无机材料学报 ›› 2020, Vol. 35 ›› Issue (10): 1071-1087.DOI: 10.15541/jim20190622 CSTR: 32189.14.10.15541/jim20190622

所属专题: 能源材料论文精选(一):锂离子电池(2020)

• 综述 • 下一篇

王亚楠1,2,3( ),李华1,2,3,王正坤1,厉青峰1,练晨1,何鑫1

),李华1,2,3,王正坤1,厉青峰1,练晨1,何鑫1

收稿日期:2019-12-06

修回日期:2020-02-27

出版日期:2020-10-20

网络出版日期:2020-03-05

作者简介:王亚楠(1981-), 男, 博士, 讲师. E-mail:wyn@sdu.edu.cn.

基金资助:

WANG Yanan1,2,3( ),LI Hua1,2,3,WANG Zhengkun1,LI Qingfeng1,LIAN Chen1,HE Xin1

),LI Hua1,2,3,WANG Zhengkun1,LI Qingfeng1,LIAN Chen1,HE Xin1

Received:2019-12-06

Revised:2020-02-27

Published:2020-10-20

Online:2020-03-05

About author:WANG Yanan(1981–), male, PhD, lecturer. E-mail: wyn@sdu.edu.cn

Supported by:摘要:

在锂离子电池的充放电过程中, 由锂离子扩散过程产生的浓度梯度和活性材料锂化膨胀产生的变形会导致扩散应力。过大的扩散应力会造成活性颗粒的破裂、活性颗粒之间的分离、活性层的断裂以及活性层与集流体的分层等多种力学失效形式, 并最终导致电池出现容量衰减、阻抗上升和寿命缩短等一系列失效现象。因此扩散应力及其诱导的锂离子电池失效机理已经成为锂离子电池研究领域的热点之一, 具有重要的理论研究意义和实际应用价值。本文尝试从活性颗粒、活性电极、半电池、电池单元和电池单体等不同尺度, 综述近年来与扩散应力诱导的锂离子电池失效机理相关的研究进展, 介绍各尺度下扩散应力的产生机制和研究手段, 分析扩散应力对电池力学和电化学性能的影响规律, 梳理和总结扩散应力的影响因素, 最后对该领域今后的研究方向与发展趋势进行了展望。

中图分类号:

王亚楠, 李华, 王正坤, 厉青峰, 练晨, 何鑫. 扩散应力诱导的锂离子电池失效机理研究进展[J]. 无机材料学报, 2020, 35(10): 1071-1087.

WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress[J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087.

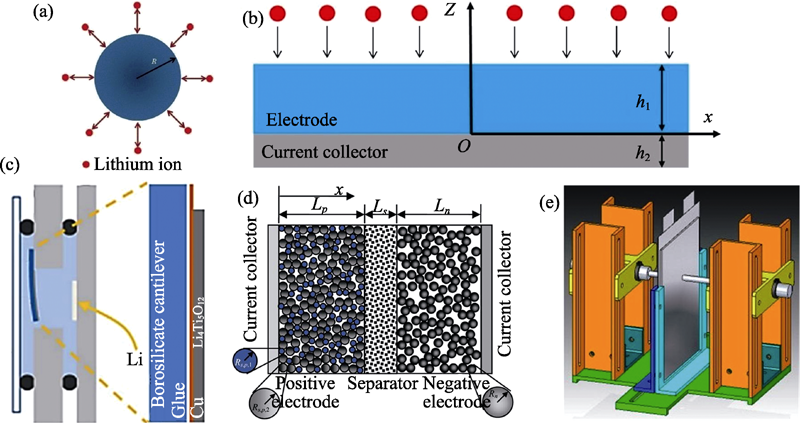

图1 锂离子电池在不同尺度上产生的扩散应力

Fig. 1 Different scales of diffusion-induced stress in lithium-ion batteries (a) Active particle[4]; (b) Active electrode[5]; (c) Half cell[6]; (d) Cell unit[7]; (e) Cell[8]

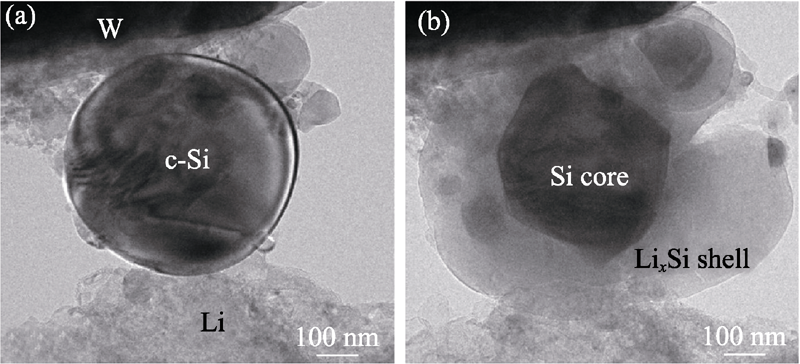

图4 球形硅颗粒的锂化过程[14]

Fig. 4 Lithiation process of the spherical silicon particle[14] (a) Initial state; (b) Outer layer expansion and surface cracking of the particle during lithiation

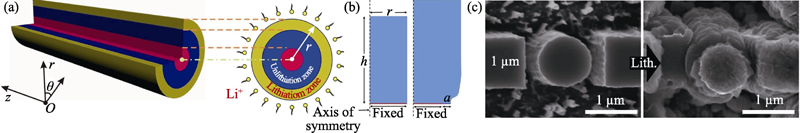

图5 (a)纳米线颗粒及其锂化过程[23]; (b)具有初始分层缺陷的纳米线颗粒的初始状态和锂化膨胀状态[25]; (c)受到机械夹持的纳米线颗粒的初始状态和锂化膨胀状态[26]

Fig. 5 (a) Nanowire particle and its lithiation process[23]; (b) Initial state and lithiation expansion state of nanowire particle with initial delamination defect[25]; (c) Initial state and lithiation expansion state of nanowire particle with mechanical clamping[26]

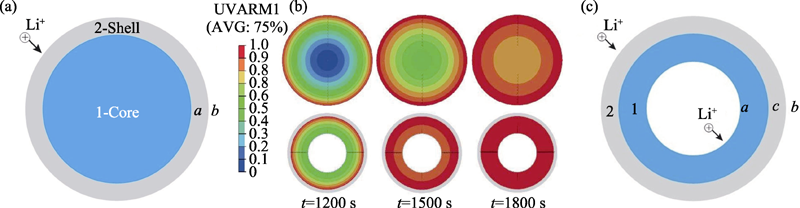

图6 (a)具有碳包覆外壳的实心球颗粒[31]; (b)碳包覆的实心球颗粒与空心球颗粒在锂化过程中的锂浓度分布[32]; (c)具有碳包覆外壳的的纳米管颗粒[33]

