无机材料学报 ›› 2022, Vol. 37 ›› Issue (7): 724-730.DOI: 10.15541/jim20210631 CSTR: 32189.14.10.15541/jim20210631

程成( ), 李建波, 田震, 王鹏将, 康慧君(

), 李建波, 田震, 王鹏将, 康慧君( ), 王同敏

), 王同敏

收稿日期:2021-10-11

修回日期:2021-11-19

出版日期:2022-07-20

网络出版日期:2021-12-02

通讯作者:

康慧君, 教授. E-mail: kanghuijun@dlut.edu.cn作者简介:程 成(1996-), 男, 硕士研究生. E-mail: cc2019@mail.dlut.edu.cn

基金资助:

CHENG Cheng( ), LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun(

), LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun( ), WANG Tongmin

), WANG Tongmin

Received:2021-10-11

Revised:2021-11-19

Published:2022-07-20

Online:2021-12-02

Contact:

KANG Huijun, professor. E-mail: kanghuijun@dlut.edu.cnAbout author:CHENG Cheng (1996-), male, Master candidate. E-mail: cc2019@mail.dlut.edu.cn

Supported by:摘要:

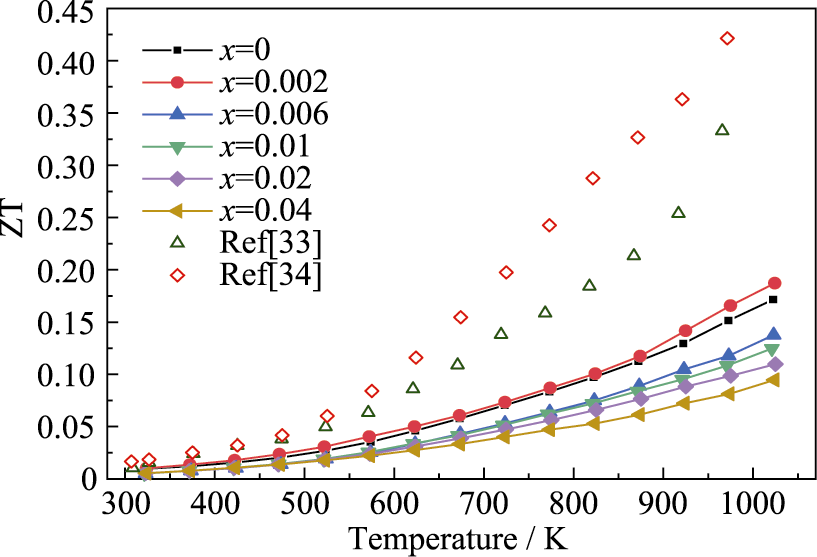

In2O3作为一种良好的光电和气敏材料, 因高温下具有优异的热电性能在热电领域也获得广泛关注。本研究通过固相反应法结合放电等离子烧结(SPS)成功将原位自生的InNbO4第二相引入到In2O3基体中, 优化了块体样品的制备工艺。同时, InNbO4改善了样品的电输运性能, 使载流子浓度明显提高, 在1023 K时电导率最高可达1548 S·cm-1, 高于大多数元素掺杂的样品。其中, 0.998In2O3/0.002InNbO4样品的热电性能测试表明, 在1023 K时, 其功率因子可达到0.67 mW·m-1·K-2, 热电优值(ZT)达到最高值0.187。综上所述, 通过在In2O3中原位复合InNbO4第二相可以很好地改善In2O3基热电陶瓷的电性能, 进而调控其高温热电性能。

中图分类号:

程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730.

CHENG Cheng, LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun, WANG Tongmin. Thermoelectric Property of In2O3/InNbO4 Composites[J]. Journal of Inorganic Materials, 2022, 37(7): 724-730.

