Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 297-302.DOI: 10.15541/jim20210604

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHOU Ganghuai1, LIU Yao2( ), SHI Yuan1, LIU Shaojun1(

), SHI Yuan1, LIU Shaojun1( )

)

Received:2021-09-30

Revised:2021-10-26

Published:2022-03-20

Online:2021-11-12

Contact:

LIU Yao, lecturer. E-mail: liuyao1985@csu.edu.com; LIU Shaojun, professor. E-mail: liumatthew@csu.edu.cn

About author:ZHOU Ganghuai (1997-), male, Master candidate. E-mail: 193312100@csu.edu.cn

Supported by:CLC Number:

ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier[J]. Journal of Inorganic Materials, 2022, 37(3): 297-302.

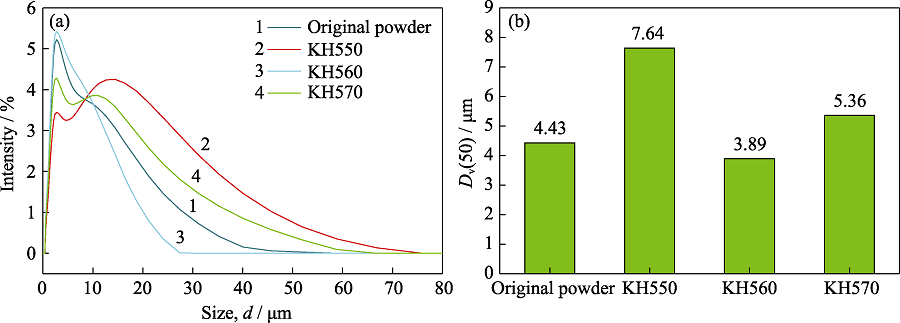

Fig. 4 Particle size distribution (a) and average particle diameter (b) of activated alumina diagram after 2% (mass percentage) KH550, KH560 and KH570 coupling agent modification

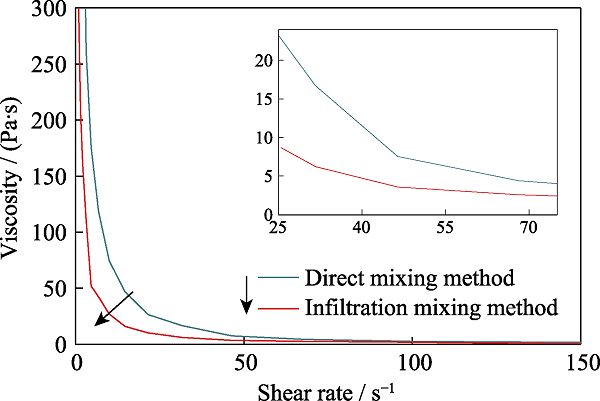

Fig. 6 Viscosity diagram of slurry with different mixing methods of modified activated alumina and resin. Inset shows the enlarged curues under shear rate less than 70 s-1

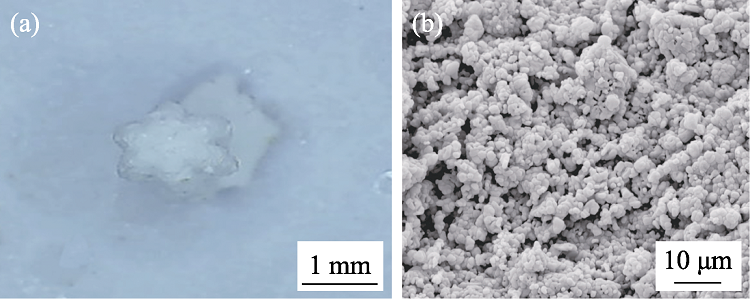

Fig. 7 Stereolithographic activated alumina sample diagram (a) after debounding and sintering and SEM image (b) of stereolithographic activated alumina sample after debounding and sintering

| [1] |

SHI L, YIN Y, WANG S, et al. Rational catalyst design for N2 reduction under ambient conditions: strategies towards enhanced conversion efficiency. ACS Catalysis, 2020, 10(12): 6870-6899.

