无机材料学报 ›› 2019, Vol. 34 ›› Issue (10): 1021-1029.DOI: 10.15541/jim20190043 CSTR: 32189.14.10.15541/jim20190043

• 综述 • 下一篇

收稿日期:2019-01-24

修回日期:2019-05-07

出版日期:2019-09-23

网络出版日期:2019-05-29

作者简介:郭容男(1987-), 女, 博士研究生. E-mail: 11626022@zju.edu.cn

Received:2019-01-24

Revised:2019-05-07

Published:2019-09-23

Online:2019-05-29

摘要:

粘结剂在锂离子电池中虽用量少, 但是对锂离子电池的性能有较大影响。传统粘结剂聚偏氟乙烯与活性物质间形成的范德华力较弱, 不能满足现代锂离子电池, 特别是高比容量锂离子电池的要求。大部分电极材料表面具有极性基团, 这些基团可与极性聚合物间形成较强的作用力, 故极性聚合物粘结剂成为当前的研究热点。极性聚合物粘结剂对锂离子电池的影响与诸多因素有关。本文主要讨论了聚合物粘结剂的结构和物性对锂离子电池性能的影响, 包括聚合物的结构特征、粘结性、力学性能和导电性等因素, 进而从分子层次提出了设计下一代粘结剂的方法, 并展望了粘结剂的未来发展方向。

中图分类号:

郭容男, 韩伟强. 极性聚合物粘结剂的结构和物性对锂离子电池的影响[J]. 无机材料学报, 2019, 34(10): 1021-1029.

GUO Rong-Nan, HAN Wei-Qiang. Effects of Structure and Properties of Polar Polymeric Binders on Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2019, 34(10): 1021-1029.

| Binder | Application | Adhesion | Specific capacity/(mAh?g-1) | Ref. |

|---|---|---|---|---|

| Linear polymer | ||||

| PAL-NaPAA | Si | 5.0 N/cm | 1914 (100 cycles, 0.84 A/g) | [17] |

| Carboxymethyl fenugreek gum | Si | — | 1790 (200 cycles, 1 A/g) | [18] |

| CCS | S | ~4 N | ~600 (400 cycles, 0.5C) | [19] |

| PF-COONa | Sn Si | — 6.6 N | 518 (500 cycles, 0.2 A/g) 2806 (100 cycles, 0.42 mA/g, 0.19 mg/cm2) | [20-21] |

| Cross-linked polymer | ||||

| c-PEO-PEDOT:PSS/PEI | Si | ~0.55 N/mm2 | 2027 (500 cycles, 1.0 A/g) | [22] |

| c-PAM-0.001 | Si | 13.98 N | 2834 (100 cycles, 0.1C) | [23] |

| PEI-ER | S | — | 1025 (500 cycles, 0.5C) | [24] |

| Cross-linked corn starch | Si | 31.2 gf/cm | 2106 (200 cycles, 0.5C) | [25] |

| SHP-PEG | Si | ~3.2 N/cm | ~1300 (150 cycles, 0.5C) | [26] |

表1 极性聚合物粘结剂在LIBs中的应用

Table 1 Applications of polar polymeric binders in LIBs

| Binder | Application | Adhesion | Specific capacity/(mAh?g-1) | Ref. |

|---|---|---|---|---|

| Linear polymer | ||||

| PAL-NaPAA | Si | 5.0 N/cm | 1914 (100 cycles, 0.84 A/g) | [17] |

| Carboxymethyl fenugreek gum | Si | — | 1790 (200 cycles, 1 A/g) | [18] |

| CCS | S | ~4 N | ~600 (400 cycles, 0.5C) | [19] |

| PF-COONa | Sn Si | — 6.6 N | 518 (500 cycles, 0.2 A/g) 2806 (100 cycles, 0.42 mA/g, 0.19 mg/cm2) | [20-21] |

