Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (1): 107-112.DOI: 10.15541/jim20150366

• Orginal Article • Previous Articles

CHEN Xue-Ning1, FAN Hong-Song1, WANG Hong-Jun2

Received:2015-08-11

Published:2015-10-30

Online:2015-12-15

About author:CHEN Xue-Ning(1982–), female, associate professor. E-mail: xchen6@scu.edu.cn

Supported by:CLC Number:

CHEN Xue-Ning, FAN Hong-Song, WANG Hong-Jun. Effect of Phase Composition of Calcium Phosphate (CaP) on Bioactivity of Osteon-like Composite Scaffolds[J]. Journal of Inorganic Materials, 2016, 31(1): 107-112.

Fig. 1 (a) Two-step fabrication process to create bi-layered scaffolds with (b-c) compact and (d-e) separate microfilaments. Methylene blue staining showed cell attachment in (f) compact, (g) separate, and (h) inner tube-free filaments

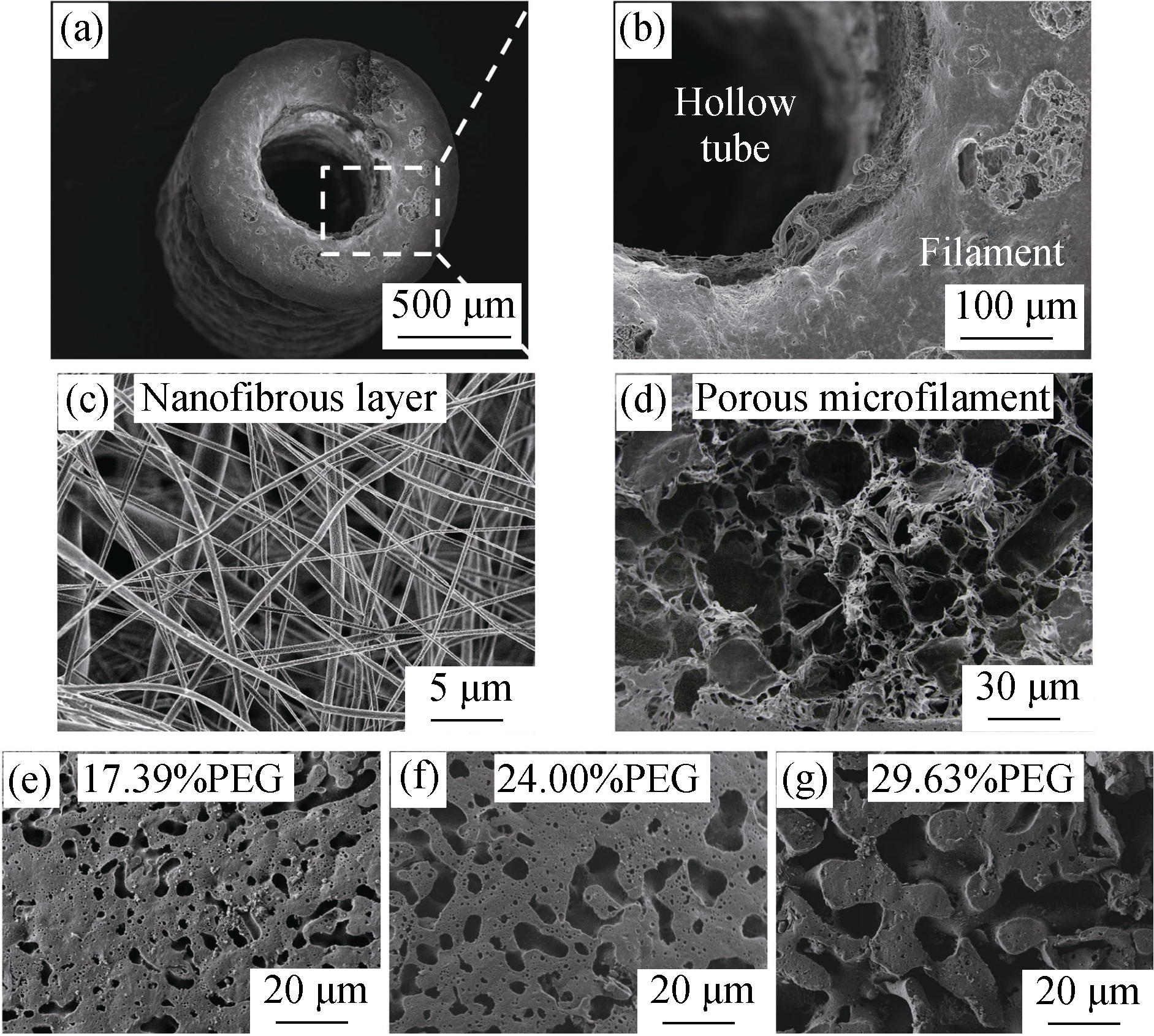

Fig. 2 SEM images of (a-b) cross-section of bi-layered scaffold, (c) nanofibrous layer of hollow tube, (d) porous structure inside the filament, and (e-g) surface structure of filament made of stock materials with different PEG amounts

