Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 333-337.DOI: 10.15541/jim20210634

• RESEARCH ARTICLE • Previous Articles Next Articles

ZENG Yong1,2,3( ), ZHANG Zijia1,2,3, SUN Lijun1,2,3, YAO Haihua1,2,3, CHEN Jiming1,2,3

), ZHANG Zijia1,2,3, SUN Lijun1,2,3, YAO Haihua1,2,3, CHEN Jiming1,2,3

Received:2021-10-12

Revised:2021-10-25

Published:2022-03-20

Online:2021-11-01

About author:ZENG Yong (1987-), male, associate professor. E-mail: zengyong@bjut.edu.cn

Supported by:CLC Number:

ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 333-337.

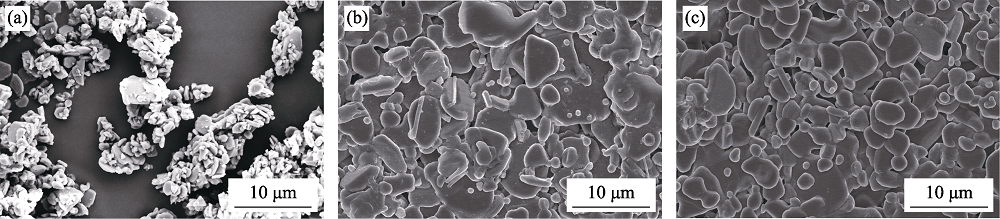

Fig. 3 SEM images of surface modified alumina powder and sintered alumina ceramics after debinding in different atmospheres (a) Surface modified alumina powder; (b) Sintered alumina ceramics after debinding in air; (c) Sintered alumina ceramics after debinding in argon

| Atmosphere | Shrinkage/% | Densification/% | ||

|---|---|---|---|---|

| X | Y | Z | ||

| Air | 4.81 | 4.55 | 9.23 | 95.39 |

| Ar | 5.62 | 5.48 | 11.54 | 96.72 |

Table 1 Shrinkage and density of sintered samples after debinding in different atmospheres

| Atmosphere | Shrinkage/% | Densification/% | ||

|---|---|---|---|---|

| X | Y | Z | ||

| Air | 4.81 | 4.55 | 9.23 | 95.39 |

| Ar | 5.62 | 5.48 | 11.54 | 96.72 |

| [1] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [2] | WANG J L, LI F L, HU B Q. Present situation and development of fine alumina in China. Ceramic, 2021(6): 12-14. |

| [3] | ZHU Z B, GUO Z J, LIU Y, et al. Development and application of alumina ceramics. Ceramic, 2003(1): 5-8. |

| [4] | SABAH A M, AZMAH H M A, JAAFAR C N A, et al. Effect of Cu metal of nanoscale particle size on the porosity and mechanical properties of porous alumina ceramics using yeast as a pore agent. Research Journal of Applied Sciences, Engineering and Technology, 2017, 14(5): 187-195. |

| [5] |

MEZA L R, DAS S, GREER J R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science, 2014, 345(6202): 1322-1326.

DOI URL |

| [6] |

ZHANG K Q, HE R J, DING G J, et al. Effects of fine grains and sintering additives on stereolithography additive manufactured Al2O3 ceramic. Ceramics International, 2021, 47(2): 2303-2310.

DOI URL |

| [7] | BENGISU M. Engineering Ceramics. Berlin: Springer Science & Business Media, 2013: 115-126. 2013: 115-126. |

| [8] |

PINARGOTE N W S, SMIRNOV A, PERETYAGIN N, et al. Direct ink writing technology (3D printing) of graphene-based ceramic nanocomposites: a review. Nanomaterials, 2020, 10(7): 1300.

DOI URL |

| [9] | JI H C, ZHANG X J, PEI W C, et al. Research progress of ceramic 3D printing technology and materials. Material Engineering, 2018, 46(7): 19-28. |

| [10] | LIANG D, HE R J, FANG D N. Research status of manufacturing technology of ceramic materials and structural additives. Advanced Ceramics, 2017, 38(4): 231-247. |

| [11] |

YANG W J, AN J, CHUA C K, et al. Acoustic absorptions of multifunctional polymeric cellular structures based on triply periodic minimal surfaces fabricated by stereolithography. Virtual and Physical Prototyping, 2020, 15(2): 242-249.

DOI URL |

| [12] |

AZARMI F, AMIRI A. Microstructural evolution during fabrication of alumina via laser stereolithography technique. Ceramics International, 2019, 45(1): 271-278.

DOI URL |

| [13] | WEI Y H, ZHAO D Y, CAO Q L, et al. Stereolithography-based additive manufacturing of high-performance osteoinductive calcium phosphate ceramics by a digital light- processing system. ACS Biomaterials Science & Engineering, 2020, 6(3): 1787-1797. |

| [14] |

LEE Y H, LEE J W, YANG S Y, et al. Dual-scale porous biphasic calcium phosphate gyroid scaffolds using ceramic suspensions containing polymer microsphere porogen for digital light processing. Ceramics International, 2021, 47(8): 11285-11293.

