Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 310-316.DOI: 10.15541/jim20210609

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Meng1,2( ), HUANG Hailu1,2, WU Jiamin1,2(

), HUANG Hailu1,2, WU Jiamin1,2( ), LIU Chunlei1,2, WU Yaru1,2, ZHANG Jingxian3, SHI Yusheng1,2

), LIU Chunlei1,2, WU Yaru1,2, ZHANG Jingxian3, SHI Yusheng1,2

Received:2021-10-02

Revised:2021-12-08

Published:2022-03-20

Online:2021-12-24

Contact:

WU Jiamin, associate professor. E-mail: jiaminwu@hust.edu.cn

About author:LI Meng (1996-), female, Master candidate. E-mail: 819448243@qq.com

Supported by:CLC Number:

LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing[J]. Journal of Inorganic Materials, 2022, 37(3): 310-316.

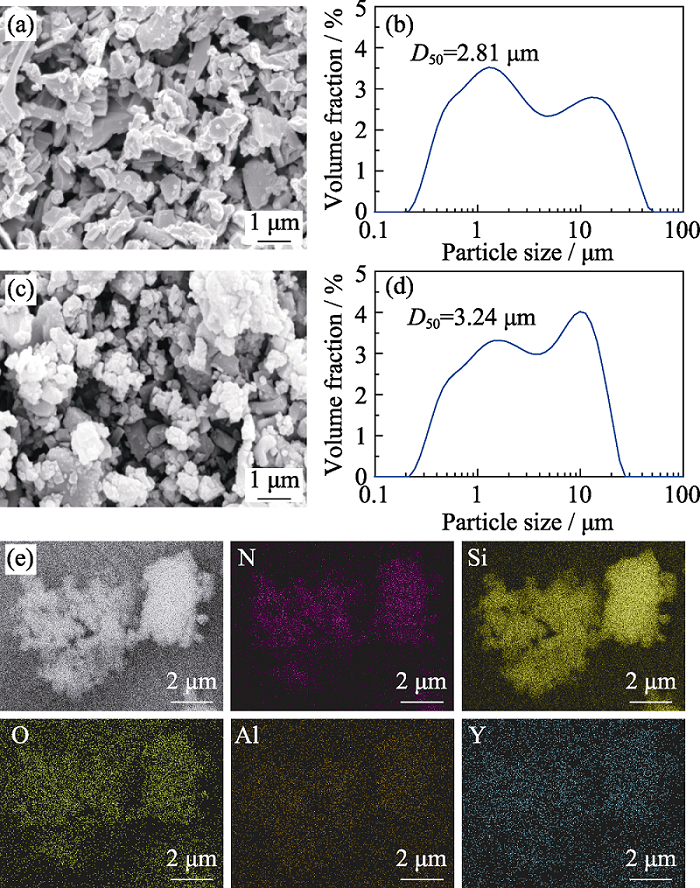

Fig. 1 Microstructures, particle size distributions, and EDX mappings of Si3N4 raw powder and Si3N4 powder after being coated (a) Microstructure of Si3N4 raw powder; (b) Particle size distribution of Si3N4 raw powder; (c) Microstructure of Si3N4 powder after being coated; (d) Particle size distribution of Si3N4 powder after being coated; (e) EDX mappings of Si3N4 powder after being coated

| [1] |

BOCANEGRA-BERNAL M H, MATOVIC B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Materials Science and Engineering: A, 2010, 527(6): 1314-1338.

DOI URL |

| [2] |

DANTE R C, KAJDAS C K. A review and a fundamental theory of silicon nitride tribochemistry. Wear, 2012, 288(3): 27-38.

DOI URL |

| [3] | SUN Y G, HE S L, LIU R A, et al. Preparation and application of silicon nitride ceramics. China Ceramic Industry, 2016, 23(5): 31-34. |

| [4] |

RILEY F L. Silicon nitride and related materials. Journal of the American Ceramic Society, 2000, 83(2): 245-265.

DOI URL |

| [5] |

KLEMM H. Silicon nitride for high-temperature applications. Journal of the American Ceramic Society, 2010, 93(6): 1501-1522.

DOI URL |

| [6] |

KRSTIC Z, KRSTIC V D. Silicon nitride: the engineering material of the future. Journal of Materials Science, 2012, 47(2): 535-552.

DOI URL |

| [7] | WANG B M. State of the art of advanced ceramic material. Progress in Chemistry, 2000, 12(3): 357-359. |

| [8] |

NISHIMURA T, MITOMO M, SUEMATSU H. High temperature strength of silicon nitride ceramics with ytterbium silicon oxynitride. Journal of Materials Research, 1997, 12(1): 203-209.

DOI URL |

| [9] |

CHEN A N, WU J M, HAN L X, et al. Preparation of Si3N4 foams by DCC method via dispersant reaction combined with protein-gelling. Journal of Alloys and Compounds, 2018, 745(1): 262-270.

DOI URL |

| [10] | XIE G R, ZHANG X G, CEN X D. Study and application of silicon nitride ceramic cutting tool. Tool Engineering, 2007, 41(2): 78-80. |

| [11] |

PYZIK A J, BEAMAN D R. Microstructure and properties of self-reinforced silicon nitride. Journal of the American Ceramic Society, 1993, 76(11): 2737-2744.

DOI URL |

| [12] |

NEUMANN A, RESKE T, HELD M, et al. Comparative investigation of the biocompatibility of various silicon nitride ceramic qualities in vitro. Journal of Materials Science: Materials in Medicine, 2004, 15(10): 1135-1140.

