无机材料学报 ›› 2019, Vol. 34 ›› Issue (12): 1257-1264.DOI: 10.15541/jim20190098 CSTR: 32189.14.10.15541/jim20190098

叶长辉,顾瑜佳,王贵欣,毕丽丽

收稿日期:2019-03-04

修回日期:2019-04-28

出版日期:2019-12-20

网络出版日期:2019-06-17

作者简介:叶长辉(1973-), 男, 教授. E-mail: chye@zjut.edu.cn

基金资助:YE Chang-Hui,GU Yu-Jia,WANG Gui-Xin,BI Li-Li

Received:2019-03-04

Revised:2019-04-28

Published:2019-12-20

Online:2019-06-17

Supported by:摘要:

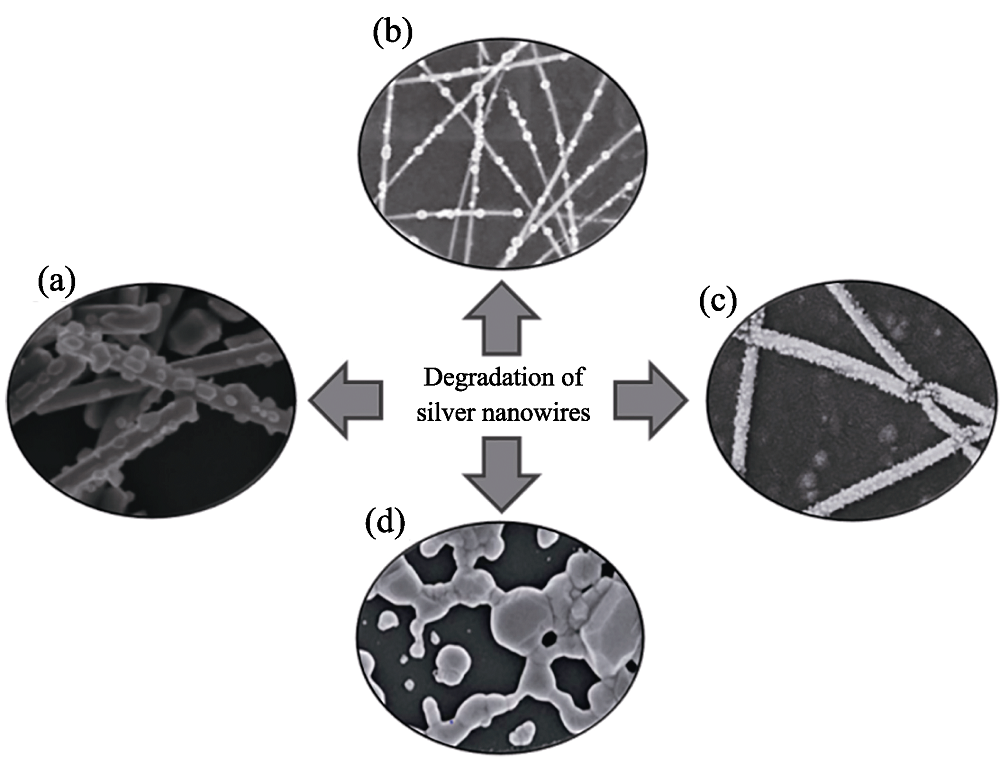

银纳米线透明导电薄膜材料作为新兴的无铟电极材料, 以其优越的光电性能和力学柔韧性, 在显示器件、触控面板、太阳能电池、智能加热和电磁屏蔽等领域崭露头角, 吸引越来越多的来自科研界及产业界的关注。然而, 银纳米线透明导电薄膜在应用中面临着较为严重的稳定性问题, 主要表现为容易被痕量含硫气体腐蚀, 在300 ℃以上的温度下纳米线出现断裂和球形化等结构失稳现象, 在紫外光照条件下腐蚀及球形化加剧, 在加载电场条件下出现离子迁移并产生孔洞及断裂现象。本文详细介绍了以上各种失效现象, 分析了失效的微观机制, 介绍了解决各种失效现象的具体措施。银纳米线透明导电薄膜失效行为的研究, 有助于进一步推动该材料的实际应用进程。

中图分类号:

叶长辉, 顾瑜佳, 王贵欣, 毕丽丽. 银纳米线透明导电薄膜的失效机理研究[J]. 无机材料学报, 2019, 34(12): 1257-1264.

