Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (9): 953-960.DOI: 10.15541/jim20180536

• RESEARCH PAPER • Previous Articles Next Articles

LUO Qing1,YUAN Qing1,2( ),JIANG Qian-Qin1,YU Nai-Sen1

),JIANG Qian-Qin1,YU Nai-Sen1

Received:2018-11-19

Revised:2019-03-04

Published:2019-09-20

Online:2019-05-13

Supported by:CLC Number:

LUO Qing,YUAN Qing,JIANG Qian-Qin,YU Nai-Sen. Cu-SSZ-13/SiC-waste Composite: Synthesis and Application for NH3-SCR[J]. Journal of Inorganic Materials, 2019, 34(9): 953-960.

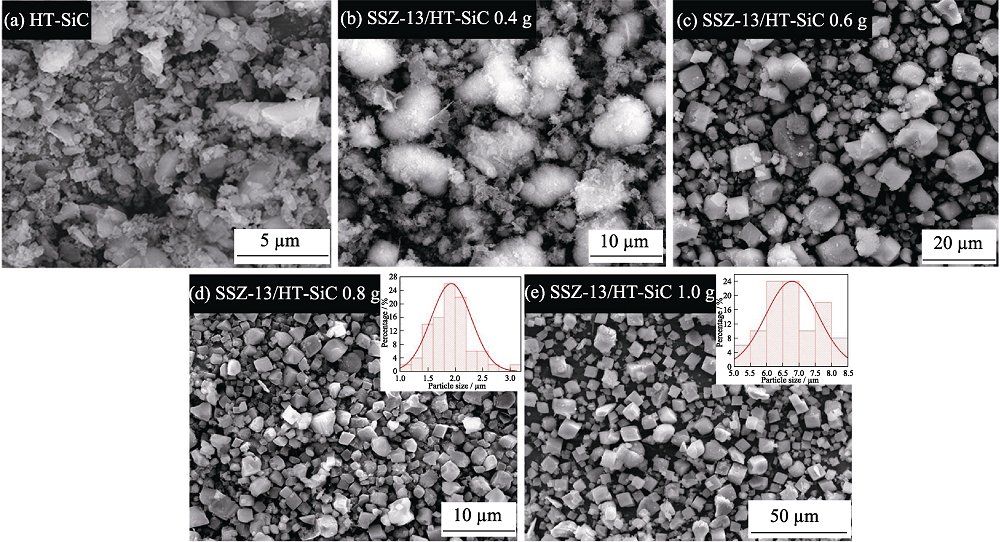

Fig. 2 SEM images of HT-SiC and SSZ-13/HT-SiC composites synthesized by using TMAdaOH as template with insets showing corresponding partiesize distributions

| Sample | SBET/(m2·g-1) | Smic/(m2·g-1) | Sext/(m2·g-1) | Vt/(cm3·g-1)a | Vmic/(cm3·g-1)b |

|---|---|---|---|---|---|

| HT-SiC | 0.5 | 0.4 | 0.006 | - | - |

| SSZ-13 | 567.7 | 560.1 | 7.600 | 0.31 | 0.30 |

| SSZ-13/HT-SiC-0.4 g | 0.9 | 0.8 | 0.010 | - | - |

| SSZ-13/HT-SiC-0.6 g | 226.5 | 223.4 | 3.000 | 0.12 | 0.11 |

| SSZ-13/HT-SiC-0.8 g | 378.5 | 373.4 | 5.100 | 0.21 | 0.20 |

| SSZ-13/HT-SiC-1.0 g | 355.7 | 350.9 | 4.800 | 0.19 | 0.18 |

Table 1 Textural properties of HT-SiC support, SSZ-13 and SSZ-13/HT-SiC composites

| Sample | SBET/(m2·g-1) | Smic/(m2·g-1) | Sext/(m2·g-1) | Vt/(cm3·g-1)a | Vmic/(cm3·g-1)b |

