Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (12): 1367-1376.DOI: 10.15541/jim20240273

Special Issue: 【结构材料】陶瓷基复合材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

YOU Bojie1( ), LI Bo1,2, LI Xuqin3, MA Xuehan1, ZHANG Yi1(

), LI Bo1,2, LI Xuqin3, MA Xuehan1, ZHANG Yi1( ), CHENG Laifei1

), CHENG Laifei1

Received:2024-06-04

Revised:2024-08-08

Published:2024-08-19

Online:2024-08-19

Contact:

ZHANG Yi, associate professor. E-mail: zhangyit@nwpu.edu.cnAbout author:YOU Bojie (2001-), male, Master candidate. E-mail: youbojie@mail.nwpu.edu.cn

Supported by:CLC Number:

YOU Bojie, LI Bo, LI Xuqin, MA Xuehan, ZHANG Yi, CHENG Laifei. Thermal Shock Damage and In-plane Shear Performance Degradation of 2D SiCf/SiC at Medium Temperature[J]. Journal of Inorganic Materials, 2024, 39(12): 1367-1376.

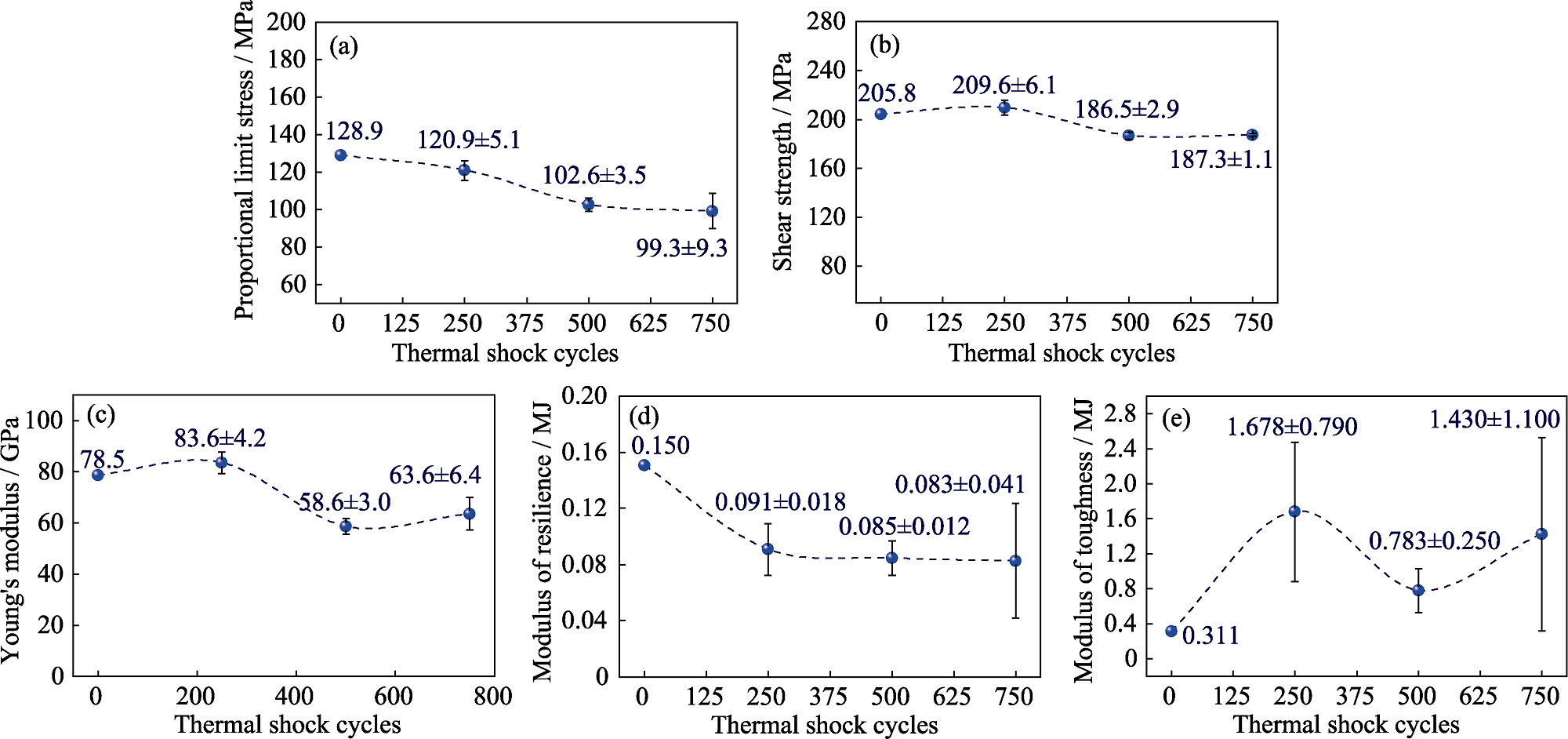

Fig. 3 In-plane shear properties of 2D SiCf/SiC (a) Proportional limit stress; (b) Shear strength; (c) Young’s modulus; (d) Modulus of resilience; (e) Modulus of toughness

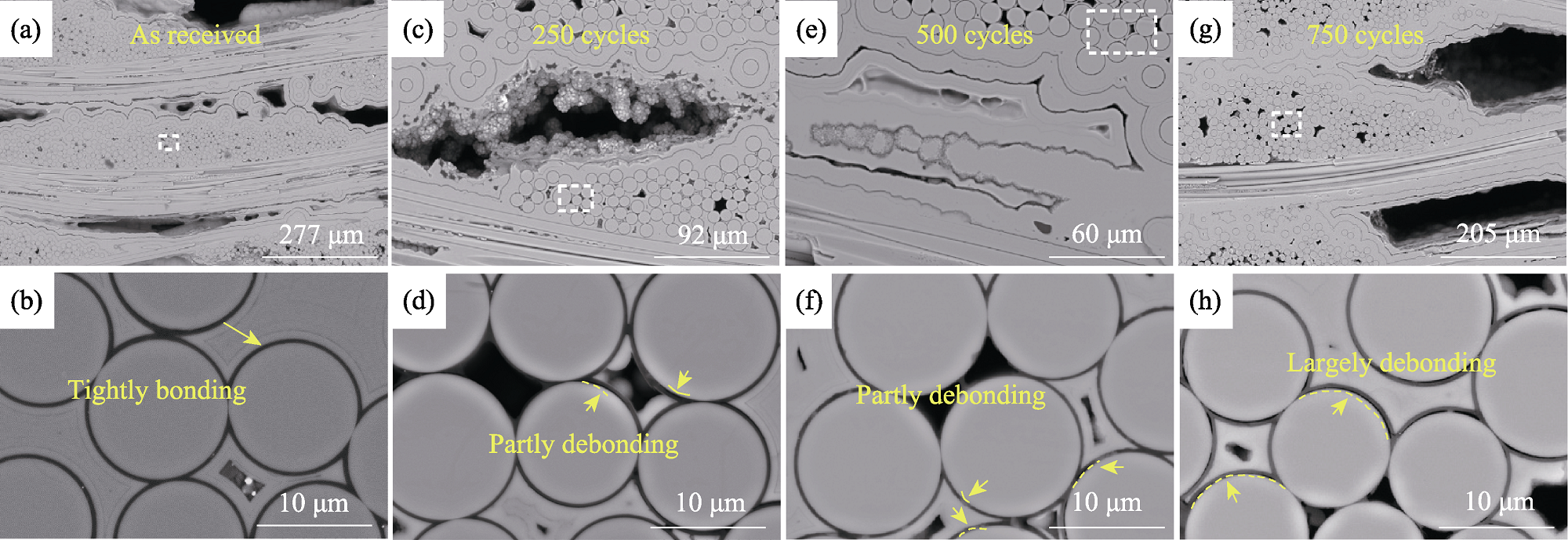

Fig. 6 Cross-sectional microstructure evolution of 2D SiCf/SiC (a, b) As-received; (c, d) After 250 cycles; (e, f) After 500 cycles; (g, h) After 750 cycles

