无机材料学报 ›› 2025, Vol. 40 ›› Issue (9): 964-970.DOI: 10.15541/jim20250051 CSTR: 32189.14.jim20250051

钟卫民1( ), 赵科2, 王珂玮3, 刘佃光4, 刘金铃1(

), 赵科2, 王珂玮3, 刘佃光4, 刘金铃1( ), 安立楠3

), 安立楠3

收稿日期:2025-02-11

修回日期:2025-04-01

出版日期:2025-09-20

网络出版日期:2025-04-09

通讯作者:

刘金铃, 教授. E-mail: liujinling@swjtu.edu.cn作者简介:钟卫民(2000-), 男, 硕士研究生. E-mail: 2772759347@qq.com

基金资助:

ZHONG Weimin1( ), ZHAO Ke2, WANG Kewei3, LIU Dianguang4, LIU Jinling1(

), ZHAO Ke2, WANG Kewei3, LIU Dianguang4, LIU Jinling1( ), AN Linan3

), AN Linan3

Received:2025-02-11

Revised:2025-04-01

Published:2025-09-20

Online:2025-04-09

Contact:

LIU Jinling, professor. E-mail: liujinling@swjtu.edu.cnAbout author:ZHONG Weimin (2000-), male, Master candidate. E-mail: 2772759347@qq.com

Supported by:摘要:

如何在实现超细晶碳化钨(WC)完全致密化的同时而不引起晶粒长大, 一直是其工业应用面临的难题。动态烧结锻造工艺可通过施加振荡压力对不致密材料坯体进行锻造, 促进致密化并抑制晶粒生长。本研究探索了动态烧结锻造中压力振幅对WC微观结构和摩擦磨损性能的影响。结果表明, 提高压力振幅能够提高WC的相对密度, 减小其晶粒尺寸并提高小角晶界和特殊晶界Σ2的占比, 同时提高其晶粒内的位错密度。当压力振幅为20 MPa时, WC的相对密度、平均晶粒尺寸和位错密度分别达到99.6%、203 nm和1.68×1015 m-2。随着压力振幅的提高, WC的摩擦系数和磨损率均逐渐减小, 磨损机制以黏着磨损和犁削为主。磨损率减小主要是由于WC几近致密的特性、细小的晶粒及较高的位错密度。晶粒细化和高密度位错有助于提高其在摩擦磨损过程中的塑性变形能力和变形抗力, 从而增大磨痕表面硬度, 同时抑制裂纹萌生和扩展。特殊晶界Σ2也能够有效阻碍位错运动而提高应变硬化能力, 有助于提高磨痕表面硬度, 进一步抑制磨损。

中图分类号:

钟卫民, 赵科, 王珂玮, 刘佃光, 刘金铃, 安立楠. 振荡压力振幅对碳化钨微观结构和摩擦磨损性能的影响[J]. 无机材料学报, 2025, 40(9): 964-970.

ZHONG Weimin, ZHAO Ke, WANG Kewei, LIU Dianguang, LIU Jinling, AN Linan. Effect of Oscillatory Pressure Amplitude on Microstructures and Wear Resistance of Tungsten Carbide[J]. Journal of Inorganic Materials, 2025, 40(9): 964-970.