Fig. 6 (a) Solid sphere particle with carbon-coated shell[31]; (b) Lithium concentration distribution of carbon-coated solid sphere particle and hollow sphere particle during lithiation[32]; (c) Nanotube particle with carbon-coated shell[33]

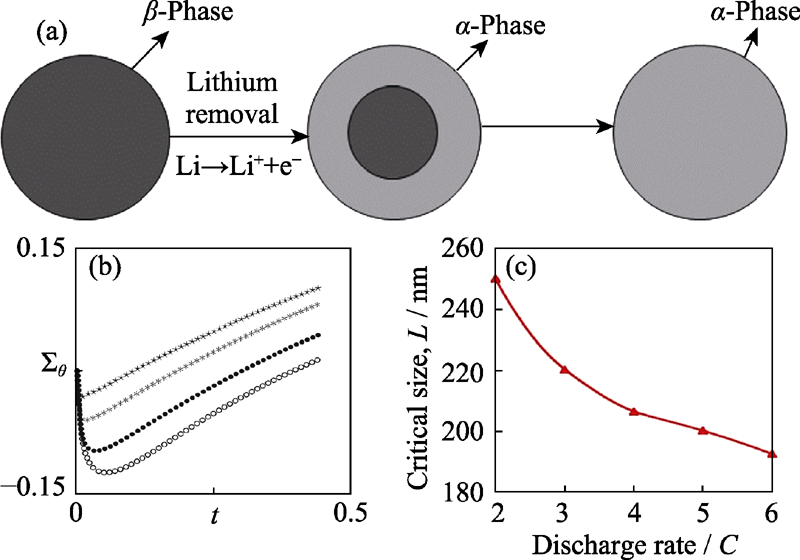

图7 (a)双相脱嵌机制的球形颗粒的脱锂过程[35]; (b)双相脱嵌机制的球形颗粒锂化过程中的表面切向应力[36], 其中空心圆, 实心圆, 星号和星形分别代表颗粒的初始无量纲尺寸为0.01, 0.1, 1.0和10.0; (c)临界尺寸L与放电倍率的关系[42]

Fig. 7 (a) Delithiation process of spherical particle with two-phase deintercalation mechanism[35]; (b) Surface tangential stress of spherical particle during lithiation process with two-phase deintercalation mechanism[36], the hollow circle, solid circle, asterisk and star represent the initial dimensionless sizes of the particles as 0.01, 0.1, 1.0 and 10.0, respectively; (c) Relationship between critical dimension and discharge rate[42]

| Factor | Specific interpretation | Ref. |

|---|---|---|

| Particle shape | Solid sphere, hollow sphere, ellipsoid, cube, etc. | [ |

| Particle size | Radius/diameter, shell thickness, aspect ratio, edge length, etc. | [ |

| Material properties | Lithium expansion coefficient, elastic modulus, plastic deformation, strain rate, partial molar volume, medium expansion rate, lithium diffusion coefficient, etc. | [ [28-30] |

| Nanowires and nanotubes | Slender linear or tubular structures with small diameters | [ |

| Coating shell | Carbon coating, alumina coating, etc. | [ |

| Phase separation | Single- and two-phase deintercalation mechanism | [ |

| Dislocation effect | Microscopic defects in crystalline materials caused by local irregular arrangement of atoms | [ |

| Charging and discharging conditions | Ratio and strategy of charging and discharging, etc. | [ |

表1 单颗粒模型中影响扩散应力的因素

Table 1 Factors affecting diffusion-induced stress in a single particle model

| Factor | Specific interpretation | Ref. |

|---|---|---|

| Particle shape | Solid sphere, hollow sphere, ellipsoid, cube, etc. | [ |

| Particle size | Radius/diameter, shell thickness, aspect ratio, edge length, etc. | [ |

| Material properties | Lithium expansion coefficient, elastic modulus, plastic deformation, strain rate, partial molar volume, medium expansion rate, lithium diffusion coefficient, etc. | [ [28-30] |

| Nanowires and nanotubes | Slender linear or tubular structures with small diameters | [ |

| Coating shell | Carbon coating, alumina coating, etc. | [ |

| Phase separation | Single- and two-phase deintercalation mechanism | [ |

| Dislocation effect | Microscopic defects in crystalline materials caused by local irregular arrangement of atoms | [ |

| Charging and discharging conditions | Ratio and strategy of charging and discharging, etc. | [ |

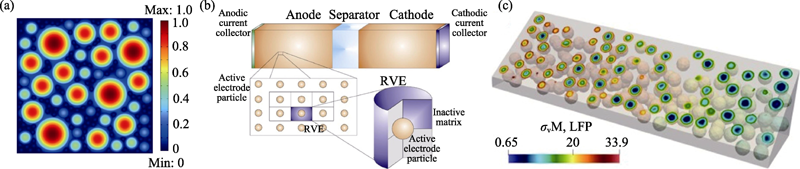

图8 (a)放电深度为60%时多颗粒模型中的锂浓度分布[46,47]; (b)考虑均匀基质的多颗粒模型及单颗粒-基质的代表性单元[48]; (c)考虑均匀基质的多颗粒-基质的电极结构及1C放电时活性颗粒的扩散应力分布[50]

Fig. 8 (a) Lithium concentration distribution in the multi-particle model at 60% Depth of Discharge (DOD)[46,47]; (b) Multi-particle model considering homogeneous matrix and single-particle-matrix representative unit[48]; (c) Multi-particle-matrix electrode structure considering homogeneous matrix and diffusion-induced stress distribution of active particles during 1C discharge[50]

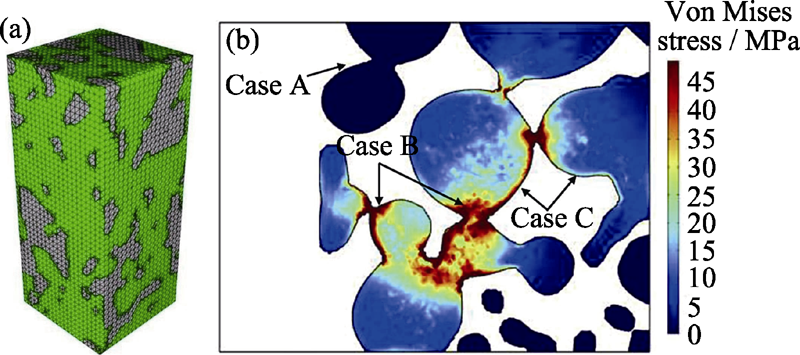

图9 (a)通过X射线扫描建立的多颗粒模型, 其中黑色部分为活性颗粒和粘结剂, 绿色部分为电解液[53]; (b)1C倍率完全充满时多颗粒模型的扩散应力分布[54]