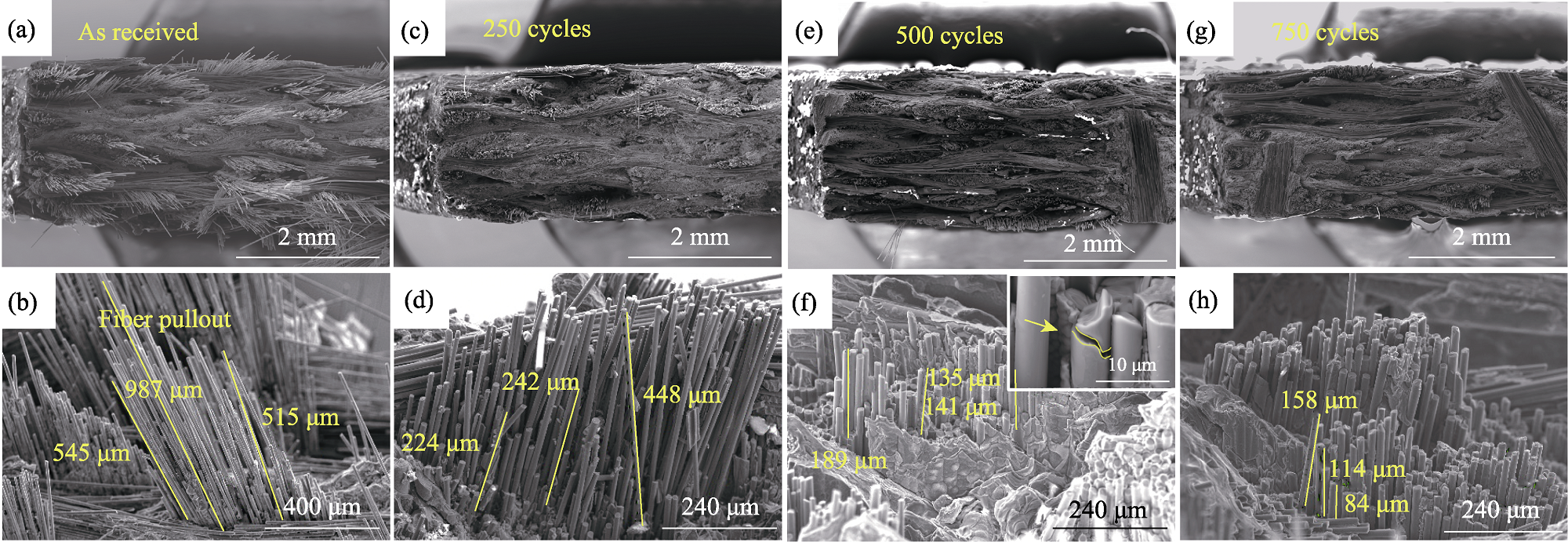

Fig. 7 Debonding and step spacing evolution at 2D SiCf/SiC shear interface (a, b) As-received; (c, d) After 250 cycles; (e, f) After 500 cycles; (g, h) After 750 cycles

Fig. 8 Fracture microstructure morphologies of 2D SiCf/SiC (a, b) As-received; (c, d) After 250 cycles; (e, f) After 500 cycles; (g, h) After 750 cycles