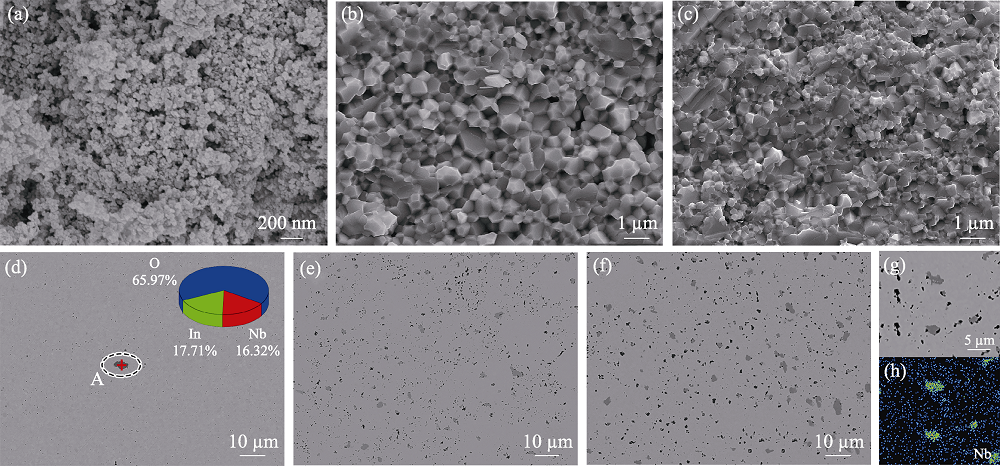

图3 纯In2O3粉体样品(a), (1-x)In2O3/xInNbO4 (x=(b) 0, (c) 0.04)块体样品断口, (1-x)In2O3/xInNbO4(x=(d) 0.002, (e) 0.02, (f) 0.04)块体样品表面的SEM照片; (g, h) 0.96In2O3/0.04InNbO4高倍数下的Nb元素分布图

Fig. 3 SEM images of (a) pure In2O3 powder, fracture surface for (1-x)In2O3/xInNbO4 (x=(b) 0, (c) 0.04), surface SEM images for (1-x)In2O3/xInNbO4 (x=0.002 (d), x=0.02 (e), x=0.04 (f)); (g-h) elemental distributions of Nb at high magnification for 0.96In2O3/0.04InNbO4

| (1-x)In2O3/xInNbO4 | ρm/(g·cm-3) | ρth/(g·cm-3) | ρr/% | n/(×1019, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|---|

| x=0 | 6.969 | 7.120 | 97.9 | 0.46 | 94.26 |

| x=0.002 | 7.016 | 7.119 | 98.6 | 0.78 | 76.22 |

| x=0.006 | 6.811 | 7.117 | 95.7 | 5.90 | 38.21 |

| x=0.01 | 6.658 | 7.116 | 93.6 | 9.80 | 38.43 |

| x=0.02 | 6.598 | 7.112 | 92.8 | 20.88 | 40.22 |

| x=0.04 | 6.547 | 7.100 | 92.2 | 45.24 | 39.86 |

表1 (1-x)In2O3/xInNbO4块体样品室温下的测试密度(ρm)、理论密度(ρth)、相对密度(ρr)、载流子浓度(n)和迁移率(μ)

Table 1 Measured densities(ρm), theoretical densities(ρth), relative densities (ρr), carrier concentrations (n) and carrier mobilities (μ) of (1-x)In2O3/xInNbO4 samples at room temperature

| (1-x)In2O3/xInNbO4 | ρm/(g·cm-3) | ρth/(g·cm-3) | ρr/% | n/(×1019, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|---|