DOI URL |

| [2] |

LIU L. Multiscale structural characterization of shaped catalysts. Trends in Chemistry, 2021, 3(11): 898-901.

DOI URL |

| [3] |

DENG Z Y, FUKASAWA T, ANDO M, et al. High-surface-area alumina ceramics fabricated by the decomposition of Al(OH)3. Journal of the American Ceramic Society, 2010, 84(3): 485-491.

DOI URL |

| [4] |

NIJMEIJER A, KRUIDHOF H, BREDESEN R, et al. Preparation and properties of hydrothermally stable-alumina membranes. Journal of the American Ceramic Society, 2010, 84(1): 136-140.

DOI URL |

| [5] |

RODIANSONO, MD ASTUTI, MUJIYANTI D R, et al. Novel preparation method of bimetallic Ni-In alloy catalysts supported on amorphous alumina for the highly selective hydrogenation of furfural. Molecular Catalysis, 2018, 445: 52-60.

DOI URL |

| [6] |

HE Y, LIU S, PRIEST C, et al. Atomically dispersed metal-nitrogen- carbon catalysts for fuel cells: advances in catalyst design, electrode performance, and durability improvement. Chemical Society Reviews, 2020, 49(11): 3484-3524.

DOI URL |

| [7] | CHEN R, LIAN Q, WANG J, et al. A stereolithographic diamond- mixed resin slurry for complex SiC ceramic structure. Journal of the European Ceramic, 2021, 41(7): 3991-3999. |

| [8] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116(2/3): 100736.

DOI URL |

| [9] |

BIKAS H, STAVROPOULOS P, CHRYSSOLOURIS G. Additive manufacturing methods and modelling approaches: a critical review. The International Journal of Advanced Manufacturing Technology, 2016, 83(1-4): 389-405.

DOI URL |

| [10] |

SALMI M. Additive manufacturing processes in medical applications. Materials, 2021, 14(1): 191.

DOI URL |

| [11] |

ZHAO S, SIQUEIRA G, D RDOVA S, et al. Additive manufacturing of silica aerogels. Nature, 2020, 584(7821): 387-392.

DOI URL |

| [12] |

XING H Y, ZOU B, LIU X Y, et al. Original Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. Journal of the European Ceramic Society, 2020, 40(15): 5797-5809.

DOI URL |

| [13] |

ZHOU T, ZHANG L, YAO Q, et al. SLA 3D printing of high quality spine shaped β-TCP bioceramics for the hard tissue repair applications. Ceramics International, 2019, 46(6): 7609-7614.

DOI URL |

| [14] | STRAATHOF M H, DRIEL C, LINGEN J, et al. Development of propellant compositions for vat photopolymerization additive manufacturing. Propellants, Explosives, Pyrotechnics, 2020, 45(1): 36-52. |

| [15] |

XU X, AWAD A, MARTINEZ P R, et al. Vat photopolymerization 3D printing for advanced drug delivery and medical device applications. Journal of Controlled Release, 2020, 329(10): 743-757.

DOI URL |

| [16] |

WEI L N, JIA M L, ZHOU M, et al. Vat polymerization-based bioprinting-process, materials, applications and regulatory challenges. Biofabrication, 2020, 12(2): 022001.

DOI URL |

| [17] |

QUAN H, ZHANG T, XU H, et al. Photo-curing 3D printing technique and its challenges. Bioactive Materials, 2020, 5(1): 110-115.

DOI URL |

| [18] |

BAE C J, RAMACHANDRAN A, HALLORAN J W. Quantifying particle segregation in sequential layers fabricated by additive manufacturing. Journal of the European Ceramic Society, 2018, 38(11): 4082-4088.

DOI URL |

| [19] |

LIU Y, CHENG L J, LI H, et al. Formation mechanism of stereolithography of Si3N4 slurry using silane coupling agent as modifier and dispersant. Ceramics International, 2020, 46(10): 14583-14590.

DOI URL |

| [20] |

SUN J, BINNER J, BAI J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. Journal of the European Ceramic Society, 2019, 39(4): 1660-1667.

DOI URL |

| [21] |

ZHANG J, WEI L, MENG X, et al. Digital light processing- stereolithography three-dimensional printing of yttria-stabilized zirconia. Ceramics International, 2020, 46(7): 8745-8753.

