Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (8): 885-890.DOI: 10.15541/jim20140181

• Orginal Article • Previous Articles Next Articles

HU Hai-Long1,2, ZENG Yu-Ping1, ZUO Kai-Hui1, XIA Yong-Feng1, YAO Dong-Xu1

Received:2013-04-14

Published:2014-08-20

Online:2014-07-15

About author:HU Hai-Long(1989–), male, candidate of master. E-mail:hlhai@student.sic.ac.cn

CLC Number:

HU Hai-Long, ZENG Yu-Ping, ZUO Kai-Hui, XIA Yong-Feng, YAO Dong-Xu. Effect of Sintering Additive Composition on the Mechanical and Tribological Properties of Si3N4/SiC Ceramics[J]. Journal of Inorganic Materials, 2014, 29(8): 885-890.

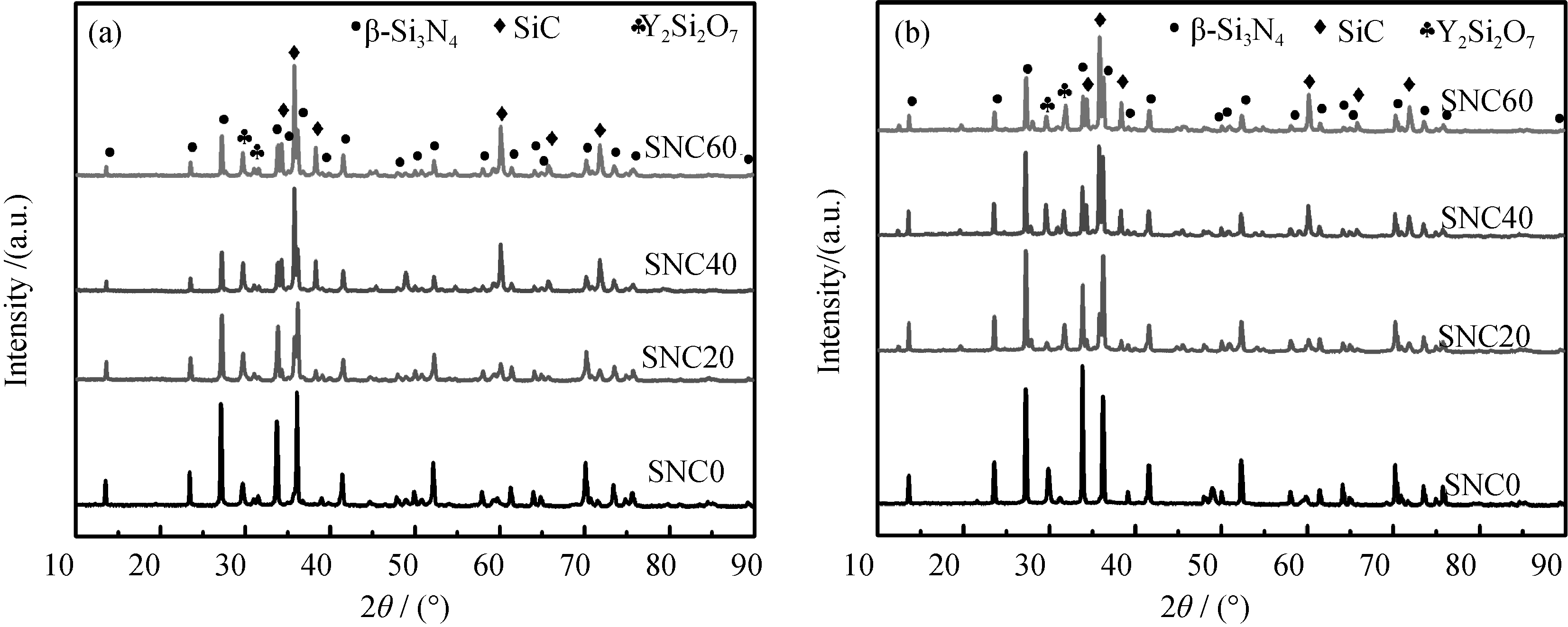

Fig. 1 XRD patterns of the sintered Si3N4/SiC ceramics with different sintering additives for various contents of SiC addition (a) With YA sintering additive; (b) With YM sintering additive