YE Chang-Hui, GU Yu-Jia, WANG Gui-Xin, BI Li-Li. Degradation Mechanism of Silver Nanowire Transparent Conductive Films: a Review[J]. Journal of Inorganic Materials, 2019, 34(12): 1257-1264.

图1 银纳米线的不同失效形式

Fig. 1 Different failure modes of silver nanowires (a) Chemical corrosion[10]; (b) Thermal failure[15]; (c) Joule heat failure[18]; (d) Electromigration[27]

图2 同一银纳米线样品在环境条件下放置不同时间的透射电镜照片[10]

Fig. 2 TEM images of the same AgNW sample stored for different time after exposure to air at ambient condtions[10] (a) The sample just after synthesis; (b) The sample stored for 3 w; (c-e) The sample stored for 4, 5, and 24 w, respectively; (f) High-resolution TEM image of one of the crystallites that compose the shell with inset showing to the FFT of the image

| Parameters | Measured values | Theoretical values |

|---|---|---|

| d(013)/nm | 0.242 | 0.242 |

| d(111)/nm | 0.305 | 0.308 |

| ${{d}_{(10\bar{2})}}/\text{nm}$ | 0.311 | 0.311 |

| (013) ∠ (111)/(°) | 49.1 | 50.0 |

| (111) ∠ $(10\bar{2})$./(°) | 79.2 | 79.4 |

| $(10\bar{2})$.∠ (013)/(°) | 51.7 | 50.6 |

表1 图2(f)经傅立叶变换(FFT)后测量所得晶面间距和晶面夹角[10]

Table 1 Interplanar distances and angles between lattice planes from the FFT in Fig. 2(f)[10]

| Parameters | Measured values | Theoretical values |

|---|---|---|

| d(013)/nm | 0.242 | 0.242 |

| d(111)/nm | 0.305 | 0.308 |

| ${{d}_{(10\bar{2})}}/\text{nm}$ | 0.311 | 0.311 |

| (013) ∠ (111)/(°) | 49.1 | 50.0 |

| (111) ∠ $(10\bar{2})$./(°) | 79.2 | 79.4 |

| $(10\bar{2})$.∠ (013)/(°) | 51.7 | 50.6 |

图3 两根相邻银纳米线之间的连接示意图[12]

Fig. 3 Schematic representation of a junction between two adjacent AgNWs[12] (a) As-deposited junction; (b) Local sintering; (c) Initiation of the deterioration of the junction; (d) SEM image of a AgNW junction after thermal load just before the failure point; (e-g) SEM images of bare AgNW electrodes (e) Before annealing and after annealing for (f) 200 ℃, 20 min and (g) 380 ℃, 20 min[14]

图4 (a)电流通过两根银纳米线网络结点的有限元模拟[22]; (b,c)方阻为12 Ω/□的银纳米线电极持续流过电流密度为17 mA/cm2的电流17 d后的SEM照片[21]; (d~f)银纳米线网络在焦耳热作用下的SEM照片[22]: (d)银纳米线网络局部断裂; (e)热点的扩大; (f)热点合并, 形成电不连续区域

Fig. 4 (a) Finite-element simulation of the current flow through a two AgNW junction[22]; (b, c) SEM images of a 12 □/sq AgNW electrode under a constant current density of 17 mA/cm2 for 17 d [21]; (d-f) SEM image of AgNW network under Joule heating[22]: (d) Local fracture of the AgNW network; (e) Expansion of hot spots; (f) Hot spots merge to form an electrically discontinuous region

图5 光照后银纳米线上或周围出现的大、小颗粒的形貌图[23]