DOI URL |

| [22] |

SHUAI Z, NA S, ZHE Z. Surface modification of α-Al2O3 with dicarboxylic acids for the preparation of UV-curable ceramic suspensions. Journal of the European Ceramic Society, 2017, 37(4): 1607-1616.

DOI URL |

| [23] |

ZHANG K Q, XIE C, WANG G, et al. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceramics International, 2019, 45(1): 203-208.

DOI URL |

| [24] |

DUFAUD O, MARCHAL P, CORBEL S. Rheological properties of PZT suspensions for stereolithography. Journal of the European Ceramic Society, 2002, 22(13): 2081-2092.

DOI URL |

| [25] |

WU X, LIAN Q, LI D, et al. Effects of soft-start exposure on the curing characteristics and flexural strength in ceramic projection stereolithography process. Journal of the European Ceramic Society, 2019, 39(13): 3788-3796.

DOI URL |

| [26] |

LI X, ZHANG J, DUAN Y, et al. Rheology and curability characterization of photosensitive slurries for 3D printing of Si3N4 ceramics. Applied Sciences, 2020, 10(18): 6438.

DOI URL |

| [27] |

GENTRY S, HALLORAN J W. Light scattering in absorbing ceramic suspensions: effect on the width and depth of photopolymerized features. Journal of the European Ceramic Society, 2015, 35(6): 1895-1904.

DOI URL |

| [28] |

BADEV A, ABOULIATIM Y, CHARTIER T, et al. Photopolymerization kinetics of a polyether acrylate in the presence of ceramic fillers used in stereolithography. Journal of Photochemistry and Photobiology A-Chemistry, 2011, 222(1): 117-122.

DOI URL |

| [29] |

ZHANG Y, XU Y, SIMON-MASSERON A, et al. Radical photoinitiation with LEDs and applications in the 3D printing of composites. Chemical Society Reviews, 2021, 50(6): 3824-3841.

DOI URL |

| [1] | WU Xiangquan, TENG Jiachen, JI Xiangxu, HAO Yubo, ZHANG Zhongming, XU Chunjie. Textured Porous Al2O3-SiO2 Composite Ceramic Platelet-sphere Slurry: Characteristics and Simulation of Light Intensity Distribution [J]. Journal of Inorganic Materials, 2024, 39(7): 769-778. |

| [2] | LIU Guoqian, YAN Changhai, ZHANG Keqiang, JIN Hua, HE Rujie. Effect of Solid Loading on the Property of Al2O3 Ceramics in Stereolithographic Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 353-360. |

| [3] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [4] | WANG Yaning, ZHANG Yuqi, SONG Suocheng, CHEN Ruomeng, LIU Yaxiong, DUAN Yugang. Laser Stereolithography for Zirconia Ceramic Fabrication and Its Debinding and Sintering Process [J]. Journal of Inorganic Materials, 2022, 37(3): 303-309. |

| [5] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [6] | ZHOU Hongli, CAI Zhiyong, WANG Xiaofeng, ZENG Jin, FENG Yan, PENG Chaoqun, WANG Richu. Direct Ink Writing of Gypsum: Developing a Printable Gypsum Paste [J]. Journal of Inorganic Materials, 2022, 37(3): 338-346. |

| [7] | LI Xing-Bang,ZHONG He,ZHANG Jing-Xian,DUAN Yu-Sen,JIANG Dong-Liang. Powder Characteristics on the Rheological Performance of Resin-based Zirconia Suspension for Stereolithography [J]. Journal of Inorganic Materials, 2020, 35(2): 231-235. |

| [8] | ZHOU Zhu-Fa,WANG Shu-Mei,WU Ming-Min. Preparation of Reticulated Ceramics by Gelcasting [J]. Journal of Inorganic Materials, 2008, 23(1): 203-208. |

| [9] | SUN Jing,GAO Lian,GUO Jingkun. Rheology Properties of Stable Slurry Formed by Nano-sized Y-TZP [J]. Journal of Inorganic Materials, 1997, 12(1): 35-40. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||