Fig. 9 (a) Multi-particle model established by X-ray scanning, (Black: The active particles and the binder; Blue: The electrolyte)[53]; (b) Diffusion-induced stress distribution of multi-particle model when fully charged at 1C rate[54]

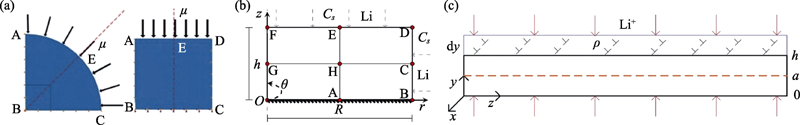

图10 模型示意图

Fig. 10 Schematic diagrams of models (a) Cylindrical and plate electrode units[55]; (b) coin-shaped thin film silicon electrode[56]; (c) thin film silicon electrode considering dislocations[58]

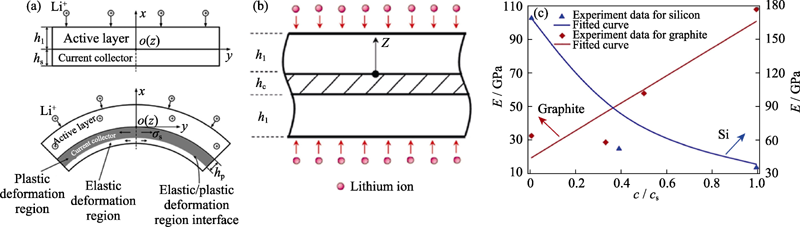

图11 (a)考虑集流体塑性变形的双层电极的初始状态和锂化变形[62]; (b)石墨活性层和铜集流体组成的对称电极模型[63]; (c)石墨和硅的弹性模量随SOC的变化[69]

Fig. 11 (a) Initial state and lithiation deformation of the double-layer electrode considering plasticity of the current collector[62]; (b) Symmetrical electrode model composed of graphite active layers and copper current collector[63]; (c) Relationship between the elastic modulus of graphite and silicon and SOC[69]

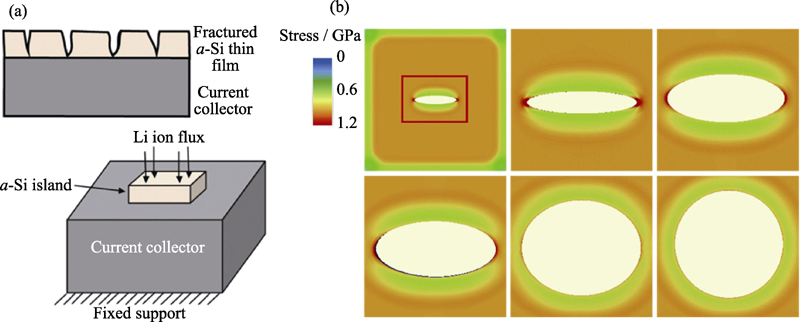

图12 (a)硅双层电极发生开裂形成硅岛(上), 以及受到集流体约束的硅岛双层电极模型(下)[73]; (b)具有初始缺陷的硅岛双层电极在锂化后的扩散应力分布, 初始缺陷的长、短轴的长度比分别为0.2, 0.4, 0.6, 0.8和1[75]

Fig. 12 (a) Double-layer silicon electrode cracks to form silicon islands (above), and double-layer electrode model of a silicon island constrained by a current collector (below)[73]; (b) Diffusion-induced stress distribution of the double-layer electrodes of silicon islands with initial defects after lithiation, the length ratios of the long and short axes of the initial defects are 0.2, 0.4, 0.6, 0.8 and 1, respectively[75]

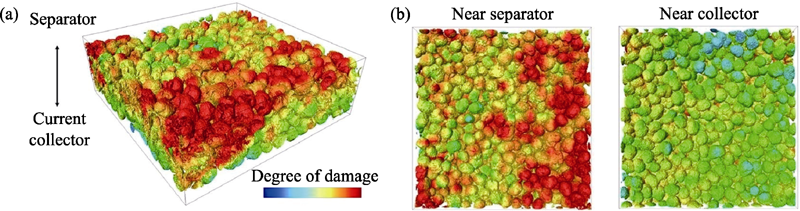

图13 NMC311正极中颗粒的失效情况[77]

Fig. 13 Failure of particles in the NMC311 positive electrode[77] (a) Three-dimensional view of the electrode; (b) Views of the location near the separator and the current collector

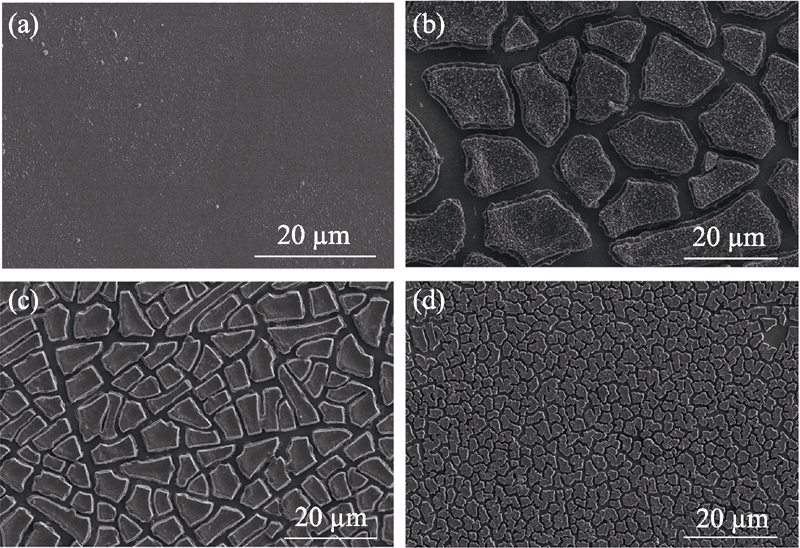

图15 硅电极的裂纹扩展现象[80]

Fig. 15 Crack propagation of a silicon electrode[80] (a) Fresh electrode; (b) Electrode of 1000 nm thickness after 5 cycles; (c) Electrode of 500 nm thickness after 5 cycles; (d) Electrode of 200 nm thickness after 10 cycles