Fig. 5 The morphology of the small nanodots and large particles emerged on/around silver nanowires after light irradiation[23] (a) The small nanodots on/around single AgNW; (b) The small nanodots on/around AgNWs with different diameters; (c) The small nanodots at the end of AgNW and also the large particle at the wire-wire junction with inset showing the high magnification image; (d) The large particle adjoined AgNWs

图6 双晶银纳米线在54 mA电流下的SEM照片[26]

Fig. 6 SEM images of a bi-crystalline AgNW under a current of 54 mA[26] (a) Prior electrical stressing; (b-e) The direction of vacancy movement when the current flows to the left; (f-i) The direction of vacancy movement when the current moves to the right; (k-n) Surface morphology SEM images of the AgNW network in different stages of degradation[27]: (k) Fresh sample; (l) Degradation with larger grain size; (m) The emergence of larger voids; (n) Complete breakdown

图7 针对银纳米线的失效形式所提出的具体解决措施

Fig. 7 Remedy strategy of silver nanowire degradation (a) A self-assembled organic 2-mercaptobenzimidazole (MBI) used as an inhibitor of AgNWs[28]; (b) ZnO-AgNW composite electrode prepared by AP-SALD[12]

| [1] | SHANG Z, LI J, FAN C , et al . In situ study on surface roughening in radiation-resistant Ag nanowires. Nanotechnology, 2018,29(21):215708. |

| [2] | BELLET D, LAGRANGE M, SANNICOLO T , et al. Transparent electrodes based on silver nanowire networks: from physical considerations towards device integration. Materials, 2017,10(6):570. |

| [3] | SUN Y, GATES B, MAYERS B , et al. Crystalline silver nanowires by soft solution processing. Nano Lett., 2002,2(2):165-168. |

| [4] | LEE J Y, CONNOR S T, CUI Y , et al. Solution-processed metal nanowire mesh transparent electrodes. Nano Lett., 2008,8(2):689-692. |

| [5] | LIANG G, YI M, HU H , et al. Coaxial-structured weavable and wearable electroluminescent fibers. Adv. Electron. Mater., 2017,3(12):1700401. |

| [6] | SCHUETTE W M, BUHRO W E . Silver chloride as a heterogeneous nucleant for the growth of silver nanowires. ACS Nano, 2013,7(5):3844-3853. |

| [7] | CHEN C, ZHAO Y, WEI W , et al. Fabrication of silver nanowire transparent conductive films with an ultra-low haze and ultra-high uniformity and their application in transparent electronics. J. Mater. Chem. C, 2017,5(9):2240-2246. |

| [8] | VOLOE L, PETERSON P J . The atmospheric sulfidation of silver in a tubular corrosion reactor. Corros. Sci., 1989,29(10):1179-1196. |

| [9] | FRANEY J P, KAMMLOTT G W, GRAEDEL T E . The corrosion of silver by atmospheric sulfurous gases. Corros. Sci., 1989,25(2):113-143. |

| [10] | ELECHIGUERRA J L, LOPEZ L L, LIU C , et al. Corrosion at the nanoscale: the case of silver nanowires and nanoparticles. Chem. Mater., 2005,17(24):6042-6052. |

| [11] | GRAEDEL T E, FRANEY J P, GUALTIERI G J , et al. On the mechanism of silver and copper sulfidation by atmospheric H2S and OCS. Corros. Sci., 1985,25(12):1163-1180. |

| [12] | KHAN A, NGUYEN V H, ROJAS D M , et al. Stability enhancement of ailver nanowire networks with conformal ZnO coatings deposited by atmospheric pressure spatial atomic layer deposition. ACS Appl. Mater. Interfaces, 2018,10(22):19208-19217. |

| [13] | ZHANG X, YAN X, CHEN J , et al. Large-size graphene microsheets as a protective layer for transparent conductive silver nanowire film heaters. Carbon, 2014,69:437-443. |

