无机材料学报 ›› 2018, Vol. 33 ›› Issue (7): 711-720.DOI: 10.15541/jim20170421 CSTR: 32189.14.10.15541/jim20170421

所属专题: 陶瓷基复合材料

刘海韬1, 杨玲伟2, 韩爽1

收稿日期:2017-08-30

修回日期:2017-10-26

出版日期:2018-07-10

网络出版日期:2018-06-19

基金资助:LIU Hai-Tao1, YANG Ling-Wei2, HAN Shuang1

Received:2017-08-30

Revised:2017-10-26

Published:2018-07-10

Online:2018-06-19

Supported by:摘要:

微观力学参数是构建连续纤维增强陶瓷基复合材料(CFRCMCs)组分、微观结构和宏观力学性能的桥梁, 但受限于CFRCMCs的脆性和微观力学参数测试水平, 微观力学研究工作进展缓慢。随着基于纳米压痕的微观力学测试技术和基于聚焦离子束微观测试样品制备技术的飞速发展, 近年来CFRCMCs的微观力学研究工作取得显著进步。本文结合国防科技大学刘海韬课题组的研究工作, 重点对CFRCMCs组分的原位模量、断裂韧性以及界面结合强度的测试方法和典型应用进行了讨论, 最后举例说明了基于微观力学参数的CFRCMCs宏观力学行为的预判方法。

中图分类号:

刘海韬, 杨玲伟, 韩爽. 连续纤维增强陶瓷基复合材料微观力学研究进展[J]. 无机材料学报, 2018, 33(7): 711-720.

LIU Hai-Tao, YANG Ling-Wei, HAN Shuang. Research Progress on Micro-mechanical Property of Continuous Fiber-reinforced Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2018, 33(7): 711-720.

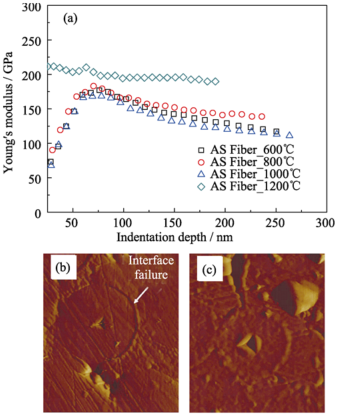

图1 (a)不同温度制备的ASf/SiO2复合材料AS纤维模量与压头压入深度关系; 600℃(b)和1200℃(c)制备的ASf/SiO2复合材料AS纤维纳米压痕测试后的SPM(Scanning Probe Microscopy)照片[10]

Fig. 1 (a) Young's modulus of the AS fiber in ASf/SiO2 composites prepared at different temperatures as a function of penetration depth; SPM images of the nanoindentation imprints of ASf/SiO2 composites fabricated at 600℃ (b) and 1200℃ (c)[10]

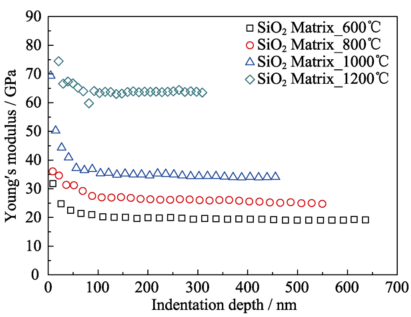

图2 不同温度制备的ASf/SiO2复合材料SiO2基体模量与压头压入深度关系[10]

Fig. 2 Young°s modulus of the SiO2 matrix in ASf/SiO2 composites prepared at different temperatures as a function of penetration depth[10]

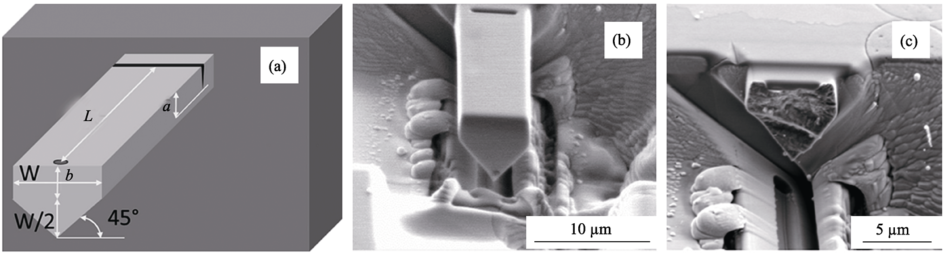

图4 (a)单边切口微梁尺寸示意图; SiCf/SiC复合材料碳化硅基体单边切口微梁加载前(b)后(c)的SEM照片[11,18]

