无机材料学报 ›› 2020, Vol. 35 ›› Issue (12): 1398-1406.DOI: 10.15541/jim20200140 CSTR: 32189.14.10.15541/jim20200140

所属专题: 生物材料论文精选(2020)

• 研究快报 • 上一篇

常宇辰1( ),林子扬1,谢昕1,吴章凡1,姚爱华1,叶松1,林健1,王德平1(

),林子扬1,谢昕1,吴章凡1,姚爱华1,叶松1,林健1,王德平1( ),崔旭2(

),崔旭2( )

)

收稿日期:2020-03-17

出版日期:2020-12-20

网络出版日期:2020-11-23

作者简介:常宇辰(1995–), 女, 硕士研究生. E-mail: changyuchencccc@163.com

CHANG Yuchen1( ),LIN Ziyang1,XIE Xin1,WU Zhangfan1,YAO Aihua1,YE Song1,LIN Jian1,WANG Deping1(

),LIN Ziyang1,XIE Xin1,WU Zhangfan1,YAO Aihua1,YE Song1,LIN Jian1,WANG Deping1( ),CUI Xu2(

),CUI Xu2( )

)

Received:2020-03-17

Published:2020-12-20

Online:2020-11-23

About author:CHANG Yuchen(1995–), female, Master candidate. E-mail: changyuchencccc@163.com

Supported by:摘要:

