 孙华君1(

), 孙策2, 史玉升3, 胡佳明2, 张庆庆2, 孙云飞2, 章嵩4, 涂溶4, 闫春泽3, 陈张伟5, 黄尚宇2, 孙华君1( )

)

收稿日期:2021-09-28

修回日期:2021-11-21

出版日期:2022-03-20

网络出版日期:2021-12-24

通讯作者:

孙华君, 教授. E-mail: huajunsun@whut.edu.cn

作者简介:刘 凯(1987-), 男, 副教授. E-mail: victor_liu@whut.edu.cn

基金资助:

LIU Kai1,2( ), SUN Ce2, SHI Yusheng3, HU Jiaming2, ZHANG Qingqing2, SUN Yunfei2, ZHANG Song4, TU Rong4, YAN Chunze3, CHEN Zhangwei5, HUANG Shangyu2, SUN Huajun1(

), SUN Ce2, SHI Yusheng3, HU Jiaming2, ZHANG Qingqing2, SUN Yunfei2, ZHANG Song4, TU Rong4, YAN Chunze3, CHEN Zhangwei5, HUANG Shangyu2, SUN Huajun1( )

)

Received:2021-09-28

Revised:2021-11-21

Published:2022-03-20

Online:2021-12-24

Contact:

SUN Huajun, professor. E-mail: huajunsun@whut.edu.cn

About author:LIU Kai (1987-), male, associate professor. E-mail: victor_liu@whut.edu.cn

Supported by:摘要:

压电陶瓷作为一类重要的功能陶瓷材料, 具备高强度、高硬度、耐腐蚀等优点, 可实现机械能和电能间的相互转换, 常被用于制备传感器、驱动器、电容器等压电器件, 在海洋探测、生物医疗、电子通讯等高端装备中发挥着重要作用。针对高端技术领域对压电功能器件智能化、集成化、轻量化的发展需求, 压电陶瓷的外形和结构越来越复杂。注浆、注射、模压、切割等传统的压电陶瓷制造工艺, 大多需借助模具或刀具完成, 很难甚至无法制造具有中空、悬垂等复杂结构的压电陶瓷, 制约了压电功能器件的进一步发展。增材制造技术基于逐层累加原理可实现任意复杂结构快速定制, 具有成型效率高、无需模具等优点, 可满足个性化、整体化、复杂化制造需求, 近年来受到国内外压电陶瓷领域研究人员的广泛关注。本文从粉体、浆料、块材三种原材料形态角度, 综述了当前增材制造压电陶瓷的主要工艺种类及发展现状, 综合对比了各种工艺成型特点; 介绍了增材制造压电陶瓷在不同领域的应用进展; 最后, 总结和展望了增材制造压电陶瓷所面临的挑战和未来可能的发展趋势。

中图分类号:

刘凯, 孙策, 史玉升, 胡佳明, 张庆庆, 孙云飞, 章嵩, 涂溶, 闫春泽, 陈张伟, 黄尚宇, 孙华君. 增材制造压电陶瓷的现状与展望[J]. 无机材料学报, 2022, 37(3): 278-288.

LIU Kai, SUN Ce, SHI Yusheng, HU Jiaming, ZHANG Qingqing, SUN Yunfei, ZHANG Song, TU Rong, YAN Chunze, CHEN Zhangwei, HUANG Shangyu, SUN Huajun. Current Status and Prospect of Additive Manufacturing Piezoceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 278-288.

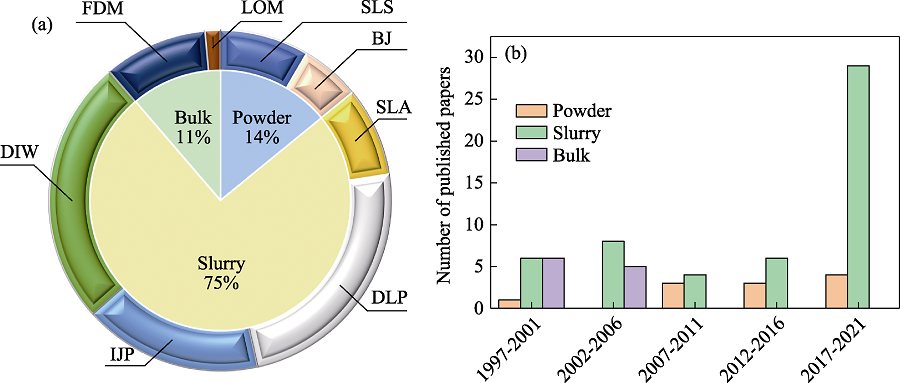

图1 增材制造压电陶瓷论文发表情况(SCI数据库)