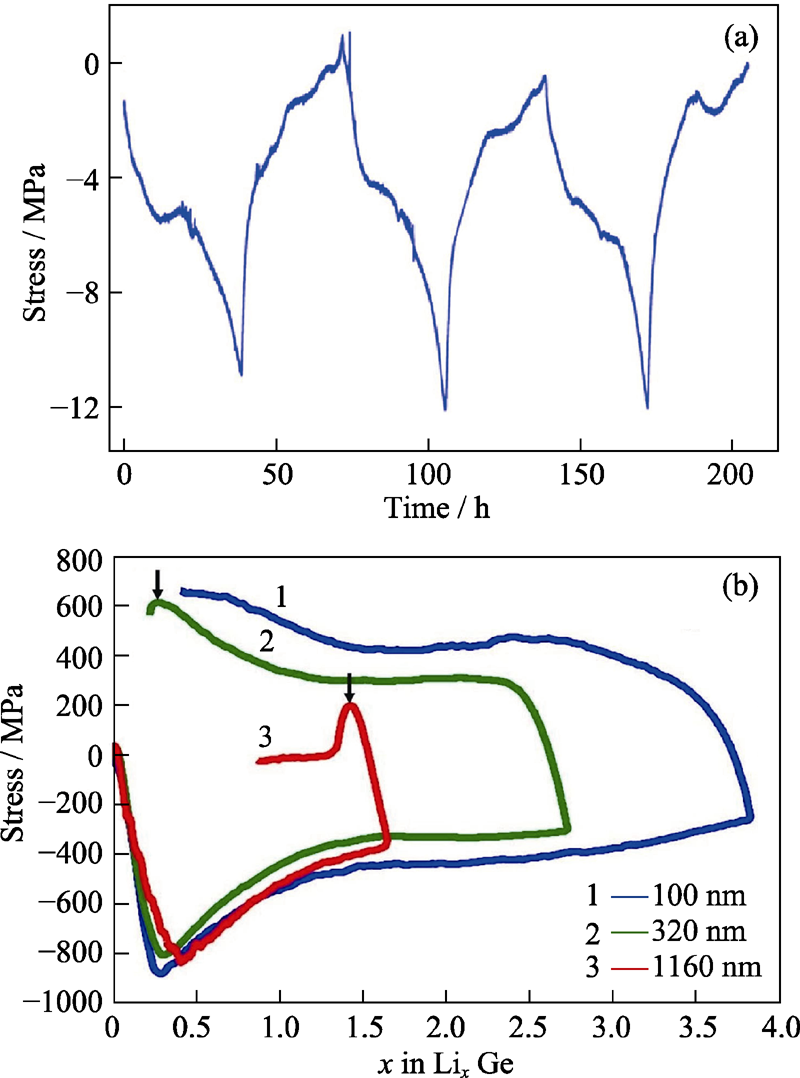

图16 (a)前三个循环期间石墨负极中的扩散应力[85]; (b)锂化和脱锂期间锗电极中扩散应力的演变, 其中箭头代表电极发生断裂的时刻[86]

Fig. 16 (a) Diffusion-induced stress in the graphite anode during the first 3 cycles[85]; (b) Evolution of diffusion-induced stress in a Ge electrode during lithiation and delithiation, the arrows represent the moment when the electrode fractures[86]

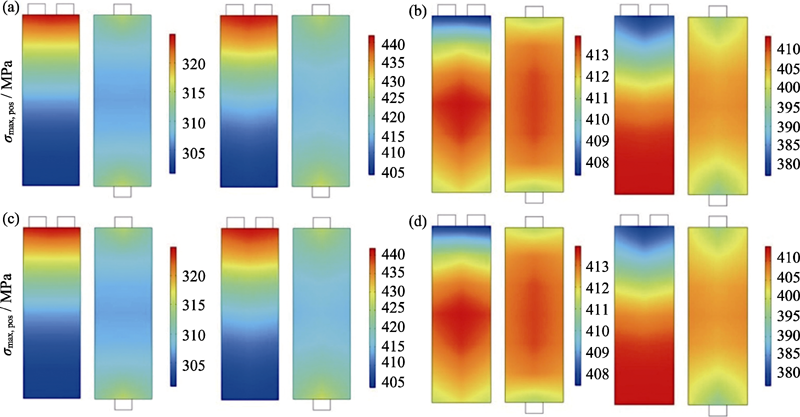

图17 放电期间电池单元中的扩散应力分布, 放电深度分别为(a) 8%, (b) 54%, (c) 67%和(d) 100% [90]

Fig. 17 Distribution of diffusion-induced stress in the cell unit during discharge, DOD are (a) 8%, (b) 54%, (c) 67% and (d) 100%, respectively[90]

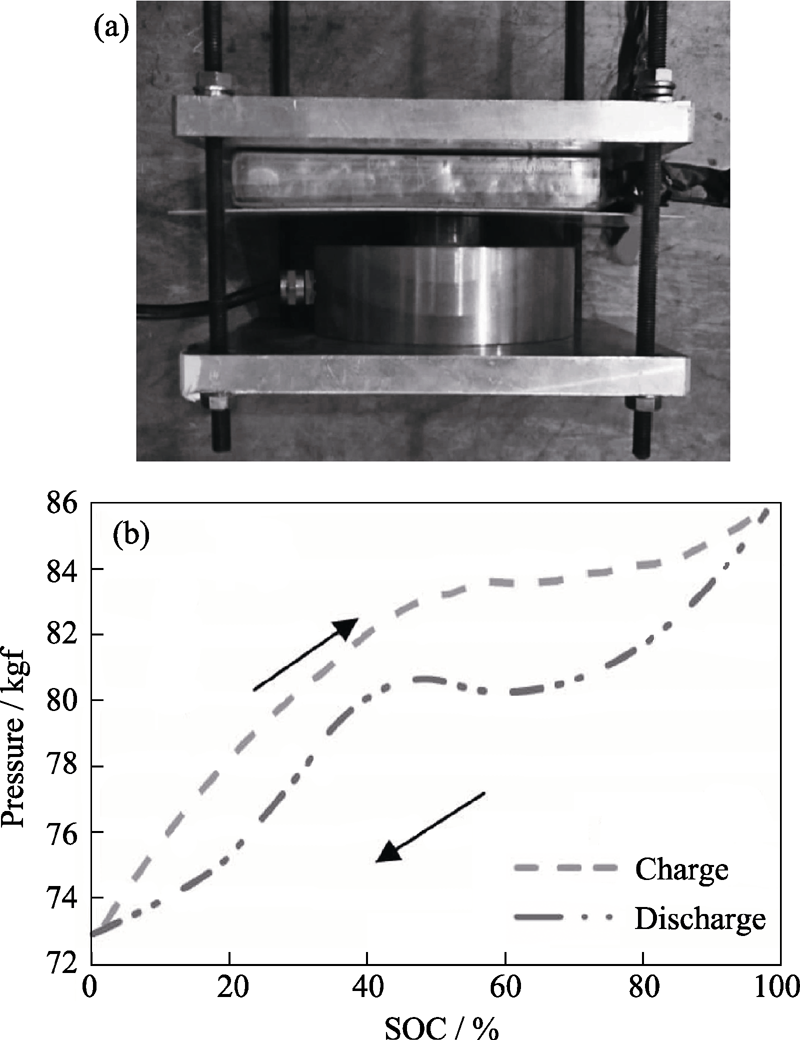

图18 方形电池在充放电过程中的表面压力的(a)实验原理图和(b)随SOC的变化曲线[93]