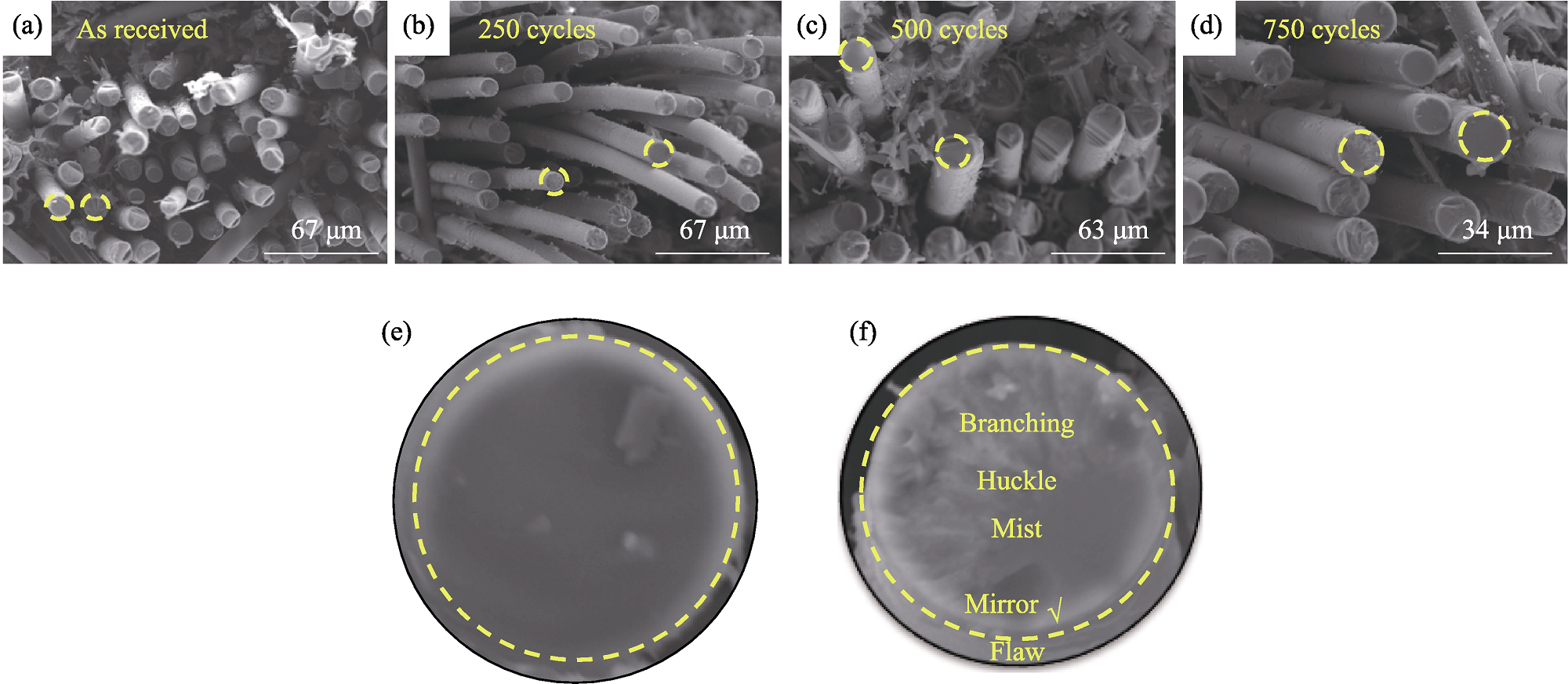

Fig. 9 Fracture morphologies of 2D SiCf/SiC fibers (a) As-received; (b) After 250 cycles; (c) After 500 cycles; (d) After 750 cycles; (e) Brittle fracture; (f) Toughness fracture

| Parameter | Symbol | Value |

|---|---|---|

| Poisson’s ration of SiC fiber | vf | 0.20 |

| Poisson’s ration of SiC matrix | vm | 0.17 |

| Fiber volume fraction | Vf/% | 0.35 |

| Matrix cracking energy | ${{\Gamma }_{\text{m}}}~$/(N·m-1) | 6.0 |

| Interface sliding stress | ${{\tau }_{\text{s}}}$/MPa | 9.2 |

| Thickness of plain woven layer | ${{t}_{\text{layer}}}$/mm | 0.2 |

| SiC fiber diameter | ${{d}_{\text{f}}}$/μm | 12.0 |

| SiC fiber modulus | ${{E}_{\text{f}}}$/GPa | 386.7 |

| SiC matrix modulus | ${{E}_{\text{m}}}$/GPa | 350.0 |

| SiC fiber shear modulus | ${{G}_{\text{f}}}/$GPa | 161.1 |

| SiC matrix shear modulus | ${{G}_{\text{m}}}$/GPa | 149.6 |

| BN interface shear modulus | ${{G}_{\text{I}}}$/GPa | 110.0 |

Table 1 Parameter value statistics

| Parameter | Symbol | Value |

|---|---|---|

| Poisson’s ration of SiC fiber | vf | 0.20 |

| Poisson’s ration of SiC matrix | vm | 0.17 |

| Fiber volume fraction | Vf/% | 0.35 |

| Matrix cracking energy | ${{\Gamma }_{\text{m}}}~$/(N·m-1) | 6.0 |

| Interface sliding stress | ${{\tau }_{\text{s}}}$/MPa | 9.2 |

| Thickness of plain woven layer | ${{t}_{\text{layer}}}$/mm | 0.2 |

| SiC fiber diameter | ${{d}_{\text{f}}}$/μm | 12.0 |

| SiC fiber modulus | ${{E}_{\text{f}}}$/GPa | 386.7 |

| SiC matrix modulus | ${{E}_{\text{m}}}$/GPa | 350.0 |

| SiC fiber shear modulus | ${{G}_{\text{f}}}/$GPa | 161.1 |

| SiC matrix shear modulus | ${{G}_{\text{m}}}$/GPa | 149.6 |

| BN interface shear modulus | ${{G}_{\text{I}}}$/GPa | 110.0 |

| Thermal shock cycles | Percentage of debonding/ % | Theoretical value/ GPa | Actual value/ GPa | Error/ % |