Fig. 4 (a) Schematic representation of the micro-cantilever bending geometry; SEM images of a micro-cantilever prepared from SiC matrix in SiCf/SiC composites before (a) and after (b) testing[11,18]

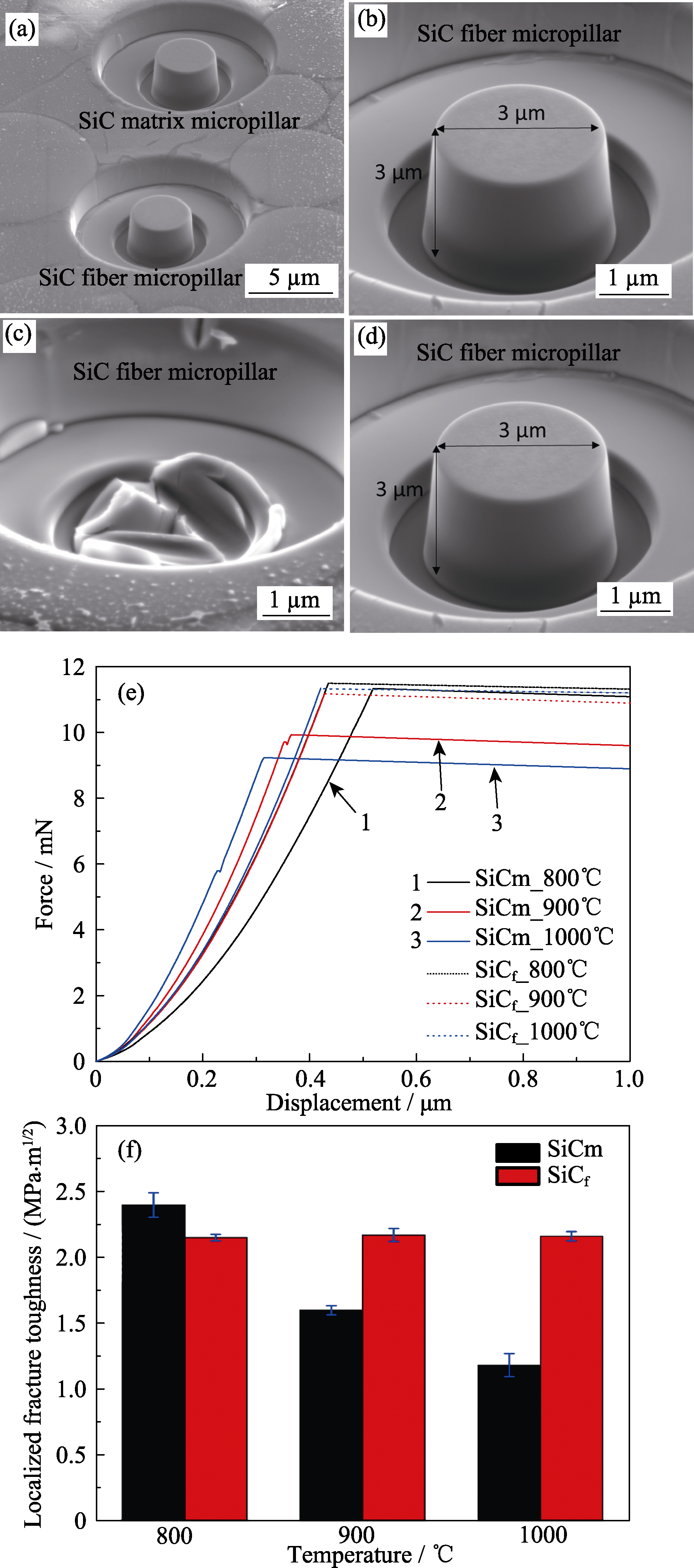

图6 (a), (b)SiC纤维与基体微柱; (c), (d)SiC纤维与基体微柱失效的SEM照片; (e)典型SiC纤维与基体微柱载荷-位移曲线; (f)不同温度制备的复合材料SiC纤维与基体韧性[28]

Fig. 6 Morphologies of the micropillars on individual SiC matrix and SiC fiber (a, b); Micropillar morphologies of SiC fiber and SiC matrix after pillar splitting tests(c, d); Representive force-displacement curves of SiC matrix and SiC fiber by the micropillar splitting tests (e); Evolution of localized fracture toughness of the SiC matrix and SiC fiber as a function of composite fabrication temperature(f)[28]