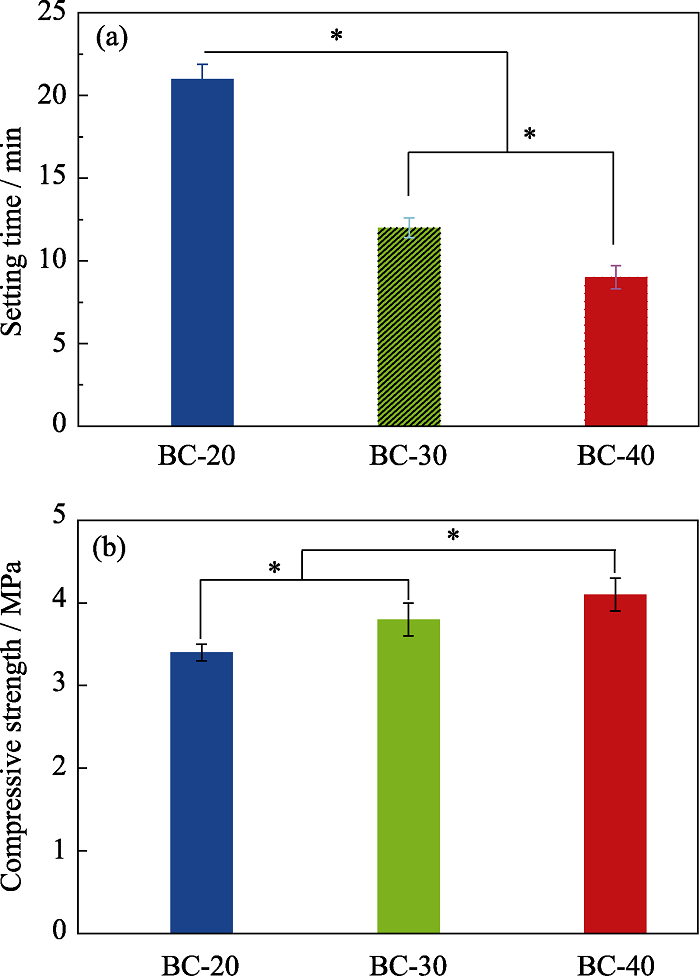

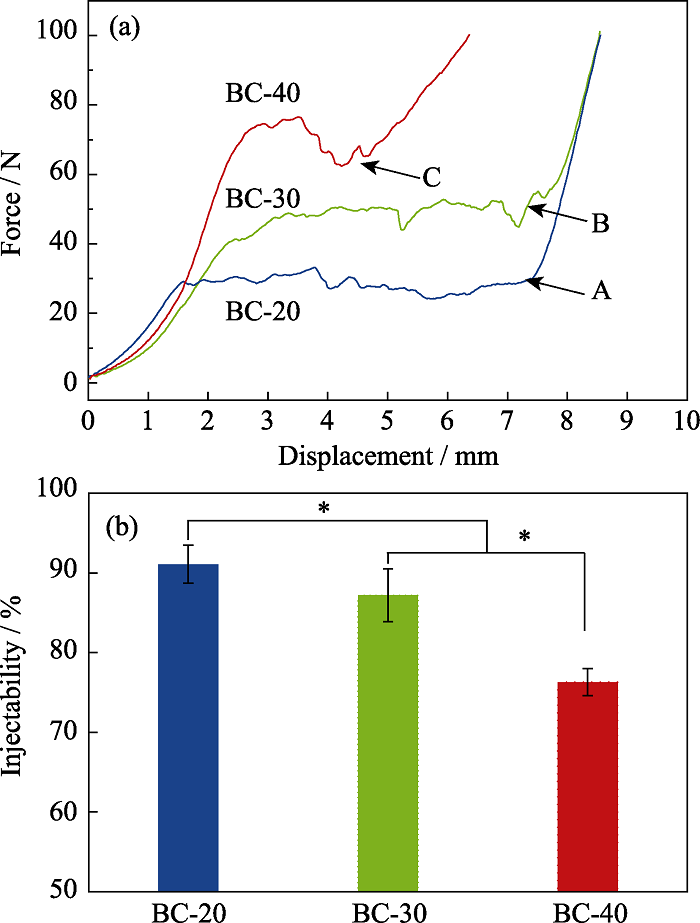

以溶胶-凝胶法制备的介孔硼硅酸盐生物活性玻璃微球(MBGS)作为固相, 海藻酸钠(SA)溶液作为液相,开发了一种可注射复合骨水泥。对MBGS中氧化硼/氧化硅的比例对其质构性能及骨水泥的可操作性、抗压强度和生物活性的影响进行表征。实验结果表明, 随着硼含量的增加, MBGS的比表面积从161.71 m2/g增大至214.28 m2/g, 平均孔径以及总孔容也随之增长, 加速了玻璃相中钙离子的释放, 使得玻璃与SA的快速交联, 改善了骨水泥可操作性能和力学性能, 凝固时间由21 min缩短至9 min, 抗压强度由3.4 MPa提升至4.1 MPa, 体外矿化性能也随之提高。综合各方面性能表现, BC-30骨水泥兼具良好的可操作性能、力学性能和体外矿化能力, 是最合适的骨水泥组分。总之, 提高MBGS的质构性能是增强复合骨水泥的可操作性、抗压强度和生物活性的有效方法。

中图分类号:

常宇辰, 林子扬, 谢昕, 吴章凡, 姚爱华, 叶松, 林健, 王德平, 崔旭. 基于介孔硼硅酸盐生物活性玻璃微球的可注射复合骨水泥[J]. 无机材料学报, 2020, 35(12): 1398-1406.

CHANG Yuchen, LIN Ziyang, XIE Xin, WU Zhangfan, YAO Aihua, YE Song, LIN Jian, WANG Deping, CUI Xu. An Injectable Composite Bone Cement Based on Mesoporous Borosilicate Bioactive Glass Spheres[J]. Journal of Inorganic Materials, 2020, 35(12): 1398-1406.

| Glass | B2O3 | SiO2 | CaO | P2O5 |

|---|---|---|---|---|

| MBGS-20 | 20 | 40 | 36 | 4 |

| MBGS-30 | 30 | 30 | 36 | 4 |

| MBGS-40 | 40 | 20 | 36 | 4 |

Table 1 The compositions of MBGS/mol%

| Glass | B2O3 | SiO2 | CaO | P2O5 |

|---|---|---|---|---|

| MBGS-20 | 20 | 40 | 36 | 4 |

| MBGS-30 | 30 | 30 | 36 | 4 |

| MBGS-40 | 40 | 20 | 36 | 4 |

| Sample | Specific surface area/(m2?g-1) | Average pore diameter/nm | Total pore volume/(mL?g-1) |

|---|---|---|---|

| MBGS-20 | 161.71 | 13.33 | 0.052 |

| MBGS-30 | 176.98 | 13.97 | 0.057 |

| MBGS-40 | 214.28 | 15.11 | 0.079 |

Table 2 Specific surface area, average pore diameter and total pore volume of the three groups of MBGS

| Sample | Specific surface area/(m2?g-1) | Average pore diameter/nm | Total pore volume/(mL?g-1) |

|---|---|---|---|

| MBGS-20 | 161.71 | 13.33 | 0.052 |

| MBGS-30 | 176.98 | 13.97 | 0.057 |

| MBGS-40 | 214.28 | 15.11 | 0.079 |

Fig. 6 (a) Setting time and (b) compressive strength of BC-20, BC-30, and BC-40, respectively * indicates significant difference between groups, p<0.05