| x=0 | 6.969 | 7.120 | 97.9 | 0.46 | 94.26 |

| x=0.002 | 7.016 | 7.119 | 98.6 | 0.78 | 76.22 |

| x=0.006 | 6.811 | 7.117 | 95.7 | 5.90 | 38.21 |

| x=0.01 | 6.658 | 7.116 | 93.6 | 9.80 | 38.43 |

| x=0.02 | 6.598 | 7.112 | 92.8 | 20.88 | 40.22 |

| x=0.04 | 6.547 | 7.100 | 92.2 | 45.24 | 39.86 |

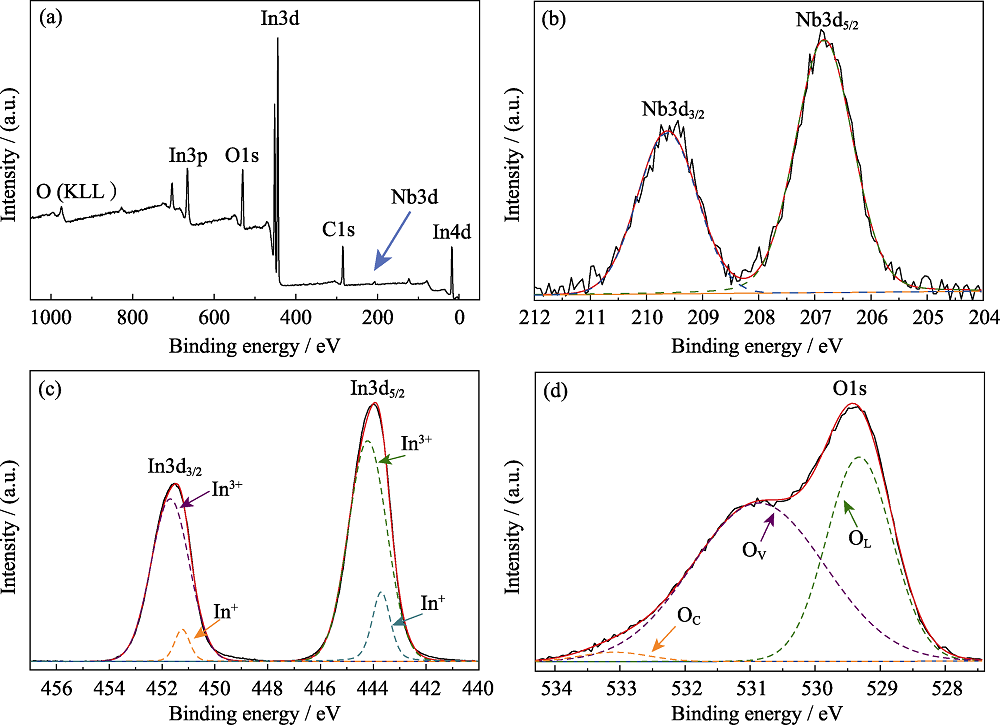

图4 0.96In2O3/0.04InNbO4样品的(a)XPS全谱图, 以及(b) Nb3d、(c) In3d和(d) O1s轨道的XPS高分辨谱图

Fig. 4 (a) XPS total survey and high-resolution XPS spectra of (b) Nb3d, (c) In3d and (d) O1s core-level regions for 0.96In2O3/0.04InNbO4 sample

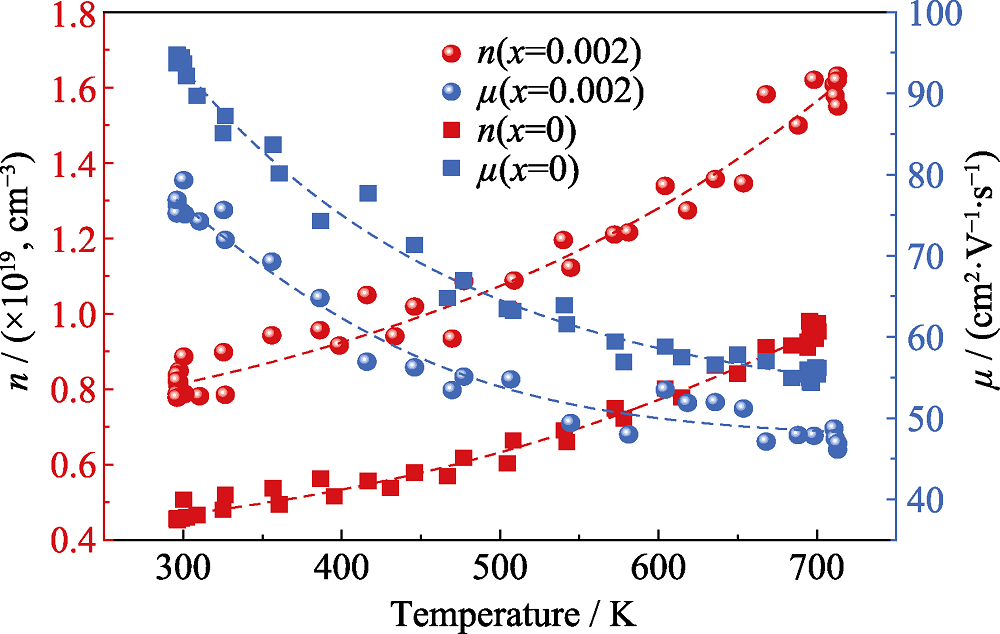

图5 (1-x)In2O3/xInNbO4(x=0, 0.002)样品的载流子浓度(n)和载流子迁移率(μ)随温度的变化曲线

Fig. 5 Temperature dependence of electrical carrier concentrations and mobilities of (1-x)In2O3/xInNbO4(x=0, 0.002)