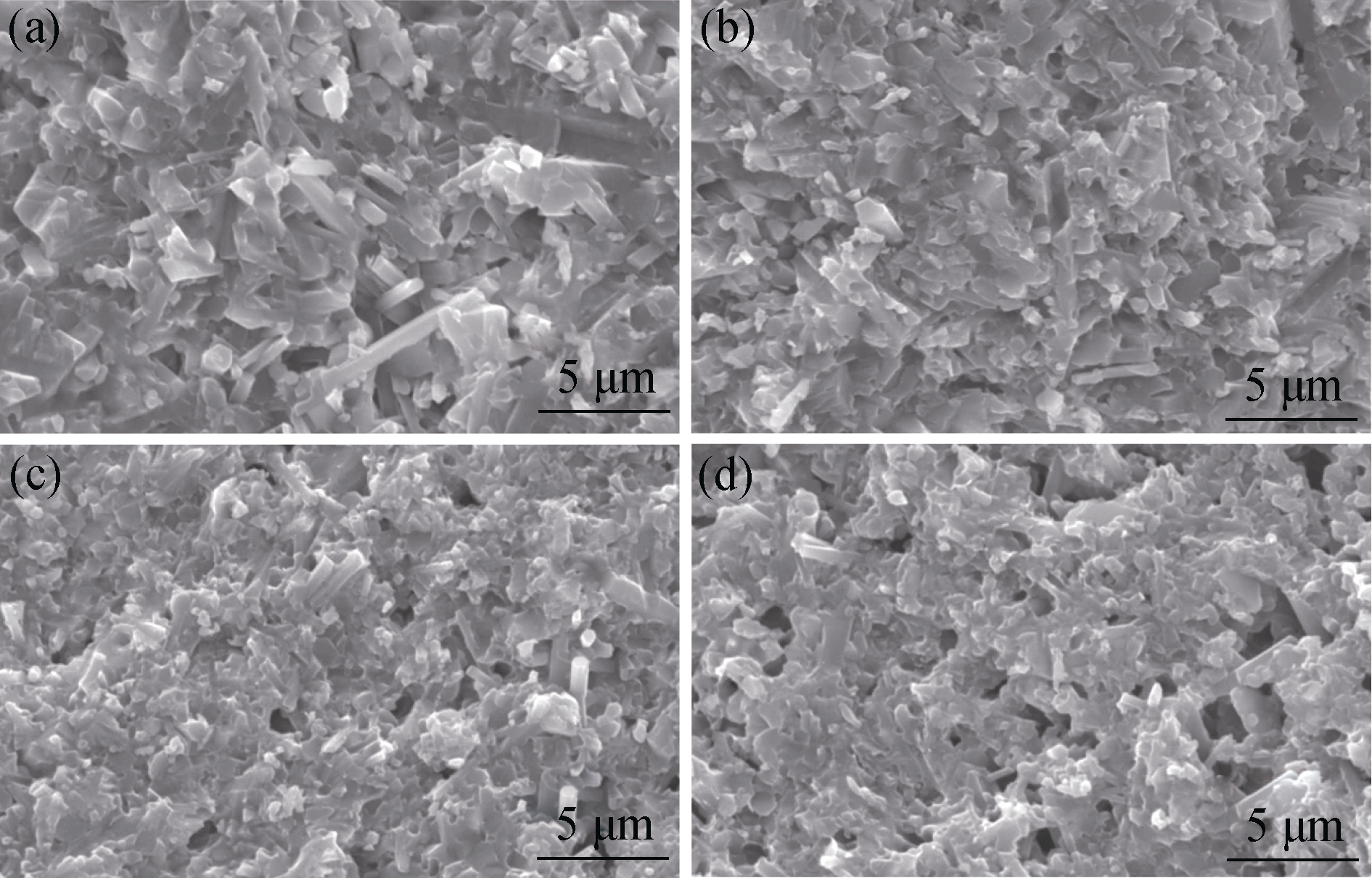

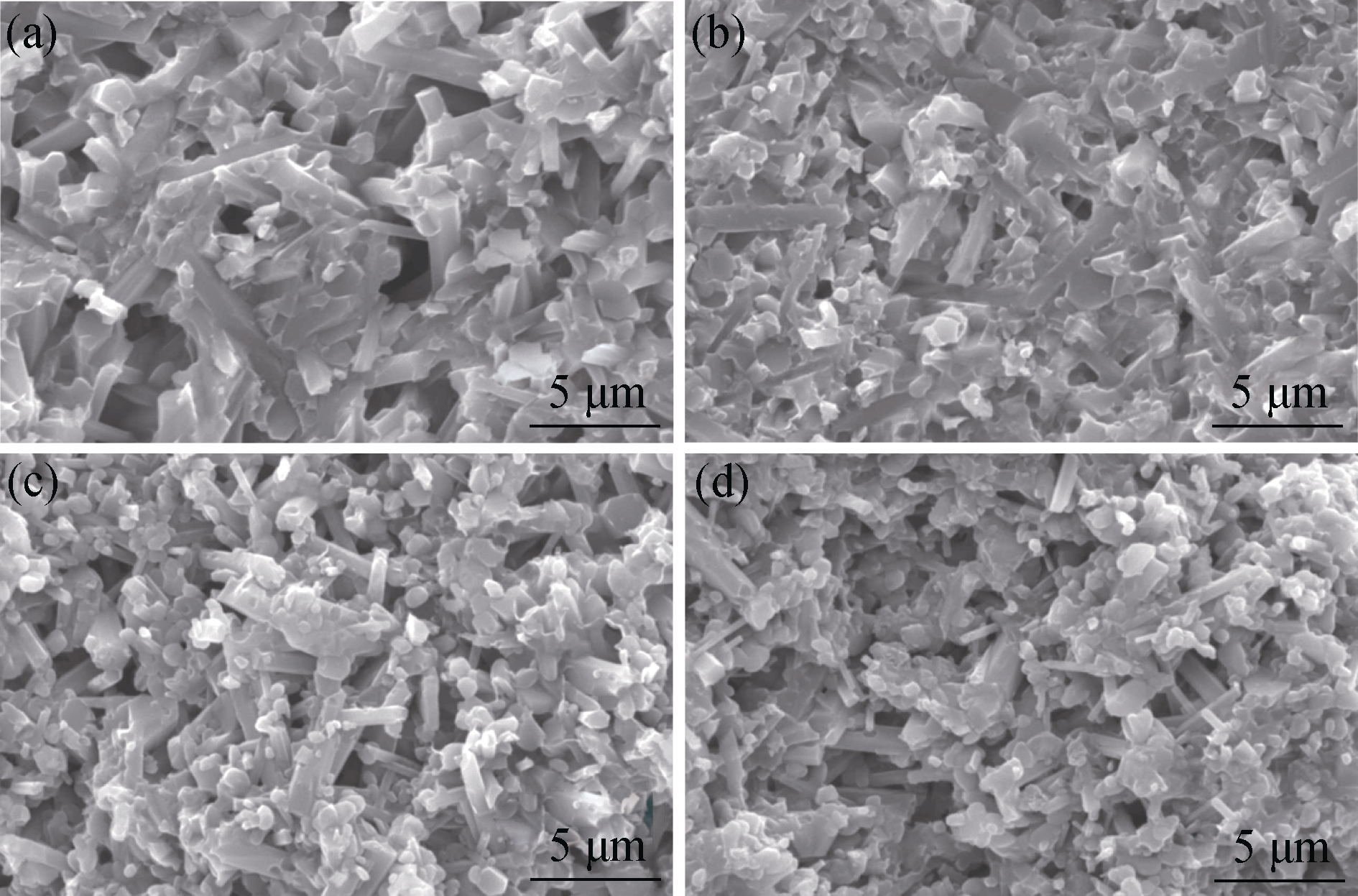

Fig. 3 SEM fracture morphologies of the sintered Si3N4/SiC ceramics with YA sintering additive for (a) without SiC, (b) 20wt% SiC, (c) 40wt% SiC and (d) 60wt% SiC addition

Fig. 4 SEM fracture morphologies of the sintered Si3N4/SiC ceramics with YM sintering additive for (a) without SiC, (b) 20wt% SiC, (c) 40wt% SiC and (d) 60wt% SiC addition