|---|---|---|---|---|

| 0 | 0 | 80.4 | 78.5 | -2.4 |

| 250 | 5.56 | 78.2 | 83.6 | 6.9 |

| 500 | 13.90 | 74.6 | 58.6 | -21.4 |

| 750 | 56.10 | 50.0 | 63.6 | 27.2 |

Table 2 Comparison of theoretical and actual values for shear modulus calculation

| Thermal shock cycles | Percentage of debonding/ % | Theoretical value/ GPa | Actual value/ GPa | Error/ % |

|---|---|---|---|---|

| 0 | 0 | 80.4 | 78.5 | -2.4 |

| 250 | 5.56 | 78.2 | 83.6 | 6.9 |

| 500 | 13.90 | 74.6 | 58.6 | -21.4 |

| 750 | 56.10 | 50.0 | 63.6 | 27.2 |

| Thermal shock cycles | Fiber step spacing/ mm | Theoretical value/ MPa | Actual value/ MPa | Error/ % |

|---|---|---|---|---|

| 0 | 79.0 | 178.6 | 205.8 | 15.2 |

| 250 | 97.5 | 193.4 | 209.6 | 8.4 |

| 500 | 49.0 | 162.6 | 186.5 | 14.7 |

| 750 | 67.3 | 170.8 | 187.3 | 9.7 |

Table 3 Comparison of theoretical and actual shear strength values

| Thermal shock cycles | Fiber step spacing/ mm | Theoretical value/ MPa | Actual value/ MPa | Error/ % |

|---|---|---|---|---|

| 0 | 79.0 | 178.6 | 205.8 | 15.2 |

| 250 | 97.5 | 193.4 | 209.6 | 8.4 |

| 500 | 49.0 | 162.6 | 186.5 | 14.7 |

| 750 | 67.3 | 170.8 | 187.3 | 9.7 |

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8):804.

DOI PMID |

| [2] | NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004, 64(2):155. |

| [3] | WANG X, GAO X, ZHANG Z, et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. Journal of the European Ceramic Society, 2021, 41(9):4671. |

| [4] | LIU B, LI F, LIU Y, et al. Experimental and numerical studies on low-velocity impact of laminated C/SiC structures. Composite Structures, 2024, 329: 117765. |

| [5] | LIU B, HAN Y, LI F, et al. High-velocity impact damage by projectile and tension after impact behavior at 1300 ℃ for SiC/SiC with environment barrier coating. Engineering Fracture Mechanics, 2024, 296: 109858. |

| [6] | WANG H, SINGH R N. Thermal shock behaviour of ceramics and ceramic composites. International Materials Reviews, 2013, 39(6):228. |

| [7] | WU S, CHENG L, ZHANG L, et al. Thermal shock damage of a 3D-SiC/SiC composite. Advanced Engineering Materials, 2005, 7(11):1046. |

| [8] | BHATT R T, SOLA-LOPEZ F, HALBIG M C, et al. Thermal stability of CVI and MI SiC/SiC composites with Hi-Nicalon™-S fibers. Journal of the European Ceramic Society, 2022, 42(8):3383. |

| [9] | ZHANG C, WANG Y, LIU Y, et al. Thermal shock resistance of a two-dimensional silicon carbon fiber reinforced SiC matrix composite. Advanced Engineering Materials, 2013, 16(1):65. |

| [10] | LIU X, GUO X, XU Y, et al. Cyclic thermal shock damage behavior in CVI SiC/SiC high pressure turbine twin guide vanes. Materials, 2021, 14(20):6104. |

| [11] | 段宏宇, 王贺权, 张佳平, 等. 不同热震工况下2.5D编织陶瓷基复合材料力学性能及损伤. 复合材料学报, 2023, 40(7):4184. |

| [12] | 胡庆宽, 许琦鹏, 万志慧, 等. SiC/SiC复合编织管的抗热冲击性能与失效机理研究. 应用力学学报, 2024, 41(2):288. |