Fig. 1 Papers published on additive manufacturing of piezoceramics (data from Web of Science) (a) Proportion of published literature of each process; (b) Number of papers published at each stage SLS: Selective laser sintering; BJ: Binder jetting; SLA: Stereolithography apparatus; IJP: Ink-jet printing; DLP: Digital light processing; DIW: Direct ink writing; FDM: Fused deposition modeling; LOM: Laminated object manufacturing

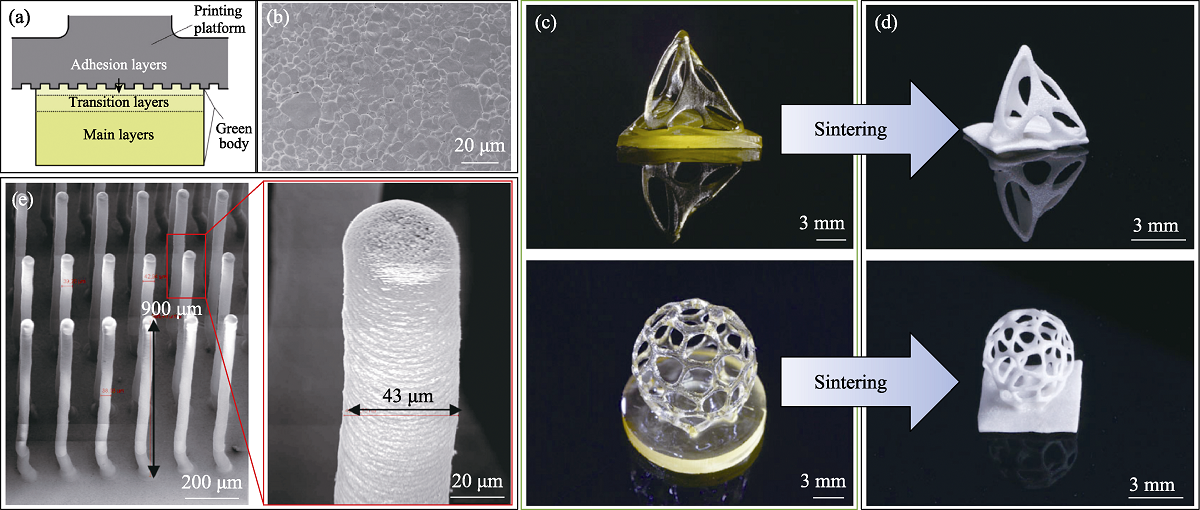

图3 分层曝光策略示意图(a)及烧结件微观形貌照片(b)[32], 数字光处理成型前驱体坯体照片(c)及烧结后的BTO样品照片(d)[35], 黏结剂喷射成型PZT陶瓷微阵列照片(e)[37]

Fig. 3 Schematic diagram of layered exposure strategy (a) and micro-topography photo of sintered part[32] (b), photo of precursor body fabricated by Digital Light Processing (c), photos of BTO sample after sintering[35] (d), photos of PZT ceramic microarrays fabricated by Binder Jetting[37] (e)

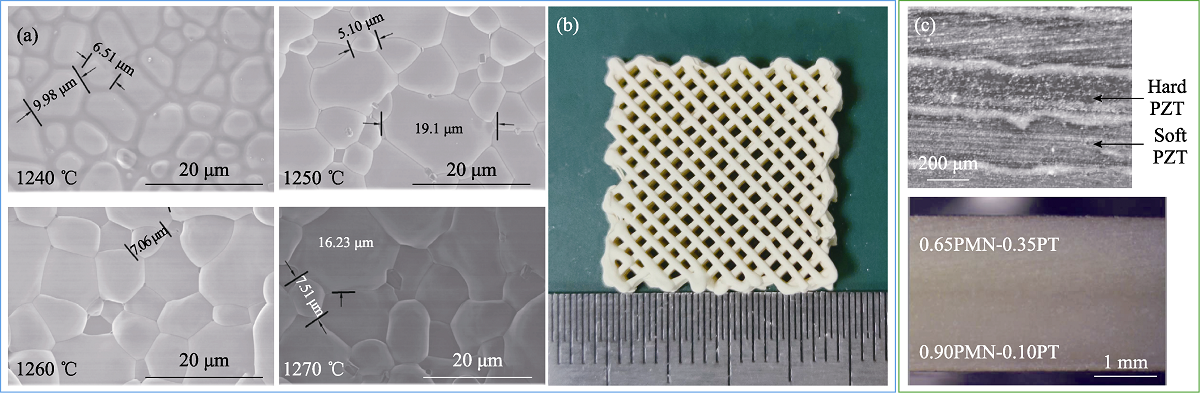

图4 不同烧结温度下PZT陶瓷微观形貌照片(a)及墨水直写成型PZT陶瓷烧结件照片(b)[41], 熔融沉积成型梯度压电陶瓷截面照片(c)[51,52]