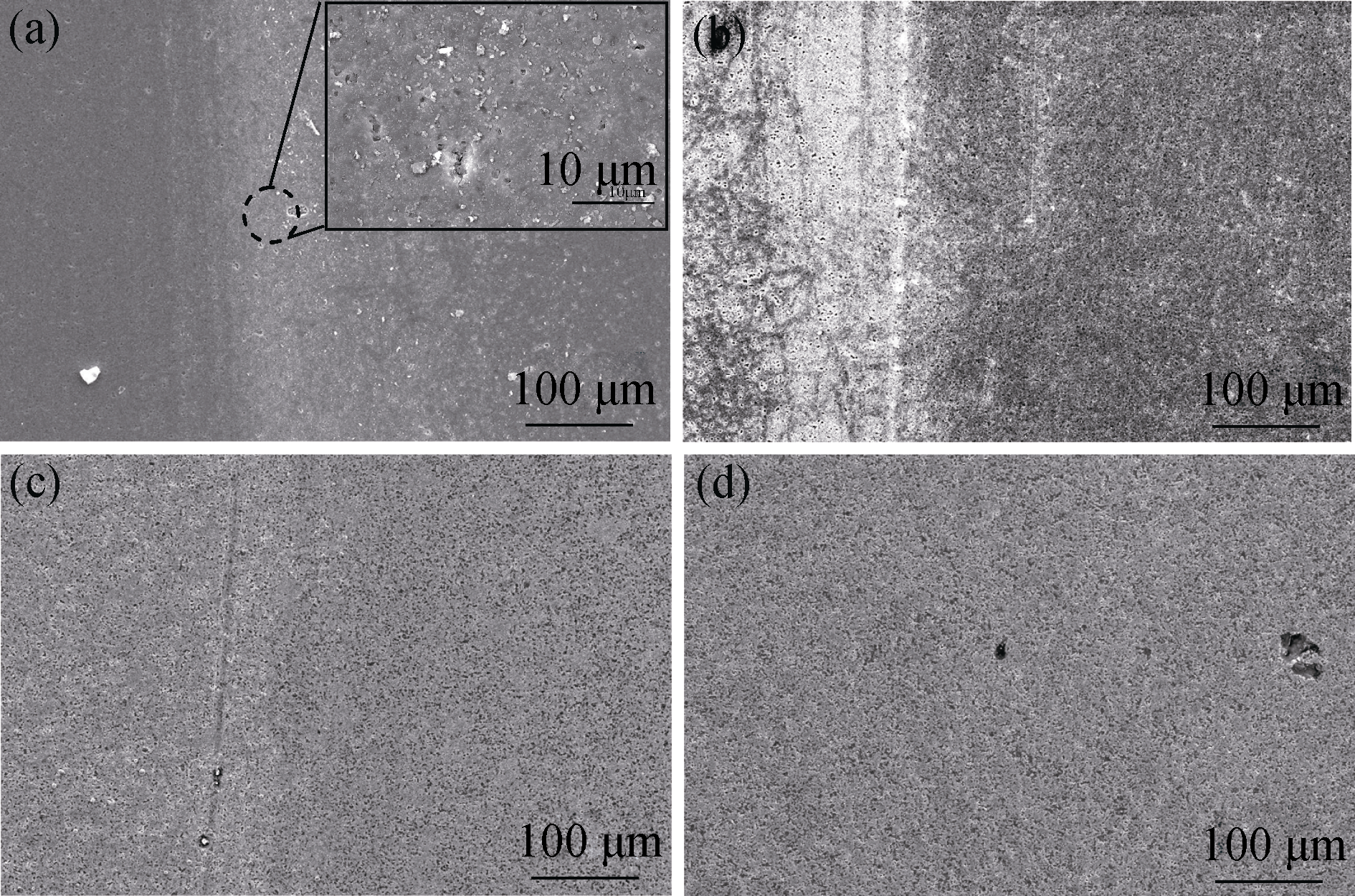

Fig. 6 SEM images of worn surface of the sintered Si3N4/SiC ceramics with YA sintering additive for (a) without SiC, (b) 20wt% SiC, (c) 40wt% SiC and (d) 60wt% SiC addition