| Cross-linked polymer | ||||

| c-PEO-PEDOT:PSS/PEI | Si | ~0.55 N/mm2 | 2027 (500 cycles, 1.0 A/g) | [22] |

| c-PAM-0.001 | Si | 13.98 N | 2834 (100 cycles, 0.1C) | [23] |

| PEI-ER | S | — | 1025 (500 cycles, 0.5C) | [24] |

| Cross-linked corn starch | Si | 31.2 gf/cm | 2106 (200 cycles, 0.5C) | [25] |

| SHP-PEG | Si | ~3.2 N/cm | ~1300 (150 cycles, 0.5C) | [26] |

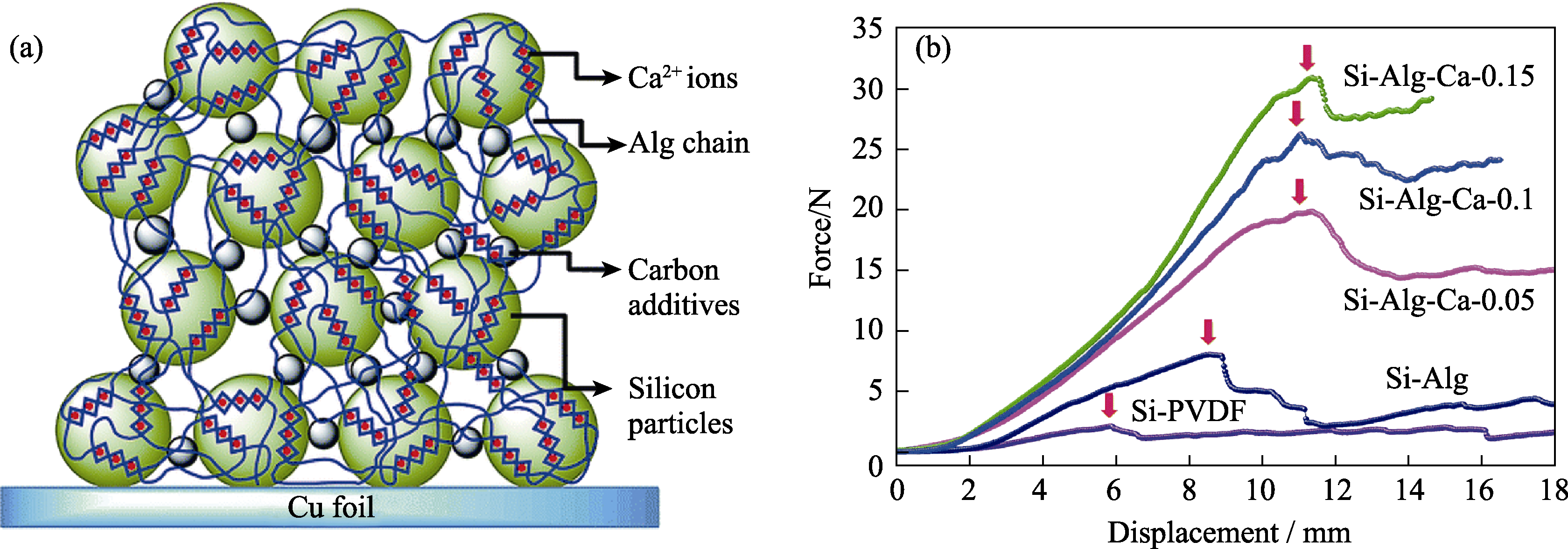

图5 (a)高度交联SA粘结剂制备的Si极片的构建示意图, (b)不同粘结剂制备的Si负极的剥离强度[42]

Fig. 5 (a) Architecture of Si electrode with highly cross-linked alginate binder, and (b) peeling forces of Si anodes with different binders[42]

图6 (a)交联粘结剂PNA-NaPAA-g-CMC的示意图, (b)电解质浸泡后的不同粘结剂的拉伸曲线和(c)不同粘结剂制备的Si电极的循环曲线[47]