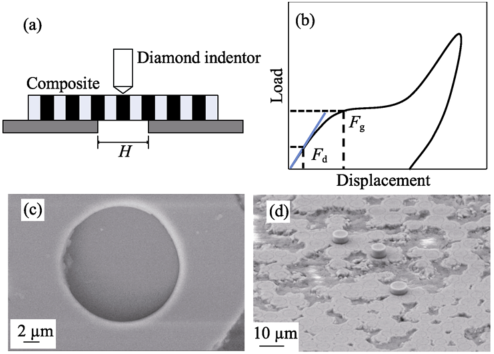

图8 (a)单纤维顶出实验实施过程示意图; (b)典型纤维顶出实验载荷-位移曲线; SiCf/SiC复合材料顶出纤维压头正面(c)和背面(d)SEM照片[43]

Fig. 8 (a) Schematic drawing of fiber push-out measurement; (b) Typical load-displacement push-out test curve; SEM images of the frontside surface (c) and backside surface (d) of SiCf/SiC minicomposite after fiber push-out test using a flat punch indenter[43]

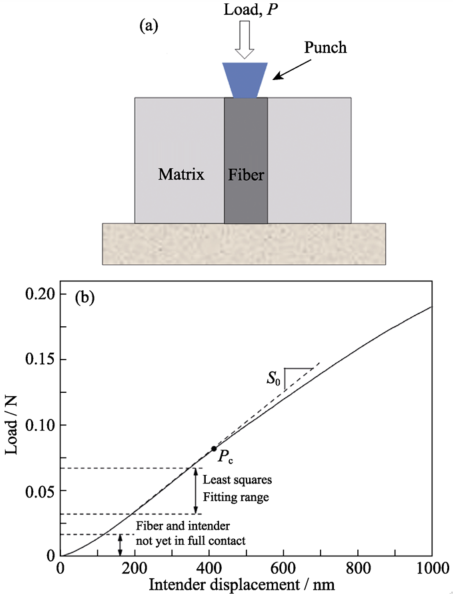

图9 (a)纤维顶入测试示意图和(b)典型纤维顶入实验载荷-位移曲线[45]

Fig. 9 (a) Schematic drawing of fiber push-in measurement, (b) Typical load-displacement push-in test curve[45]

| Composites | Interphase | τ/MPa | Flexural strength/MPa | Fracture mode | Ref. |

|---|---|---|---|---|---|

| PIP 3D Cf/SiC | None | 105 | 23 | Brittle | [19] |

| PyC | 30 | 378 | Toughened | ||

| PIP 3D Nextel440 ASf/SiC | None | 293 | 45 | Brittle | [34] |

| PyC | 42 | 163 | Toughened | ||

| Sol-Gel 3D SiCf/Mullite | None | 537 | 230 | Brittle | [46] |

| PyC | 155 | 35 | Toughened | ||

| PIP 3D SiCf/SiC | None | 450 | 90 | Brittle | [28] |

| BN | 50 | 200 | Toughened | ||

| Sol-Gel 3D ALF ASf/SiO2(600℃) | None | 50 | 105 | Toughened | [10] |

| Sol-Gel 3D ALF ASf/SiO2(1200℃) | None | 260 | 45 | Brittle |

表1 国防科技大学刘海韬课题组CFRCMCs界面结合强度研究工作

Table 1 Interfacial bonding strength of typical CFRCMCs investigated in our research group

| Composites | Interphase | τ/MPa | Flexural strength/MPa | Fracture mode | Ref. |