| [13] | GUO H, WANG B, JIA P, et al. In-plane shear behaviours of a 2D-SiC/SiC composite under various loading conditions. Ceramics International, 2015, 41(9):11562. |

| [14] | YAN K F, ZHANG C Y, QIAO S R, et al. Failure and strength of 2D-C/SiC composite under in-plane shear loading at elevated temperatures. Materials & Design, 2011, 32(6):3504. |

| [15] | 郭洪宝, 王波, 贾普荣, 等. 平纹编织陶瓷基复合材料面内剪切细观损伤行为研究. 力学学报, 2016, 48: 361. |

| [16] | 冯宇琦, 王龙, 李艳芬, 等. 平纹陶瓷基复合材料面内剪切解析模型. 中国科技论文, 2022, 17(4):361. |

| [17] | DUAN J, LI Y, LI F, et al. Corrosion behavior of LSI-based 3D needled C/SiC composites subjected to burner rig test. Corrosion Science, 2022, 197: 109982. |

| [18] | LI Y, XIAO P, LI Z, et al. Oxidation behavior of C/C composites with SiC/ZrSiO4-SiO2 coating. Transactions of Nonferrous Metals Society of China, 2017, 27(2):397. |

| [19] | WANG X, SONG Z, CHENG Z, et al. Tensile creep properties and damage mechanisms of 2D-SiCf/SiC composites reinforced with low-oxygen high-carbon type SiC fiber. Journal of the European Ceramic Society, 2020, 40(14):4872. |

| [20] | LI B, CHEN X, TIAN L, et al. In-situ formation of the BSG bubbles toward SiC/SiC composites protection mechanisms under thermal shock treatment. Journal of Materials Research and Technology, 2023, 26: 7097. |

| [21] | SUN G, ZHANG C, ZHANG Q, et al. Microstructure and mechanical properties of SiCf/SiC composite prepared by chemical vapor infiltration. Ceramics International, 2022, 48(24):36983. |

| [22] | HAY R S. Growth stress in SiO2 during oxidation of SiC fibers. Journal of Applied Physics, 2012, 111(6):063527. |

| [23] | WANG Y, ZHANG L, CHENG L, et al. Characterization of tensile behavior of a two-dimensional woven carbon/silicon carbide composite fabricated by chemical vapor infiltration. Materials Science and Engineering: A, 2008, 497(1/2):295. |

| [24] | MAZERAT S, EL-MORSLI J, SARRAZIN R, et al. Oxidation embrittlement of SiC fibers at intermediate temperatures. Journal of the European Ceramic Society, 2024, 44(7):4465. |

| [25] | ZHANG Y, ZHANG L, LIU Y, et al. Oxidation effects on in-plane and interlaminar shear strengths of two-dimensional carbon fiber reinforced silicon carbide composites. Carbon, 2016, 98: 144. |

| [26] | NANCE J, SUBHASH G, SANKAR B, et al. Measurement of residual stress in silicon carbide fibers of tubular composites using Raman spectroscopy. Acta Materialia, 2021, 217: 117164. |

| [27] | GAO X, LEI B, ZHANG Y, et al. Identification of microstructures and damages in silicon carbide ceramic matrix composites by deep learning. Materials Characterization, 2023, 196: 112608. |

| [28] | AVESTON J, KELLY A. Theory of multiple fracture of fibrous composites. Journal of Materials Science, 1973, 8: 352. |

| [29] | MA X, ZHAO L, ZHANG Y, et al. Uncertainty analysis and B-basis value of tensile strength of 2D SiC/SiC composite. Journal of Materials Research and Technology, 2023, 24: 7058. |

| [30] | PETERS P W M, MARTIN E, PLUVINAGE P. Influence of porosity and fibre coating on engineering elastic moduli of fibre-reinforced ceramics (SiC/SiC). Composites, 1995, 26(2):108. |

| [31] | BERTRAND S, FORIO P, PAILLER R, et al. Hi-nicalon/SiC minicomposites with (pyrocarbon/SiC)n nanoscale multilayered interphases. Journal of the American Ceramic Society, 2004, 82(9):2465. |

| [32] | RAJAN V P, ZOK F W. Matrix cracking of fiber-reinforced ceramic composites in shear. Journal of the Mechanics and Physics of Solids, 2014, 73: 3. |