Fig. 6 (a) Scheme for the cross-linked binder of PNA-NaPAA-g-CMC, (b) tensile tests of different binders impregnated with electrolyte and (c) cycling performances of Si electrodes with different binders[47]

| [1] | HE W, TIAN H, ZHANG S , et al. Scalable synjournal of Si/C anode enhanced by FeSix nanoparticles from low-cost ferrosilicon for lithium-ion batteries.[J]. Power Sources, 2017,353:270-276. |

| [2] | CHEN Y, LIU L, XIONG J , et al. Porous Si nanowires from heap metallurgical silicon stabilized by a surface oxide layer for lithium ion batteries. Adv. Funct. Mater., 2015,25(43):6701-6709. |

| [3] | PARK M H, KIM M G, JOO J , et al. Silicon nanotube battery anodes. Nano Lett., 2009,9(11):3844-3847. |

| [4] | LIU Y, TAI Z, ZHOU T , et al. An all-integrated anode via interlinked chemical bonding between double-shelled-yolk- structured silicon and binder for lithium-ion batteries. Adv. Mater., 2017, 29(44): 1703028-1-11. |

| [5] | AKHTAR N, SHAO H, AI F , et al. Gelatin-polyethylenimine composite as a functional binder for highly stable lithium-sulfur batteries. Electrochim. Acta, 2018,282:758-766. |

| [6] | HE J, ZHANG L . Polyvinyl alcohol grafted poly (acrylic acid) as water-soluble binder with enhanced adhesion capability and electrochemical performances for Si anode. J. Alloy. Compound, 2018,763:228-240. |

| [7] | LING M, ZHANG L, ZHENG T , et al. Nucleophilic substitution between polysulfides and binders unexpectedly stabilizing lithium sulfur battery. Nano Energy, 2017,38:82-90. |

| [8] | CHOI S, KWON T W, COSKUN A , et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science, 2017,357(6348):279-283. |

| [9] | ZHAO X Y, YIM C H, DU N Y , et al. Crosslinked chitosan networks as binders for silicon/graphite composite electrodes in Li-ion batteries.[J]. Electrochem. Soc., 2018,165(5):A1110-A1121. |

| [10] | HU S, CAI Z, HUANG T , et al. A modified natural polysaccharide as a high-performance binder for silicon anodes in lithium-ion batteries. ACS Appl. Mater. Interfaces, 2019,11(4):4311-4317. |

| [11] | DROFENIK J, GABERSCEK M, DOMINKO R , et al. Cellulose as a binding material in graphitic anodes for Li ion batteries: a performance and degradation study. Electrochim. Acta, 2003,48(7):883-889. |

| [12] | ZHANG R, YANG X, ZHANG D , et al. Water soluble styrene butadiene rubber and sodium carboxyl methyl cellulose binder for ZnFe2O4 anode electrodes in lithium ion batteries.[J]. Power Sources, 2015,285:227-234. |

| [13] | MIN K, RAMMOHAN A R, LEE S H , et al. Grafting functional groups in polymeric binder toward enhancing structural integrity of LixSiO2 anode during electrochemical cycling. J. Phys. Chem. C, 2018,122(30):17190-17198. |

| [14] | YOO J K, JEON J, KANG K , et al. Glyoxalated polyacrylamide as a covalently attachable and rapidly cross-linkable binder for Si electrode in lithium ion batteries. Electron. Mater. Lett., 2017,13(2):136-141. |

| [15] | JIAO Y, CHEN W, LEI T , et al. A Novel polar copolymer design as a multi-functional binder for strong affinity of polysulfides in lithium-sulfur batteries.Nanoscale Res. Lett., 2017, 12: 195-1-8. |

| [16] | HOCHGATTERER N S, SCHWEIGER M R, KOLLER S , et al. Silicon/graphite composite electrodes for high-capacity anodes: influence of binder chemistry on cycling stability. Electrochem. Solid State Lett., 2008,11(5):A76-A80. |

| [17] | LUO C, DU L, WU W , et al. Novel lignin-derived water-soluble binder for micro silicon anode in lithium-ion batteries. ACS Sustain. Chem. Eng., 2018,6(10):12621-12629. |

| [18] | QIU L W, SHEN Y D, FAN H B , et al. Carboxymethyl fenugreek gum: rheological characterization and as a novel binder for silicon anode of lithium-ion batteries. Int.[J]. Biol. Macromol., 2018,115:672-679. |

| [19] | YI H, LAN T, YANG Y , et al. Aqueous-processable polymer binder with strong mechanical and polysulfide-trapping properties for high performance of lithium-sulfur batteries. J. Mater. Chem. A, 2018,6(38):18660-18668. |