Fig. 7 (a) Force-displacement curves and (b) injectabilities of mesoporous borosilicate bone cements for different B2O3 contents * indicates significant difference between groups, p<0.05

| [1] | VERRIER S, HUGHES L, ALVES A, et al. Evaluation of the in vitro cell-material interactions and in vivo osteo-integration of a spinal acrylic bone cement. European Spine Journal, 2012,21(6):S800-S809. |

| [2] | KRETLOW J D, KLOUDA L, MIKOS A G. Injectable matrices and scaffolds for drug delivery in tissue engineering. Adv. Drug Delivery Rev., 2007,59(4/5):263-273. |

| [3] |

LV Y, LI A L, ZHOU F, et al. A novel composite PMMA-based bone cement with reduced potential for thermal necrosis. ACS Appl. Mater. Interfaces, 2015,7(21):11280-11285.

DOI URL PMID |

| [4] | CABANAS M V, RODRIGUEZ-LORENZO L M, VALLET-REGI M. Setting behavior and in vitro bioactivity of hydroxyapatite/ calcium sulfate cements. Chem. Mater., 2002,14(8):3550-3555. |

| [5] |

JAMALI A, HILPERT A, DEBES J, et al. Hydroxyapatite/calcium carbonate (HA/CC) vs. plaster of Paris: a histomorphometric and radiographic study in a rabbit tibial defect model. Calcif Tissue Int., 2002,71(2):172-178.

DOI URL PMID |

| [6] |

BOHNER M, BAROUD G. Injectability of calcium phosphate pastes. Biomaterials, 2005,26(13):1553-1563.

DOI URL PMID |

| [7] |

HABIB M, BAROUD G, GITZHOFER F, et al. Mechanisms underlying the limited injectability of hydraulic calcium phosphate paste. Acta Biomaterialia, 2008,4(5):1465-1471.

DOI URL PMID |

| [8] |

HOPPE A, GULDAL N S, BOCCACCINI A R. A review of the biological response to ionic dissolution products from bioactive glasses and glass-ceramics. Biomaterials, 2011,32(11):2757-2774.

DOI URL PMID |

| [9] |

KANG M S, LEE N H, SINGH R K, et al. Nanocements produced from mesoporous bioactive glass nanoparticles. Biomaterials, 2018,162:183-199.

DOI URL PMID |

| [10] |

CHEN C, LI H, PAN J F, et al. Biodegradable composite scaffolds of bioactive glass/chitosan/carboxymethyl cellulose for hemostatic and bone regeneration. Biotechnol. Lett., 2015,37(2):457-465.

DOI URL PMID |

| [11] | LI H B, WANG D P, WU Y Y, et al. Effect of citric acid concentration on the properties of borate glass bone cement. Journal of Inorganic Materials, 2017,32(8):831-836. |

| [12] | CUI X, HUANG W H, ZHANG Y D, et al. Evaluation of an injectable bioactive borate glass cement to heal bone defects in a rabbit femoral condyle model. Materials Science & Engineering C-Materials for Biological Applications, 2017,73:585-595. |

| [13] | CUI X, ZHANG Y D, WANG H, et al. An injectable borate bioactive glass cement for bone repair: preparation, bioactivity and setting mechanism. Journal of Non-Crystalline Solids, 2016,432:150-157. |

| [14] | WU Y Y, YE S, YAO A H, et al. Effect of gas-foaming porogen- nahco3 and citric acid on the properties of injectable macroporous borate bioactive glass cement. Journal of Inorganic Materials, 2017,32(7):777-784. |

| [15] | MOSEMAN R F. Chemical disposition of boron in animals and humans. Environmental Health Perspectives, 1994,102(suppl 7):113-117. |

| [16] |

DELLA PEPA G, BRANDI M L. Microelements for bone boost: the last but not the least. Clinical Cases in Mineral and Bone Metabolism, 2016,13(3):181-185.

DOI URL PMID |

| [17] |

DURAND L A H, GONGORA A, LOPEZ J M P, et al. In vitro endothelial cell response to ionic dissolution products from boron- doped bioactive glass in the SiO2-CaO-P2O5-Na2O system. Journal of Materials Chemistry B, 2014,2(43):7620-7630.

