无机材料学报 ›› 2019, Vol. 34 ›› Issue (4): 379-386.DOI: 10.15541/jim20180225 CSTR: 32189.14.10.15541/jim20180225

曾祥雄1,杨进超1,左联1,杨奔奔1,秦峻1,彭志航2

收稿日期:2018-05-14

修回日期:2018-08-22

出版日期:2019-04-20

网络出版日期:2019-04-15

作者简介:曾祥雄(1993-), 男, 助理工程师. E-mail:675091944@qq.com

Xiang-Xiong ZENG1,Jin-Chao YANG1,Lian ZUO1,Ben-Ben YANG1,Jun QIN1,Zhi-Hang PENG2

Received:2018-05-14

Revised:2018-08-22

Published:2019-04-20

Online:2019-04-15

摘要:

采用固相反应法制备(Li0.5Ce0.25La0.25)xCa1-xBi2Nb2O9铋层状结构压电陶瓷, 分析多元稀土元素掺杂对CaBi2Nb2O9(CBN)陶瓷晶体结构、微观形貌及电学性能的影响。Rietveld结构精修表明, 多元稀土元素进入晶格内部形成固溶体, 掺杂使晶体结构有由斜方晶系向四方晶系转变的趋势, 反位缺陷中A位的Bi 3+具备6s2孤对电子, 抑制这种变化趋势。SEM照片显示, 掺杂主要抑制晶粒沿垂直c轴平面生长, 这是由于稀土氧化物具备较高的熔点, 在烧结过程中不易扩散。准同型相界附近, 垂直b轴方向的a滑移面被打破, 极化方向沿a轴和b轴, 导致压电性能增强。其中, (Li0.5Ce0.25La0.25)0.17Ca0.83Bi2Nb2O9陶瓷具备最优异的性能: 居里温度为913 ℃, 压电系数高达16.4 pC/N; 经850 ℃退火2 h, 其d33值为14.0 pC/N, 约为原始值的85.4%。

中图分类号:

曾祥雄, 杨进超, 左联, 杨奔奔, 秦峻, 彭志航. Li/Ce/La共掺杂对CaBi2Nb2O9陶瓷晶体结构及电学性能的影响[J]. 无机材料学报, 2019, 34(4): 379-386.

Xiang-Xiong ZENG, Jin-Chao YANG, Lian ZUO, Ben-Ben YANG, Jun QIN, Zhi-Hang PENG. Li/Ce/La Multidoping on Crystal Structure and Electric Properties of CaBi2Nb2O9 Piezoceramics[J]. Journal of Inorganic Materials, 2019, 34(4): 379-386.

| CBN | CBNLCL-5 | CBNLCL-10 | CBNLCL-12 | CBNLCL-15 | CBNLCL-17 | |

|---|---|---|---|---|---|---|

| Space group | A21am | A21am | A21am | A21am | A21am | A21am |

| Rp/% | 6.31 | 7.25 | 4.86 | 5.16 | 4.72 | 5.01 |

| Rwp/% | 8.62 | 9.57 | 6.35 | 6.76 | 6.04 | 6.66 |

| Rexp/% | 4.77 | 5.26 | 5.38 | 5.15 | 5.37 | 5.34 |

| Chi2 | 3.26 | 3.31 | 1.39 | 1.72 | 1.26 | 1.56 |

| a/nm | 0.54778(3) | 0.54802(2) | 0.54778(2) | 0.54761(2) | 0.54725(2) | 0.54704(2) |

| b/nm | 0.54355(3) | 0.54372(2) | 0.54379(2) | 0.54378(2) | 0.54396(2) | 0.54390(2) |

| c/nm | 2.48626(8) | 2.48738(7) | 2.48689(6) | 2.48641(7) | 2.48581(8) | 2.48495(7) |

| V/nm3 | 0.740273(5) | 0.741164(4) | 0.740778(4) | 0.742398(4) | 0.739980(5) | 0.739362(4) |