|---|---|---|---|---|---|

| HT-SiC | 0.5 | 0.4 | 0.006 | - | - |

| SSZ-13 | 567.7 | 560.1 | 7.600 | 0.31 | 0.30 |

| SSZ-13/HT-SiC-0.4 g | 0.9 | 0.8 | 0.010 | - | - |

| SSZ-13/HT-SiC-0.6 g | 226.5 | 223.4 | 3.000 | 0.12 | 0.11 |

| SSZ-13/HT-SiC-0.8 g | 378.5 | 373.4 | 5.100 | 0.21 | 0.20 |

| SSZ-13/HT-SiC-1.0 g | 355.7 | 350.9 | 4.800 | 0.19 | 0.18 |

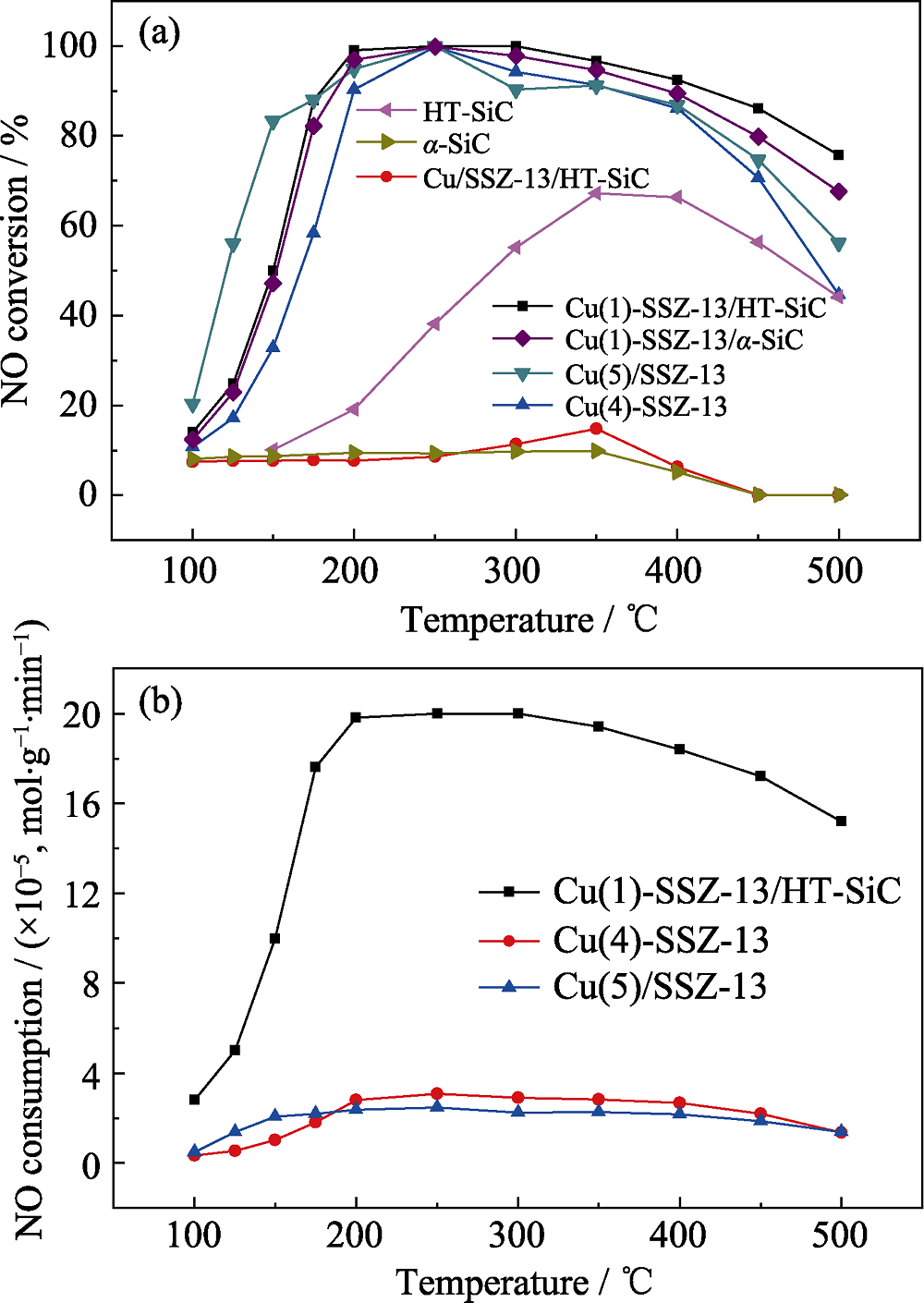

Fig. 6 (a) Denitrification activity of HT-SiC, Cu-SSZ-13 and Cu-SSZ-13/HT-SiC catalysts synthesized by using TMAdaOH or Cu-TEPA as template with different Cu contents; (b) The mole of NO consumed (molNO/(gCu·min)) by Cu(1)-SSZ-13/HT-SiC, Cu(4)-SSZ-13 and Cu(5)/SSZ-13 catalysts

| [1] | LIU H Y, MA X, LI B W ,et al. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends. Fuel, 2017,209:62-68. |

| [2] | ELSANUSI O A, ROY M M, SIDHU M S . Experimental investigation on a diesel engine fueled by diesel-biodiesel blends and their emulsions at various engine operating conditions. Appl. Energy, 2017,203:582-593. |

| [3] | LIU F D, YU Y B, HE H . Environmentally-benign catalysts for the selective catalytic reduction of Nox from diesel engines: structure- activity relationship and reaction mechanism aspects. Chem. Commun., 2014,50(62):8445-8463 |