|---|---|---|---|---|---|

| PIP 3D Cf/SiC | None | 105 | 23 | Brittle | [19] |

| PyC | 30 | 378 | Toughened | ||

| PIP 3D Nextel440 ASf/SiC | None | 293 | 45 | Brittle | [34] |

| PyC | 42 | 163 | Toughened | ||

| Sol-Gel 3D SiCf/Mullite | None | 537 | 230 | Brittle | [46] |

| PyC | 155 | 35 | Toughened | ||

| PIP 3D SiCf/SiC | None | 450 | 90 | Brittle | [28] |

| BN | 50 | 200 | Toughened | ||

| Sol-Gel 3D ALF ASf/SiO2(600℃) | None | 50 | 105 | Toughened | [10] |

| Sol-Gel 3D ALF ASf/SiO2(1200℃) | None | 260 | 45 | Brittle |

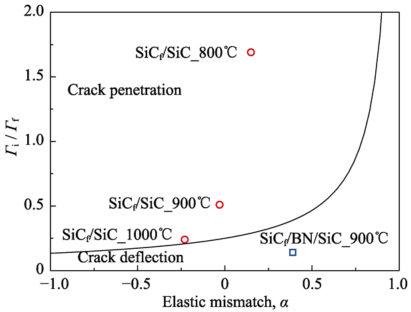

| Composites | Em/GPa | Ef/GPa | Γm/(J·m-2) | Γf/(J·m-2) | EBN interphase/GPa | ΓBN interphase/(J·m-2) |

|---|---|---|---|---|---|---|

| SiCf/SiC (800℃) | 118 | 160 | 49 | 29 | - | - |

| SiCf/SiC (900℃) | 170 | 160 | 15 | 29 | - | - |

| SiCf/SiC (1000℃) | 256 | 160 | 5 | 29 | - | - |

| SiCf/BN/SiC | - | 160 | - | 29 | 70 | 4 |

表2 国防科技大学刘海韬课题组研究的SiCf/SiC和SiCf/BN/SiC复合材料微观力学参数[28]

Table 2 Micro-mechanical parameters of SiCf/SiC and SiCf/BN/SiC composites investigated in Liu’s group[28]

| Composites | Em/GPa | Ef/GPa | Γm/(J·m-2) | Γf/(J·m-2) | EBN interphase/GPa | ΓBN interphase/(J·m-2) |

|---|---|---|---|---|---|---|

| SiCf/SiC (800℃) | 118 | 160 | 49 | 29 | - | - |

| SiCf/SiC (900℃) | 170 | 160 | 15 | 29 | - | - |

| SiCf/SiC (1000℃) | 256 | 160 | 5 | 29 | - | - |

| SiCf/BN/SiC | - | 160 | - | 29 | 70 | 4 |

图11 基于H-H模型的SiCf/SiC和SiCf/BN/SiC复合材料宏观力学行为预判[28]

Fig. 11 Predictions on macro-mechanical behavior of SiCf/SiC and SiCf/BN/SiC composites based on H-H model[28]

| [1] | 陈朝辉, 李伟, 王松, 等. 先驱体转化陶瓷基复合材料, 北京: 科学出版社, 2012. |

| [2] | 张立同. 纤维增韧碳化硅陶瓷复合材料—模拟、表征与设计.北京: 化学工业出版社, 2009. |

| [3] | KRENKEL WALTER. Ceramic Matrix Composites.Weinheim: WILEY-VCH Verlag GmbH & Co.KGaA, 2008. |

| [4] | WANG YI, LIU HAI-TAO, CHENG HAI-FENG.Research progress on oxide/oxide ceramic matrix composites.Journal of Inorganic Materials, 2014, 29(7): 673-680. |

| [5] | MA QING-SONG, LIU HAI-TAO, PAN YU,et al.Research progress on the application of C/SiC composites in scramjet.Journal of Inorganic Materials, 2013, 28(3): 247-255. |

| [6] | MEYER P, WAAS A M.FEM predictions of damage in continuous fiber ceramic matrix composites under transverse tension using the crack band method.Acta Materialia, 2016, 102: 292-303. |

| [7] | Li L B, SONG Y D, SUN Y C.Modeling the tensile behavior of unidirectional C/SiC ceramic-matrix composites.Mechanics of Composite Materials, 2014, 49(6): 659-672. |

| [8] | WANG L, WANG Z, DONG S M,et al.Finite element simulation of stress distribution and development of Cf/SiC ceramice-matrix composite coated with single layer SiC coating during thermal shock.Composites: Part B, 2013, 51: 204-214. |

| [9] | EVANS A G, ZOK F W.The physics and mechanics of fibre-reinforced brittle matrix composites.Journal of Materials Science, 1994, 29: 3857-3896. |

| [10] | YANG L W, WANG J Y, LIU H T,et al.Sol-Gel temperature dependent ductile-to-brittle transition of aluminosilicate fiber reinforced silica matrix composite.Composites: Part B, 2017, 119: 79-89. |

| [11] | FRAZER D, ABAD M D, KRUMWIEDE D,et al.Localized mechanical property assessment of SiC/SiC composite materials.Composites: Part A, 2015, 70: 93-101. |