| a/b | 1.00778 | 1.00790 | 1.00734 | 1.00706 | 1.00606 | 1.00577 |

| Occupancy of Bi3+ at A site | 0.108 | 0.116 | 0.106 | 0.108 | 0.092 | 0.094 |

表1 CBNLCL-100x陶瓷的精修结果及晶胞参数

Table 1 Crystal data and structure refinement results for CBNLCL-100x ceramics

| CBN | CBNLCL-5 | CBNLCL-10 | CBNLCL-12 | CBNLCL-15 | CBNLCL-17 | |

|---|---|---|---|---|---|---|

| Space group | A21am | A21am | A21am | A21am | A21am | A21am |

| Rp/% | 6.31 | 7.25 | 4.86 | 5.16 | 4.72 | 5.01 |

| Rwp/% | 8.62 | 9.57 | 6.35 | 6.76 | 6.04 | 6.66 |

| Rexp/% | 4.77 | 5.26 | 5.38 | 5.15 | 5.37 | 5.34 |

| Chi2 | 3.26 | 3.31 | 1.39 | 1.72 | 1.26 | 1.56 |

| a/nm | 0.54778(3) | 0.54802(2) | 0.54778(2) | 0.54761(2) | 0.54725(2) | 0.54704(2) |

| b/nm | 0.54355(3) | 0.54372(2) | 0.54379(2) | 0.54378(2) | 0.54396(2) | 0.54390(2) |

| c/nm | 2.48626(8) | 2.48738(7) | 2.48689(6) | 2.48641(7) | 2.48581(8) | 2.48495(7) |

| V/nm3 | 0.740273(5) | 0.741164(4) | 0.740778(4) | 0.742398(4) | 0.739980(5) | 0.739362(4) |

| a/b | 1.00778 | 1.00790 | 1.00734 | 1.00706 | 1.00606 | 1.00577 |

| Occupancy of Bi3+ at A site | 0.108 | 0.116 | 0.106 | 0.108 | 0.092 | 0.094 |

| Bond type | CBN | CBNLCL-5 | CBNLCL-10 | CBNLCL-12 | CBNLCL-15 | CBNLCL-17 |

|---|---|---|---|---|---|---|

| Nb—O | ||||||

| Nb—O1—Nb/(°) | 158.47 | 151.84 | 153.94 | 152.96 | 158.99 | 152.68 |

| O1—Nb—O2/(°) | 174.11 | 172.79 | 172.99 | 171.85 | 171.33 | 171.81 |

| Nb—O1/nm | 0.2120 | 0.2159 | 0.2148 | 0.2143 | 0.2127 | 0.2151 |

| Nb—O2/nm | 0.2047 | 0.1888 | 0.1817 | 0.1836 | 0.1804 | 0.1805 |

| Nb—O4 (1)/nm | 0.1938 | 0.1846 | 0.1854 | 0.1848 | 0.1897 | 0.1872 |

| Nb—O4 (2)/nm | 0.2066 | 0.2180 | 0.2174 | 0.2162 | 0.2146 | 0.2127 |

| Nb—O5 (1)/nm | 0.1837 | 0.1968 | 0.1956 | 0.1945 | 0.1943 | 0.1955 |

| Nb—O5 (2)/nm | 0.2135 | 0.1979 | 0.1971 | 0.1997 | 0.1968 | 0.2002 |

| Ca1/Bi1/Li/Ce/La—O (A—O) | ||||||

| A—O1(1ong bond along a axis)/nm | 0.3191 | 0.3424 | 0.3233 | 0.3250 | 0.3123 | 0.3167 |

| A—O1(short bond along a axis)/nm | 0.2312 | 0.2058 | 0.2291 | 0.2277 | 0.2382 | 0.2364 |

| A—O1(short bond along b axis)/nm | 0.2365 | 0.2627 | 0.2323 | 0.2337 | 0.2315 | 0.2267 |

| A—O1(1ong bond along b axis)/nm | 0.3143 | 0.2980 | 0.3199 | 0.3191 | 0.3176 | 0.3235 |

| A—O4 (1)/nm | 0.2604×2 | 0.2539×2 | 0.2532×2 | 0.2546×2 | 0.2573×2 | 0.2526×2 |

| A—O4 (2)/nm | 0.2605×2 | 0.2549×2 | 0.2567×2 | 0.2557×2 | 0.2584×2 | 0.2585×2 |

| A—O5 (1)/nm | 0.2305×2 | 0.3208×2 | 0.3226×2 | 0.3269×2 | 0.3235×2 | 0.3257×2 |

| A—O5 (2)/nm | 0.2380×2 | 0.2422×2 | 0.2466×2 | 0.2486×2 | 0.2448×2 | 0.2477×2 |

| Bi2/Ca2—O | ||||||

| Bi2/Ca2—O2 (1)/nm | 0.2660 | 0.2553 | 0.2574 | 0.2516 | 0.2587 | 0.2599 |

| Bi2/Ca2—O2 (2)/nm | 0.2775 | 0.3165 | 0.2832 | 0.2827 | 0.2748 | 0.2789 |

| Bi2/Ca2—O2 (3)/nm | 0.2961 | 0.2733 | 0.3075 | 0.3086 | 0.3170 | 0.3111 |

| Bi2/Ca2—O2 (4)/nm | 0.3039 | 0.3313 | 0.3296 | 0.3356 | 0.3310 | 0.3277 |

表2 CBNLCL-100x陶瓷部分键长(nm)和键角(°)