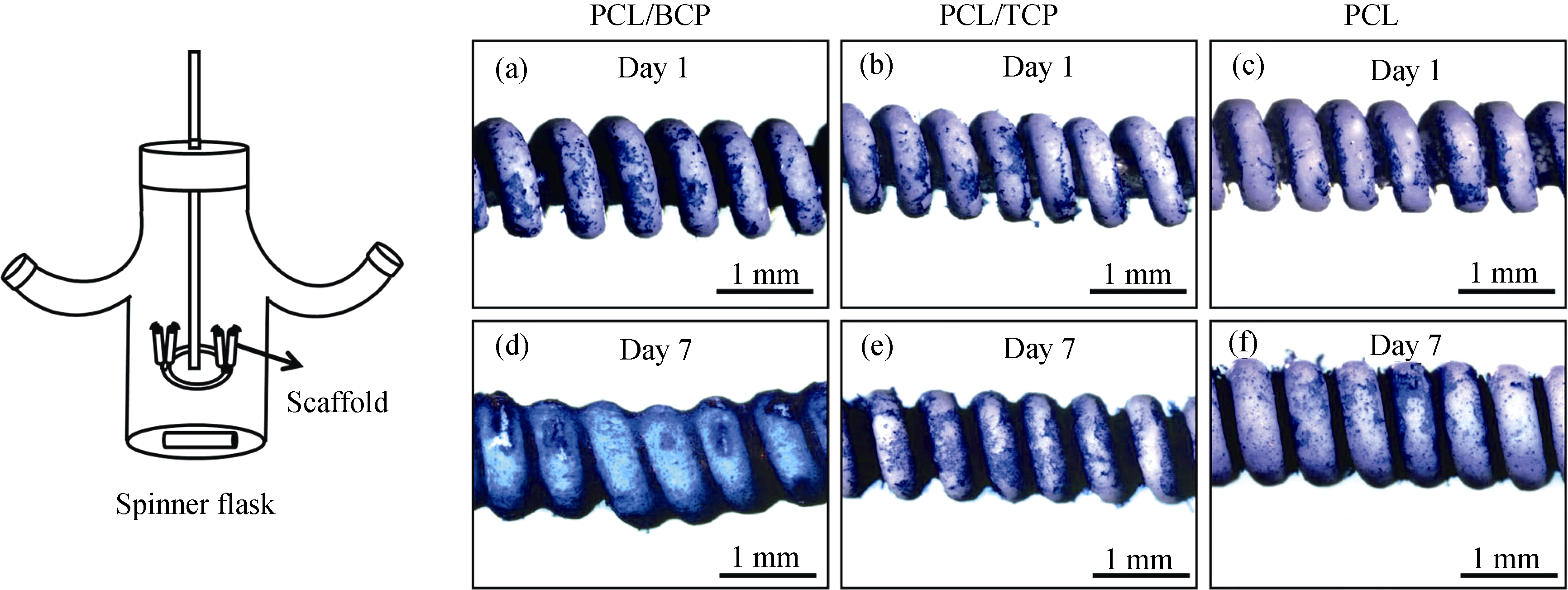

Fig. 3 The growth of MC3T3-E1 cells seeded in microfilament layers of bi-layered (a,d) PCL/BCP, (b,e) PCL/TCP and (c,f) PCL scaffolds at (a-c) day 1 and (d-f) day 7