| [20] | ZHAO Y, YANG L Y, LIU D , et al. A conductive binder for high-performance Sn electrodes in lithium-ion batteries. ACS Appl. Mater. Interfaces, 2018,10(2):1672-1677. |

| [21] | LIU D, ZHAO Y, TAN R , et al. Novel conductive binder for high-performance silicon anodes in lithium ion batteries. Nano Energy, 2017,36:206-212. |

| [22] | ZENG W, WANG L, PENG X , et al. Enhanced ion conductivity in conducting polymer binder for high-performance silicon anodes in advanced lithium-ion batteries. Adv. Energy Mater., 2018, 8(11): 1702314-1-8. |

| [23] | ZHU X, ZHANG F, ZHANG L , et al. A highly stretchable cross-linked polyacrylamide hydrogel as an effective binder for silicon and sulfur electrodes toward durable lithium-ion storage. Adv. Funct. Mater., 2018, 28(11): 1705015-1-12. |

| [24] | YAN L, GAO X, WAHID-PEDRO F , et al. A novel epoxy resin-based cathode binder for low cost, long cycling life, and high-energy lithium-sulfur batteries. J. Mater. Chem. A, 2018,6(29):14315-14323. |

| [25] | ROHAN R, KUO T C, CHIOU C Y , et al. Low-cost and sustainable corn starch as a high-performance aqueous binder in silicon anodes via in situ cross-linking.[J]. Power Sources, 2018,396:459-466. |

| [26] | MUNAOKA T, YAN X Z, LOPEZ J , et al.Ionically conductive self-healing binder for low cost Si microparticles anodes in Li-ion batteries. Adv. Energy Mater., 2018, 8(14): 1703138-1-11. |

| [27] | LUO L, XU Y, ZHANG H , et al. Comprehensive understanding of high polar polyacrylonitrile as an effective binder for Li-ion battery nano-si anodes. ACS Applied Materials & Interfaces, 2016,8(12):8154-8161. |

| [28] | PARK H K, KONG B S, OH E S . Effect of high adhesive polyvinyl alcohol binder on the anodes of lithium ion batteries. Electrochem. Commun., 2011,13(10):1051-1053. |

| [29] | RYOU M H, KIM J, LEE I , et al. Mussel-inspired adhesive binders for high-performance silicon nanoparticle anodes in lithium-ion batteries. Adv. Mater., 2013,25(11):1571-1576. |

| [30] | WEI L, CHEN C, HOU Z, et al. Poly (acrylic acid sodium) grafted carboxymethyl cellulose as a high performance polymer binder for silicon anode in lithium ion batteries.Sci. Rep., 2016, 6: 19583-1-8. |

| [31] | BUQA H, HOLZAPFEL M, KRUMEICH F , et al. Study of styrene butadiene rubber and sodium methyl cellulose as binder for negative electrodes in lithium-ion batteries.[J]. Power Sources, 2006,161(1):617-622. |

| [32] | MAGASINSKI A, ZDYRKO B, KOVALENKO I , et al. Toward efficient binders for Li-ion battery Si-based anodes: polyacrylic acid. ACS Appl. Mater. Interfaces, 2010,2(11):3004-3010. |

| [33] |

KOVALENKO I, ZDYRKO B, MAGASINSKI A , et al. A major constituent of brown algae for use in high-capacity Li-ion batteries. Science, 2011,334(6052):75-79.

DOI |

| [34] | HAN Z J, YABUUCHI N, HASHIMOTO S , et al. Cross-linked poly(acrylic acid) with polycarbodiimide as advanced binder for Si/graphite composite negative electrodes in Li-ion batteries. ECS Electrochem. Lett., 2013,2(2):A17-A20. |

| [35] | WANG L, LIU T, PENG X , et al. Highly stretchable conductive glue for high-performance silicon anodes in advanced lithium-ion batteries. Adv. Funct. Mater., 2017, 28(3): 1704858-1-8. |

| [36] | YANG J, ZHANG L, ZHANG T , et al. Self-healing strategy for Si nanoparticles towards practical application as anode materials for Li-ion batteries. Electrochemistry Communications, 2018,87:22-26. |