Fig. 4 Micro-morphology photos of the PZT ceramics sintered at different temperatures (a) and photos of sintered PZT ceramics fabricated by Direct Ink Writing (b)[41], and cross-section photo of gradient piezoelectric ceramics fabricated by Fused Deposition Modeling (c)[51,52]

| Materials | Process | Density/(g·cm-3) | Relative density/% | d33/(pC·N-1) | Relative dielectric constant (εr) | Dielectric loss (tan δ) | Ref. |

|---|---|---|---|---|---|---|---|

| BTO | SLS | - | 97 | - | 1800 | - | [ |

| PZT | SLS | 4 | 50.6 | - | - | - | [ |

| PZT | LENS | - | 90 | - | 430 | 0.05 | [ |

| BTO | BJ | - | 93-94 | 183 | - | - | [ |

| BTO | SLA | 5.69 | 95 | 163 | 2762 | 0.016 | [ |

| BTO | DIW | 5.13 | 85.24 | 204.61 | 2551 | - | [ |

| PZT | DIW | (7.21±0.06) | 94.9 | 678 | (4132±575) | (3.4±1%) | [ |

| BTO | DIW | 5.42 | 90 | 200 | 2200 | - | [ |

| BTO | DIW | - | 89.97 | 350 | 2576 | - | [ |

| PLZT | DIW | - | 98 | 481 | 1986 | - | [ |

| BCZT | DIW | - | 93 | 100 | 1046 | 0.021 | [ |

| BTO | DIW | - | 96 | 159 | 1900 | - | [ |

| BTO | BJ | 2.21 | 37 | 113(Horizontal) 152.7(Vertical) | 581.6(Horizontal) 698(Vertical) | - | [ |

| KNN | SLA | 4.32 | 96 | - | 1800-1900 | 0.2-0.3 | [ |

| PMN-PT | DLP | 7.98 | 97.8 | 620 | - | - | [ |

| PZT | DLP | 7 | - | 345 | 1390 | 0.021 | [ |

| KNN | DLP | 4.09 | 92 | 170 | 2150 | 0.058 | [ |

| PZT-5H | DLP | 7.35 | 96 | 600 | 2875 | 0.029 | [ |

| BTO | DLP | 5.44 | 90 | 200 | 1965 | 0.017 | [ |

| PZT | IJP | - | (86±3) | - | 190 | 0.05 | [ |

| BTO | DIW | 3.93 | 65.3 | 200 | 4730 | 0.033 | [ |

| BTO | DIW | - | 98 | 195 | - | - | [ |

| BTO | DIW | - | 97.8 | - | 533 | - | [ |

| BTO | DIW | 5.66 | 94 | 420 | 4380 | 0.02 | [ |

| PZT | FDM | 7.7 | - | 664 | 3340 | 0.023 | [ |

表1 增材制造压电陶瓷性能对比

Table 1 Comparison of properties of piezoceramics formed by additive manufacturing

| Materials | Process | Density/(g·cm-3) | Relative density/% | d33/(pC·N-1) | Relative dielectric constant (εr) | Dielectric loss (tan δ) | Ref. |

|---|---|---|---|---|---|---|---|

| BTO | SLS | - | 97 | - | 1800 | - | [ |

| PZT | SLS | 4 | 50.6 | - | - | - | [ |

| PZT | LENS | - | 90 | - | 430 | 0.05 | [ |

| BTO | BJ | - | 93-94 | 183 | - | - | [ |

| BTO | SLA | 5.69 | 95 | 163 | 2762 | 0.016 | [ |

| BTO | DIW | 5.13 | 85.24 | 204.61 | 2551 | - | [ |

| PZT | DIW | (7.21±0.06) | 94.9 | 678 | (4132±575) | (3.4±1%) | [ |

| BTO | DIW | 5.42 | 90 | 200 | 2200 | - | [ |

| BTO | DIW | - | 89.97 | 350 | 2576 | - | [ |

| PLZT | DIW | - | 98 | 481 | 1986 | - | [ |

| BCZT | DIW | - | 93 | 100 | 1046 | 0.021 | [ |

| BTO | DIW | - | 96 | 159 | 1900 | - | [ |

| BTO | BJ | 2.21 | 37 | 113(Horizontal) 152.7(Vertical) | 581.6(Horizontal) 698(Vertical) | - | [ |