Table 2 Selected bond lengths (nm) and bond angles (°) for CBNLCL-100x

| Bond type | CBN | CBNLCL-5 | CBNLCL-10 | CBNLCL-12 | CBNLCL-15 | CBNLCL-17 |

|---|---|---|---|---|---|---|

| Nb—O | ||||||

| Nb—O1—Nb/(°) | 158.47 | 151.84 | 153.94 | 152.96 | 158.99 | 152.68 |

| O1—Nb—O2/(°) | 174.11 | 172.79 | 172.99 | 171.85 | 171.33 | 171.81 |

| Nb—O1/nm | 0.2120 | 0.2159 | 0.2148 | 0.2143 | 0.2127 | 0.2151 |

| Nb—O2/nm | 0.2047 | 0.1888 | 0.1817 | 0.1836 | 0.1804 | 0.1805 |

| Nb—O4 (1)/nm | 0.1938 | 0.1846 | 0.1854 | 0.1848 | 0.1897 | 0.1872 |

| Nb—O4 (2)/nm | 0.2066 | 0.2180 | 0.2174 | 0.2162 | 0.2146 | 0.2127 |

| Nb—O5 (1)/nm | 0.1837 | 0.1968 | 0.1956 | 0.1945 | 0.1943 | 0.1955 |

| Nb—O5 (2)/nm | 0.2135 | 0.1979 | 0.1971 | 0.1997 | 0.1968 | 0.2002 |

| Ca1/Bi1/Li/Ce/La—O (A—O) | ||||||

| A—O1(1ong bond along a axis)/nm | 0.3191 | 0.3424 | 0.3233 | 0.3250 | 0.3123 | 0.3167 |

| A—O1(short bond along a axis)/nm | 0.2312 | 0.2058 | 0.2291 | 0.2277 | 0.2382 | 0.2364 |

| A—O1(short bond along b axis)/nm | 0.2365 | 0.2627 | 0.2323 | 0.2337 | 0.2315 | 0.2267 |

| A—O1(1ong bond along b axis)/nm | 0.3143 | 0.2980 | 0.3199 | 0.3191 | 0.3176 | 0.3235 |

| A—O4 (1)/nm | 0.2604×2 | 0.2539×2 | 0.2532×2 | 0.2546×2 | 0.2573×2 | 0.2526×2 |

| A—O4 (2)/nm | 0.2605×2 | 0.2549×2 | 0.2567×2 | 0.2557×2 | 0.2584×2 | 0.2585×2 |

| A—O5 (1)/nm | 0.2305×2 | 0.3208×2 | 0.3226×2 | 0.3269×2 | 0.3235×2 | 0.3257×2 |

| A—O5 (2)/nm | 0.2380×2 | 0.2422×2 | 0.2466×2 | 0.2486×2 | 0.2448×2 | 0.2477×2 |