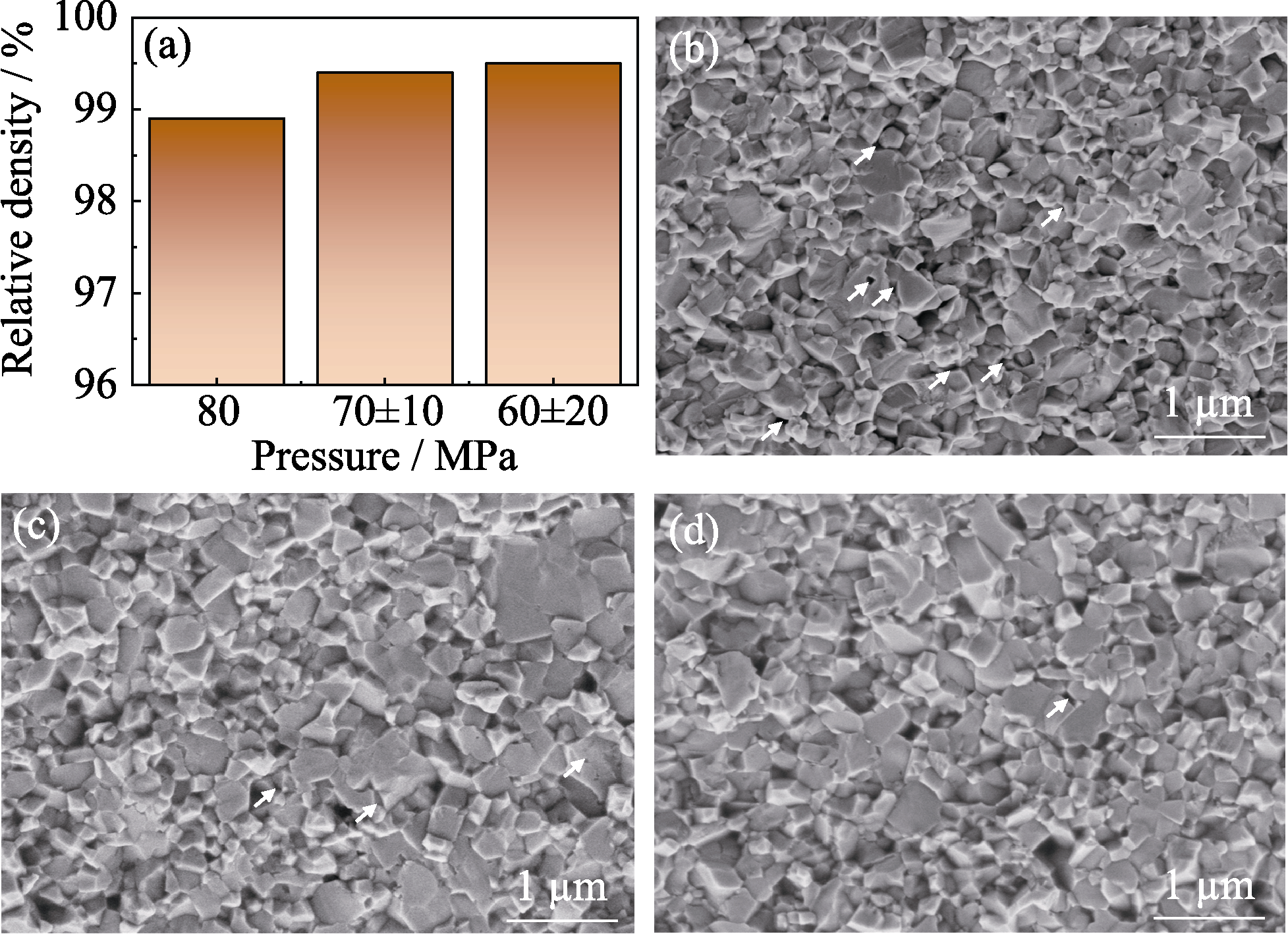

图4 不同压力振幅下WC样品的相对密度和断口形貌

Fig. 4 Relative densities and fracture morphologies of WC samples prepared under different pressure amplitudes (a) Histogram of relative density against pressure for WC samples; (b-d) Fracture morphologies of WC samples prepared under (b) 80, (c) (70±10), and (d) (60±20) MPa