| KNN | SLA | 4.32 | 96 | - | 1800-1900 | 0.2-0.3 | [ |

| PMN-PT | DLP | 7.98 | 97.8 | 620 | - | - | [ |

| PZT | DLP | 7 | - | 345 | 1390 | 0.021 | [ |

| KNN | DLP | 4.09 | 92 | 170 | 2150 | 0.058 | [ |

| PZT-5H | DLP | 7.35 | 96 | 600 | 2875 | 0.029 | [ |

| BTO | DLP | 5.44 | 90 | 200 | 1965 | 0.017 | [ |

| PZT | IJP | - | (86±3) | - | 190 | 0.05 | [ |

| BTO | DIW | 3.93 | 65.3 | 200 | 4730 | 0.033 | [ |

| BTO | DIW | - | 98 | 195 | - | - | [ |

| BTO | DIW | - | 97.8 | - | 533 | - | [ |

| BTO | DIW | 5.66 | 94 | 420 | 4380 | 0.02 | [ |

| PZT | FDM | 7.7 | - | 664 | 3340 | 0.023 | [ |

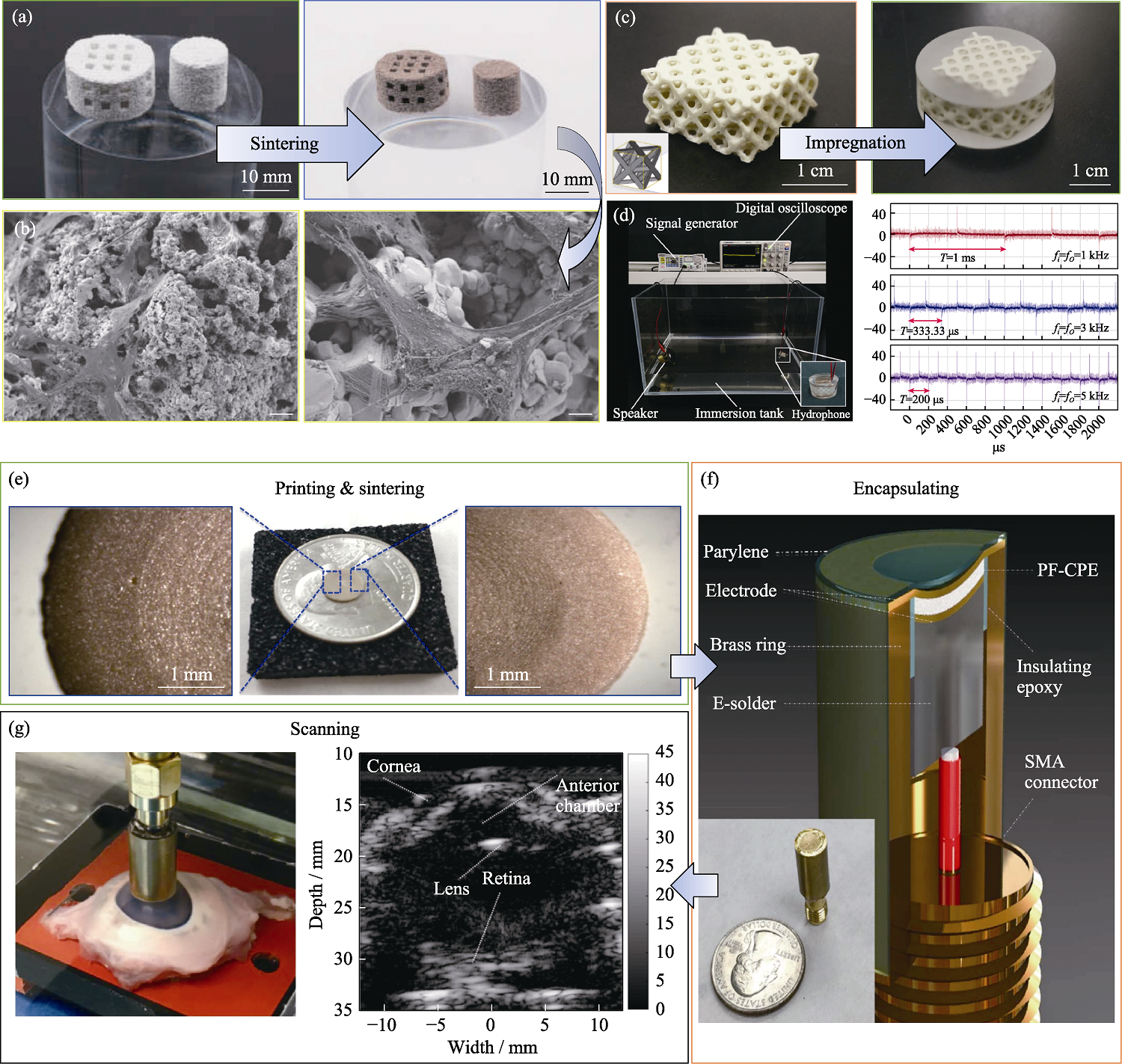

图5 黏结剂喷射成型BTO/HA压电陶瓷(a)及MC3T3-E1细胞24 h体外培养结果显微照片(b)[70], 数字光处理成型压电陶瓷照片及其压电复合材料(c), 水声测试装置及不同声激励频率下水听器的输出电压(d)[32], 数字光处理成型CPE样品照片(e)及其封装的超声扫描设备(f)和猪眼超声成像结果(g)[74]