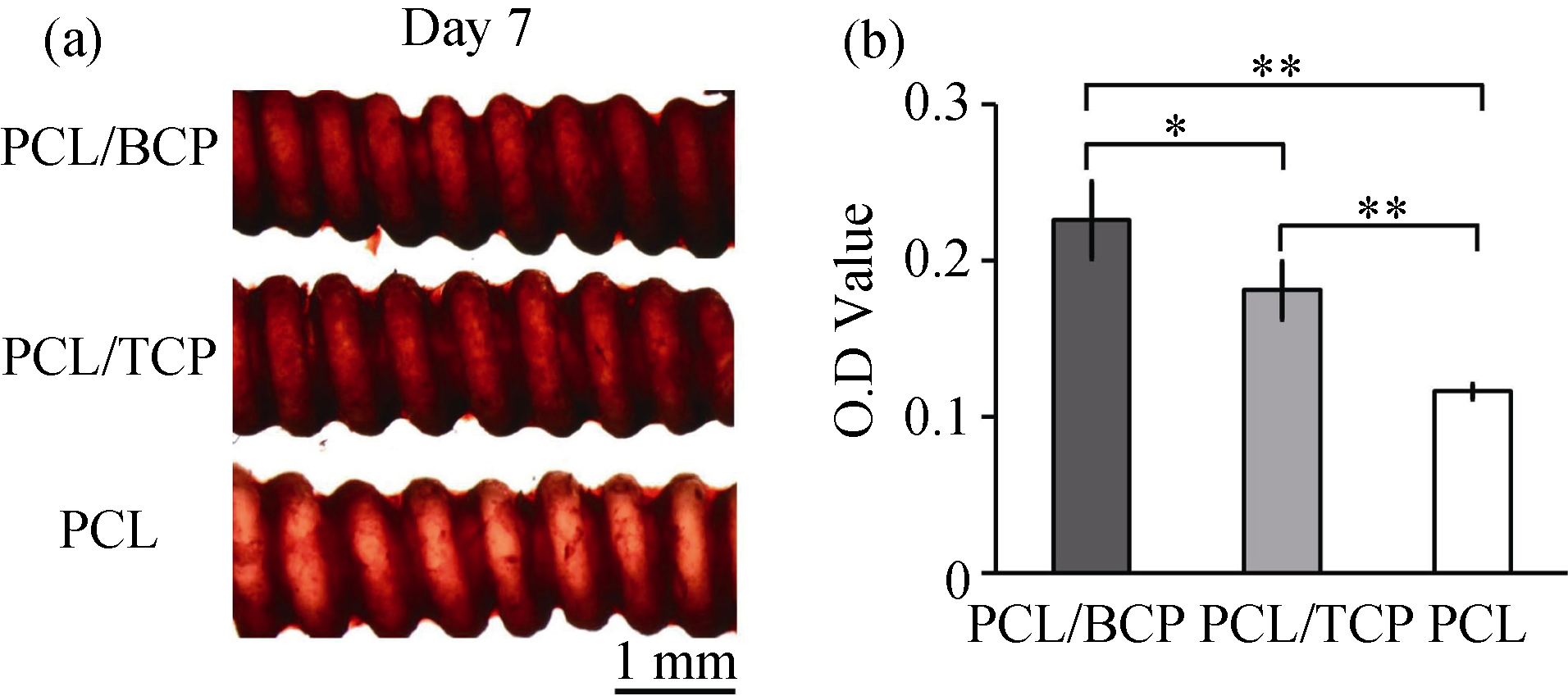

Fig. 4 Alizarin Red staining showed the osteogenic differentiation of MC3T3-E1 cells seeded in microfilament layers of bi- layered scaffolds(a) and quantification of calcium deposition on scaffolds with different composition (b)