Fig. 18 Surface pressure during charge and discharge of a prismatic cell [93] (a) Experimental schematic diagram; (b) Change of surface pressure with SOC

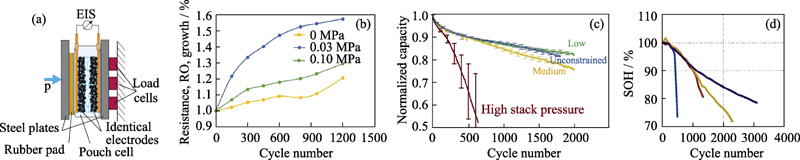

图19 (a)外部约束和EIS测试的实验原理[94]; (b)不同外部压力下阻抗随循环次数的变化[95]; (c)外部约束对电池循环寿命的影响, 蓝色、绿色、黄色和红色线条分别代表0, 0.05, 0.5和5 MPa的外部约束[96]; (d)健康状态(State of Health, SOH)随循环次数的变化, 蓝色、红色、黄色和紫色线条分别代表无外部约束, 恒定厚度约束, 弹性元件约束和恒力弹簧约束[97]

Fig. 19 (a) Experimental schematic diagram of the external constraint and EIS test[94]; (b) Impedance as a function of cycle times at different external pressures[95]; (c) Effect of external constraints on cycle lifetime of the cell, of which blue, green, yellow and red lines representing external constraints of 0, 0.05, 0.5 and 5 MPa, respectively[96]; (d) SOH as a function of cycle times, of which blue, red, yellow, and purple lines representing no external constraint, constant thickness constraint, elastic element constraint, and constant force spring constraint, respectively[97]

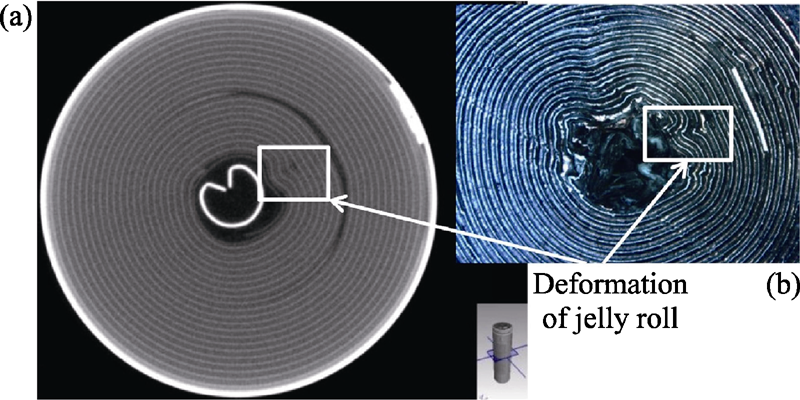

图20 充放电循环后卷芯的变形情况(a)X射线扫描结果和 (b)激光显微镜结果[101]

Fig. 20 Deformation of jelly roll after charge and discharge cycles (a) X-ray scan result and (b) Laser microscope result[101]

| Failure phenomenon | Corresponding mechanism | Ref. |

|---|---|---|

| Capacity decay/lifetime reduction | Side reaction of active particles and electrolyte results in regeneration of SEI film | [99] |

| Excessive stress causes fracture of electrode | [100] | |

| Uneven distribution of pressure inside cell brings about lithium precipitation on electrode | [100, 103] | |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] | |

| Impedance rise | Porosity decreasing and tortuosity increasing of positive and negative electrodes and separator | [94-95] |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] |

表2 与扩散应力有关的电池单体的失效现象及机理

Table 2 Failure phenomenon of cell and their corresponding mechanism

| Failure phenomenon | Corresponding mechanism | Ref. |

|---|---|---|

| Capacity decay/lifetime reduction | Side reaction of active particles and electrolyte results in regeneration of SEI film | [99] |

| Excessive stress causes fracture of electrode | [100] | |

| Uneven distribution of pressure inside cell brings about lithium precipitation on electrode | [100, 103] | |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] | |

| Impedance rise | Porosity decreasing and tortuosity increasing of positive and negative electrodes and separator | [94-95] |

| Deformation of jelly roll leads to delamination between active layer and current collector | [101] |

| [1] | WANG Q Y, WANG S, ZHANG J N , et al. Overview of the failure analysis of lithium ion batteries. Energy Storage Sci. Technol., 2017,6(5):1008. |

| [2] | BELOVA I V, MURCH G E . Thermal and diffusion-induced stresses in crystalline solids. J. Appl. Phys., 1995,77(1):127-134. |

| [3] | ZHAO Y, STEIN P, BAI Y , et al. A review on modeling of electro- chemo-mechanics in lithium-ion batteries. J. Power Sources, 2019,413:259-283. |

| [4] | LI H L, SONG Y C, LU B , et al. Effects of stress dependent electrochemical reaction on voltage hysteresis of lithium ion batteries. Appl. Math. Mech-Engl., 2018,39(10):1453-1464. |

| [5] | LU Y J, CHE Q, SONG X , et al. Stress self-relaxation arising from diffusion-induced creep in bilayer lithium-ion battery electrode. Scr. Mater., 2018,150:164-167. |

| [6] | CHOI Z S, KRAMER D, MÖNIG R, et al. Correlation of stress and structural evolution in Li4Ti5O12-based electrodes for lithium ion batteries. J. Power Sources, 2013,240:245-251. |

| [7] | DAI Y L, CAI L, WHITE R E . Simulation and analysis of stress in a Li-ion battery with a blended LiMn2O4 and LiNi0.8Co0.15Al0.05O2 cathode. J. Power Sources, 2014,247:365-376. |

| [8] | FU R J, XIAO M, CHOE S Y . Modeling, validation and analysis of mechanical stress generation and dimension changes of a pouch type high power Li-ion battery. J. Power Sources, 2013,224:211-224. |

| [9] | MEI W X, DUAN Q L, QIN P , et al. A three-dimensional electrochemical-mechanical model at the particle level for lithium-ion battery. J. Electrochem. Soc., 2019,166(14):A3319-A3331. |

| [10] | ZHANG X Y, CHEN H S, FANG D N . Diffusion-induced stress of electrode particles with spherically isotropic elastic properties in lithium-ion batteries. J. Solid State Electrochem., 2016,20(10):2835-2845. |

| [11] | CHEN B B, ZHOU J Q, PANG X M , et al. Fracture damage of nanowire lithium-ion battery electrode affected by diffusion- induced stress and bending during lithiation. RSC Adv. , 2014,4(40):21072-21078. |

| [12] | CHRISTENSEN J, NEWMAN J . Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem., 2006,10(5):293-319. |

| [13] | SUN H H, MANTHIRAM A . Impact of microcrack generation and surface degradation on a nickel-rich layered Li[Ni0.9Co0.05Mn0.05]O2 cathode for lithium-ion batteries. Chem. Mater., 2017,29(19):8486-8493. |

| [14] |

LIU X H, ZHONG L, HUANG S , et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano , 2012,6(2):1522-1531.