Fig. 5 Photos of BTO/HA piezoelectric ceramics fabricated by Binder Jetting (a) and SEM images of the sample after 24 h MC3T3-E1 cells incubation (b)[70], piezoelectric ceramics and piezoelectric composite materials fabricated by Digital Light Processing (c), the underwater acoustic testing device and the output voltage of the hydrophone under different acoustic excitation frequencies (d) [32], the photo of CPE sample (e) and the packaged ultrasound scanning equipment (f), and pig eye ultrasound imaging results (g)[74]

| [1] |

HOOPER T E, ROSCOW J I, MATHIESON A, et al. High voltage coefficient piezoelectric materials and their applications. Journal of the European Ceramic Society, 2021, 41(13): 6115-6129.

DOI URL |

| [2] |

WASTON B H, BROVA Ml J, FANTON M, et al. Textured Mn- doped PIN-PMN-PT ceramics: harnessing intrinsic piezoelectricity for high-power transducer applications. Journal of the European Ceramic Society, 2021, 41(2): 1270-1279.

DOI URL |

| [3] |

JIA H R, YANG S, ZHU W T, et al. Improved piezoelectric properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 textured ferroelectric ceramics via Sm-doping method. Journal of Alloys and Compounds, 2021, 881(10): 160666.

DOI URL |

| [4] |

LÜ N, ZHONG C, WANG L K. Bending vibration characteristics of the piezoelectric composite double laminated vibrator. Ceramics International, 2021, 47(22): 31259-31267.

DOI URL |

| [5] |

CHEN A N, LI M, WU J M, et al. Enhancement mechanism of mechanical performance of highly porous mullite ceramics with bimodal pore structures prepared by selective laser sintering. Journal of Alloys and Compounds, 2018, 776: 486-494.

DOI URL |

| [6] |

DONG Y, JIANG H Y, CHEN A N, et al. Near-zero-shrinkage Al2O3 ceramic foams with coral-like and hollow-sphere structures via selective laser sintering and reaction bonding. Journal of European Ceramic Society, 2021, 41(16): 239-246.

DOI URL |

| [7] |

ZHANG X, WANG F, WU Z P, et al. Direct selective laser sintering of hexagonal barium titanate ceramics. Journal of American Ceramic Society, 2021, 104: 1271-1280.

DOI URL |

| [8] |

LIU K, SHI Y S, LI C H, et al. Indirect selective laser sintering of epoxy resin-Al2O3 ceramic powders combined with cold isostatic pressing. Ceramics International, 2014, 40(5): 7099-7106.

DOI URL |

| [9] | SHI Y S, LIU K, LI C H, et al. Additive manufacturing of zirconia parts via selective laser sintering combined with cold isostatic pressing. Journal of Mechanical Engineering, 2014, 50(21): 118-123. |

| [10] |

LIU K, SUN H J, SHI Y S, et al. Research on selective laser sintering of kaolin-epoxy resin ceramic powders combined with cold isostatic pressing and sintering. Ceramics International, 2016, 42(9): 10711-10718.

DOI URL |

| [11] |

LIU K, WU T, BOURELL D L, et al. Laser additive manufacturing and homogeneous densification of complicated shape SiC ceramic parts. Ceramics International, 2018, 44(17): 21067-21075.

DOI URL |

| [12] |

KOVSKY I, MOROZOV Y, KUZNETSOV M. Layering fabrication, structure, and electromagnetic properties of perovskite phases by hybrid process: self-propagated high-temperature synthesis and selective laser sintering. Phase Transitions, 2013, 86(11): 1085-1093.

DOI URL |

| [13] | KUZNETSOV M, SHISHKOVSKY I, MOROZOV Y, et al. Design of three-dimensional functional articles via layer-by-layer laser sintering of exothermic powder mixtures. Advanced Manufacturing Processes, 2008, 23(6): 571-578. |

| [14] | BERNARD S A, BALLA V K, BOSE S, et al. Direct laser processing of bulk lead zirconate titanate ceramics. Materials Science & Engineering B, 2010, 172(1): 85-88. |

| [15] |

DINI F, GHAFFARI S A, JAFAR J, et al. A review of binder jet process parameters; powder, binder, printing and sintering condition. Metal Powder Report, 2019, 75(2): 95-100.

DOI URL |

| [16] |

LV X Y, YE F, CHENG L F, et al. Binder jetting of ceramics: powders, binders, printing parameters, equipment, and post-treatment. Ceramics International, 2019, 45(10): 12609-12624.

DOI URL |

| [17] |

GAYTAN S M, CADENA M A, KARIM H, et al. Fabrication of barium titanate by binder jetting additive manufacturing technology. Ceramics International, 2015, 41(5): 6610-6619.