| [37] | ZHANG G, YANG Y, CHEN Y , et al. A wuadruple-hydrogen- bonded supramolecular binder for high-performance silicon anodes in lithium-ion batteries. Small, 2018, 14(29): 1801189-1-10. |

| [38] | XU Z, YANG J, ZHANG T , et al. Silicon microparticle anodes with self-healing multiple network binder. Joule, 2018,2(5):818-819. |

| [39] | KWON T W, JEONG Y K, DENIZ E , et al. Dynamic cross-linking of polymeric binders based on host-guest interactions for silicon anodes in lithium ion batteries. ACS Nano, 2015,9(11):11317-11324. |

| [40] | BRIDEL J S, AZAIS T, MORCRETTE M , et al. In situ observation and long-term reactivity of Si/C/CMC composites electrodes for Li-ion batteries.[J]. Electrochem. Soc., 2011,158(6):A750-A759. |

| [41] | WEI Y J, WANG Z J, YE H , et al. A stable cross-linked binder network for SnO2 anode with enhanced sodium-ion storage performance. ChemistrySelect, 2017,2(35):11365-11369. |

| [42] | ZHANG L, ZHANG L, CHAI L , et al. A coordinatively cross-linked polymeric network as a functional binder for high-performance silicon submicro-particle anodes in lithium-ion batteries. J. Mater. Chem. A, 2014,2(44):19036-19045. |

| [43] | MAZOUZI D, LESTRIEZ B, ROUE L , et al. Silicon composite electrode with high capacity and long cycle life . Electrochemical and Solid-State Letters, 2009,12(11):A215-A218. |

| [44] | BAUNACH M, JAISER S, SCHMELZLE S , et al. Delamination behavior of lithium-ion battery anodes: influence of drying temperature during electrode processing. Dry. Techn., 2016,34(4):462-473. |

| [45] | KARKAR Z, MAZOUZI D, HERNANDEZ C R , et al. Threshold-like dependence of silicon-based electrode performance on active mass loading and nature of carbon conductive additive. Electrochim. Acta, 2016,215:276-288. |

| [46] | HE W, TIAN H, XIN F , et al. Scalable fabrication of micro-sized bulk porous Si from Fe-Si alloy as a high performance anode for lithium-ion batteries. J. Mater. Chem. A, 2015,3(35):17956-17962. |

| [47] | WEI L M, HOU Z Y . High performance polymer binders inspired by chemical finishing of textiles for silicon anodes in lithium ion batteries. J. Mater. Chem. A, 2017,5(42):22156-22162. |

| [48] | NUNES R W, MARTIN J R, JOHNSON J F . Influence of molecular- weight and molecular-weight distribution on mechanical-properties. Polym. Eng. Sci., 1982,22(4):205-228. |

| [49] | WU Q, HENRIKSSON M, LIU X , et al. A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromolecules, 2007,8(12):3687-3692. |

| [50] | WANG Y, GOZEN A, CHEN L , et al. Gum-like nanocomposites as conformable, conductive,adhesive electrode matrix for energy storage devices. Adv. Energy Mater., 2017, 7(6): 1601767-1-11. |

| [51] | YUCA N, CETINTASOGLU M E, DOGDU M F , et al. Highly efficient poly(fluorene phenylene) copolymer as a new class of binder for high-capacity silicon anode in lithium-ion batteries. Int. J. Energy Res., 2018,42(3):1148-1157. |

| [52] | HUANG S, REN J G, LIU R , et al. Low addition amount of self-healing ionomer binder for Si/graphite electrodes with enhanced cycling . New J. Chem, 2018,42(9):6742-6749. |

| [53] | WANG Z Q, TIAN S K, LI S D , et al. Lithium sulfonate-grafted poly(vinylidenefluoride-hexafluoro propylene) ionomer as binder for lithium-ion batteries. RSC Adv., 2018,8(36):20025-20031. |

| [54] | MILROY C, MANTHIRAM A . An elastic, conductive, electroactive nanocomposite binder for flexible sulfur cathodes in lithium-sulfur batteries. Adv. Mater., 2016,28(44):9744-9751. |