| Bi2/Ca2—O | ||||||

| Bi2/Ca2—O2 (1)/nm | 0.2660 | 0.2553 | 0.2574 | 0.2516 | 0.2587 | 0.2599 |

| Bi2/Ca2—O2 (2)/nm | 0.2775 | 0.3165 | 0.2832 | 0.2827 | 0.2748 | 0.2789 |

| Bi2/Ca2—O2 (3)/nm | 0.2961 | 0.2733 | 0.3075 | 0.3086 | 0.3170 | 0.3111 |

| Bi2/Ca2—O2 (4)/nm | 0.3039 | 0.3313 | 0.3296 | 0.3356 | 0.3310 | 0.3277 |

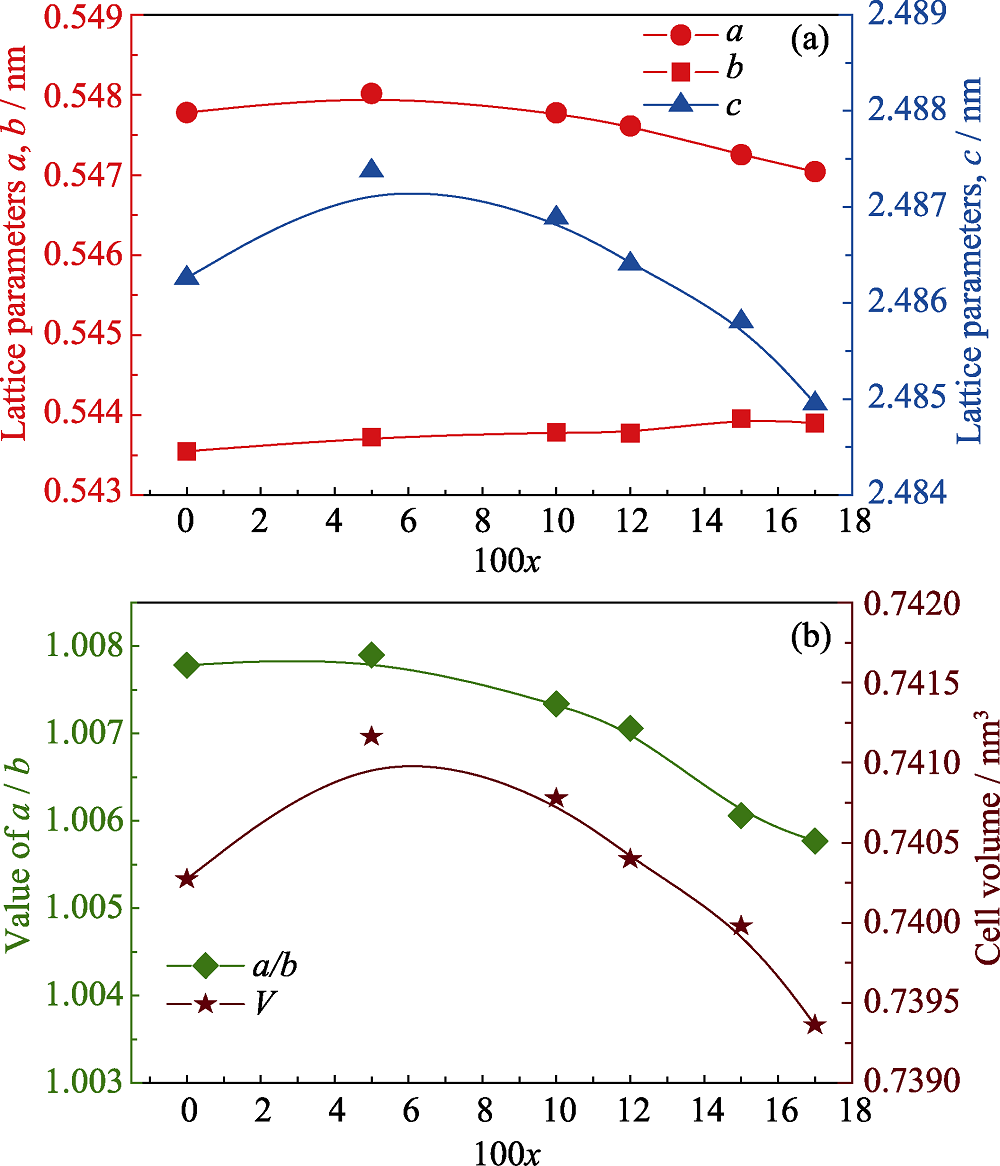

图2 CBNLCL-100x陶瓷的(a)晶胞参数以及(b)晶胞体积和a/b值随掺杂浓度变化关系

Fig. 2 Doping content dependencies of (a) lattice parameters and (b) value of a/b and volume of the CBNLCL-100x ceramics

