无机材料学报 ›› 2018, Vol. 33 ›› Issue (4): 363-372.DOI: 10.15541/jim20170278 CSTR: 32189.14.10.15541/jim20170278

• • 下一篇

朱东彬1,2, 宋艳军2, 梁金生2, 张晓旭1, 楚锐清1, 吴民强1

收稿日期:2017-06-05

修回日期:2017-09-11

出版日期:2018-04-30

网络出版日期:2018-03-27

作者简介:朱东彬(1975-), 男, 博士, 副教授. E-mail: zhudongbin@hebut.edu.cn

基金资助:ZHU Dong-Bin1,2, SONG Yan-Jun2, LIANG Jin-Sheng2, ZHANG Xiao-Xu1, CHU Rui-Qing1, WU Min-Qiang1

Received:2017-06-05

Revised:2017-09-11

Published:2018-04-30

Online:2018-03-27

About author:ZHU Dong-Bin. E-mail: zhudongbin@hebut.edu.cn

Supported by:摘要:

氧化锆陶瓷具有高强度、高韧性、高硬度、耐磨损、生物相容性好等优点, 广泛应用于齿科修复。但氧化锆陶瓷相变增韧会缩短其服役寿命, 尤其在极潮湿的口腔唾液等复杂的生物化学条件下, 因承受咀嚼力、温度的频繁变化, 而导致其失效断裂。本文概述了氧化锆陶瓷在齿科修复领域的应用研究进展, 总结了氧化锆陶瓷的增韧机理以及常用齿科氧化锆陶瓷的研究现状, 并对临床服役中氧化锆陶瓷的韧性老化现象进行分析, 总结了韧性老化机理及其预防措施和方法。随着齿科氧化锆陶瓷综合力学性能的提高以及健康功能化的未来需求, 其在生物医用领域的应用将会越来越广泛。

中图分类号:

朱东彬, 宋艳军, 梁金生, 张晓旭, 楚锐清, 吴民强. 齿科用氧化锆陶瓷韧性研究进展[J]. 无机材料学报, 2018, 33(4): 363-372.

ZHU Dong-Bin, SONG Yan-Jun, LIANG Jin-Sheng, ZHANG Xiao-Xu, CHU Rui-Qing, WU Min-Qiang. Progress of Toughness in Dental Zirconia Ceramics[J]. Journal of Inorganic Materials, 2018, 33(4): 363-372.