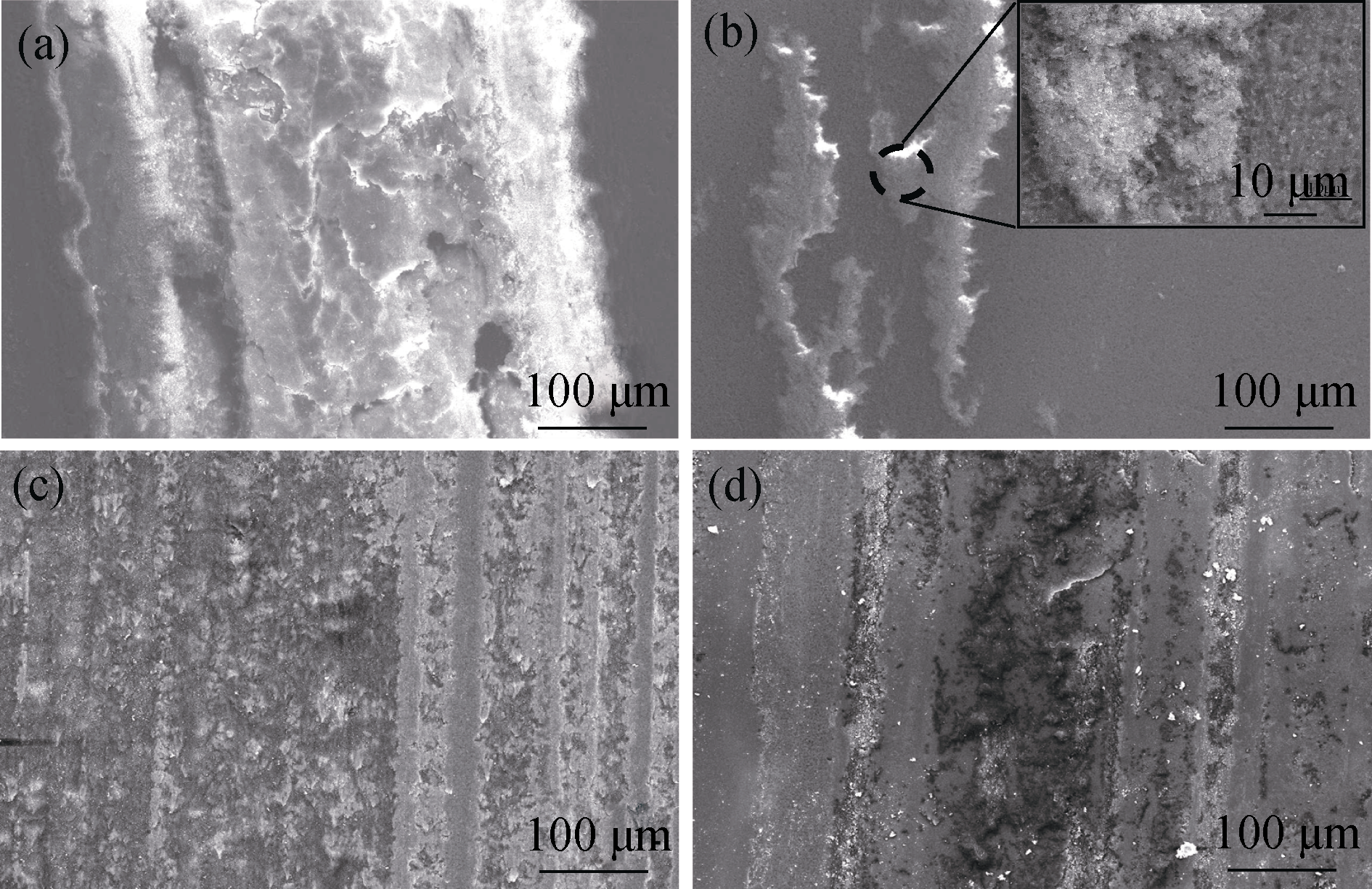

Fig. 7 SEM images of worn surface of the sintered Si3N4/SiC ceramics with YM sintering additive for (a) without SiC, (b) 20wt% SiC, (c) 40wt% SiC and(d) 60wt% SiC addition