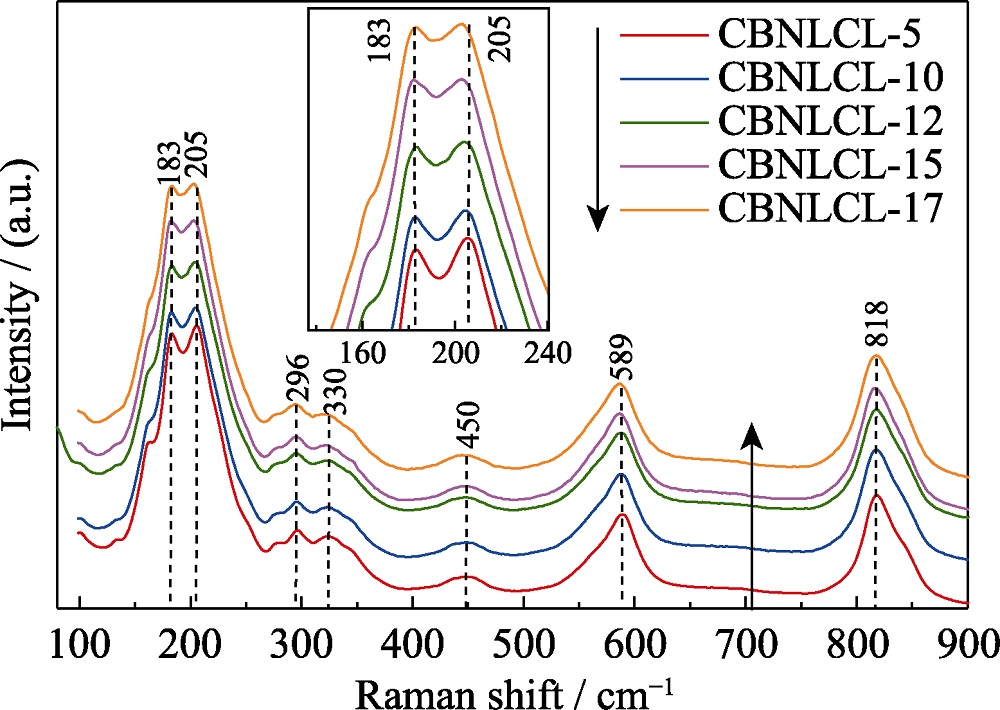

图3 常温下CBNLCL-100x陶瓷的拉曼图谱, 插图为局域放大图谱

Fig. 3 Raman spectra of the CBNLCL-100x samples at room temperature with insets showing regionally enlarged spectra

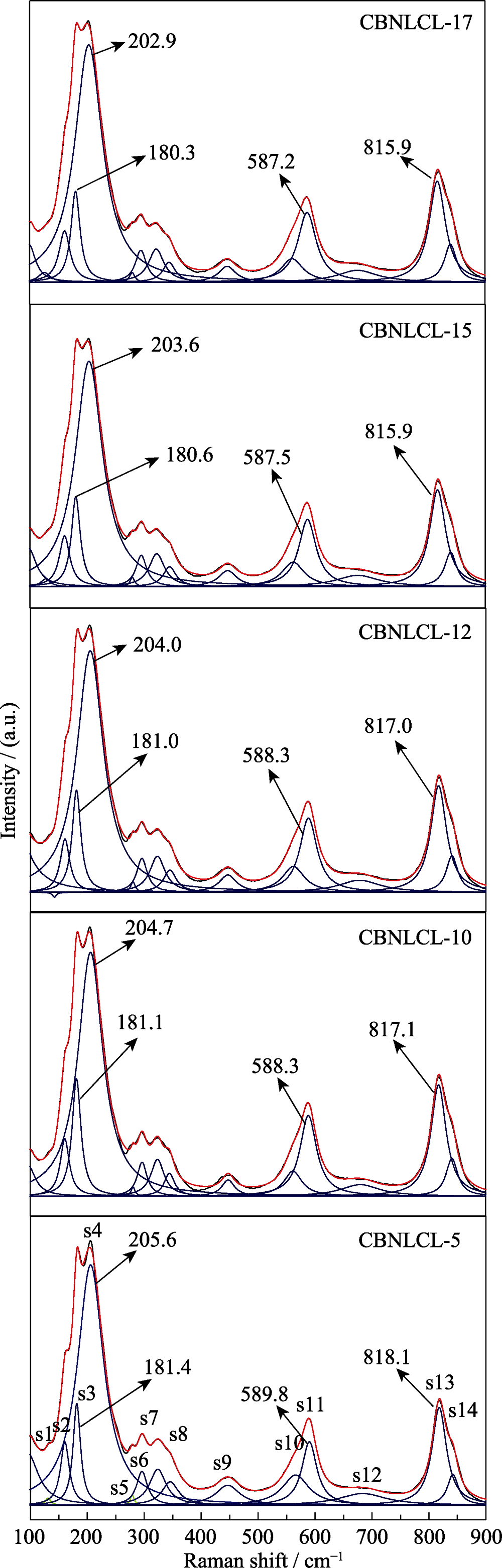

图4 CBNLCL-100x陶瓷拉曼曲线拟合图谱

Fig. 4 Fitting curves of Raman spectra of CBNLCL-100x ceramicsBlack line is the measured spectra, red line is the fitted spectra and blue lines are the deconvoluted Lorentzian peaks (Please refer it in Web Edition)