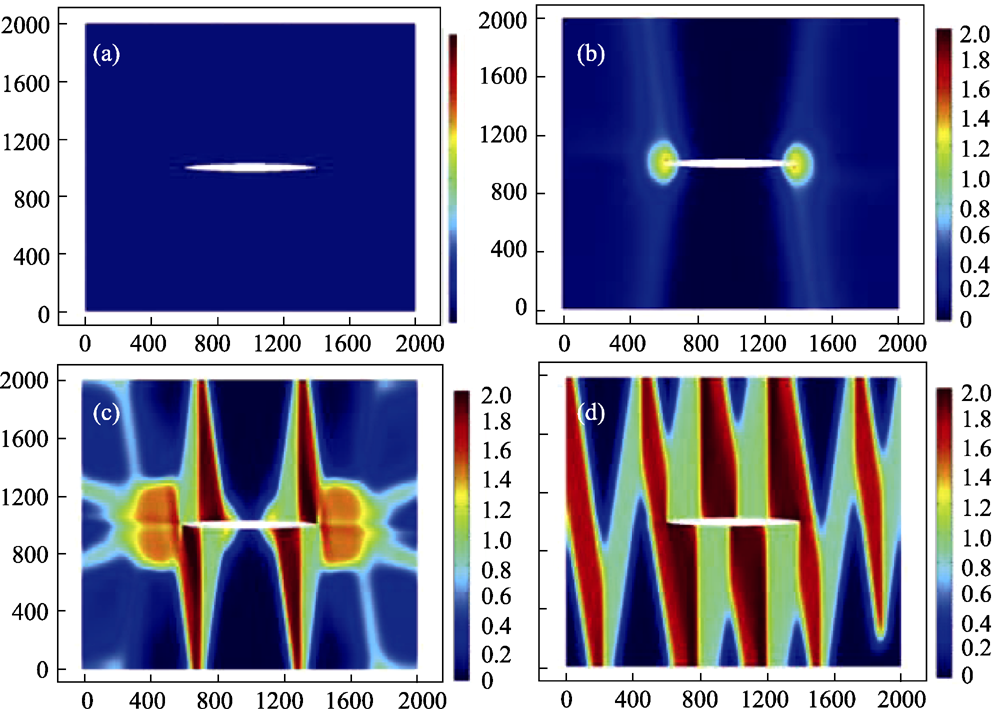

图1 应力诱导t→m相变过程[6]

Fig. 1 Nucleation and evolution of monoclinic phase in a cracked tetragonal single crystal under tension stress[6](a)-(d): Correspond to time 0, 1.4 μs, 1.6 μs, 2.5 μs, respectively

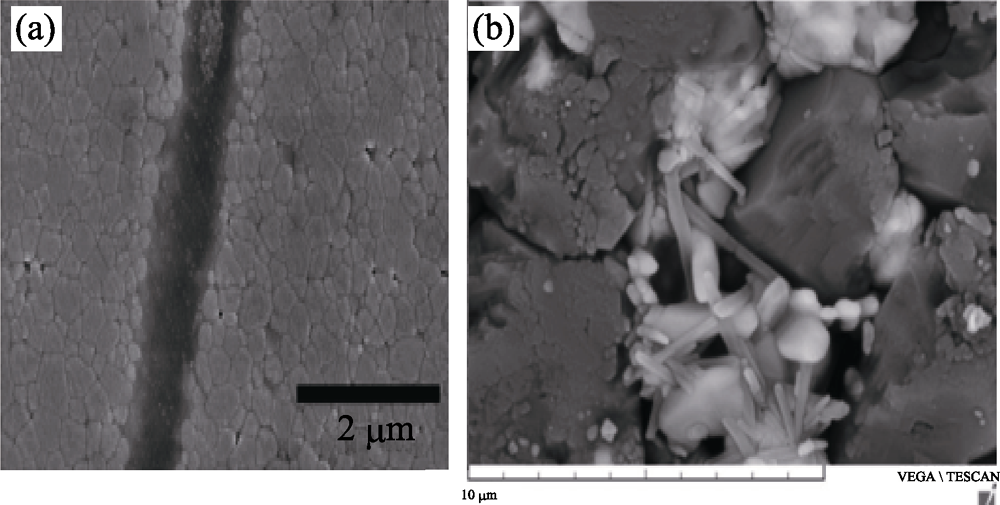

图5 (a)SiC晶须增韧ZrO2表面形貌[24]和(b)Mullite晶须增韧ZTA表面形貌[25]

Fig. 5 Morphologies of whisker reinforced zirconia ceramics (a) SiCw/ZrO2[24] and (b) Mullitew/ZTA[25]

| Ref. | Preparation method | Preparation conditions | Grain size/nm |

|---|---|---|---|

| [37] | Co-precipitation | Sintering condition: 1173 K for10 min | 3.3 |

| [38] | Vapor-phase hydrolysis | Precursor solution: ZrCl4: H2O=1:40 | 15.0 |

| [39] | Detonation synthesis | Hot pressure moulding | 24.0 |

表1 不同方法制备3Y-TZP得到的晶粒尺寸

Table 1 Grain size of 3Y-TZP prepared by different methods

| Ref. | Preparation method | Preparation conditions | Grain size/nm |

|---|---|---|---|

| [37] | Co-precipitation | Sintering condition: 1173 K for10 min | 3.3 |

| [38] | Vapor-phase hydrolysis | Precursor solution: ZrCl4: H2O=1:40 | 15.0 |

| [39] | Detonation synthesis | Hot pressure moulding | 24.0 |

| Crystal phase | Strength/MPa | Genre |

|---|---|---|

| Al2O3 | 594±52 | In-Ceram Al2O3 |

| Spinel | 378±65 | In-Ceram Spinel |

| 12Ce-TZP-Al2O3 | 630±58 | In-Ceram 12Ce-TZP-Al2O3 |

表2 不同类型In-Ceram陶瓷强度对比[45]

