Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (12): 1310-1314.DOI: 10.15541/jim20150255

• Orginal Article • Previous Articles Next Articles

ZHU Wei-Wei1, CHEN Ji-Chun2

Received:2015-05-27

Revised:2015-07-22

Published:2015-12-20

Online:2015-11-24

CLC Number:

ZHU Wei-Wei, CHEN Ji-Chun. Crystallization Behavior of Glass Ceramic Filler During Joining Process[J]. Journal of Inorganic Materials, 2015, 30(12): 1310-1314.

| CaO | Al2O3 | SiO2 | Li2O | Fe2O3 |

|---|---|---|---|---|

| 22 | 23 | 45 | 5 | 10 |

Table1 Chemical composition of the glass/wt%

| CaO | Al2O3 | SiO2 | Li2O | Fe2O3 |

|---|---|---|---|---|

| 22 | 23 | 45 | 5 | 10 |

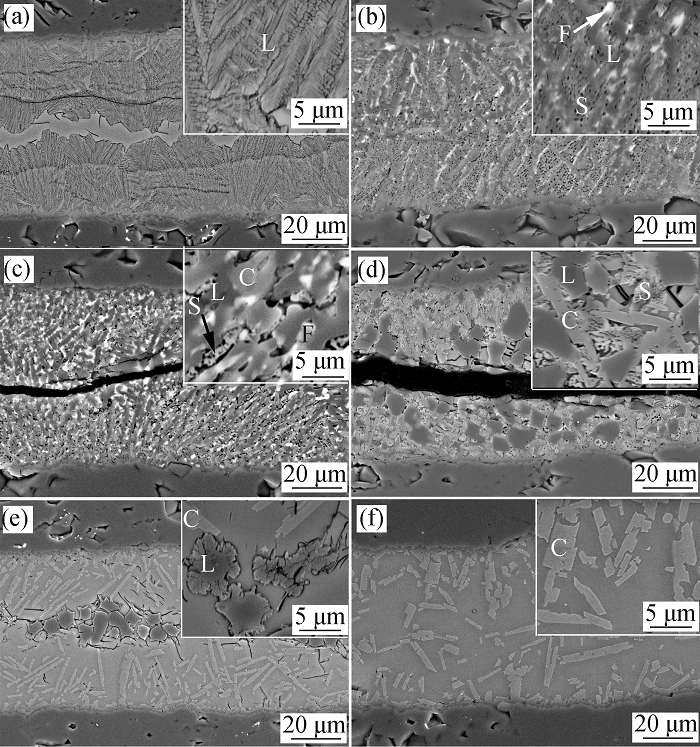

Fig. 6 SEM images of the joints obtained with heating curve II and crystallized at different temperatures. (a) 730℃; (b) 820℃; (c) 860℃; (d) 980℃; (e) 1070℃; (f) 1080℃. L=LiAlSi2O6; S=CaSiO3; F=Ca3Fe2Si3O12; C=CaAl2Si2O8

Fig. 7 XRD patterns of the joints obtained with heating curve II and crystallized at different temperatures. (a) 730℃; (b) 820℃; (c) 860℃; (d) 980℃; (e) 1070℃; (f) 1080℃

| Samples | Crystalline phase | Strength/MPa |

|---|---|---|

| 1 | No | 175±8 |

| 2 | L | 111.2±9 |

| 3 | L+S+F | 57±15 |

| 4 | L+S+F+C | 10±5 |

| 5 | L+S+C | 15±7 |

| 6 | L+C | 135.3±7 |

| 7 | C | 247.5±10 |

Table 2 Phase composition and strength of joints

| Samples | Crystalline phase | Strength/MPa |

|---|---|---|

| 1 | No | 175±8 |

| 2 | L | 111.2±9 |

| 3 | L+S+F | 57±15 |

| 4 | L+S+F+C | 10±5 |

| 5 | L+S+C | 15±7 |

| 6 | L+C | 135.3±7 |

| 7 | C | 247.5±10 |

| [1] | MURARI A, ALBRECHTB H, BARARZONA A, et al.An upgraded brazing technique to manufacture ceramic-metal joints for UHV applications.Vacuum, 2003, 68(4): 321-328. |

| [2] | LUO ZHAO-HUA, JIANG DONG-LIANG, ZHANG JING-XIAN, et al.Thermal shock of the SiC-SiC joints joined with Na2O- B2O3-SiO2 glass solder.Journal of Inorganic Materials, 2012, 27(3): 234-238. |

| [3] | MARKS R A, CHAPMAN D R, DANIELSON D T, et al.Joining of alumina via copper/niobium/copper interlayers.Acta Mater., 2000, 48(18/19): 4425-4438. |

| [4] | LIU YAN, HUANG ZHENG-REN, LIU XUE-JIAN, et al.Joining strength and microstructure of sintered SiC/SiC joints prepared by active brazing process.Journal of Inorganic Materials, 2009, 24(2): 297-300. |