| [55] | TAMURA T, AOKI Y, OHSAWA T , et al. Polyaniline as a functional binder for LiFePO4 cathodes in lithium batteries. Chem. Lett., 2011,40(8):828-830. |

| [56] | SHI Y, ZHANG J, BRUCK A M , et al. A tunable 3D nanostructured conductive gel framework electrode for high- performance lithium ion batteries. Adv. Mater., 2017, 29(22): 1603922-1-8. |

| [57] | PIECZONKA N P W, BORGEL V, ZIV B , et al. Lithium polyacrylate (LiPAA) as an advanced binder and a passivating agent for high-voltage Li-ion batteries. Adv. Energy Mater., 2015, 5(23): 1501008-1-10. |

| [58] | LIU J, ZHANG Q, ZHANG T , et al. A robust ion-conductive biopolymer as a binder for Si anodes of lithium-ion batteries. Adv. Funct. Mater., 2015,25(23):3599-3605. |

| [59] | GENDENSUREN B, OH E S . Dual-crosslinked network binder of alginate with polyacrylamide for silicon/graphite anodes of lithium ion battery.[J]. Power Sources, 2018,384:379-386. |

| [60] | PAN J, XU G, DING B , et al. PAA/PEDOT:PSS as a multifunctional, water-soluble binder to improve the capacity and stability of lithium-sulfur batteries. RSC Adv., 2016,6(47):40650-40655. |

| [61] | LING M, ZHAO H, XIAO X , et al. Low cost and environmentally benign crack-blocking structures for long life and high power Si electrodes in lithium ion batteries. J. Mater. Chem. A, 2015,3(5):2036-2042. |

| [62] | GUO R, ZHANG S, YING H , et al. A new, effective and low cost dual-functional binder for porous silicon anodes in lithium-ion batteries.ACS Appl. Mater. Interfaces, 2019,11(15):14051-14058. |

| [63] | CHEN Z, CHRISTENSEN L, DAHN J R . Comparison of PVDF and PVDF-TFE-P as binders for electrode materials showing large volume changes in lithium-ion batteries..J. Electrochem. Soc, 2003,150(8):A1073-A1078. |

| [64] | LAIDLER K J . The development of the Arrhenius equation.[J]. Chem. Educ., 1984,61(6):494-498. |

| [65] | KARKAR Z, GUYOMARD D, ROUE L , et al. A comparative study of polyacrylic acid (PAA) and carboxymethyl cellulose (CMC) binders for Si-based electrodes.Electrochim. Acta, 2017,258:453-466. |

| [66] | LEE S H, LEE J H, NAM D H , et al. Epoxidized natural rubber/chitosan network binder for silicon anode in lithium-ion battery.ACS Appl. Mater. Interfaces, 2018,10(19):16449-16457. |

| [67] | GAO H, ZHOU W, JANG J H , et al. Cross-linked chitosan as a polymer network binder for an antimony anode in sodium-ion batteries. Adv. Energy Mater., 2016, 6(6): 1502130-1-7. |

| [68] | WANG H, LING M, BAI Y , et al. Cationic polymer binder inhibit shuttle effects through electrostatic confinement in lithium sulfur batteries. J. Mater. Chem.A, 2018,6(16):6959-6966. |

| [69] | LIAO J, LIU Z, LIU X , et al. Water-soluble linear poly (ethylenimine) as a superior bifunctional binder for lithium-sulfur batteries of improved cell performance. J. Phys. Chem. C, 2018,122(45):25917-25929. |

| [70] | SONG J, ZHOU M, YI R , et al. Interpenetrated gel polymer binder for high-performance silicon anodes in lithium-ion batteries. Adv. Funct. Mater., 2014,24(37):5904-5910. |

| [71] | FEI J, SUN Q Q, CUI Y L , et al. Sodium carboxyl methyl cellulose and polyacrylic acid binder with enhanced electrochemical properties for ZnMoO4·0.8H2O anode in lithium ion batteries.. J. Electroanal. Chem, 2017,804:158-164. |

| [72] | LEE S Y, CHOI Y, HONG K S , et al.Influence of EDTA in poly(acrylic acid) binder for enhancing electrochemical performance and thermal stability of silicon anode. Appl. Surf. Sci., 2018,447:442-451. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||