Table 2 Strength comparison of different genres of In-Ceram ceramics[45]

| Crystal phase | Strength/MPa | Genre |

|---|---|---|

| Al2O3 | 594±52 | In-Ceram Al2O3 |

| Spinel | 378±65 | In-Ceram Spinel |

| 12Ce-TZP-Al2O3 | 630±58 | In-Ceram 12Ce-TZP-Al2O3 |

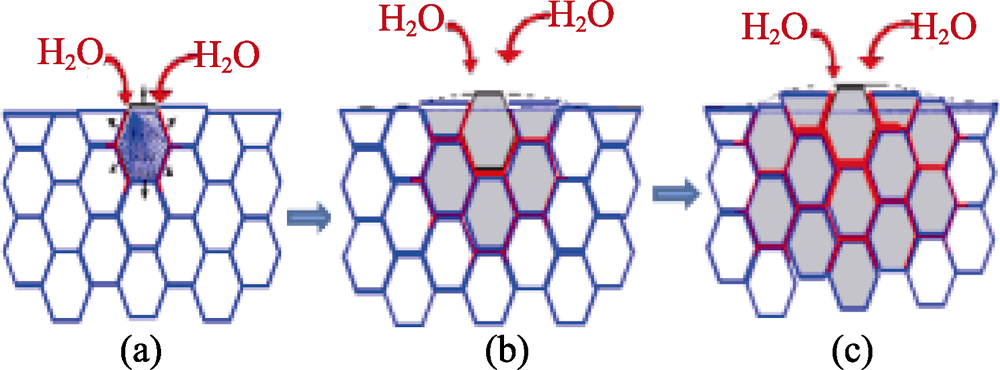

图10 氧化锆在水中的老化过程[55]

Fig. 10 Scheme of the aging process[55](a) Nucleation on a particular grain at the surface, leading to microcracking and stresses to the neighbors; (b) Growth of the transformed zone, leading to surface roughening; (c) Further development of transformation