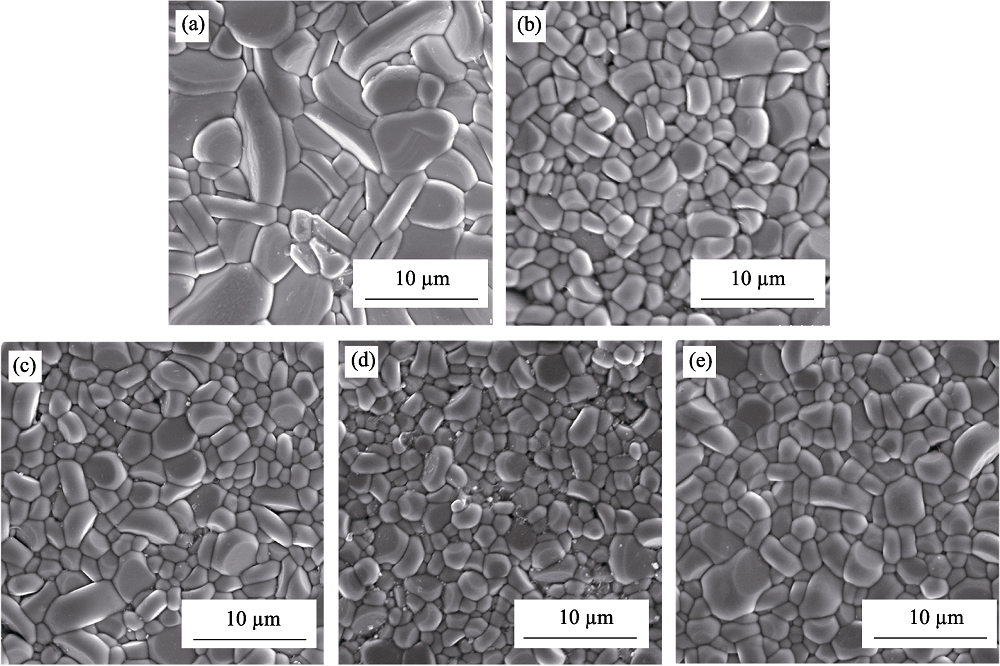

图8 (a) CBNLCL-5, (b) CBNLCL-10, (c) CBNLCL-12, (d) CBNLCL-15, (e) CBNLCL-17陶瓷的SEM照片

Fig. 8 SEM images of (a) CBNLCL-5, (b) CBNLCL-10, (c) CBNLCL-12, (d) CBNLCL-15, (e) CBNLCL-17 ceramics