| [4] | BEALE A M, GAO F, LEZCANO-GONZALEZ I ,et al. Recent advances in automotive catalysis for NOx emission control by small-pore microporous materials. Chem. Soc. Rev., 2015,44(20):7371-7405. |

| [5] | ANGGARA T, PAOLUCCI C, SCHNEIDER W F . Periodic DFT characterization of NOx adsorption in Cu-Exchanged SSZ-13 zeolite catalysts. J. Phys. Chem. C, 2016,120(49):27934-27943. |

| [6] | SHWAN S, JANSSON J, OLSSON L ,et al. Chemical deactivation of H-BEA and Fe-BEA as NH3-SCR catalysts—effect of potassium. Appl. Catal. B-Environ., 2015,166:277-286. |

| [7] | WANG H Y, WANG B D, SUN Q ,et al. New insights into the promotional effects of Cu and Fe over V2O5-WO3/TiO2 NH3-SCR catalysts towards oxidation of Hg0. Catal. Commun., 2017,100:169-172. |

| [8] | WANG J H, ZHAO H W, HALLER G ,et al. Recent advances in the selective catalytic reduction of NOx with NH3 on Cu-Chabazite catalysts. Appl. Catal. B-Environ., 2017,202:346-354. |

| [9] | FICKEL D W, D'ADDIO E, LAUTERBACH J A , et al. The ammonia selective catalytic reduction activity of copper-exchanged small-pore zeolites. Appl. Catal. B-Environ., 2011,102(3/4):441-448. |

| [10] | SZANYI J, KWAK J H, ZHU H Y ,et al. Characterization of Cu-SSZ-13 NH3 SCR catalysts: an in situ FT-IR study. Phys. Chem. Chem. Phys., 2013,15(7):2368-2380. |

| [11] | GUNTER T, PESEK J, SCHAFER K ,et al. Cu-SSZ-13 as pre-turbine NOx-removal-catalyst: impact of pressure and catalyst poisons. Appl. Catal. B-Environ., 2016,198:548-557. |

| [12] | MASIH D, ROHANI S, KONDO J N ,et al. Low-temperature methanol dehydration to dimethyl ether over various small-pore zeolites. Appl. Catal. B-Environ., 2017,217:247-255. |

| [13] | ZHENG Y H, HU N, WANG H M ,et al. Preparation of steam-stable high-silica CHA (SSZ-13) membranes for CO2/CH4 and C2H4/C2H6 separation. J. Membrane Sci., 2015,475:303-310. |

| [14] | OORD R, TEN HAVE I C, ARENDS J M , et al. Enhanced activity of desilicated Cu-SSZ-13 for the selective catalytic reduction of NOx and its comparison with steamed Cu-SSZ-13. Catal. Sci. Technol., 2017,7(17):3851-3862. |

| [15] | CHINTALA V, SUBRAMANIAN K A . Hydrogen energy share improvement along with NOx(oxides of nitrogen) emission reduction in a hydrogen dual-fuel compression ignition engine using water injection. Energy. Convers. Manage., 2014,83:249-259. |

| [16] | KAWAMURA T, HORI D, KANGAWA Y ,et al. Thermal conductivity of SiC calculated by molecular dynamics. Jpn. J. Appl. Phys., 2008,47(12):8898-8901. |

| [17] | ZHAO L, KONG L P, LIU C Z ,et al. AgCu/SiC-powder: a highly stable and active catalyst for gas-phase selective oxidation of alcohols. Catal. Commun., 2017,98:1-4. |

| [18] | WANG H, SCMACK R, PAUL B ,et al. Porous silicon carbide as a support for Mn/Na/W/SiC catalyst in the oxidative coupling of methane. Appl. Catal. A-Gen., 2017,537:33-39. |

| [19] | DUONG-VIET C, TRUONG-PHUOC L, TRAN-THANH T ,et al. Nitrogen-doped carbon nanotubes decorated silicon carbide as a metal-free catalyst for partial oxidation of H2S. Appl. Catal. A-Gen., 2014,482:397-406. |

| [20] | ZHOU T Y, YUAN Q, PAN X L ,et al. Growth of Cu/SSZ-13 on SiC for selective catalytic reduction of NO with NH3. Chinese J. Catal., 2018,39(1):71-78. |

| [21] | MARTIN N, VENNESTROM P N R, THOGERSEN J R , et al. Fe-containing zeolites for NH3-SCR of NOx: effect of structure, synthesis procedure, and chemical composition on catalytic performance and stability. Chem. -Eur. J., 2017,23(54):13404-13414. |

| [22] | REN Z Y, FAN H, WANG R . A novel ring-like Fe2O3-based catalyst: tungstophosphoric acid modification, NH3-SCR activity and tolerance to H2O and SO2. Catal. Commun., 2017,100:71-75. |