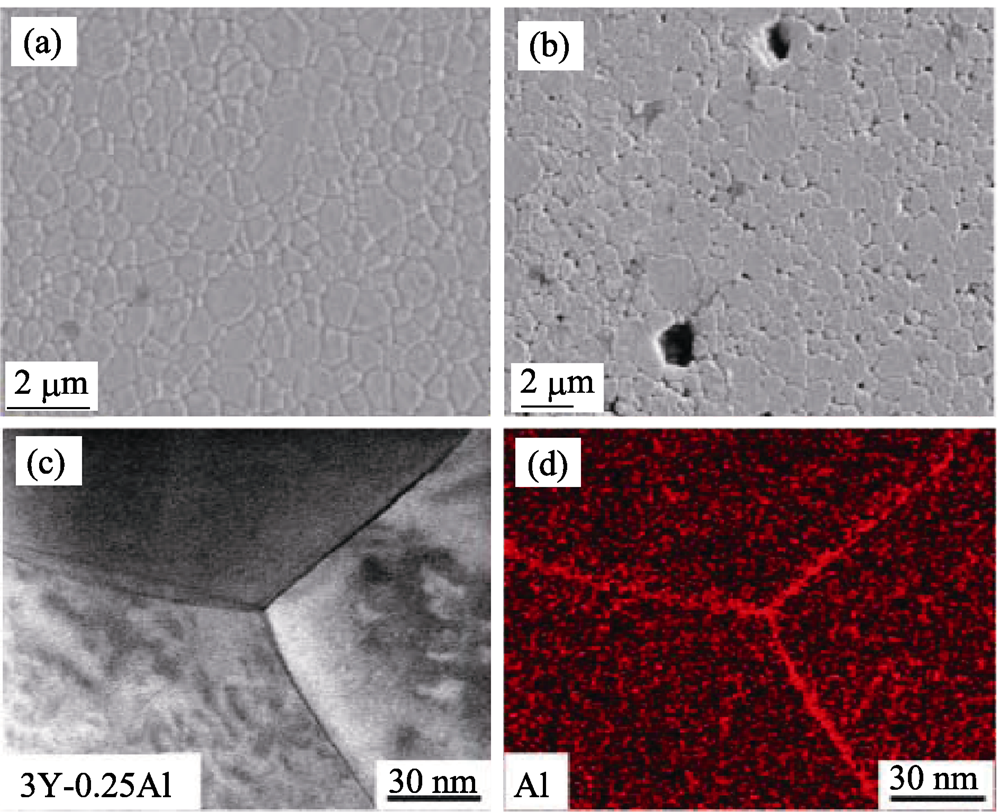

图11 Y-TZP老化(a)前(b)后表面形貌[56], (c)3Y-0.25Al晶界图, (d)3Y-0.25Al中Al元素的分布[59]

Fig. 11 Topographies of Y-TZP before (a) and after (b) aging[56], STEM images of 3Y-0.25Al grain boundaries (c) and corresponding Al-distribution map (d)[59]

| Ceramics | Hardness/GPa | KIC/(MPa·m1/2) |

|---|---|---|

| ATZ | 21±1.2 | 4.2±0.1 |

| ATZ with LTD | 12±1.5 | 3.7±0.2 |

| 3Y-TZP | 25±0.8 | 5.1±0.2 |

| 3Y-TZP with LTD | 15±1.5 | 4.1±0.3 |

| 8Y-CSZ | 31.3±0.2 | 3.77±0.02 |

| 8Y-CSZ with LTD | 31.2±0.3 | 3.78±0.03 |

表3 纳米压痕法评估陶瓷样品的力学性能[60]

Table 3 Mechanical properties of the ceramics samples evaluated by nanoindentation[60]

| Ceramics | Hardness/GPa | KIC/(MPa·m1/2) |

|---|---|---|

| ATZ | 21±1.2 | 4.2±0.1 |

| ATZ with LTD | 12±1.5 | 3.7±0.2 |

| 3Y-TZP | 25±0.8 | 5.1±0.2 |

| 3Y-TZP with LTD | 15±1.5 | 4.1±0.3 |

| 8Y-CSZ | 31.3±0.2 | 3.77±0.02 |

| 8Y-CSZ with LTD | 31.2±0.3 | 3.78±0.03 |

| [1] | SOON G, PINGGUAN-MURPHY B, LAI K W,et al. Review of zirconia-based bioceramic: surface modification and cellular response. Ceramics International, 2016, 42(11): 12543-12555. |

| [2] | FERNANDEZ-GARCIA E, CHEN X, GUTIERREZ-GONZALEZ C F,et al. Peptide-functionalized zirconia and new zirconia/titanium biocermets for dental applications. Journal of Dentistry, 2015, 43(9): 1162-1174. |

| [3] | GARVIE R C, HANNINK R H, PASCOE R T.Ceramic steel?Nature, 1975, 258(5537): 703-704. |

| [4] | DENRY I, KELLY J R.Emerging ceramic-based materials for dentistry.Journal of Dental Research, 2014, 93(12): 1235-1242. |

| [5] | GARVIE R C, NICHOLSON P S.Phase analysis in zirconia systems.Journal of the American Ceramic Society, 2010, 55(6): 303-305. |

| [6] | MAMIVAND M, ZAEEM M A, EL KADIRI H.Phase field modeling of stress-induced tetragonal to monoclinic transformation in zirconia and its effect on transformation toughening.Acta Materialia, 2014, 64: 208-219. |

| [7] | WANG J, STEVENS R.Zirconia toughened alumina (ZTA) ceramics.Journal of Materials Science, 1989, 24(10): 3421-3440. |

| [8] | MANICONE P F, IOMMETTI P R, RAAFFAELLI L.An overview of zirconia ceramics: basic properties and clinical applications.Journal of Dentistry, 2007, 35(11): 819-826. |

| [9] | TORRICELLI P, VERNE E, BROVARONE C V,et al. Biological glass coating on ceramic materials: in vitro evaluation using primary osteoblast cultures from healthy and osteopenic rat bone. Biomaterials, 2001, 22(18): 2535-2543. |