| [12] | BLAESE D, GARCIA D E, GUGLIELMI P,et al.ZrO2 fiber- matrix interfaces in alumina fiber-reinforced model composites.Journal of European Ceramic Society, 2015, 35: 1593-1598. |

| [13] | UDAYAKUMAR A, SRI GANESH A, RAJA S,et al.Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI.Journal of the European Ceramic Society, 2011, 31: 1145-1153. |

| [14] | YAN W, PUN C L, WU Z,et al.Some issues on nanoindentation method to measure the elastic modulus of particles in composites.Composites: Part B, 2011, 42: 2093-2097. |

| [15] | ZHANG L, REN C, ZHOU C,et al.Single fiber push-out characterization of interfacial mechanical properties in unidirectional CVI-C/SiC composites by the nano-indentation technique.Applied Surface Science, 2015, 357: 1427-1433. |

| [16] | HINOKI T, ZHANG W, KOHYAMA A, ,et al. . Effect of fiber coating on interfacial shear strength of SiC/SiC by nano-indentation technique. Journal of Nuclear Materials, 1998, 258-263: 1567-1571. |

| [17] | SEBASTIANI M, JOHANNS K E, HERBERT E G,et al.A novel pillar indentation splitting test for measuring fracture toughness of thin ceramic coatings.Philosophical Magazine, 2015, 95: 1928-1944. |

| [18] | SEBASTIANI M, JOHANNS K E, HERBERT E G,et al.Measurement of fracture toughness by nanoindentation methods: recent advances and future challenges.Current Opinion in Solid State and Materials Science, 2015, 19: 324-333. |

| [19] | LIU H T, YANG L W, SUN X,et al.Enhancing the fracture resistance of carbon fiber reinforced SiC matrix composites by interface modification through a simple fiber heat-treatment process.Carbon, 2016, 109: 435-443. |

| [20] | LEATHERBARROW A, WU H Z.Mechanical behaviour of the constituents inside carbon-fibre/carbon-silicon carbide composites characterised by nano-indentation.Journal of the European Ceramic Society, 2012, 32: 579-588. |

| [21] | MARX D T, RIESTER L.Mechanical properties of carbon-carbon composite components determined using nanoindentation.Carbon, 1999, 37: 1679-1684. |

| [22] | DISS P, LAMON J, CARPENTIER L,et al.Sharp indentation behavior of carbon/carbon composites and varieties of carbon.Carbon, 2002, 40: 2567-2579. |

| [23] | MULLER W M, MOOSBURGER-WILL J, SAUSE M G R,et al.Quantification of crack area in ceramic matrix composites at single- fiber push-out testing and influence of pyrocarbon fiber coating thickness on interfacial fracture toughness.Journal of the European Ceramic Society, 2015, 35: 2981-2989. |

| [24] | OLIVER W C, PHARR G M.An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments.Journal of Materials Research, 1992, 7(6): 1564-1583. |

| [25] | VANLANDINGHAM M R.Review of instrumented indentation.Journal of Research of the National Institute of Standards and Technology, 2003, 108(4): 249-265. |

| [26] | OLIVER W C, PHARR G M.Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. Journal of Materials Research, 2004, 19(1): 3-20. |

| [27] | FISCHER-CRIPPS A C. Critical review analysis and interpretation of nanoindentation test data.Surface& Coatings Technology, 2006, 200: 4153-4165. |

| [28] | YANG L W, LIU H T, CHENG H F.Processing-temperature dependent micro- and macro-mechanical properties of SiC fiber reinforced SiC matrix composites.Composites: Part B, 2017, 129: 152-161. |

| [29] | HONJO K.Fracture toughness of PAN-based carbon fibers estimated from strength-mirror size relation.Carbon, 2003, 41: 979-984. |

| [30] | MORISHITA K, OCHIAI S, OKUDA H,et al.Fracture toughness of a crystalline silicon carbide fiber (tyranno-SA3®).Journal of the American Ceramic Society, 2006, 89(8): 2571-2576. |

| [31] | OCHIAI S, KUBOSHIMA S, MORISHITA K,et al.Fracture toughness of Al2O3 fibers with an artificial notch introduced by a focused-ion-beam.Journal of the European Ceramic Society, 2010, 30: 1659-1667. |

| [32] | CASELLAS D, CARO J, MOLAS S,et al.Fracture toughness of carbides in tool steels evaluated by nanoindentation.Acta Materialia, 2007, 55: 4277-4286. |