DOI URL |

| [13] | ORTH J, LUDWIG M, PIENING W, et al. Biocompatibility of Silicon Carbide and Silicon Nitride Ceramics. Results of an Animal Experiment. Bioceramics and the Human Body. Berlin: Springer, 1992, 28(12): 372-377. |

| [14] |

KANDI K K, THALLAPALLI N, CHILAKALAPALLI S P R. Development of silicon nitride-based ceramic radomes-a review. International Journal of Applied Ceramic Technology, 2015, 12(5): 909-920.

DOI URL |

| [15] | WU W J, LIU J, ZHANG J, et al. Preparation and application status of porous Si3N4 ceramic. China Ceramics, 2016, 52(7): 10-13. |

| [16] | HE J H, WU J M, CHEN A N, et al. Ceramic materials for additive manufacturing and their forming technologies. Materials China, 2020, 39(5): 337-348. |

| [17] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [18] |

LIU S S, LI M, WU J M, et al. Preparation of high-porosity Al2O3 ceramic foams via selective laser sintering of Al2O3 poly-hollow microspheres. Ceramics International, 2020, 46(4): 4240-4247.

DOI URL |

| [19] | WONG K V, HERNANDEZ A. A review of additive manufacturing. ISRN Mechanical Engineering, 2012, 34(15): 30-38. |

| [20] |

CHEN F, ZHU H, WU J M, et al. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology. Ceramics International, 2020, 46(8): 11268-11274.

DOI URL |

| [21] |

DMITRII A K, PETR S S, ANASTASIYA D E, et al. Rheological and curing behavior of acrylate-based suspensions for the DLP 3D printing of complex zirconia parts. Materials, 2018, 11(12): 2350-2362

DOI URL |

| [22] |

LI S, DUAN W, ZHAO T, et al. The fabrication of SiBCN ceramic components from preceramic polymers by digital light processing (DLP) 3D printing technology. Journal of the European Ceramic Society, 2018, 38(14): 4597-4603.

DOI URL |

| [23] | WU J M, YANG Y Q, WANG C, et al. Photopolymerization technologies for ceramics and their applications. Journal of Mechanical Engineering, 2020, 56(19): 221-238. |

| [24] |

SHUAI X, ZENG Y, LI P, et al. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science, 2020, 55(3): 6771-6782.

DOI URL |

| [25] |

HE R, LIU W, WU Z, et al. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceramics International, 2018, 44(3): 3412-3416.

DOI URL |

| [26] | HUA S B, ZHU H, WU J M, et al. Performance of lattice structure scaffold prepared via digital light processing manufacture by DLP technology. Journal of Chinese Ceramic Society, 2021, 49(4): 608-617. |

| [27] | GRIFFITH M L, HALLORAN J W. Ultraviolet Curing of Highly Loaded Ceramic Suspensions for Stereolithography of Ceramics. Proc. Solid Freeform Fabr. Symp., 1994: 396-403. |

| [28] |

WU X Q, XU C J, ZHANG Z M. Preparation and optimization of Si3N4 ceramic slurry for low-cast LCD mask stereolithography. Ceramics International, 2021, 47(7): 9400-9408.

DOI URL |

| [29] |

DING G J, HE R J, ZHANG K Q, et al. Stereolithography-based additive manufacturing of gray-colored SiC ceramic green body. Journal of the American Ceramic Society, 2019, 102(12): 7198-7209.

DOI URL |

| [30] |

HUANG R J, JIANG Q G, WU H D, et al. Fabrication of complex shaped ceramic parts with surface-oxidized Si3N4 powder via digital light processing based stereolithography method. Ceramics International, 2019, 45(4): 5158-5162.

DOI URL |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | QIU Zihao, TIAN Zhilin, ZHENG Liya, LI Bin. Corrosion Behavior of Si3N4 Ceramic in High-temperature Molten Salt-water Vapor Environment [J]. Journal of Inorganic Materials, 2024, 39(3): 274-282. |

| [3] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [4] | ZHANG Ye, YAO Dongxu, ZUO Kaihui, XIA Yongfeng, YIN Jinwei, ZENG Yuping. Combustion Synthesis of Si3N4-BN-SiC Composites by in-situ Introduction of BN and SiC [J]. Journal of Inorganic Materials, 2022, 37(5): 574-578. |

| [5] | LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating [J]. Journal of Inorganic Materials, 2022, 37(4): 467-472. |

| [6] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [7] | LIU Guoqian, YAN Changhai, ZHANG Keqiang, JIN Hua, HE Rujie. Effect of Solid Loading on the Property of Al2O3 Ceramics in Stereolithographic Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 353-360. |

| [8] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [9] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [10] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [11] | Chao LEI, Fei WEI. Mass Production of α-silicon Nitride Single-crystalline Nanowires [J]. Journal of Inorganic Materials, 2019, 34(6): 667-672. |

| [12] | ZHOU Xin, MA Lei, LIU Tao, GUO Yong-Bin, WANG Dao, DONG Pei-Lin. Crystal Structure and Magnetic Property of Si3N4/FePd/Si3N4 Thin Films [J]. Journal of Inorganic Materials, 2018, 33(8): 909-913. |

| [13] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [14] | LI Shuang, XIE Zhi-Peng. Preparation of Zirconia Ceramics with High Density and Fine Grains by Oscillatory Pressure Sintering [J]. Journal of Inorganic Materials, 2016, 31(2): 207-212. |

| [15] | LEI Zhuo-Yan, WANG Zhi, FAN Heng-Bing, MA Wen-Bin, CHEN Jian, WANG Xu. Effect of B2O3 Doping and Phosphate Impregnation on Oxidation Resistance and Mechanical Properties of Mesocarbon Microbead Composites [J]. Journal of Inorganic Materials, 2015, 30(7): 769-773. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||