| [10] | TAN JIAN-GUO, ZHOU YONG-SHENG.Dental ceramic materials.Journal of Practical Department of Stomatology, 2009(7): 395-397. |

| [11] | HAN J, ZHAO J, SHEN Z.Zirconia ceramics in metal free implant dentistry.Advances in Applied Ceramics, 2017, 116(3): 138-150. |

| [12] | DAUD M H M, ZENN Y H, ZAMAN J Q,et al. Evaluation of shear bond strength of a novel nano-zirconia and veneering ceramics. Ceramics International, 2017, 43(1): 1272-1277. |

| [13] | MONTAZERIAN M, ZANOTTO E D.Bioactive and inert dental glass-ceramics. Journal of Biomedical Materials Research Part A, 2017, 105(2): 619-639. |

| [14] | DEVILLE S, CHEVALIERR J, GREMILLARD L.Influence of surface finish and residual stresses on the ageing sensitivity of biomedical grade zirconia.Biomaterials, 2006, 27(10): 2186-2192. |

| [15] | LAWSON S.Environmental degradation of zirconia ceramics.Journal of the European Ceramic Society, 1995, 15(6): 485-502. |

| [16] | PALMERO P, FORNABAIO M, MONTANARO L,et al. Towards long lasting zirconia-based composites for dental implants. Part I: Innovative synthesis, microstructural characterization and in vitro stability. Biomaterials, 2015, 50: 38-46. |

| [17] | EVANS A G, HEUER A H.Review-transformation toughening in ceramics: martensitic transformations in crack-tip stress fields.Journal of the American Ceramic Society, 1980, 63(5/6): 241-248. |

| [18] | HANNINK R H J, KELLY P M, MUDDLE B C. Transformation toughening in zirconia-containing ceramics.Journal of the American Ceramic Society, 2000, 83(3): 461-487. |

| [19] | KELLY J R, DENRY I.Stabilized zirconia as a structural ceramic: an overview.Dental Materials Official Publication of the Academy of Dental Materials, 2008, 24(3): 289-298. |

| [20] | MCMEEKING R M, EVANS A G.Mechanics of transformation- toughening in brittle materials.Journal of the American Ceramic Society, 1982, 65(5): 242-246. |

| [21] | AMAZIGO J C, BUDIANSKY B.Steady state crack growth in supercritically transforming materials.International Journal of Solids and Structures, 1988, 24(7): 751-755. |

| [22] | ZHAO T, ZHU J, LUO J.Study of crack propagation behavior insingle crystalline tetragonal zirconia with the phase field method.Engineering Fracture Mechanics, 2016, 159: 155-173. |

| [23] | SMIRNOV A, BELTRAN J I, RODRIGUEZ S T,et al. Unprecedented simultaneous enhancement in damage tolerance and fatigue resistance of zirconia/Ta composites. Scientific Reports, 2017, 7: 44922. |

| [24] | LIU D, GAO Y, LIU J,et al. SiC whisker reinforced ZrO2 composites prepared by flash-sintering. Journal of the European Ceramic Society, 2016, 36(8): 2051-2055. |

| [25] | ROBERTSON T, HUANG X, KEARSEY R.High temperature performance of mullite whisker-reinforced ZTA. Journal of Composite Materials, 2016, 50(26): 3719-3729. |

| [26] | PECHARROMáN C, BELTRAN J I, ESTEBAN-BETEGON F,et al. Zirconia/nickel interface sinmicro-annano composites. Zeitschrift für Metallkunde, 2005, 96(5): 507-514. |

| [27] | ZHANG LI-TONG, CHENG LAI-FEI.Discussion on strategy of sustainable development of ceramic matrix composites reinforced by continuous fiber.Journal of Composite Materials, 2007, 24(2): 1-6. |

| [28] | DUSZA J, BLUGAN G, MORGIEL J,et al. Hot pressed and spark plasma sintered zirconia/carbon nanofiber composites. Journal of the European Ceramic Society, 2009, 29(15): 3177-3184. |