DOI URL |

| [18] |

SUFIIAROV V, KANTYUKOV A, POPOVICH A, et al. Structure and properties of barium titanate lead-free piezoceramic manufactured by binder jetting process. Materials, 2021, 14(16): 4419.

DOI URL |

| [19] |

SCHULT M, BUCKOW E, SEITZ H. Experimental studies on 3D printing of barium titanate ceramics for medical applications. Current Directions in Biomedical Engineering, 2016, 2(1): 95-99.

DOI URL |

| [20] |

ZHANG X, WU X, SHI J. Additive manufacturing of zirconia ceramics: a state-of-the-art review. Journal of Materials Research and Technology, 2020, 9(4): 9029-9048.

DOI URL |

| [21] |

LAYANI M, WANG X F, MAGDASSI S. Novel materials for 3D printing by photopolymerization. Advanced Materials, 2018, 30(41): 1706344.

DOI URL |

| [22] |

ZAKERI S, VIPPOLA M, LEVANEN E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Additive Manufacturing, 2020, 35: 101177.

DOI URL |

| [23] |

WANG W, SUN J X, GUO B B, et al. Fabrication of piezoelectric nano-ceramics via stereolithography of low viscous and non-aqueous suspensions. Journal of the European Ceramic Society, 2020, 40(3): 682-688.

DOI URL |

| [24] |

CHA J M, LEE J W, BAE B, et al. Fabrication and characterization of PZT suspensions for stereolithography based on 3D printing. Journal of the Korean Ceramic Society, 2019, 56(4): 360-364.

DOI URL |

| [25] | DUFAUD O, GALL H L, CORBEL S. Stereolithography of lead zirconate titanate ceramics for MEMS applications. Proceedings of SPIE-the International Society for Optical Engineering, 2003, 5116: 28-37. |

| [26] |

DUFAUD O, MARCHAL P, CORBEL S. Rheological properties of PZT suspensions for stereolithography. Journal of the European Ceramic Society, 2002, 22(13): 2081-2092.

DOI URL |

| [27] |

DUFAUD O, CORBEL S. Oxygen diffusion in ceramic suspensions for stereolithography. Chemical Engineering Journal, 2003, 92: 55-62.

DOI URL |

| [28] | SUN C, ZHANG X. The influences of the material properties on ceramic micro-stereolithography. Sensors & Actuators A Physical, 2002, 101(3): 364-370. |

| [29] |

SMIRNOV A, CHUGUNOV S, KHOLODKOVA A, et al. Progress and challenges of 3D-printing technologies in the manufacturing of piezoceramics. Ceramics International, 2021, 47(8): 10478-10511.

DOI URL |

| [30] |

LIN L F, WU H D, XU Y R, et al. Fabrication of dense aluminum nitride ceramics via digital light processing-based stereolithography. Materials Chemistry and Physics, 2020, 249: 122969.

DOI URL |

| [31] |

ZENG Y S, JIANG L M, SUN Y Z, et al. 3D-printing piezoelectric composite with honeycomb structure for ultrasonic devices. Micromachines, 2020, 11(8): 713.

DOI URL |

| [32] |

LIU K, ZHOU C Y, HU J M, et al. Fabrication of barium titanate ceramics via digital light processing 3D printing by using high refractive index monomer. Journal of the European Ceramic Society, 2021, 41(12): 5909-5917.

DOI URL |

| [33] | CHEN Z Y, JIANG Q G, SONG X, et al. Piezoelectric Array for Transducer Application Using Additive Manufacturing. 2017 IEEE International Ultrasonics Symposium (IUS), Washington, 2017. |

| [34] |

SONG X, CHEN Z Y, LEI L W, et al. Piezoelectric component fabrication using projection-based stereolithography of barium titanate ceramic suspensions. Rapid Prototyping Journal, 2017, 23(1): 44-53.

DOI URL |

| [35] |

ROSENTAL T, MIZRAHI S, KAMYSHNY A, et al. Particle-free compositions for printing dense 3D ceramic structures by digital light processing. Virtual and Physical Prototyping, 2021, 16(3): 255-266.

DOI URL |

| [36] |

NOGUERA R, LEJEUNE M, CHARTIER T. 3D fine scale ceramic components formed by ink-jet prototyping process. Journal of the European Ceramic Society, 2005, 25(12): 2055-2059.

DOI URL |

| [37] |

LEJEUNE M, CHARTIER T, DOSSOU-YOVO C, et al. Ink-jet printing of ceramic micro-pillar arrays. Journal European Ceramic Society, 2009, 29: 905-911.

DOI URL |

| [38] |

LEE D H, DERBY B. Preparation of PZT suspensions for direct ink jet printing. Journal of the European Ceramic Society, 2004, 24(6): 1069-1072.