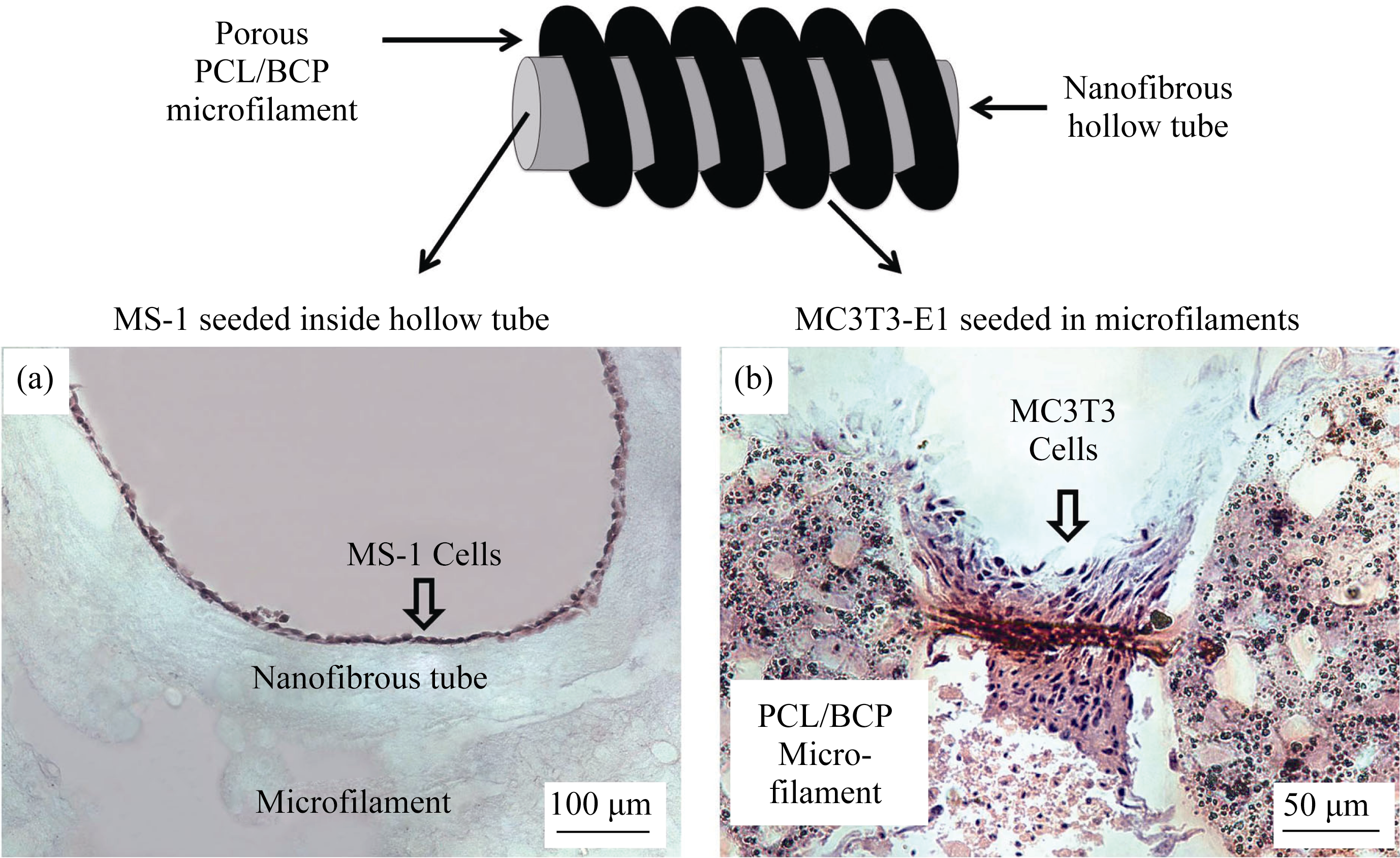

Fig. 5 Bi-layered scaffold controlled the spatial distribution of different cells (a) A confluent layer of MS-1 cells was lined inside the nanofibrous hollow tube. (b) MC3T3-E1 cells were seeded in outer microfilament layer to form cell-rich tissue

| [1] | AMINI A R, LAURENCIN C T, NUKAVARAPU S P.Bone tissue engineering: recent advances and challenges.Crit. Rev. Biomed. Eng., 2012, 40(5): 363-408. |

| [2] | DROSSE I, VOLKMER E, CAPANNA R, et al.Tissue engineering for bone defect healing: an update on a multi-component approach.Injury, 2008, 39(Suppl 2): S9-S20. |

| [3] | ANDRIC T, SAMPSON A C, FREEMAN J W.Fabrication and characterization of electrospun osteon mimicking scaffolds for bone tissue engineering. Mater. Sci. Eng. C, 2011, 31: 2-8. |

| [4] | ERGUN A, YU X, VALDEVIT A, et al.In vitro analysis and mechanical properties of twin screw extruded single-layered and coextruded multilayered poly(caprolactone) scaffolds seeded with human fetal osteoblasts for bone tissue engineering.J. Biomed. Mater. Res. A, 2011, 99: 354-366. |

| [5] | OZKAN S, KALYON D, YU X, et al.Multifunctional protein- encapsulated polycaprolactone scaffolds: fabrication and in vitro assessment for tissue engineering.Biomaterials, 2009, 30: 4336-4347. |

| [6] | ERISKEN C, KALYON D, WANG H.Functionally graded electrospun polycaprolactone and beta-tricalcium phosphate nanocomposites for tissue engineering applications.Biomaterials, 2008, 29: 4065-4073. |