| [5] | HAN J H.Joining alumina ceramics in green state using a paste of ceramic slurry.J. Mater. Pro. Tech., 2011, 211(6): 1191-1196. |

| [6] | FAGA M G, GUICCIARDI S, ESPOSITO L, et al.Alumina/alumina and alumina-zirconia/alumina-zirconia joints through glass interlayers, microstructure, mechanical properties and residual stresses.Adv. Eng. Mater., 2005, 7(6): 535-540. |

| [7] | AHN B G, SHIRAISHI Y.SiO2-CaO-Al2O3 glass solder for joining of Al2O3 to Al2O3.High Temp. Mater. Processes (London), 1998, 17(4): 209-216. |

| [8] | TOMSIA A P, GLAESER A M, MOYA J S. Interfaces between alumina and refractory glasses for high temperature applications. Key Eng. Mater., 1995, 111-112: 191-208. |

| [9] | ZHU WEI-WEI, CHEN JI-CHEN, HAO CHUAN-YONG, et al.Microstructure and strength of Al2O3/Al2O3 joints bonded with ZnO-Al2O3-B2O3-SiO2 glass-ceramic,J. Mater. Sci. Tech., 2014, 30(9): 944-948. |

| [10] | ESPOSITO L, BELLOSI A.Ceramic oxide bonds using calcium aluminosilicate glasses.J. Mater. Sci., 2005, 40(9/10): 2493-2498. |

| [11] | TEIXEIRA S R, ROMERO M, RINCON J M.Crystallization of SiO2-CaO-Na2O glass using sugarcane bagasse ash as silica source.J. Am. Ceram. Soc., 2010, 93(2): 450-455. |

| [12] | SCHROERS J, MASUHR A, JOHNSON W L, et al.Pronounced asymmetry in the crystallization behavior during constant heating and cooling of a bulk metallic glass-forming liquid.Phys. Rev. B, 1999, 60(17): 11855-11858. |

| [13] | KNICKERBOCKER S, TUZZOLO M R, LAWHORNE S.Sinterable β-spodumene glass-ceramics.J. Am. Ceram. Soc., 1989, 72(10): 1873-1879. |

| [14] | MADON M, IBARGUCHI J I G, VIA J, et al. Characterization and thermodynamic properties of andradite, Ca3Fe2Si3O12.Am. Mineral., 1991, 76: 1249-1260. |

| [15] | SVANCAREK P, GALUSEK D, LOUGHRAN F.Microstructure-stress relationship in liquid-phase sintered alumina modified by the addition of 5wt% of calcia-silica additives.Acta Mater., 2006, 54(18): 4853-4863. |

| [1] | WU Xiangquan, TENG Jiachen, JI Xiangxu, HAO Yubo, ZHANG Zhongming, XU Chunjie. Textured Porous Al2O3-SiO2 Composite Ceramic Platelet-sphere Slurry: Characteristics and Simulation of Light Intensity Distribution [J]. Journal of Inorganic Materials, 2024, 39(7): 769-778. |

| [2] | LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body [J]. Journal of Inorganic Materials, 2023, 38(4): 461-468. |

| [3] | LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend [J]. Journal of Inorganic Materials, 2023, 38(2): 113-124. |

| [4] | JIA Yuna, CAO Xu, JIAO Xiuling, CHEN Dairong. Preparation of Alumina Ceramic Continuous Fibers with Inorganic Acidic Aluminum Sol as Precursor [J]. Journal of Inorganic Materials, 2023, 38(11): 1257-1264. |

| [5] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [6] | WANG Xingang, YANG Qingqing, LIN Genlian, GAO Wei, QIN Fulin, LI Rongzhen, KANG Zhuang, WANG Xiaofei, JIANG Danyu, YAN Jina. High Temperature Tensile Property of Domestic 550-grade Continuous Alumina Ceramic Fiber [J]. Journal of Inorganic Materials, 2022, 37(6): 629-635. |

| [7] | LIU Jinling, LIU Dianguang, REN Ke, WANG Yiguang. Research Progress on the Flash Sintering Mechanism of Oxide Ceramics and Its Application [J]. Journal of Inorganic Materials, 2022, 37(5): 473-480. |

| [8] | ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier [J]. Journal of Inorganic Materials, 2022, 37(3): 297-302. |

| [9] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [10] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [11] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [12] | WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites [J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280. |

| [13] | PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(7): 673-684. |

| [14] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| [15] | HAN Hai-Bo, WANG You-He, LI Kang, LEI Jie, LIU Dan-He, YAN Zi-Feng. Acetic Acid Leaching on the Structure, Acidity and Performance of HMOR Catalyst [J]. Journal of Inorganic Materials, 2019, 34(2): 179-185. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||