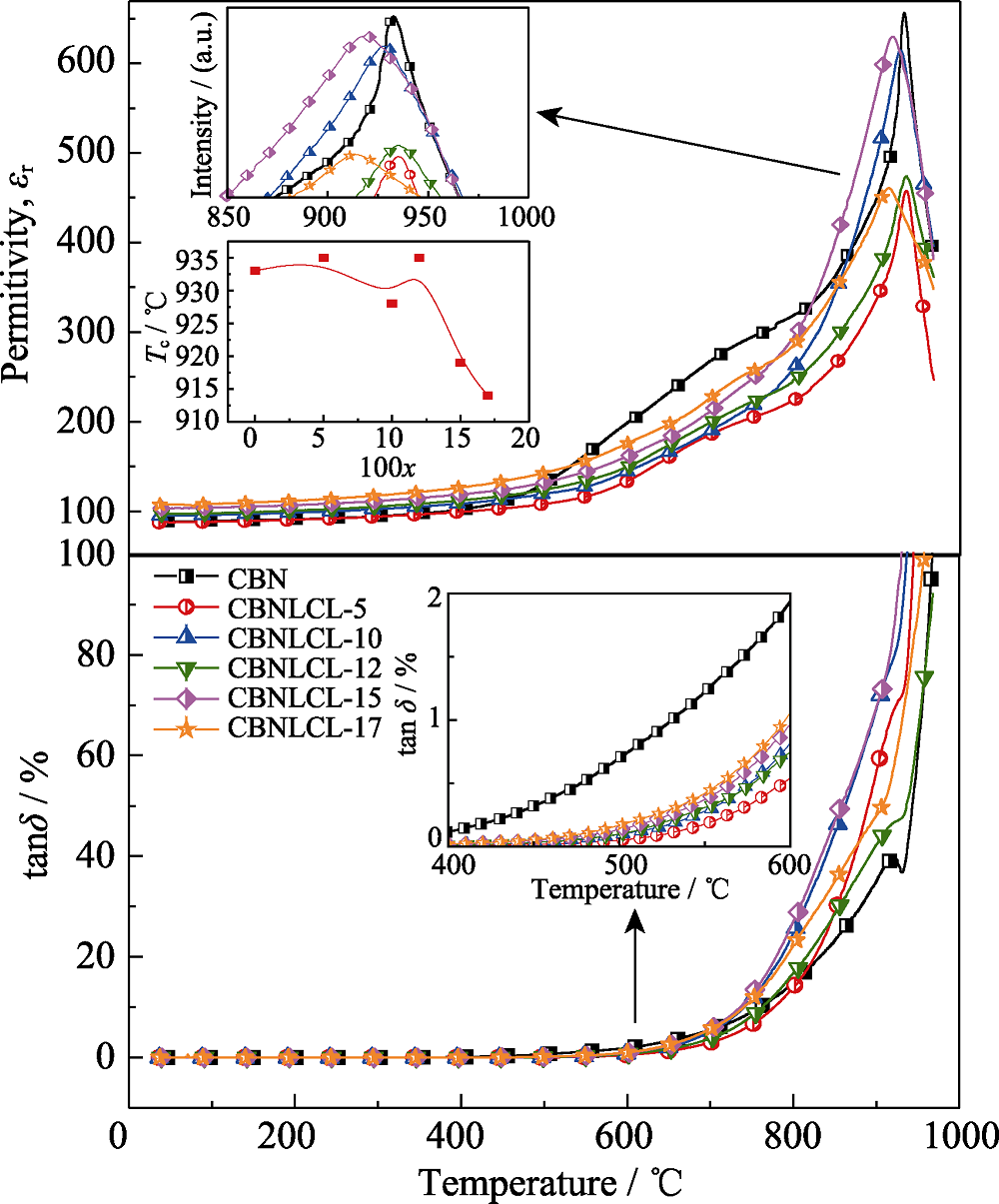

图10 CBNLCL-100x陶瓷的(a)介电常数和(b)介质损耗随温度变化关系

Fig. 10 Temperature dependence of (a) dielectric constant εr and (b) dielectric loss tanδ of CBNLCL-100x ceramics

| [1] | ZHANG S, YU F . Piezoelectric materials for high temperature sensors. Journal of the American Ceramic Society, 2011,94(10):3153-3170. |

| [2] | TURNER R C, FUIERER P A, NEWNHAM R E , et al. Materials for high temperature acoustic and vibration sensors: a review. Applied Acoustics, 1994,41(4):299-324. |

| [3] | JI X, WANG S, SHAO C , et al. High-temperature corrosion behavior of SiBCN fibers for aerospace applications. ACS Applied Materials & Interfaces, 2018,10(23):19712-19720. |

| [4] | FRIT B, MERCURIO J P . The crystal chemistry and dielectric properties of the Aurivillius family of complex bismuth oxides with perovskite-like layered structures. Journal of Alloys and Compounds, 1992,188(1/2):27-35. |

| [5] | PARK B H, KANG B S, BU S D , et al. Lanthanum-substituted bismuth titanate for use in non-volatile memories. Nature, 1999,401(6754):682-684. |

| [6] | SUBBARAO E C . A family of ferroelectric bismuth compounds. Journal of Physics and Chemistry of Solids, 1962,23(6):665-676. |

| [7] | NEWNHAM R E, WOLFE R W, DORRIAN J F . Structural basis of ferroelectricity in the bismuth titanate family. Materials Research Bulletin, 1971,6(10):1029-1039. |

| [8] | YAN H, ZHANG H, REECE M J , et al. Thermal depoling of high Curie point Aurivillius phase ferroelectric ceramics. Applied Physics Letters, 2005, 87(8): 082911-1-3. |

| [9] | YAN H, ZHANG H, UBIC R , et al. A lead-free high-Curie-point ferroelectric ceramic, CaBi2Nb2O9. Advanced Materials, 2005,17(10):1261-1265. |

| [10] | PENG Z, CHEN Q, LIU D , et al. Evolution of microstructure and dielectric properties of (LiCe)-doped Na0.5Bi2.5Nb2O9 Aurivillius type ceramics. Current Applied Physics, 2013,13(7):1183-1187. |

| [11] | LI F, LIN D, CHEN Z , et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nature Materials, 2018,17(4):349-354. |

| [12] | DU X, CHEN I W . Ferroelectric thin films of bismuth-containing layered perovskites: Part I, Bi4Ti3O12. Journal of the American Ceramic Society, 1998,81(12):3260-3264. |

| [13] | YAN H X, ZHANG Z, ZHU W M , et al. The effect of (Li,Ce) and (K,Ce) doping in Aurivillius phase material CaBi4Ti4O15. Materials Research Bulletin, 2004,39(9):1237-1246. |