DOI URL PMID |

| [15] |

HU Y H, ZHAO X H, SUO Z G . Averting cracks caused by insertion reaction in lithium-ion batteries. J. Mater. Res., 2011,25(6):1007-1010.

DOI URL |

| [16] |

ZHU M, PARK J, SASTRY A M . Fracture analysis of the cathode in Li-ion batteries: a simulation study. J. Electrochem. Soc., 2012,159(4):A492-A498.

DOI URL |

| [17] |

PURKAYASTHA R, MCMEEKING R . Stress due to the intercalation of lithium in cubic-shaped particles: a parameter study. Meccanica, 2016,51(12):3081-3096.

DOI URL |

| [18] |

DELUCA C M, MAUTE K, DUNN M L . Effects of electrode particle morphology on stress generation in silicon during lithium insertion. J. Power Sources, 2011,196(22):9672-9681.

DOI URL |

| [19] | CHEN B B, ZHOU J Q, LIU Z . Effects of thermal diffusion in hollow lithium ion battery with spherical particle electrode. J. Nanjing Tech. U.: NAT. SCI. ED., 2016,38(3):1-7. |

| [20] |

LI J, FANG Q H, WU H , et al. Investigation into diffusion induced plastic deformation behavior in hollow lithium ion battery electrode revealed by analytical model and atomistic simulation. Electrochim. Acta , 2015,178:597-607.

DOI URL |

| [21] |

ZHAO K J, PHARR M, CAI S Q , et al. Large plastic deformation in high-capacity lithium-ion batteries caused by charge and discharge. J. Am. Ceram. Soc., 2011,94:s226-s235.

DOI URL |

| [22] |

LI Y, ZHANG K, ZHENG B , et al. Effect of local velocity on diffusion-induced stress in large-deformation electrodes of lithium-ion batteries. J. Power Sources, 2016,319:168-177.

DOI URL |

| [23] |

MA Z S, GAO X, WANG Y , et al. Effects of size and concentration on diffusion-induced stress in lithium-ion batteries. J. Appl. Phys., 2016,120(2):025302

DOI URL |

| [24] | RYU I, CHOI J W, CUI Y , et al. Size-dependent fracture of Si nanowire battery anodes. J. Mech. Phys. Solids , 2011,59(9):1717-1730. |

| [25] | HARDIN G R, ZHANG Y, FINCHER C D , et al. Interfacial fracture of nanowire electrodes of lithium-ion batteries. JOM, 2017,69(9):1-5. |

| [26] |

LEE S W, LEE H W, RYU I , et al. Kinetics and fracture resistance of lithiated silicon nanostructure pairs controlled by their mechanical interaction. Nat. Commun. , 2015,6:7533.

DOI URL PMID |

| [27] | CHANG S, MOON J, CHO K , et al. Multiscale analysis of prelithiated silicon nanowire for Li-ion battery. Comput. Mater. Sci., 2015,98:99-104. |

| [28] | PENG Y Z, ZHANG K, ZHENG B L . Stress analysis of a cylindrical composition-gradient electrode of lithium-ion battery in generalized plane strain condition. Acta Phys. Sin., 2016,65(10):1-8. |

| [29] | PENG Y Z, LI Y, ZHENG B L , et al. Influence of local velocity on diffusion-induced stress and axial reaction force in a hollow cylindrical electrode of lithium-ion batteries with considering expasion rate of medium. Acta Phys. Sin., 2018,67(7):27-35. |

| [30] | DESHPANDE R, QI Y, CHENG Y T , et al. Effects of concentration-dependent elastic modulus on diffusion-induced stresses for battery applications. J. Electrochem. Soc., 2010,157(8):A967-A971. |

| [31] | HAO F, FANG D . Diffusion-induced stresses of spherical core- shell electrodes in lithium-ion batteries: the effects of the shell and surface/interface stress. J. Electrochem. Soc., 2013,160(4):A595-A600. |

| [32] | SUN F N, FENG L, BU J H , et al. Effect of stress on electrochemical performance of hollow carbon-coated silicon snode in lithium ion batteries. Acta Phys. Sin. , 2019,68(12):42-51. |

| [33] | HAO F, FANG D . Tailoring diffusion-induced stresses of core-shell nanotube electrodes in lithium-ion batteries. J. Appl. Phys., 2013,113(1):013507 |

| [34] | ZHAO K J, PHARR M, HARTLE L , et al. Fracture and debonding in lithium-ion batteries with electrodes of hollow core-shell nanostructures. J. Power Sources , 2012,218:6-14. |

| [35] | DESHPANDE R, CHENG Y T, VERBRUGGE M W , et al. Diffusion induced stresses and strain energy in a phase-transforming spherical electrode particle. Electrochem. Soc., 2011,158(6):A718-A724. |

| [36] |

DROZDOV A D . A model for the mechanical response of electrode particles induced by lithium diffusion in Li-ion batteries. Acta Mech., 2014,225(11):2987-3005.

DOI URL |

| [37] |

HUANG S, FAN F, LI J , et al. Stress generation during lithiation of high-capacity electrode particles in lithium ion batteries. Acta Mater. , 2013,61(12):4354-4364.

DOI URL |

| [38] |

LIU Z J, ZHOU J Q, CHEN B B , et al. Interaction between dislocation mechanics on diffusion induced stress and electrochemical reaction in a spherical lithium ion battery electrode. RSC Adv. , 2015,5(91):74835-74843.