DOI URL |

| [39] | DERBY B, LEE D H, WANG T, et al. Development of PZT suspensions for ceramic ink-jet printing. Materials Research Society Symposium Proceeding, 2003, 758: 113-118. |

| [40] |

WANG T M, DERBY B. Ink-jet printing and sintering of PZT. Journal of the American Ceramic Society, 2005, 88(8): 2053-2058.

DOI URL |

| [41] |

LIU K, ZHANG Q Q, ZHOU C Y, et al. 4D printing of lead zirconate titanate piezoelectric composites transducer based on direct ink writing. Frontiers in Materials, 2021, 8: 659441.

DOI URL |

| [42] |

WALTON R L, BROVA M J, WASTON B H, et al. Direct writing of textured ceramics using anisotropic nozzles. Journal of the European Ceramic Society, 2020, 41(3): 1945-1953.

DOI URL |

| [43] |

WALTON R L, FANTON M A, MEYER R J, et al. Dispersion and rheology for direct writing lead-based piezoelectric ceramic pastes with anisotropic template particles. Journal of the American Ceramic Society, 2020, 103(11): 6157-6168.

DOI URL |

| [44] |

RENTERIA A, DIAZ J A, HE B T, et al. Particle size influence on material properties of BaTiO3 ceramics fabricated using freeze- form extrusion 3D printing. Materials Research Express, 2019, 6(11): 115211.

DOI URL |

| [45] |

HALL S E, REGIS J E, RENTERIA A, et al. Paste extrusion 3D printing and characterization of lead zirconate titanate piezoelectric ceramics. Ceramics International, 2021, 47: 22042-22048.

DOI URL |

| [46] |

RENTERIA A, FONTES H, DIAZ J A, et al. Optimization of 3D printing parameters for BaTiO3 piezoelectric ceramics through design of experiments. Materials Research Express, 2019, 6(8): 085706.

DOI URL |

| [47] |

RENTERIA A, GARCIA L F, BALCORTA V H, et al. Influence of bimodal particle distribution on material properties of BaTiO3 fabricated by paste extrusion 3D printing. Ceramics International, 2021, 47(13): 18477-18486.

DOI URL |

| [48] |

LI Y Y, LI L T, LI B. Direct ink writing of 3-3 piezoelectric composite. Journal of Alloys and Compounds, 2015, 620: 125-128.

DOI URL |

| [49] |

NAN B, OLHERO S, PINHO R, et al. Direct ink writing of macro- porous lead-free piezoelectric Ba0.85Ca0.15Zr0.1Ti0.9O3. Journal of the American Ceramic Society, 2019, 102(6): 3191-3203.

DOI URL |

| [50] |

GADEA C, SPELTA T, SIMONSEN S B, et al. Hybrid inks for 3D printing of tall BaTiO3-based ceramics. Open Ceramics, 2021, 6: 100110.

DOI URL |

| [51] |

JAFARI M A, HAN W, MOHAMMADI F, et al. A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyping Journal, 2000, 6(3): 161-175.

DOI URL |

| [52] |

HALL A, ALLAHVERDI M, AKDOGAN E K, et al. Piezoelectric/ electrostrictive multimaterial PMN-PT monomorph actuators. Journal of the European Ceramic Society, 2005, 25(12): 2991-2997.

DOI URL |

| [53] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [54] | MIAO K, ZHOU H, GAO Y P, et al. Laser powder-bed-fusion of Si3N4 reinforced AlSi10Mg composites: processing, mechanical properties and strengthening mechanisms. Materials Science & Engineering A, 2021, 825: 141874. |

| [55] |

LU Z L, CAO J W, SONG Z Q, et al. Research progress of ceramic matrix composite parts based on additive manufacturing technology. Virtual and Physical Prototyping, 2019, 14(4): 333-348.

DOI URL |

| [56] |

CHAVEZ L A, WILBURN B R, LBAVE P, et al. Fabrication and characterization of 3D printing induced orthotropic functional ceramics. Smart Materials and Structures, 2019, 28(12): 125007.

DOI URL |

| [57] |

ZHANG L, WANG T, SUN J X, et al. A study of lead-free (K0.5N0.5)NbO3 piezoelectric ceramics processed by additive manufacturing. Journal of Micromechanics and Molecular Physics, 2020, 5(4): 2050011.

DOI URL |

| [58] | WOODWARD D I, PURSSELL C P, BILLSON D R, et al. Additively-manufactured piezoelectric devices. Physica Status Solidi (A) Applications and Materials, 2015, 212(10): 2017-2113. |

| [59] |

CHEN Y, BAO X L, WONG C M, et al. PZT ceramics fabricated based on stereolithography for an ultrasound transducer array application. Ceramics International, 2018, 44(18): 22725-22730.

DOI URL |

| [60] |

CHEN W C, WANG F F, YAN K, et al. Micro-stereolithography of KNN-based lead-free piezoceramics. Ceramics International, 2019, 45(4): 4880-4885.