| [29] | 黄红燕. 牙科纳米氧化锆氧化铝(Al2O3/ZrO2)复合陶瓷的基础研究. 北京: 中国医科大学博士学位论文, 2009. |

| [30] | NETTLESHIP I, STEVENS R.Tetragonal zirconia polycrystal (TZP)-a review.International Journal of High Technology Ceramics, 1987, 3(1): 1-32. |

| [31] | PJETURSSON B E, SAILER I, MAKAROV N A,et al. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses(FDPs)? a systematic review of the survival and complication rates. Part II: Multiple-unit FDPs. Dental Material, 2015, 31(6): 624-639. |

| [32] | LE COADOU C, KARST N, EMIEUX F,et al. Assessment of ultrathin yttria-stabilized zirconia foils forbiomedical applications. Journal Material Science, 2015, 50(18): 6197-6207. |

| [33] | BELLI R, GEINZER E, MUSCHWECK A,et al. Mechanical fatigue degradation of ceramics versus resin composites for dental restorations. Dental Material, 2014, 30(4): 424-432. |

| [34] | PICONI C, MACCAURO G.Review: zirconia as a ceramic biomaterial. Biomaterials, 1999, 20(1): 1-25. |

| [35] | ZHANG F, VANMEENSEL K, INOKOSHI M,et al. 3Y-TZP ceramics with improved hydrothermal degradation resistance and fracture toughness. Journal of the European Ceramic Society, 2014, 34(10): 2453-2463. |

| [36] | AMARAL M, VALANDRO L F.Low-temperature degradation of a Y-TZP ceramic after surface treatments.Society for Biomaterial, 2013, 101(8): 1387-1392. |

| [37] | HUANG H J, WANG M C.The phase formation and stability of tetragonal ZrO2 prepared in a silica bath.Ceramics International, 2013, 39(2): 1729-1739. |

| [38] | WANG Q, LI C, GUO M,et al. Controllable synthesis of zirconia nano-powders using vapor-phasehy drolysis and the oretical analysis. Journal of Materials Chemistry A, 2014, 2(5): 1346-1352. |

| [39] | KERN F, LINDNER V, GADOW R J CERAM. Low temperature degradation behaviour and mechanical properties of a 3Y-TZP manufactured from detonation synthesized powder.Journal of Ceramic Science and Technology, 2016, 7(4): 313-321. |

| [40] | CHINTAPALLI R K, MESTRA R A, GARCIA M F,et al. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. Journal of the Mechanical Behavior of Biomedical Materials, 2014, 29: 126-137. |

| [41] | MUñOZ-TABARES J A, ANGLADA M. Hydrothermal degradation of ground 3Y-TZP.Journal of the European Ceramic Society, 2012, 32(2): 325-333. |

| [42] | INOKOSHI M, ZHANG F, VANMEENSEL K,et al. Residual compressive surface stress increases the bending strength of dental zirconia. Dental Materials, 2017. 33(4): 147-154. |

| [43] | AMARAL M, CESAR P F, BOTTINO M A,et al. Fatigue behavior of Y-TZP ceramic after surface treatments. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 57: 149-156. |

| [44] | EL-GHANY O S A, SHERIEF A H. Zirconia based ceramics, some clinical and biological aspects: review.Future Dental Journal, 2016, 2(2): 55-64. |

| [45] | DENRY I, HOLLOWAY J A.Ceramics for dental applications: a review.Materials, 2010, 3(1): 351-368. |

| [46] | CHAAR M S, PASSIA N, KERN M.Ten-year clinical outcome of three-unit posterior FDPs made from a glass-infiltrated zirconia reinforced alumina ceramic (In-Ceram Zirconia).Journal of Dentistry, 2015, 43(5): 512-517. |

| [47] | ROY M E, WHITESIDE L A, KATERBERG B J,et al. Phase transformation, roughness, and microhardness oartificially aged yttria-and magnesia-stabilized zirconia femoral heads. International Science, 2007, 83(4): 1096-1102. |

| [48] | GARVIE R C, URBANI C, KENNEDY D R,et al. Biocompatibility of magnesia-partially stabilized zirconia (Mg-PSZ) ceramics. Journal of Materials Science, 1984, 19(10): 3224-3228. |