| [7] | MCCLURE M, SELL S, SIMPSON D, et al.A three-layered electrospun matrix to mimic native arterial architecture using polycaprolactone, elastin, and collagen: a preliminary study.Acta Biomater., 2010, 6: 2422-2433. |

| [8] | BOHNER M, TADIER S N, VAN GARDEREN N, et al.Synthesis of spherical calcium phosphate particles for dental and orthopedic applications.Biomatter., 2013, 3(2): e25103. |

| [9] | BOSE S, TARAFDER S.Calcium phosphate ceramic systems in growth factor and drug delivery for bone tissue engineering: a review.Acta Biomater., 2012, 8(4): 1401-1421. |

| [10] | CHEN X Q, CHEN X N, ZHU X D, et al.Effect of surface topography of hydroxyapatite on human osteosarcoma MG-63 cell.Journal of Inorganic Materials, 2013, 28(8): 901-906. |

| [11] | WANG J, CHEN Y, ZHU X, et al.Effect of phase composition on protein adsorption and osteoinduction of porous calcium phosphate ceramics in mice.J. Biomed. Mater. Res. A, 2014, 102(12): 4234-4243. |

| [12] | SAMAVEDI S, WHITTINGTON A R, GOLDSTEIN A S.Calcium phosphate ceramics in bone tissue engineering: a review of properties and their influence on cell behavior.Acta Biomater., 2013, 9(9): 8037-8045. |

| [13] | ZHANG L, HANAGATA N, MAEDA M, et al.Porous hydroxyapatite and biphasic calcium phosphate ceramics promote ectopic osteoblast differentiation from mesenchymal stem cells.Sci. Technol. Adv. Mater., 2009, 10: 025003. |

| [14] | ULERY B D, NAIR L S, LAURENCIN C T.Biomedical applications of biodegradable polymers.J. Polym. Sci. B Polym. Phys., 2011, 49(12): 832-864. |

| [15] | CHEN X, ERGUN A, GEVGILILI H, et al.Shell-core bi-layered scaffolds for engineering of vascularized osteon-like structures.Biomaterials, 2013, 34: 8203-8212. |

| [16] | GREGORY C, GUNN W, PEISTER A, et al.An Alizarin red-based assay of mineralization by adherent cells in culture: comparison with cetylpyridinium chloride extraction.Anal. Biochem., 2004, 329: 77-84. |

| [17] | YANG X, CHEN X, WANG H.Acceleration of osteogenic differentiation of preosteoblastic cells by chitosan containing nanofibrous scaffolds.Biomacromolecules, 2009, 10: 2772-2778. |

| [18] | RAJZER I, MENASZEK E, KWIATKOWSKI R, et al.Electrospun gelatin/poly(ε-caprolactone) fibrous scaffold modified with calcium phosphate for bone tissue engineering.Mater. Sci. Eng. C, 2014, 44: 183-190. |

| [19] | LE NIHOUANNEN D, SAFFARZADEH A, GAUTHIER O, et al.Bone tissue formation in sheep muscles induced by a biphasic calcium phosphate ceramic and fibrin glue composite.J. Mater. Sci. Mater. Med., 2008, 19: 667-675. |

| [20] | MILLER J, STEVENS K, YANG M, et al.Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues.Nat. Mater., 2012, 11: 768-774. |

| [1] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [2] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | CHEN Xi, YUAN Yuan, TAN Yeqiang, LIU Changsheng. Strategic Study on the Development of Inorganic Non-metallic Biomaterials [J]. Journal of Inorganic Materials, 2025, 40(5): 449-456. |

| [5] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [6] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [7] | YANG Shuqi, YANG Cunguo, NIU Huizhu, SHI Weiyi, SHU Kewei. GeP3/Ketjen Black Composite: Preparation via Ball Milling and Performance as Anode Material for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(3): 329-336. |

| [8] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [9] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [10] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [11] | LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism [J]. Journal of Inorganic Materials, 2025, 40(2): 205-214. |

| [12] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [13] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [14] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [15] | MA Binbin, ZHONG Wanling, HAN Jian, CHEN Liangyu, SUN Jingjing, LEI Caixia. ZIF-8/TiO2 Composite Mesocrystals: Preparation and Photocatalytic Activity [J]. Journal of Inorganic Materials, 2024, 39(8): 937-944. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||