DOI URL PMID |

| [18] | YAO A H, WANG D P, HUANG W H, et al. In vitro bioactive characteristics of borate-based glasses with controllable degradation behavior. Journal of The American Ceramic Society, 2007,90(1):303-306. |

| [19] | FU Q A, RAHAMAN M N, FU H L, et al. Silicate, borosilicate, and borate bioactive glass scaffolds with controllable degradation rate for bone tissue engineering applications. I. Preparation and in vitro degradation. Journal of Biomedical Materials Research Part A, 2010,95A(1):164-171. |

| [20] | FU Q A, RAHAMAN M N, BAL B S, et al. Silicate, borosilicate, and borate bioactive glass scaffolds with controllable degradation rate for bone tissue engineering applications. II. In vitro and in vivo biological evaluation. Journal of Biomedical Materials Research Part A, 2010,95A(1):172-179. |

| [21] |

BROWN R F, RAHAMAN M N, DWILEWICZ A B, et al. Effect of borate glass composition on its conversion to hydroxyapatite and on the proliferation of MC3T3-E1 cells. Journal of Biomedical Materials Research Part A, 2009,88(2):392-400.

DOI URL PMID |

| [22] |

TURCO G, MARSICH E, BELLOMO F, et al. Alginate/ hydroxyapatite biocomposite for bone ingrowth: a trabecular structure with high and isotropic connectivity. Biomacromolecules, 2009,10(6):1575-1583.

DOI URL PMID |

| [23] |

LEE K Y, MOONEY D J. Alginate: properties and biomedical applications. Progress in Polymer Science, 2012,37(1):106-126.

DOI URL PMID |

| [24] | SCHERDEL C, REICHENAUER G, WIENER M. Relationship between pore volumes and surface areas derived from the evaluation of N2-sorption data by DR-, BET- and t-plot. Microporous Mesoporous Mater., 2010,132(3):572-575. |

| [25] | LANDERS J, GOR G Y, NEIMARK A V. Density functional theory methods for characterization of porous materials. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2013,437:3-32. |

| [26] | XIE X, PANG L B, YAO A H, et al. Nanocement produced from borosilicate bioactive glass nanoparticles composited with alginate. Australian Journal of Chemistry, 2019,72(5):354-361. |

| [27] |

GBURECK U, BARRALET J E, SPATZ K, et al. Ionic modification of calcium phosphate cement viscosity. Part I: hypodermic injection and strength improvement of apatite cement. Biomaterials, 2004,25(11):2187-2195.

DOI URL PMID |

| [28] |

CHEN C C, WANG C W, HSUEH N S, et al. Improvement of in vitro physicochemical properties and osteogenic activity of calcium sulfate cement for bone repair by dicalcium silicate. Journal of Alloys and Compounds, 2014,585:25-31.

DOI URL |

| [29] |

O'NEILL R, MCCARTHY H O, MONTUFAR E B, et al. Critical review: Injectability of calcium phosphate pastes and cements. Acta Biomaterialia, 2017,50:1-19.

DOI URL PMID |

| [30] |

CATAURO M, BOLLINO F, RENELLA R A, et al. Sol-Gel synthesis of SiO2-CaO-P2O5 glasses: Influence of the heat treatment on their bioactivity and biocompatibility. Ceramics International, 2015,41(10):12578-12588.

DOI URL |

| [31] |

LIU X, RAHAMAN M N, DAY D E. Conversion of melt-derived microfibrous borate (13-93B3) and silicate (45S5) bioactive glass in a simulated body fluid. Journal of Materials Science-Materials in Medicine, 2013,24(3):583-595.

DOI URL |

| [32] |

CUI J, CAO X, SHI L, et al. Influence of the slight adjustment of oxides on the structural and physico-chemical properties of thin film transistor-liquid crystal display substrate glass. Royal Soc. Open Sci., 2020,7(1):191425-1-12.

DOI URL |

| [33] |

ZHANG Y, ZHANG Z F, YAN W, et al. Hexagonal mesoporous silica islands to enhance photovoltaic performance of planar junction perovskite solar cells. Journal of Materials Chemistry A, 2017,5(4):1415-1420.

DOI URL |

| [34] |

REN X, TUO Q, TIAN K, et al. Enhancement of osteogenesis using a novel porous hydroxyapatite scaffold in vivo and in vitro. Ceramics International, 2018,44(17):21656-21665.