| [49] | DURET F, BLOUIN J L, DURET B.CAD-CAM in dentistry.Journal American Dental Association, 1988, 117(6): 715-720. |

| [50] | CARVALHO A O, BRUZI G, GIANNINI M,et al. Fatigue resistance of CAD/CAM complete crowns with a simplified cementation process. The Journal of Prosthetic Dentistry, 2014, 111(4): 310-317. |

| [51] | GUAZZATO M, ALBAKRY M, RINGER S P,et al. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dental Materials, 2004, 20(5): 449-456. |

| [52] | ZHENG K, Li Z, LIAO W,et al. Friction and wear performance on ultrasonic vibration assisted grinding dental zirconia ceramics against natural tooth. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 39(3): 833-843. |

| [53] | ZARONE F, RUSSO S, SORRENTINO R.From porcelain fused to metal to zirconia: clinical and experimental considerations.Dental Material, 2011, 27(1): 83-96. |

| [54] | KOBAYASHI K, KUWAJIMA H, MASAKI T.Phase change and mechanical properties of ZrO2-Y2O3 solid electrolyte after ageing.Solid State Ionics, 1981, 3(4): 489-493. |

| [55] | CHEVALIER J.What future for zirconia as a biomaterial?Biomaterials, 2006, 27(4): 535-543. |

| [56] | HALLMANN L, ULMER P, REUSSER E,et al. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. Journal of the European Ceramic Society, 2012, 32(16): 4091-4104. |

| [57] | INOKOSHI M, ZHANG F, DE MUNCK J,et al. Influence of sintering conditions on low-temperature degradation of dental zirconia. Dental Materials, 2014, 30(6): 669-678. |

| [58] | COTIC J, JEVNIKAR P, KOCJAN A,et al. Complexity of the relationships between the sintering-temperature-dependent grain size, airborne-particle abrasion, ageing and strength of 3Y-TZP ceramics. Dental Materials, 2016, 32(4): 510-518. |

| [59] | ZHANG F, VANMEENSEL K, INOKOSHI M,et al. Critical influence of alumina content on the low temperature degradation of 2-3mol% yttria-stabilized TZP for dental restorations. Journal of the European Ceramic Society, 2015, 35(2): 741-750. |

| [60] | ARAGON-DUARTE M C, NEVAREZ-RASCóN A, ESPARZA- PONCE H E,et al. Nanomechanical properties of zirconia-yttria and alumina zirconia-yttria biomedical ceramics, subjected to low temperature aging. Ceramics International, 2017, 43(5): 3931-3939. |

| [61] | HUAN C T, XIA J F, JIANG D Y, et al. Aging properties of yttria- stabilized zirconia ceramics.Key Engineering Materials, 2012, 512-515: 435-438. |

| [62] | MOHAMED E, TAHERI M, MEHRJOO M,et al. In vitro biocompatibility and ageing of 3Y-TZP/CNTs composites.Ceramics International, 2015, 41(10): 12773-12781. |

| [63] | KIM J W, COVEL N S, GUESS P C,et al. Concerns of hydrothermal degradation in CAD/CAM zirconia. Journal of Dental Research, 2010, 89(1): 91-95. |

| [64] | HÜBSCH C, DELLINGER P, MAIER H J,et al. Protection of yttria- stabilized zirconia for dental applications by oxidic PVD coating. Acta Biomaterialia, 2015, 11(1): 488-493. |

| [65] | TRUBY R L, LEWIS J A.Printing soft matter in three dimensions.Nature, 2016, 540(7633): 371-378. |

| [66] | ZHU D B, XU A P, QU Y X,et al. Functionalized bio-artifact fabricated via selective slurry extrusion. Part 1: Preparation of slurry containing tourmaline superfine powders. Journal of Nanoscience and Nanotechnology, 2011, 11(12): 10891-10895. |

| [67] | ZHU D B, LIANG J P, QU Y X,et al. Functionalized bio-artifact fabricated via selective slurry extrusion. Part 2: Fabrication of ceramic dental crown. Journal of Nanoscience and Nanotechnology, 2014, 14(5): 3703-3706. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||