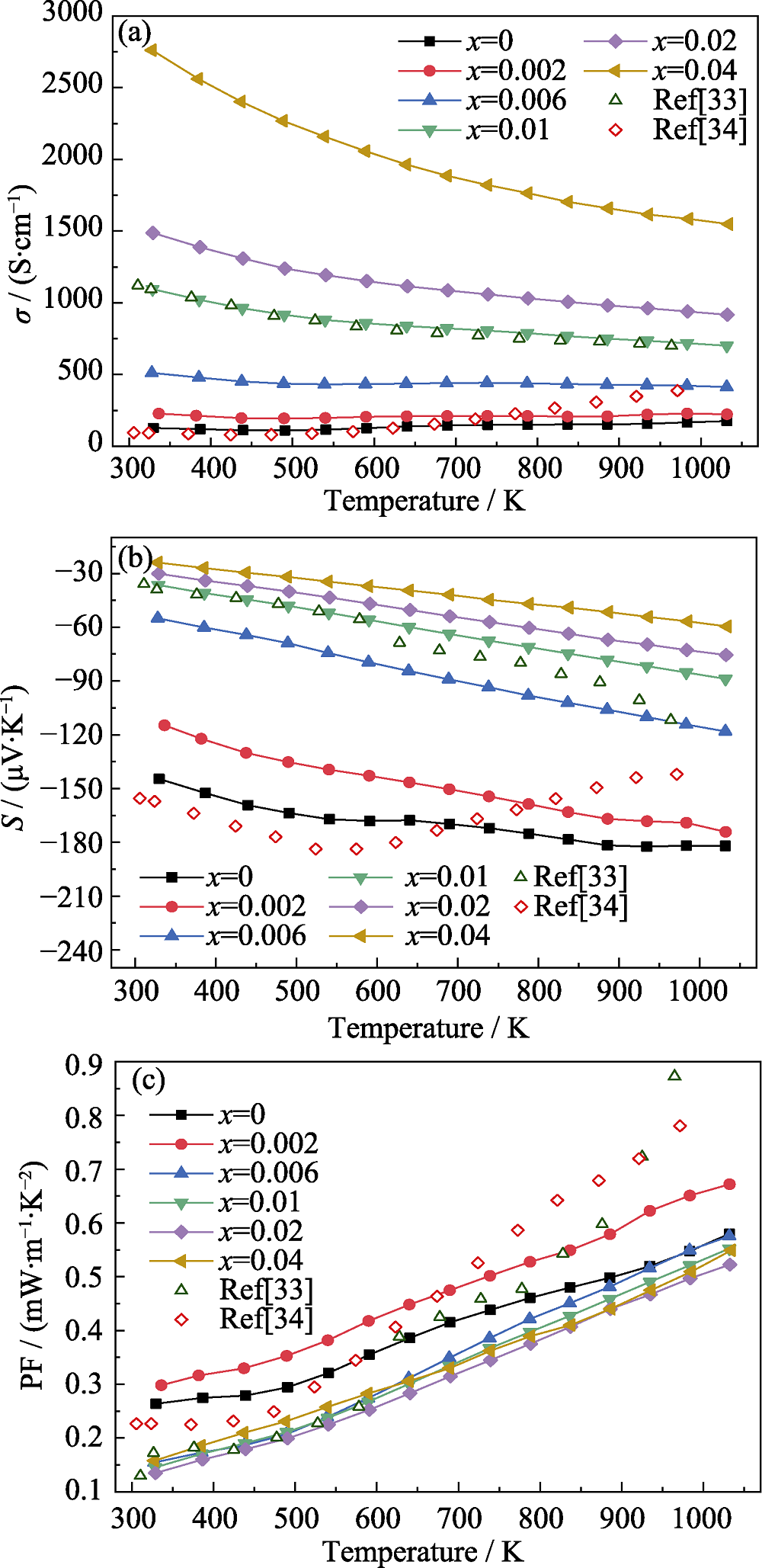

图6 (1-x)In2O3/xInNbO4、In1.76(Zn0.12Ge0.12)O3[33]和In1.88V0.12O3[34]的(a) 电导率、(b) Seebeck系数和(c) 功率因子随温度的变化曲线