| [14] | WANG C M, ZHAO L, WANG J F , et al. Cerium-modified Aurivillius-type sodium lanthanum bismuth titanate with enhanced piezoactivities. Materials Science and Engineering: B, 2009,163(3):179-183. |

| [15] | KUMAR A, VARSHNEY D . Crystal structure refinement of Bi1-xNdxFeO3 multiferroic by the Rietveld method. Ceramics International, 2012,38(5):3935-3942. |

| [16] | BLAKE S M, FALCONER M J, MCCREEDY M , et al. Cation disorder in ferroelectric Aurivillius phases of the type Bi2ANb2O9 (A=Ba, Sr, Ca). Journal of Materials Chemistry, 1997,7(8):1609-1613. |

| [17] | WU Y, CHEN J, YUAN J . Structurerefinements and the influences of A-site vacancies on properties of Na0.5Bi2.5Nb2O9-based high temperature piezoceramics. Journal of Applied Physics, 2016, 120(19): 194103-1-6. |

| [18] | ZHANG F Q, LI Y X . Recent progress on bismuth layer-structured ferroelectrics. Journal of Inorganic Materials, 2014,29(5):449-460. |

| [19] | SIMÕES A Z, AGUIAR E C, RICCARDI C S , et al. Effect of oxidizing atmosphere on ferroelectric and piezoelectric response of CaBi2Nb2O9 thin films. Materials Chemistry and Physics, 2010,124(23):894-899. |

| [20] | LONG C B, FAN H Q, LI M M . High temperature Aurivillius piezoelectrics: the effect of (Li, Ln) modification on the structure and properties of (Li, Ln)(0.06)(Na, Bi)(0.44)Bi2Nb2O9 (Ln=Ce, Nd, La and Y). Dalton Transactions, 2013,42(10):3561-3570. |

| [21] | DIAO C L, XU J B, ZHENG H W , et al. Dielectric and piezoelectric properties of cerium modified BaBi4Ti4O15 ceramics. Ceramics International, 2013,39(6):6991-6995. |

| [22] | PENG Z, YAN D, CHEN Q , et al. Crystal structure, dielectric and piezoelectric properties of Ta/W codoped Bi3TiNbO9 Aurivillius phase ceramics. Current Applied Physics, 2014,14(12):1861-1866. |

| [23] | SHIMAKAWA Y, KUBO Y, NAKAGAWA Y , et al. Crystal structure and ferroelectric properties of ABi2Ta2O9 (A=Ca, Sr, and Ba). Physical Review B, 2000,61(10):6559-6564. |

| [24] | DAMJANOVIC D . Contributions to the piezoelectric effect in ferroelectric single crystals and ceramics. Journal of the American Ceramic Society, 2005,88(10):2663-2676. |

| [25] | TIAN X, QU S, MA H , et al. Effect of grain size on dielectric and piezoelectric properties of bismuth layer structure CaBi2Nb2O9 ceramics. Journal of Materials Science: Materials in Electronics, 2016,27(12):13309-13313. |

| [26] | CHEN H, SHEN B, XU J , et al. Correlation between grain sizes and electrical properties of CaBi2Nb2O9 piezoelectric ceramics. Journal of the American Ceramic Society, 2012,95(11):3514-3518. |

| [1] | 王晓波, 朱于良, 薛稳超, 史汝川, 骆柏锋, 罗骋韬. PT含量变化对PMN-PT单晶的大功率性能影响[J]. 无机材料学报, 2025, 40(7): 840-846. |

| [2] | 陈相杰, 李玲, 雷添福, 王佳佳, 汪尧进. 相界工程和畴工程调控(1-x)(0.8PZT-0.2PZN)-xBZT陶瓷的压电性能[J]. 无机材料学报, 2025, 40(6): 729-734. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [5] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [6] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [7] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [8] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [9] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [10] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [11] | 赵凯旋, 刘文鹏, 丁守军, 窦仁勤, 罗建乔, 高进云, 孙贵花, 任浩, 张庆礼. 熔融法制备Nd:YLF原料及其晶体生长和性能研究[J]. 无机材料学报, 2025, 40(5): 529-535. |

| [12] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [13] | 高天宇, 刘东, 赵思雪, 邓伟, 张波萍, 朱立峰. 温度稳定性优异的K0.5Na0.5NbO3基压电陶瓷及其1-3型换能器[J]. 无机材料学报, 2025, 40(3): 297-304. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||