| Samples | Elastic modulus/GPa | Hardness/GPa | Fracture toughness/(MPa•m½) |

|---|---|---|---|

| YA | 271 | 10.8±0.24 | 4.02±0.03 |

| YA-20wt%SiC | 311 | 14.6±0.10 | 4.12±0.01 |

| YA-40wt%SiC | 272 | 13.5±0.39 | 3.92±0.22 |

| YA-60wt%SiC | 251 | 11.8±0.35 | 3.93±0.02 |

| YM | 187 | 5.8±0.14 | 4.06±0.04 |

| YM-20wt%SiC | 242 | 10.3±0.39 | 4.93±0.13 |

| YM-40wt%SiC | 176 | 5.8±0.20 | 4.24±0.04 |

| YM-60wt%SiC | 142 | 3.6±0.15 | 2.92±0.12 |

Table 1 Elastic modulus, hardness and fracture toughness of the sintered Si3N4/SiC ceramics with YA or YM sintering <br/>additive for various contents of SiC

| Samples | Elastic modulus/GPa | Hardness/GPa | Fracture toughness/(MPa•m½) |

|---|---|---|---|

| YA | 271 | 10.8±0.24 | 4.02±0.03 |

| YA-20wt%SiC | 311 | 14.6±0.10 | 4.12±0.01 |

| YA-40wt%SiC | 272 | 13.5±0.39 | 3.92±0.22 |

| YA-60wt%SiC | 251 | 11.8±0.35 | 3.93±0.02 |

| YM | 187 | 5.8±0.14 | 4.06±0.04 |

| YM-20wt%SiC | 242 | 10.3±0.39 | 4.93±0.13 |

| YM-40wt%SiC | 176 | 5.8±0.20 | 4.24±0.04 |

| YM-60wt%SiC | 142 | 3.6±0.15 | 2.92±0.12 |

| [1] | RILEY F L. Silicon nitride and related material. J. Am. Ceram. Soc., 2000, 83(2): 245-265. |

| [2] | PETZOW G, HERRMANN M. Silicon nitride ceramics. Struct. Bond., 2002, 102: 147-167. |

| [3] | HERRMANN M, SCHUBER C, RENDTEL A, et al. Si3N4/SiC nanocomposite materials. I. Fabrication and mechanical properties at room temperature. J. Am. Ceram. Soc., 1998, 81(5): 1095-1108. |

| [4] | SAJGALIK P, HNATKO M, LOFAJ F. SiC/Si3N4 nano/micro-composite - processing, RT and HT mechanical properties. J. Eur. Ceram. Soc., 2000, 20(4): 453-462. |

| [5] | HNATKO M, GALUSEK D, SAJGALIK P. Low-cost preparation of Si3N4-SiC micro/nano composites by in-situ carbothermal reduction of silica in silicon nitride matrix. J. Eur. Ceram. Soc., 2004, 24(2): 189-195. |

| [6] | KASIAROVA M, DUSZA J, HNATKO M, et al. Microstructure and fracture mechanical properties of carbon derived Si3N4/SiC nanomaterials. Mater. Sci. Eng., 2006, 26: 862-866. |

| [7] | MIYAZAKI H, HYUGA H, YOSHIZAWA Y, et al. Correlation of wear behavior and indentation fracture resistance in silicon nitride ceramics hot-pressed with alumina and yttria. J. Eur. Ceram. Soc., 2009, 29: 1535-1542. |

| [8] | KIM S S, CHAE Y H, KIM D J. Tribological characteristics of silicon nitride at elevated temperatures. Tribol. Lett., 2000, 9(3/4): 227-232. |

| [9] | ZUTSHI A, HABER R A, NIESZ D E, et al. Processing, microstructure, and wear behavior of silicon nitride hot-pressed with alumina and yttria. J. Am. Ceram. Soc., 1994, 77(4): 883-890. |

| [10] | WANG D F, MAO Z Y. Studies on abrasive wear of monolithic silicon nitride and a silicon carbide whisker-reinforced silicon nitride composite. J. Am. Ceram. Soc., 1995, 78(10): 2705-2708. |