Fig. 6 Temperature dependence of (a) electrical conductivities, (b) Seebeck coefficients and (c) power factors of (1-x)In2O3/xInNbO4, In1.76(Zn0.12Ge0.12)O3[33] and In1.88V0.12O3[34]

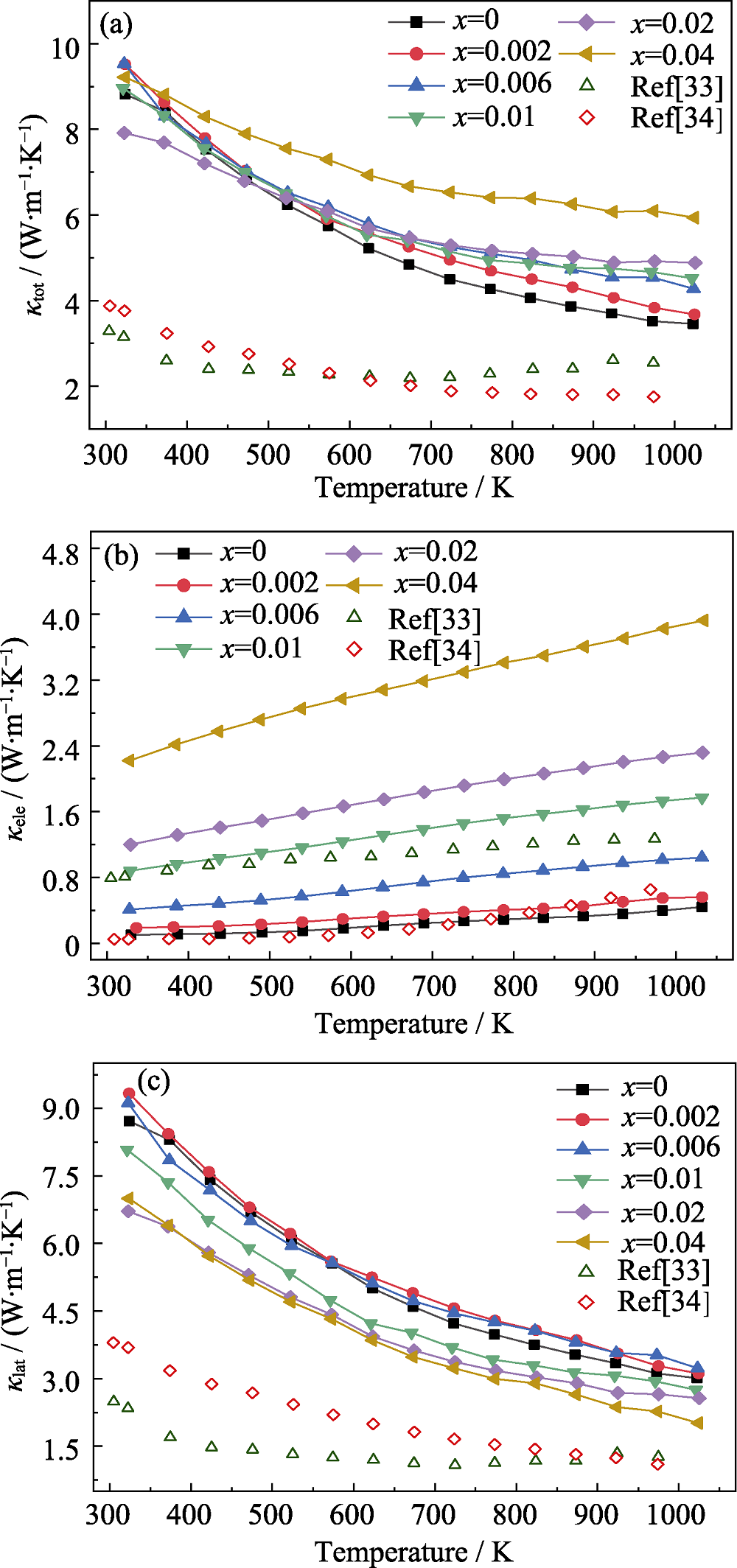

图7 (1-x)In2O3/xInNbO4、In1.76(Zn0.12Ge0.12)O3[33]和In1.88V0.12O3[34]的(a)总热导率、(b)电子热导率和(c)晶格热导率随温度的变化曲线