DOI URL |

| [35] |

LI S, SONG C, YANG S, et al. Supercritical CO2 foamed composite scaffolds incorporating bioactive lipids promote vascularized bone regeneration via Hif-1α upregulation and enhanced type H vessel formation. Acta Biomaterialia, 2019,94:253-267.

DOI URL PMID |

| [36] |

ZHANG J T, LIU W Z, SCHNITZLER V, et al. Calcium phosphate cements for bone substitution: Chemistry, handling and mechanical properties. Acta Biomaterialia, 2014,10(3):1035-1049.

DOI URL |

| [37] | WANG Y, LIAO T, SHI M, et al. Facile synthesis and in vitro bioactivity of radial mesoporous bioactive glasses. Materials Letters, 2017,206:205-209. |

| [1] | 倪晓诗, 林子扬, 秦沐严, 叶松, 王德平. 硅烷化介孔硼硅酸盐生物玻璃微球对PMMA骨水泥生物活性和力学性能的影响[J]. 无机材料学报, 2023, 38(8): 971-977. |

| [2] | 吴锐, 张敏慧, 金成韵, 林健, 王德平. 光热核壳TiN@硼硅酸盐生物玻璃纳米颗粒的降解和矿化性能[J]. 无机材料学报, 2023, 38(6): 708-716. |

| [3] | 庞力斌, 王德平. 介孔硼硅酸盐玻璃微球药物载体的制备及其性能表征[J]. 无机材料学报, 2022, 37(7): 780-786. |

| [4] | 魏子钦, 夏翔, 李勤, 李国荣, 常江. 钛酸钡/硅酸钙复合生物活性压电陶瓷的制备及性能研究[J]. 无机材料学报, 2022, 37(6): 617-622. |

| [5] | 唐洁吟, 王刚, 刘聪, 邹学农, 陈晓峰. 微纳米生物活性玻璃诱导牙本质再矿化研究[J]. 无机材料学报, 2022, 37(4): 436-444. |

| [6] | 施吉翔, 翟东, 朱敏, 朱钰方. 生物活性玻璃-二氧化锰复合支架的制备与表征[J]. 无机材料学报, 2022, 37(4): 427-435. |

| [7] | 舒朝琴, 朱敏, 朱钰方. 熔盐法制备含钴氯磷灰石及其抗氧化性能和细胞相容性研究[J]. 无机材料学报, 2022, 37(11): 1225-1235. |

| [8] | 陈铖, 丁晶鑫, 王会, 王德平. 掺钕介孔硼硅酸盐生物活性玻璃陶瓷骨水泥的制备与性能表征[J]. 无机材料学报, 2022, 37(11): 1245-1258. |

| [9] | 朱子旻, 张敏慧, 张轩宇, 姚爱华, 林健, 王德平. 硼硅酸盐生物活性玻璃在直流电场下的体外矿化性能[J]. 无机材料学报, 2021, 36(9): 1006-1012. |

| [10] | 林子扬, 常宇辰, 吴章凡, 包荣, 林文庆, 王德平. 不同模拟体液对硼硅酸盐生物活性玻璃基骨水泥矿化性能的影响[J]. 无机材料学报, 2021, 36(7): 745-752. |

| [11] | 吴金结, 李艳, 魏仁初, 汪建新, 屈树新, 翁杰, 智伟. 微振动应力环境影响羟基磷灰石陶瓷生物活性及力学稳定性的体外评价[J]. 无机材料学报, 2019, 34(4): 417-424. |

| [12] | 张彪, 杨长安, 施佩. 等离子活化烧结制备石墨烯/羟基磷灰石复相生物陶瓷[J]. 无机材料学报, 2018, 33(12): 1355-1359. |

| [13] | 王明辉, 钟洪彬, 范宇驰, 陈 婷. SPS烧结制备生物活性镁黄长石陶瓷[J]. 无机材料学报, 2017, 32(8): 825-830. |

| [14] | 马鹏飞, 李日红, 张 龙. 溶胶-凝胶法制备高比表面积铝磷钙生物活性玻璃[J]. 无机材料学报, 2017, 32(1): 107-112. |

| [15] | 董志红, 聂志萍, 周长春. 自然唾液中介孔生物活性玻璃诱导牙釉质仿生再矿化研究[J]. 无机材料学报, 2016, 31(1): 88-94. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||