| [11] | HYUGA H, JONES M I, HIRAO K, et al. Influence of rare-earth additives on wear properties of hot-pressed silicon nitride ceramics under dry sliding conditions. J. Am. Ceram. Soc., 2004, 87(9): 1683-1686. |

| [12] | BELMONTE M, MIRANZO P, OSENDI M I, et al. Wear of aligned silicon nitride under dry sliding conditions. Wear, 2009, 266(1/2): 6-12. |

| [13] | GEE M G, BUTTERFIELD D. The combined effect of speed and humidity on the wear and friction of silicon nitride. Wear, 1993, 162-164: 234-245. |

| [14] | DONG X, JAHANMIR S. Wear transition diagram for silicon nitride. Wear, 1993, 165(2): 169-180. |

| [15] | GOMES J R, OSENDI M I, MIRANZO P, et al. Tribological characteristics of self-mated couples of Si3N4-SiC composites in the range 22-700℃.Wear, 1999, 233-235: 222-228. |

| [16] | KASIAROVA M, RUDNAYOVA E, DUSZA J, et al. Some tribological properties of a carbon-derived Si3N4/SiC nanocomposite. J. Eur. Ceram. Soc., 2004, 24: 3431-3435. |

| [17] | VILA M, CARRAPICHANO J M, GOMES J R, et al. Ultra-high performance of DLC-coated Si3N4 rings for mechanical seals. Wear, 2008, 265(3/4): 59-68. |

| [18] | LEE B T, KIM H D. Effect of sintering additives on nitridation behaviour of reaction-bonded silicon nitride. Mater. Sci. Eng., 2004, A364: 126-131. |

| [19] | KIM J H, KUMAR B V M, YAMAKAWA A. Fabrication of silicon nitride nanoceramics and their tribological properties. J. Am. Ceram. Soc., 2010, 93(5): 1461-1466. |

| [20] | DOGAN C P, HAWK J A. Microstructure and abrasive wear in silicon nitride ceramics. Wear, 2001, 250: 256-263. |

| [21] | WANG X, PADTURE N P, TANAKA H, et al. Wear-resistant ultra-fine-grained ceramics. Acta Mater., 2005, 53: 271-277. |

| [1] | ZHANG Jinghui, LU Xiaotong, MAO Haiyan, TIAN Yazhou, ZHANG Shanlin. Effect of Sintering Additives on Sintering Behavior and Conductivity of BaZr0.1Ce0.7Y0.2O3-δ Electrolytes [J]. Journal of Inorganic Materials, 2025, 40(1): 84-90. |

| [2] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [3] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [4] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [5] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [6] | LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating [J]. Journal of Inorganic Materials, 2022, 37(4): 467-472. |

| [7] | LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing [J]. Journal of Inorganic Materials, 2022, 37(3): 310-316. |

| [8] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [9] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [10] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [11] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [12] | GU Yu-Kang, CAO Lei, WAN Yong, GAO Jian-Guo. Tribological Performance and Lubrication Mechanism of Carbon Microspheres as Oil-based Lubricant Additive on Aluminum Alloy Substrate [J]. Journal of Inorganic Materials, 2017, 32(6): 625-630. |

| [13] | ZHANG Chang-Song, LIU Qiang, CHEN Wei. Effect of hBN Content on Property and Microstructure of Si3N4-hBN Composite Ceramics [J]. Journal of Inorganic Materials, 2017, 32(5): 509-516. |

| [14] | LI Miao-Lei, WANG En-Qing, YUE Jian-Ling, HUANG Xiao-Zhong. Microstructure, Mechanical and Tribological Property of TiAlN/VN Nano-multilayer Films [J]. Journal of Inorganic Materials, 2017, 32(12): 1280-1284. |

| [15] | LEI Zhuo-Yan, WANG Zhi, FAN Heng-Bing, MA Wen-Bin, CHEN Jian, WANG Xu. Effect of B2O3 Doping and Phosphate Impregnation on Oxidation Resistance and Mechanical Properties of Mesocarbon Microbead Composites [J]. Journal of Inorganic Materials, 2015, 30(7): 769-773. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||