DOI URL |

| [61] | ZHANG Y H, CHEN W C, WU D W. Geometric deformation prediction and compensation for micro-stereolithography of piezoceramic. Electronic Components and Materials, 2019, 38(4): 77-82. |

| [62] |

SOTOV A, KANTYUKOV A, POPOVICH A, et al. LCD-SLA 3D printing of BaTiO3 piezoelectric ceramics. Ceramics International, 2021, 47(21): 30358-30366.

DOI URL |

| [63] | KUSCER D, DRNOVSEK S, LEVASSORT F. Inkjet-printing- derived lead-zirconate-titanate-based thick films for printed electronics. Materials & Design, 2021, 198(8): 109324. |

| [64] |

KIM H, RENTERIA-MARQUEZ A, ISLAM M D, et al. Fabrication of bulk piezoelectric and dielectric BaTiO3 ceramics using paste extrusion 3D printing technique. Journal of the American Ceramic Society, 2019, 102(6): 3685-3694.

DOI URL |

| [65] |

LORENZ M, MARTIN A, WEBBER K G, et al. Electromechanical properties of robocasted barium titanate ceramics. Advanced Engineering Materials, 2020, 22(9): 2000325.

DOI URL |

| [66] |

RSOENTAL T, MAGDASSI S. A new approach to 3D printing dense ceramics by ceramic precursor binders. Advanced Engineering Materials, 2019, 21(10): 1900604.

DOI URL |

| [67] |

WEI X X, LIU Y H, ZHAO D J, et al. 3D printing of piezoelectric barium titanate with high density from milled powders. Journal of the European Ceramic Society, 2020, 40(15): 5423-5430.

DOI URL |

| [68] |

LOUS G M, CORNEJO I A, MCNULTY T F, et al. Fabrication of piezoelectric ceramic/polymer composite transducers using fused deposition of ceramics. Journal of the American Ceramic Society, 2000, 83(1): 124-128.

DOI URL |

| [69] | CHABOK H, ZHOU C, CHEN Y, et al. Ultrasound Transducer Array Fabrication Based on Additive Manufacturing of Piezocomposites. Proceedings of the ASME/ISCIE 2012 International Symposium on Flexible Automation, St. Louis, 2012: 433. |

| [70] |

POLLEY C, DISTLER T, DETSCH R, et al. 3D printing of piezoelectric barium titanate-hydroxyapatite scaffolds with interconnected porosity for bone tissue engineering. Materials, 2020, 13(7): 1773.

DOI URL |

| [71] |

XU H, XIE Y M, ZHOU S W, et al. Piezoelectric properties of triply periodic minimum surface structures. Composites Science and Technology, 2020, 200: 108417.

DOI URL |

| [72] |

SONG X, HE L, YANG W H, et al. Additive manufacturing of bi-continuous piezocomposites with triply periodic phase interfaces for combined flexibility and piezoelectricity. Journal of Manufacturing Science and Engineering, 2019, 141: 111004.

DOI URL |

| [73] |

CHENG J, CHEN Y, WU J W, et al. 3D printing of BaTiO3 piezoelectric ceramics for a focused ultrasonic array. Sensors, 2019, 19(19): 4078.

DOI URL |

| [74] |

CHEN Z Y, SONG X, LEI L W, et al. 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy, 2016, 27: 78-86.

DOI URL |

| [75] |

ANDEREGG D A, BRYANT H A, RUFFIN D C, et al. In-situ monitoring of polymer flow temperature and pressure in extrusion based additive manufacturing. Additive Manufacturing, 2019, 26: 76-83.

DOI URL |

| [76] |

CLIJSTERS S, CRAEGHS T, BULS S, et al. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. The International Journal of Advanced Manufacturing Technology, 2014, 75: 1089-1101.

DOI URL |

| [77] |

FANG T, JAFARI M A, DANFORTH S C, et al. Signature analysis and defect detection in layered manufacturing of ceramic sensors and actuators. Machine Vision and Applications, 2003, 15: 63-75.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [5] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [6] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [7] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [8] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [9] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [10] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [11] | 赵凯旋, 刘文鹏, 丁守军, 窦仁勤, 罗建乔, 高进云, 孙贵花, 任浩, 张庆礼. 熔融法制备Nd:YLF原料及其晶体生长和性能研究[J]. 无机材料学报, 2025, 40(5): 529-535. |

| [12] | 郭子玉, 朱云洲, 王力, 陈健, 李红, 黄政仁. Zn2+催化剂对酚醛树脂/乙二醇制备多孔碳微观孔结构的影响[J]. 无机材料学报, 2025, 40(5): 466-472. |

| [13] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [14] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [15] | 洪培萍, 梁龙, 吴炼, 马颖康, 庞浩. ZIF-67结构调控及其对盐酸金霉素的吸附性能研究[J]. 无机材料学报, 2025, 40(4): 388-396. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||