| [33] | KEITH W P, KEDWARD K T. Shear damage mechanisms in a woven, nicalon-reinforced ceramic-matrix composite. Journal of the American Ceramic Society, 2005, 80(2):357. |

| [1] | LIU Huilai, LI Zhihao, KONG Defeng, CHEN Xing. Preparation of FePc/MXene Composite Cathode and Electro-Fenton Degradation of Sulfadimethoxine [J]. Journal of Inorganic Materials, 2025, 40(1): 61-69. |

| [2] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [3] | YE Maosen, WANG Yao, XU Bing, WANG Kangkang, ZHANG Shengnan, FENG Jianqing. II/Z-type Bi2MoO6/Ag2O/Bi2O3 Heterojunction for Photocatalytic Degradation of Tetracycline under Visible Light Irradiation [J]. Journal of Inorganic Materials, 2024, 39(3): 321-329. |

| [4] | CHEN Mengjie, WANG Qianqian, WU Chengtie, HUANG Jian. Predicting the Degradability of Bioceramics through a DFT-based Descriptor [J]. Journal of Inorganic Materials, 2024, 39(10): 1175-1181. |

| [5] | CAI Mengyu, LI-YANG Hongmiao, YANG Caiyun, ZHOU Yuting, WU Hao. Activated Sludge Incineration Ash Derived Fenton-like Catalyst: Preparation and Degradation Performance on Methylene Blue [J]. Journal of Inorganic Materials, 2024, 39(10): 1135-1142. |

| [6] | WANG Bo, CAI Delong, ZHU Qishuai, LI Daxin, YANG Zhihua, DUAN Xiaoming, LI Yanan, WANG Xuan, JIA Dechang, ZHOU Yu. Mechanical Properties and Thermal Shock Resistance of SrAl2Si2O8 Reinforced BN Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(10): 1182-1188. |

| [7] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [8] | WANG Lei, LI Jianjun, NING Jun, HU Tianyu, WANG Hongyang, ZHANG Zhanqun, WU Linxin. Enhanced Degradation of Methyl Orange with CoFe2O4@Zeolite Catalyst as Peroxymonosulfate Activator: Performance and Mechanism [J]. Journal of Inorganic Materials, 2023, 38(4): 469-476. |

| [9] | CHEN Ying, LUAN Weiling, CHEN Haofeng, ZHU Xuanchen. Multi-scale Failure Behavior of Cathode in Lithium-ion Batteries Based on Stress Field [J]. Journal of Inorganic Materials, 2022, 37(8): 918-924. |

| [10] | CHEN Shikun, WANG Chuchu, CHEN Ye, LI Li, PAN Lu, WEN Guilin. Magnetic Ag2S/Ag/CoFe1.95Sm0.05O4 Z-scheme Heterojunction: Preparation and Its Photocatalytic Degradation Property [J]. Journal of Inorganic Materials, 2022, 37(12): 1329-1336. |

| [11] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [12] | LI Tie, LI Yue, WANG Yingyi, ZHANG Ting. Preparation and Catalytic Properties of Graphene-Bismuth Ferrite Nanocrystal Nanocomposite [J]. Journal of Inorganic Materials, 2021, 36(7): 725-732. |

| [13] | AN Weijia, LI Jing, WANG Shuyao, HU Jinshan, LIN Zaiyuan, CUI Wenquan, LIU Li, XIE Jun, LIANG Yinghua. Fe(III)/rGO/Bi2MoO6 Composite Photocatalyst Preparation and Phenol Degradation by Photocatalytic Fenton Synergy [J]. Journal of Inorganic Materials, 2021, 36(6): 615-622. |

| [14] | XIONG Jinyan, LUO Qiang, ZHAO Kai, ZHANG Mengmeng, HAN Chao, CHENG Gang. Facilely Anchoring Cu nanoparticles on WO3 Nanocubes for Enhanced Photocatalysis through Efficient Interface Charge Transfer [J]. Journal of Inorganic Materials, 2021, 36(3): 325-331. |

| [15] | LAN Qing, SUN Shengrui, WU Ping, YANG Qingfeng, LIU Yangqiao. Co-doped CuO/Visible Light Synergistic Activation of PMS for Degradation of Rhodamine B and Its Mechanism [J]. Journal of Inorganic Materials, 2021, 36(11): 1171-1177. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||