| [33] | MUELLER M G, PEJCHAL V, ŽAGAR G,et al.Fracture toughness testing of nanocrystalline alumina and fused quartz using chevron-notched microbeams.Acta Materialia, 2015, 86: 385-395. |

| [34] | LIU H T, YANG L W, HAN S,et al.Interface controlled micro- and macro-mechanical properties of aluminosilicate fiber reinforced SiC matrix composites.Journal of the European Ceramic Society, 2017, 37: 883-890. |

| [35] | CAO S Y, WANG J, WANG H.High-temperature behavior and degradation mechanism of SiC fibers annealed in Ar and N2 atmospheres.Journal of Materials Science, 2016, 51: 4650-4659. |

| [36] | DAVIES I J, ISHIKAWA T, SHIBUYA M,et al.Fibre and interfacial properties measured in situ for a 3D woven SiC/SiC-based composite with glass sealant.Composites: Part A, 1999, 30: 587-591. |

| [37] | DAVIES I J, OGASAWARA T, ISHIKAWA T.Distribution of fibre pullout length and interface shear strength within a single fibre bundle for an orthogonal 3-D woven Si-Ti-C-O fibre/Si-Ti-C-O matrix composite tested at 1100℃ in air.Journal of the European Ceramic Society, 2005, 25: 599-604. |

| [38] | BRANDSTETTER J, PETERLIK H, KROMP K,et al.A new fibre- bundle pull-out test to determine interface properties of a 2D- woven carbon/carbon composite.Composites Science Technology, 2003, 63: 653-660. |

| [39] | BERTRAND S, FORIO P, PAILLER R,et al.Hi-Nicalon/SiC minicomposites with (pyrocarbon/SiC)n nanoscale multilayered interphases.Journal of the American Ceramic Society, 1999, 82(9): 2465-2473. |

| [40] | SAUDER C, BRUSSON A, LAMON J.Influence of interface characteristics on the mechanical properties of Hi-Nicalon type-S or Tyranno-SA3 fiber-reinforced SiC/SiC minicomposites.International Journal of Applied Ceramic Technology, 2010, 7(3): 291-303. |

| [41] | MORSCHER G N, MARTINEZ-FERNANDEZ J.Fiber effects on minicomposite mechanical properties for several silicon carbide fiber-chemically vapor-infiltrated silicon carbide matrix systems.Journal of the American Ceramic Society, 1999, 82(1): 145-155. |

| [42] | REBILLAT F, LAMON J, GUETTE A.The concept of a strong interface applied to SiC/SiC composites with a BN interphase.Acta Materialia, 2000, 48: 4609-4618. |

| [43] | BUET E, SAUDER C, SORNIN D,et al.Influence of surface fibre properties and textural organization of a pyrocarbon interphase on the interfacial shear stress of SiC/SiC minicomposites reinforced with Hi-Nicalon S and Tyranno SA3 fibres.Journal of the European Ceramic Society, 2014, 34: 179-188. |

| [44] | MUELLER W M, MOOSBURGER-WILL J, SAUSE M G R,et al.Microscopic analysis of single-fiber push-out tests on ceramic matrix composites performed with Berkovich and flat-end indenter and evaluation of interfacial fracture toughness.Journal of the European Ceramic Society, 2013, 33: 441-451. |

| [45] | RODRÍGUEZ M, MOLINA-ALDAREGUÍA J M, GONZÁLEZ C,et al.A methodology to measure the interface shear strength by means of the fiber push-in test.Composites Science and Technology, 2012, 72: 1924-1932. |

| [46] | HAN S, YANG L W, LIU H T,et al.Micro-mechanical properties and interfacial engineering of SiC fiber reinforced Sol-Gel fabricated mullite matrix composites.Materials and Design, 2017, 131: 265-272. |

| [47] | HE M Y, HUTCHINSON J W.Crack deflection at the interface between dissimilar materials.International Journal of Solids and Structures, 1989, 25(9): 1053-1067. |

| [48] | HE M Y, EVANS A G, HUTCHINSON J W.Crack deflection at an interface between dissimilar elastic materials: role of residual stresses.International Journal of Solids and Structures, 1994, 31(24): 3443-3455. |

| [49] | FUJITA H, JEFFERSON G, MCMEEKING R M,et al.Mullite/alumina mixtures for use as porous matrices in oxide fiber composites.Journal of the American Ceramic Society, 2004, 87(2): 261-267. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||