| [14] | HWANG B, AN Y, LEE H , et al. Highly flexible and transparent Ag nanowire electrode encapsulated with ultra-thin Al2O3: thermal, ambient, and mechanical stabilities. Sci. Rep., 2017,7:41336. |

| [15] | AHN Y, JEONG Y, LEE Y . Improved thermal oxidation stability of solution-processable silver nanowire transparent electrode by reduced graphene oxide. ACS Appl. Mater. Interfaces, 2012,4(12):6410-6414. |

| [16] | LAGRANGE M, LANGLEY D P, GIUSTI G , et al. Optimization of silver nanowire-based transparent electrodes: effects of density, size and thermal annealing. Nanoscale, 2015,7(41):17410-17423. |

| [17] | LAGRANGE M, SANNICOLO T, ROJAS D M , et al. Understanding the mechanisms leading to failure in metallic nanowire- based transparent heaters, and solution for stability enhancement. Nanotechnology, 2017,28(5):055709. |

| [18] | KHALIGH H H, XU L, KHOSROPOUR A , et al. The Joule heating problem in silver nanowire transparent electrodes. Nanotechnology, 2017,28(42):425703. |

| [19] | SANNICOLO T, CHARVIN N, FLANDIN L , et al. Electrical mapping of silver nanowire networks: a versatile tool for imaging network homogeneity and degradation dynamics during failure. ACS Nano, 2018,12(5):4648-4659. |

| [20] | FANTANAS D, BRUNTON A, HENLEY S J , et al. Investigation of the mechanism for current induced network failure for spray deposited silver nanowires. Nanotechnology, 2018,29(46):465705. |

| [21] | KHALIGH H H, GOLDTHORPE I A . Failure of silver nanowire transparent electrodes under current flow. Nanoscale Res.Lett., 2013, 8(1):235. |

| [22] | CHEN D, ZHAO F, TONG K , et al. Mitigation of electrical failure of silver nanowires under current flow and the application for long lifetime organic light-emitting diodes. Adv. Electron. Mater., 2016,2(8):1600167. |

| [23] | WANG J, JIU J, ZHANG S , et al. The comprehensive effects of visible light irradiation on silver nanowire transparent electrode. Nanotechnology, 2018,29(43):435701. |

| [24] | LEE G P, SHI Y, LAVOIE E , et al. Light-driven transformation processes of anisotropic silver nanoparticles. ACS Nano, 2013,7(7):5911-5921. |

| [25] | GRILLET N, MANCHON D, COTTANCIN E , et al. Photo- oxidation of individual silver nanoparticles: a real-time tracking of optical and morphological changes. J. Phys. Chem. C, 2013,117(5):2274-2282. |

| [26] | SINDERMANN S P, LATZ A, SPODDIG D , et al. Lattice degradation by moving voids during reversible electromigration. J. Appl. Phys., 2014,116(3):034502. |

| [27] | CHEUK K W, PEI K, CHAN P K L . Degradation mechanism of a junction-free transparent silver network electrode. RSC Adv., 2016,6(77):73769-73775. |

| [28] | LIU G S, XU Y, KONG Y , et al. Comprehensive stability improvement of silver nanowire networks via self-assembled mercapto inhibitors. ACS Appl. Mater. Interfaces, 2018,10(43):37699-37708. |

| [29] | DENG B, HSU P C, CHEN G , et al. Roll-to-roll encapsulation of metal nanowires between graphene and plastic substrate for high-performance flexible transparent electrodes. Nano Lett., 2015,15(6):4206-4213. |

| [30] | RAMASAMY P, SEO D M, KIM S H , et al. Effects of TiO2 shells on optical and thermal properties of silver nanowires. J. Mater. Chem., 2012,22(23):11651-11657. |

| [31] | CHEN D, LIANG J, LIU C , et al. Thermally stable silver nanowire-polyimide transparent electrode based on atomic layer deposition of zinc oxide on silver nanowires. Adv. Funct. Mater., 2015,25(48):7512-7520. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||