DOI URL |

| [39] | WEI P F, ZHOU J Q, DENG K J , et al. Effect of dislocation on spherical particle electrode for lithium ion battery. Chin. J. Power Sources , 2015, ( 4):719-722. |

| [40] | ZHU J W, ZHOU J Q, CHEN B B , et al. Dislocation effect on diffusion-induced stress for lithiation in hollow spherical electrode. J. Solid State Electrochem. , 2015,20(1):37-46. |

| [41] | LI J, FANG Q H, LIU F , et al. Analytical modeling of dislocation effect on diffusion induced stress in a cylindrical lithium ion battery electrode. J. Power Sources, 2014,272:121-127. |

| [42] | ZHAO K J, PHARR M, VLASSAK J J , et al. Fracture of electrodes in lithium-ion batteries caused by fast charging. J. Appl. Phys., 2010,108(7):073517. |

| [43] | LU B, SONG Y C, ZHANG J Q . Selection of charge methods for lithium ion batteries by considering diffusion induced stress and charge time. J. Power Sources, 2016,320:104-110. |

| [44] | ZHAO Y F, LÜ B . Stress evolution induced by charging shut-down in lithium-ion batteries. J. Mech. Strength, 2018,40(1):77-82. |

| [45] | KIM S, HUANG H Y S. Mechanical stresses at the cathode- electrolyte interface in lithium-ion batteries. J. Mater. Res., 2016,31(22):3506-3512. |

| [46] | JI L, GUO Z S . Analytical modeling and simulation of porous electrodes: Li-ion distribution and diffusion-induced stress. Acta Mech. Sin., 2018,34(1):187-198. |

| [47] | JI L, GUO Z S, WU Y J . Computational and experimental observation of Li-ion concentration distribution and diffusion-induced stress in porous battery electrodes. Energy Technol-Ger., 2017,5(9):1702-1711. |

| [48] | DIMITRIJEVIC B J, AIFANTIS K E, HACKL K . The influence of particle size and spacing on the fragmentation of nanocomposite anodes for Li batteries . J. Power Sources, 2012,206:343-348. |

| [49] | XU R, ZHAO K J . Mechanical interactions regulated kinetics and morphology of composite electrodes in Li-ion batteries. Extreme Mech. Lett., 2016,8:13-21. |

| [50] | MAI W J, YANG M, SOGHRATI S . A particle-resolved 3D finite element model to study the effect of cathode microstructure on the behavior of lithium ion batteries. Electrochim. Acta, 2019,294:192-209. |

| [51] | RENGANATHAN S, SIKHA G, SANTHANAGOPALAN S , et al. Theoretical analysis of stresses in a lithium ion cell. J. Electrochem. Soc., 2010,157(2):A155-A163. |

| [52] | RAHANI E K, SHENOY V B . Role of plastic deformation of binder on stress evolution during charging and discharging in lithium- ion battery negative electrodes. J. Electrochem. Soc., 2013 160(8):A1153-A1162. |

| [53] | MENDOZA H, ROBERTS S A, BRUNINI V E , et al. Mechanical and electrochemical response of a LiCoO2 cathode using reconstructed microstructures. Electrochim. Acta, 2016,190:1-15. |

| [54] | WU L M, XIAO X H, WEN Y H , et al. Three-dimensional finite element study on stress generation in synchrotron X-ray tomography reconstructed nickel-manganese-cobalt based half cell. J. Power Sources , 2016,336:8-18. |

| [55] | QI H R, FENG L, WANG S B , et al. Stress relaxation through electrochemical diffusion in electrodes. Scientia Sinica (Physica, Mechanica & Astronomica), 2016,46(8):1-15. |

| [56] | LIU M . Finite element analysis of lithium insertion-induced expansion of a silicon thin film on a rigid substrate under potentiostatic operation. J. Power Sources, 2015,275:760-768. |

| [57] | GAO Y F, ZHOU M . Coupled mechano-diffusional driving forces for fracture in electrode materials. J. Power Sources, 2013,230:176-193. |

| [58] | CHEN B B, ZHOU J Q, ZHU J W , et al. Diffusion induced stress and the distribution of dislocations in a nanostructured thin film electrode during lithiation. RSC Adv. , 2014,4(109):64216-64224. |

| [59] | WU B, LU W . A battery model that fully couples mechanics and electrochemistry at both particle and electrode levels by incorporation of particle interaction. J. Power Sources, 2017,360:360-372. |

| [60] | ZHANG J Q, LÜ B, SONG Y C . A review of fracture in lithium- ion battery electrodes. Chin. Quart. Mech., 2017,38(1):18-37. |

| [61] | JI L, GUO Z S, DU S Y , et al. Stress induced by diffusion, curvature, and reversible electrochemical reaction in bilayer lithium-ion battery electrode plates. Int. J. Mech. Sci., 2017,134:599-609. |

| [62] | SONG X, LU Y J, SHI M L , et al. Effects of plastic deformation in current collector on lithium diffusion and stress in bilayer lithium- ion battery electrode. Acta Phys. Sin. , 2018,67(14):1-9. |

| [63] | SONG Y C, LI Z Z, ZHANG J Q . Reducing diffusion induced stress in planar electrodes by plastic shakedown and cyclic plasticity of current collector. J. Power Sources, 2014,263:22-28. |

| [64] | LIU M, GAO C H, YANG F Q . Analysis of diffusion-induced delamination of an elastic-perfectly plastic film on a deformable substrate under potentiostatic operation. Modell. Simul. Mater. Sci. Eng., 2017,25(6):065019. |

| [65] | LIU D Y, CHEN W Q, SHEN X D . Diffusion-induced stresses in an imperfect bilayer electrode of coin-shaped lithium-ion batteries. Eur. J. Mech. A-Solid, 2016,55:167-180. |

| [66] | HAO F, FANG D N . Reducing diffusion-induced stresses of electrode- collector bilayer in lithium-ion battery by pre-strain. J. Power Sources, 2013,242:415-420. |

| [67] | SONG Y C, LI Z Z, SOH A K , et al. Diffusion of lithium ions and diffusion-induced stresses in a phase separating electrode under galvanostatic and potentiostatic operations: phase field simulations. Mech. Mater. , 2015,91:363-371. |

| [68] | LI Y, ZHANG J, ZHANG K , et al. A defect-based viscoplastic model for large-deformed thin film electrode of lithium-ion battery. Int. J. Plast., 2019,115:293-306. |

| [69] | HE Y L, HU H J, SONG Y C , et al. Effects of concentration- dependent elastic modulus on the diffusion of lithium ions and diffusion induced stress in layered battery electrodes. J. Power Sources , 2014,248:517-523. |

| [70] | LIU D Y, CHEN W Q, SHEN X D . Diffusion-induced stresses in graphene-based composite bilayer electrode of lithium-ion battery. Compos. Struct., 2017,165:91-98. |

| [71] | ZHANG X Y, HAO F, CHEN H S , et al. Diffusion-induced stress and delamination of layered electrode plates with composition- gradient. Mech. Mater. , 2015,91:351-362. |

| [72] | LU B, SONG Y C, GUO Z S , et al. Modeling of progressive delamination in a thin film driven by diffusion-induced stresses. Int. J. Solids Struct., 2013,50(14/15):2495-2507. |