DOI URL |

| [15] |

YVES-CHRISTIAN H, JAN W, WILHELM M, et al. Net shaped high performance oxide ceramic parts by selective laser melting. Physics Procedia, 2010, 5: 587-594.

DOI URL |

| [16] |

LIU K, SUN H J, TAN Y L, et al. Additive manufacturing of traditional ceramic powder via selective laser sintering with cold isostatic pressing. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 945-952.

DOI URL |

| [17] |

KRUTH J P, MERCELIS P, van VAERENBERGH J, et al. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyping Journal, 2005, 11(1): 26-36.

DOI URL |

| [18] |

CHEN F, ZHU H, WU J M, et al. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology. Ceramics International, 2020, 46(8): 11268-11274.

DOI URL |

| [19] |

ENNETI R K, PARK S J, GERMAN R M, et al. Review: thermal debinding process in particulate materials processing. Materials and Manufacturing Processes, 2012, 27(2): 103-118.

DOI URL |

| [20] |

XING H Y, ZUO B, LI S S, et al. Study on surface quality, precision and mechanical properties of 3D printed ZrO2 ceramic components by laser scanning stereolithography. Ceramics International, 2018, 43(18): 16340-16347.

DOI URL |

| [21] |

LIAN Q, WU X Q, LI D C, et al. Accurate printing of a zirconia molar crown bridge using three-part auxiliary supports and ceramic mask projection stereolithography. Ceramics International, 2019, 45(15): 18814-18822.

DOI URL |

| [22] |

WANG K, QIU M B, CHEN J, et al. Study on defect-free debinding green body of ceramic formed by DLP technology. Ceramics International, 2020, 46(2): 2438-244.

DOI URL |

| [1] | WU Xiangquan, TENG Jiachen, JI Xiangxu, HAO Yubo, ZHANG Zhongming, XU Chunjie. Textured Porous Al2O3-SiO2 Composite Ceramic Platelet-sphere Slurry: Characteristics and Simulation of Light Intensity Distribution [J]. Journal of Inorganic Materials, 2024, 39(7): 769-778. |

| [2] | LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body [J]. Journal of Inorganic Materials, 2023, 38(4): 461-468. |

| [3] | JIA Yuna, CAO Xu, JIAO Xiuling, CHEN Dairong. Preparation of Alumina Ceramic Continuous Fibers with Inorganic Acidic Aluminum Sol as Precursor [J]. Journal of Inorganic Materials, 2023, 38(11): 1257-1264. |

| [4] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [5] | WANG Xingang, YANG Qingqing, LIN Genlian, GAO Wei, QIN Fulin, LI Rongzhen, KANG Zhuang, WANG Xiaofei, JIANG Danyu, YAN Jina. High Temperature Tensile Property of Domestic 550-grade Continuous Alumina Ceramic Fiber [J]. Journal of Inorganic Materials, 2022, 37(6): 629-635. |

| [6] | ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier [J]. Journal of Inorganic Materials, 2022, 37(3): 297-302. |

| [7] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [8] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [9] | PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(7): 673-684. |

| [10] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| [11] | HAN Hai-Bo, WANG You-He, LI Kang, LEI Jie, LIU Dan-He, YAN Zi-Feng. Acetic Acid Leaching on the Structure, Acidity and Performance of HMOR Catalyst [J]. Journal of Inorganic Materials, 2019, 34(2): 179-185. |

| [12] | CHEN Wen-Bo, CHEN Lun-Jiang, LIU Chuan-Dong, CHENG Chang-Ming, TONG Hong-Hui, ZHU Hai-Long. Preparation of Spherical Alumina Powder by RF Thermal Plasma: Numerical Simulation and Experimentation [J]. Journal of Inorganic Materials, 2018, 33(5): 550-556. |

| [13] | YANG Jing-Feng, WANG Qi-Hua, WANG Ting-Mei. Synthesis and Property of Alumina Aerogel [J]. Journal of Inorganic Materials, 2018, 33(3): 259-265. |

| [14] | WANG You-He, WANG Xiao-Dong, XU Jing-Wei, SUN Hong-Man, WU Cheng-Cheng, YAN Zi-Feng, JI Sheng-Fu. Hierarchical ZSM-5 Zeolite: Preparation by Sequential Desilication-dealumination and Catalytic Performance in Methanol to Gasoline Reaction [J]. Journal of Inorganic Materials, 2018, 33(11): 1193-1200. |

| [15] | YUAN Kang, LIAO Qi-Long, WANG Fu, DAI Yun-Ya, HUANG Jin-Shan. Effects of Sintering Aids (Y3+, La3+ and Mg2+) on the Optical Transmittance of Translucent Alumina Ceramic [J]. Journal of Inorganic Materials, 2017, 32(9): 1004-1008. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||