Fig. 7 Temperature dependence of (a) total thermal conductivity, (b) electronic thermal conductivity and (c) lattice thermal conductivity of (1-x)In2O3/xInNbO4, In1.76(Zn0.12Ge0.12)O3[33] and In1.88V0.12O3[34]

图8 (1-x)In2O3/xInNbO4、In1.76(Zn0.12Ge0.12)O3[33]和In1.88V0.12O3[34]的热电优值ZT随温度的变化曲线

Fig. 8 Temperature dependence of ZT for (1-x)In2O3/xInNbO4, In1.76(Zn0.12Ge0.12)O3[33] and In1.88V0.12O3[34]

| [1] | BAKKER F L, SLACHTER A, ADAM J P, et al. Interplay of peltier and seebeck effects in nanoscale nonlocal spin valves. Physical Review Letters, 2010, 105(13): 136601. |

| [2] |

BELL L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science, 2008, 321(5895): 1457-1461.

DOI URL |

| [3] |

LI J B, WANG J, LI J F, et al. Broadening the temperature range for high thermoelectric performance of bulk polycrystalline strontium titanate by controlling the electronic transport properties. Journal of Materials Chemistry C, 2018, 6(28): 7594-7603.

DOI URL |

| [4] |

KANG H J, ZHANG X Y, WANG Y X, et al. Effect of rare-earth variable-valence element Eu doping on thermoelectric property of BiCuSeO. Journal of Inorganic Materials, 2020, 35(9): 1041-1046.

DOI URL |

| [5] |

SNYDER G J, TOBERER E S. Complex thermoelectric materials. Nature Materials, 2008, 7(2): 105-114.

DOI URL |

| [6] |

TAN G, ZHAO L D, KANATZIDIS M G. Rationally designing high-performance bulk thermoelectric materials. Chemical Reviews, 2016, 116(19): 12123-12149.

DOI URL |

| [7] | ROWE D M. CRC Handbook of Thermoelectrics. Boca Raton: CRC, 1995: 407. |

| [8] |

ZHANG C C, WANG X, PENG L M. Thermoelectric transport characteristics of n-type (PbTe)1-x-y(PbS)x(Sb2Se3)y systems via stepwise addition of dual components. Journal of Inorganic Materials, 2021, 36(9): 936-942.

DOI URL |

| [9] |

MEHTA R J, ZHANG Y, KARTHIK C, et al. A new class of doped nanobulk high-figure-of-merit thermoelectrics by scalable bottom-up assembly. Nature Materials, 2012, 11(3): 233-240.

DOI URL |

| [10] |

BISWAS K, HE J, BLUM I D, et al. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature, 2012, 489(7416): 414-418.

DOI URL |

| [11] | SARAMAT A, SVENSSON G, PALMQVIST A E C, et al. Large thermoelectric figure of merit at high temperature in Czochralski- grown clathrate Ba8Ga16Ge30. Journal of Applied Physics, 2006, 99(2): 023708. |

| [12] |

LAN J L, LIN Y H, LIU Y, et al. High thermoelectric performance of nanostructured In2O3-based ceramics. Journal of the American Ceramic Society, 2012, 95(8): 2465-2469.

DOI URL |

| [13] | KING P D C, VEAL T D, FUCHS F, et al. Band gap, electronic structure, and surface electron accumulation of cubic and rhombohedral In2O3. Physical Review B, 2009, 79(20): 205211. |

| [14] | GUILMEAU E, BERARDAN D, SIMON C, et al. Tuning the transport and thermoelectric properties of In2O3 bulk ceramics through doping at in-site. Journal of Applied Physics, 2009, 106(5): 053715. |

| [15] |

MILLER D R, AKBAR S A, MORRIS P A. Nanoscale metal oxide-based heterojunctions for gas sensing: a review. Sensors and Actuators B-Chemical, 2014, 204: 250-272.

DOI URL |

| [16] |

HAMBERG I, GRANQVIST C G, BERGGREN K F, et al. Band- gap widening in heavily Sn-doped In2O3. Physical Review B, 1984, 30(6): 3240-3249.