| [73] | PAL S, DAMLE S S, KUMTA P N , et al. Modeling of lithium segregation induced delamination of a-Si thin film anode in Li-ion batteries. Comput. Mater. Sci., 2013,79:877-887. |

| [74] | HAFTBARADARAN H, XIAO X C, VERBRUGGE M W , et al. Method to deduce the critical size for interfacial delamination of patterned electrode structures and application to lithiation of thin-film silicon islands. J. Power Sources , 2012,206:357-366. |

| [75] | YANG L, CHEN H S, SONG W L , et al. In situ optical observations and simulations on defect induced failure of silicon island anodes. J. Power Sources, 2018,405:101-105. |

| [76] | CHEN D, KRAMER D, MÖNIG R. Chemomechanical fatigue of LiMn1.95Al0.05O4 electrodes for lithium-ion batteries. Electrochim. Acta, 2018,259:939-948. |

| [77] | XU R, YANG Y, YIN F , et al. Heterogeneous damage in Li-ion batteries: experimental analysis and theoretical modeling. J. Mech. Phys. Solids , 2019,129:160-183. |

| [78] | YIM T, CHOI S J, JO Y N , et al. Effect of binder properties on electrochemical performance for silicon-graphite anode: method and application of binder screening. Electrochim. Acta , 2014,136:112-120. |

| [79] | LI C L, SUN Q, JIANG J Y , et al. Electrochemistry and morphology evolution of carbon micro-net films for rechargeable lithium ion batteries. J. Phys. Chem. C , 2008,112:13782-13788. |

| [80] | LI J C, DOZIER A K, LI Y C , et al. Crack pattern formation in thin film lithium-ion battery electrodes. J. Electrochem. Soc., 2011,158(6):A689-A694. |

| [81] | ZHANG J Z, ZHANG J, WANG D , et al. Stress evolution in SiO electrodes for lithium-ion batteries during electrochemical cycling. Mater. Lett. , 2017,190:79-82. |

| [82] |

QU F, LI C L, WANG Z M , et al. Eutectic nano-droplet template injection into bulk silicon to construct porous frameworks with concomitant conformal coating as anodes for Li-ion batteries. Sci. Rep. , 2015,5:10381.

URL PMID |

| [83] |

QU F, LI C L, WANG Z M , et al. Metal-induced crystallization of highly corrugated silicon thick films as potential anodes for Li-ion batteries. ACS Appl. Mater. Interfaces , 2014,6:8782-8788.

DOI URL PMID |

| [84] | ZHANG Z A, ZENG T, LAI Y Q , et al. A comparative study of different binders and their effects on electrochemical properties of LiMn2O4 cathode in lithium ion batteries. J. Power Sources, 2014,247:1-8. |

| [85] | SETHURAMAN V A, WINKLE N V, ABRAHAM D P , et al. Real-time stress measurements in lithium-ion battery negative- electrodes. J. Power Sources , 2012,206:334-342. |

| [86] | PHARR M, CHOI Y S, LEE D W , et al. Measurements of stress and fracture in germanium electrodes of lithium-ion batteries during electrochemical lithiation and delithiation. J. Power Sources , 2016,304:164-169. |

| [87] | SUTHAR B, NORTHROP P W C, RIFE D, et al. Effect of porosity, thickness and tortuosity on capacity fade of anode. J. Electrochem. Soc., 2015,162(9):A1708-A1717. |

| [88] | YANG X G, BAUER C, WANG C Y . Sinusoidal current and stress evolutions in lithium-ion batteries. J. Power Sources, 2016,327:414-422. |

| [89] | WU W, XIAO X R, WANG M , et al. A microstructural resolved model for the stress analysis of lithium-ion batteries. J. Electrochem. Soc., 2014,161(5):A803-A813. |

| [90] | RIEGER B, ERHARD S V, KOSCH S , et al. Multi-dimensional modeling of the influence of cell design on temperature, displacement and stress inhomogeneity in large-format lithium-ion cells. J. Electrochem. Soc., 2016,163(14):A3099-A3110. |

| [91] | RIEGER B, SCHUSTER S F, ERHARD S V , et al. Multi-directional laser scanning as innovative method to detect local cell damage during fast charging of lithium-ion cells. J. Energy Storage , 2016,8:1-5. |

| [92] | ZHANG L J, CHENG H Z, MENG D J . Experiment study on ETSS coupling mechanism and identification of key parameter for lithium-ion batteries. J. Xi'an Jiaotong Univ., 2017,51(8):142-148. |

| [93] | YU C C, DAI H F. The stress measurement and analysis of the lithium-ion battery. Mechatronics, 2015, 21(8): 14-17+32. |

| [94] | SAUERTEIG D, HANSELMANN N, ARZBERGER A , et al. Electrochemical-mechanical coupled modeling and parameterization of swelling and ionic transport in lithium-ion batteries. J. Power Sources , 2018,378:235-247. |

| [95] | BARAI A, TANGIRALA R, UDDIN K , et al. The effect of external compressive loads on the cycle lifetime of lithium-ion pouch cells. J. Energy Storage, 2017,13:211-219. |

| [96] | CANNARELLA J, ARNOLD C B . Stress evolution and capacity fade in constrained lithium-ion pouch cells. J. Power Sources, 2014,245:745-751. |

| [97] | WÜNSCH M, KAUFMAN J, SAUER D U . Investigation of the influence of different bracing of automotive pouch cells on cyclic lifetime and impedance spectra. J. Energy Storage, 2019,21:149-155. |

| [98] | LI R H, REN D S, GUO D X , et al. Volume deformation of large-format lithium ion batteries under different degradation paths. J. Electrochem. Soc., 2019,166(16):A4106-A4114. |

| [99] | MUSSA A S, KLETT M, LINDBERGH G , et al. Effects of external pressure on the performance and ageing of single-layer lithium- ion pouch cells. J. Power Sources , 2018,385:18-26. |

| [100] | ZHANG J, HAN X, HU C J , , et al. An optimization of the pressing force applied onto the module structure of soft-package lithium-ion battery. Automot. Eng.., 2016, 38(6): 669-673+715. |

| [101] | PFRANG A, KERSYS A, KRISTON A , et al. Long-term cycling induced jelly roll deformation in commercial 18650 cells. J. Power Sources , 2018,392:168-175. |

| [102] | SCHUSTER S F, BACH T, FLEDER E , et al. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage , 2015,1:44-53. |

| [103] | BACH T C, SCHUSTER S F, FLEDER E , et al. Nonlinear aging of cylindrical lithium-ion cells linked to heterogeneous compression. J. Energy Storage , 2016,5:212-223. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||