| [23] | SHISHKIN A, KANNISTO H, CARLSSON P A ,et al. Synthesis and functionalization of SSZ-13 as an NH3-SCR catalyst. Catal. Sci. Technol., 2014,4(11):3917-3926. |

| [24] | XU R N, ZHANG R D, LIU N ,et al. Template design and economical strategy for the synthesis of SSZ-13 (CHA-Type) zeolite as an excellent catalyst for the selective catalytic reduction of NOx by ammonia. ChemCatChem, 2015,7(23):3842-3847. |

| [25] | REN L M, ZHU L F, YANG C G , et al. Designed copper-amine complex as an efficient template for one-pot synthesis of Cu-SSZ-13 zeolitewith excellent activity for selective catalytic reduction of NOx by NH3. Chem. Commun., 2011,47(35):9789-9791. |

| [26] | XIE K P, WOO J, BERNIN D ,et al. Insights into hydrothermal aging of phosphorus-poisoned Cu-SSZ-13 for NH3-SCR. Appl. Catal. B-Environ., 2018,241:205-216. |

| [27] | WANG J, SHAO L, WANG C ,et al. Controllable preparation of various crystal size and nature of intra-crystalline diffusion in Cu/SSZ-13 NH3-SCR catalysts. J. Catal., 2018,367:221-228. |

| [28] | HAN L N, ZHAO X G, YU H F ,et al. Preparation of SSZ-13 zeolites and their NH3-selective catalytic reduction activity. Micropor. Mesopor. Mater., 2018,261:126-136. |

| [29] | TAKATA T, TSUNOJI N, TAKAMITSU Y ,et al. Nanosized CHA zeolites with high thermal and hydrothermal stability derived from the hydrothermal conversion of FAU zeolite. Micropor. Mesopor. Mater., 2016,225:524-533. |

| [30] | GE S B, GENG W C, HE X W ,et al. Effect of framework structure, pore size and surface modification on the adsorption performance of methylene blue and Cu2+ in mesoporous silica. Colloid Surface A, 2018,539:154-162. |

| [31] | GAO F, WASHTON N M, WANG Y L ,et al. Effects of Si/Al ratio on Cu/SSZ-13 NH3-SCR catalysts: implications for the active Cu species and the roles of Brønsted acidity. J. Catal., 2015,331:25-38. |

| [32] | OHLIN L, BEREZOVSKY V, OBERG S ,et al. Effect of water on the adsorption of methane and carbon dioxide in zeolite Na-ZSM-5 studied using in situ ATR-FT-IR spectroscopy. J. Phys. Chem. C, 2016,120(51):29144-29152. |

| [33] | GENG W C, GE S B, HE X W ,et al. Volatile organic compound gas-sensing properties of bimodal porous α-Fe2O3 with ultrahigh sensitivity and fast response. ACS Appl. Mater. Interfaces, 2018,10(16):13702-13711. |

| [34] | YU L M, ZHONG Q, ZHANG S L . Research of copper contained SAPO-34 zeolite for NH3-SCR DeNOx by solvent-free synthesis with Cu-TEPA. Micropor. Mesopor. Mater., 2016,234:303-309. |

| [35] | ZHANG T, CHANG H Z, YOU Y C ,et al. Excellent activity and selectivity of one-pot synthesized Cu SSZ-13 catalyst in the selective catalytic oxidation of ammonia to nitrogen. Environ. Sci. Technol., 2018,52(8):4802-4808. |

| [1] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [4] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [5] | YANG Shuqi, YANG Cunguo, NIU Huizhu, SHI Weiyi, SHU Kewei. GeP3/Ketjen Black Composite: Preparation via Ball Milling and Performance as Anode Material for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(3): 329-336. |

| [6] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [9] | LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism [J]. Journal of Inorganic Materials, 2025, 40(2): 205-214. |

| [10] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [11] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [12] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [13] | MA Binbin, ZHONG Wanling, HAN Jian, CHEN Liangyu, SUN Jingjing, LEI Caixia. ZIF-8/TiO2 Composite Mesocrystals: Preparation and Photocatalytic Activity [J]. Journal of Inorganic Materials, 2024, 39(8): 937-944. |

| [14] | HE Sizhe, WANG Junzhou, ZHANG Yong, FEI Jiawei, WU Aimin, CHEN Yifeng, LI Qiang, ZHOU Sheng, HUANG Hao. Fe/Submicron FeNi Soft Magnetic Composites with High Working Frequency and Low Loss [J]. Journal of Inorganic Materials, 2024, 39(8): 871-878. |

| [15] | WU Xiangquan, TENG Jiachen, JI Xiangxu, HAO Yubo, ZHANG Zhongming, XU Chunjie. Textured Porous Al2O3-SiO2 Composite Ceramic Platelet-sphere Slurry: Characteristics and Simulation of Light Intensity Distribution [J]. Journal of Inorganic Materials, 2024, 39(7): 769-778. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||