DOI URL |

| [17] |

MAREZIO M. Refinement of the crystal structure of In2O3 at two wavelengths. Acta Crystallographica, 1966, 20: 723-728.

DOI URL |

| [18] | DU K, DENG S P, QI N, et al. Ultralow thermal conductivity in In2O3 mediated by porous structures. Microporous and Mesoporous Materials, 2019, 288: 109525. |

| [19] |

LIU Y, XU W, LIU D B, et al. Enhanced thermoelectric properties of Ga-doped In2O3 ceramics via synergistic band gap engineering and phonon suppression. Physical Chemistry Chemical Physics, 2015, 17(17): 11229-11233.

DOI URL |

| [20] | CHENG B, LIN Y H, LAN J L, et al. Preparation of In2O3-Sr2RuErO6 composite ceramics by the spark plasma sintering and their thermoelectric performance. Journal of Materials Science & Technology, 2011, 27(12): 1165-1168. |

| [21] | GREGORY O J, AMANI M, FRALICK G C. Thermoelectric power factor of In2O3:Pd nanocomposite films. Applied Physics Letters, 2011, 99(1): 013107. |

| [22] | LÜ J, KAKO T, ZOU Z G, et al. Band structure design and photocatalytic activity of In2O3/N-InNbO4 composite. Applied Physics Letters, 2009, 95(3): 032107. |

| [23] |

WANG J, LI J B, YU H Y, et al. Enhanced thermoelectric performance in n-type SrTiO3/SiGe composite. ACS Applied Materials Interfaces, 2020, 12(2): 2687-2694.

DOI URL |

| [24] | CHEN Q F, WANG X X, WU Z S, et al. Recent advances in SnSe- based thermoelectric materials. Chinese Journal of Rare Metals, 2020, 44(12): 1316-1324. |

| [25] |

YANG Y X, WU Y H, ZHANG Q, et al. Enhanced thermoelectric performance of Bi2Se3/TiO2 composite. Rare Metals, 2020, 39(8): 887-894.

DOI URL |

| [26] |

ZHOU M, ZU X T, SUN K, et al. Enhanced photocatalytic hydrogen generation of nano-sized mesoporous InNbO4 crystals synthesized via a polyacrylamide gel route. Chemical Engineering Journal, 2017, 313: 99-108.

DOI URL |

| [27] |

BADRINARAYANAN S, MANDALE A B. Oxygen interaction with ternary chalcogenide: an electron spectroscopy for chemical analysis study of AgInTe2. Journal of Materials Research, 1995, 10(5): 1091-1098.

DOI URL |

| [28] |

CHATTERJI D, VEST R W. Thermodynamic properties of system indium-oxygen. Journal of the American Ceramic Society, 1972, 55(11): 575-578.

DOI URL |

| [29] | ZHANG B, BAO N, WANG T, et al. High-performance room temperature NO2 gas sensor based on visible light irradiated In2O3 nanowires. Journal of Alloys and Compounds, 2021, 867: 159076. |

| [30] |

ZHANG B, CHENG M, LIU G, et al. Room temperature NO2 gas sensor based on porous Co3O4 slices/reduced graphene oxide hybrid. Sensors and Actuators B: Chemical, 2018, 263: 387-399.

DOI URL |

| [31] | LI J B, WANG Y X, YANG X, et al. Processing bulk insulating CaTiO3 into a high-performance thermoelectric material. Chemical Engineering Journal, 2022, 428: 131121. |

| [32] | YANG D, SU X, LI J, et al. Blocking ion migration stabilizes the high thermoelectric performance in Cu2Se composites. Advanced Materials, 2020, 32(40): 2003730. |

| [33] | AHMAD A, HUSSAIN M, LIN Y H. Synergistically improving the thermoelectric performance of In2O3 via a dual-doping and nanostructuring approach. Materials Research Express, 2019, 6(10): 105507. |

| [34] |

AHMAD A, HUSSAIN M, ZHOU Z F, et al. Thermoelectric performance enhancement of vanadium doped n-type In2O3 ceramics via carrier engineering and phonon suppression. ACS Applied Energy Materials, 2020, 3(2): 1552-1558.

DOI URL |

| [35] |

CHENG B, FANG H, LAN J L, et al. Thermoelectric performance of Zn and Ge co-doped In2O3 fine-grained ceramics by the spark plasma sintering. Journal of the American Ceramic Society, 2011, 94(8): 2279-2281.

DOI URL |

| [36] |

LIU Y, LIN Y H, LAN J L, et al. Effect of transition-metal cobalt doping on the thermoelectric performance of In2O3 ceramics. Journal of the American Ceramic Society, 2010, 93(10): 2938-2941.

DOI URL |

| [37] |

BERARDAN D, GUILMEAU E, MAIGNAN A, et al. In2O3:Ge, a promising n-type thermoelectric oxide composite. Solid State Communications, 2008, 146(1/2): 97-101.

DOI URL |

| [38] |

LIU Y, LIN Y H, XU W, et al. High-temperature transport property of In2-xCexO3 (0≤x≤0.10) fine grained ceramics. Journal of the American Ceramic Society, 2012, 95(8): 2568-2572.

DOI URL |

| [39] | MORELLI D T, HEREMANS J P, SLACK G A. Estimation of the isotope effect on the lattice thermal conductivity of group IV and group III-V semiconductors. Physical Review B, 2002, 66(19): 195304. |

| [1] | 程俊, 张家伟, 仇鹏飞, 陈立东, 史迅. P掺杂β-FeSi2材料的制备与热电输运性能[J]. 无机材料学报, 2024, 39(8): 895-902. |

| [2] | 陈浩, 樊文浩, 安德成, 陈少平. 能带优化和载流子调控改善SnTe的热电性能[J]. 无机材料学报, 2024, 39(3): 306-312. |

| [3] | 田震, 蒋全伟, 李建波, 于砺锋, 康慧君, 王同敏. 热变形协同优化BiSbSe1.50Te1.50材料电热输运[J]. 无机材料学报, 2024, 39(12): 1316-1324. |

| [4] | 张哲, 孙婷婷, 王连军, 江莞. 不同维度Ag2Se构筑柔性热电薄膜的性能优化与器件集成研究[J]. 无机材料学报, 2024, 39(11): 1221-1227. |

| [5] | 孟雨婷, 王雪梅, 章淑娴, 陈志炜, 裴艳中. Bi2Te3基热电材料的单带和双带传输特性转变[J]. 无机材料学报, 2024, 39(11): 1283-1291. |

| [6] | 苏浩健, 周敏, 李来风. 多元素掺杂优化SnTe的热电性能[J]. 无机材料学报, 2024, 39(10): 1159-1166. |

| [7] | 肖娅妮, 吕嘉南, 李振明, 刘铭扬, 刘伟, 任志刚, 刘弘景, 杨东旺, 鄢永高. Bi2Te3基热电材料的湿热稳定性研究[J]. 无机材料学报, 2023, 38(7): 800-806. |

| [8] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [9] | 李建波, 田震, 蒋全伟, 于砺锋, 康慧君, 曹志强, 王同敏. 不同元素掺杂对CaTiO3微观结构及热电性能的影响[J]. 无机材料学报, 2023, 38(12): 1396-1404. |

| [10] | 王鹏将, 康慧君, 杨雄, 刘颖, 程成, 王同敏. 熵调控抑制ZrNiSn基half-Heusler热电材料的晶格热导率[J]. 无机材料学报, 2022, 37(7): 717-723. |

| [11] | 娄许诺, 邓后权, 李爽, 张青堂, 熊文杰, 唐国栋. Ge掺杂MnTe材料的热电输运性能[J]. 无机材料学报, 2022, 37(2): 209-214. |

| [12] | 金敏, 白旭东, 张如林, 周丽娜, 李荣斌. 区熔法制备金属硫化物Ag2S及其热电性能研究[J]. 无机材料学报, 2022, 37(1): 101-106. |

| [13] | 张岑岑, 王雪, 彭良明. 基于分步式双重调控n型(PbTe)1-x-y(PbS)x(Sb2Se3)y体系的热电传输特性[J]. 无机材料学报, 2021, 36(9): 936-942. |

| [14] | 杨青雨, 仇鹏飞, 史迅, 陈立东. 熵工程在热电材料中的应用[J]. 无机材料学报, 2021, 36(4): 347-354. |

| [15] | 蔡剑锋, 王泓翔, 刘国强, 蒋俊. 热电材料中的高熵结构设计[J]. 无机材料学报, 2021, 36(4): 399-404. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||