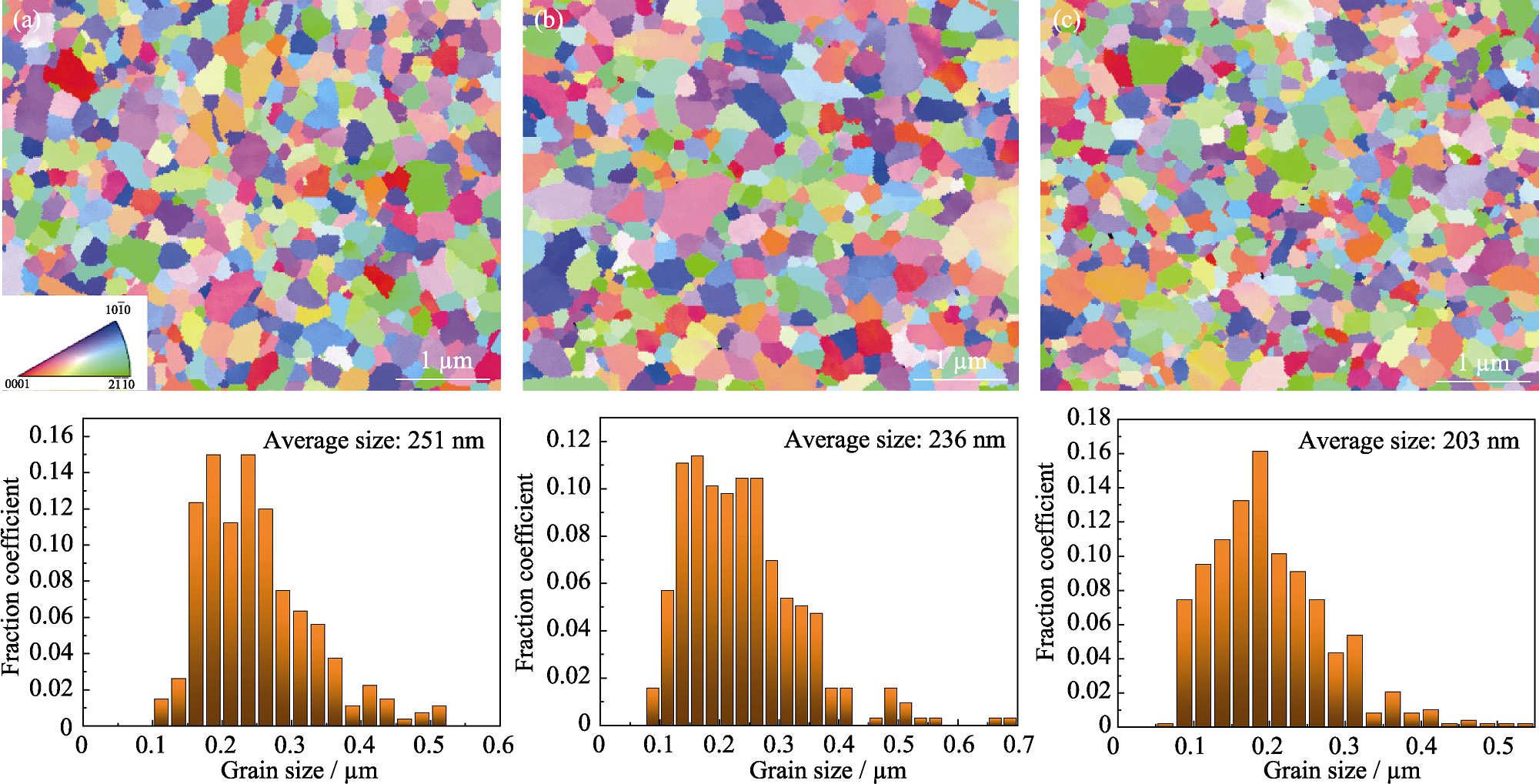

图5 不同压力振幅下制备的WC样品的晶粒取向分布图(上)和晶粒尺寸统计图(下)

Fig. 5 Diagrams of grain orientations (up) and grain size distributions (down) for WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa. Colorful figures are available on website

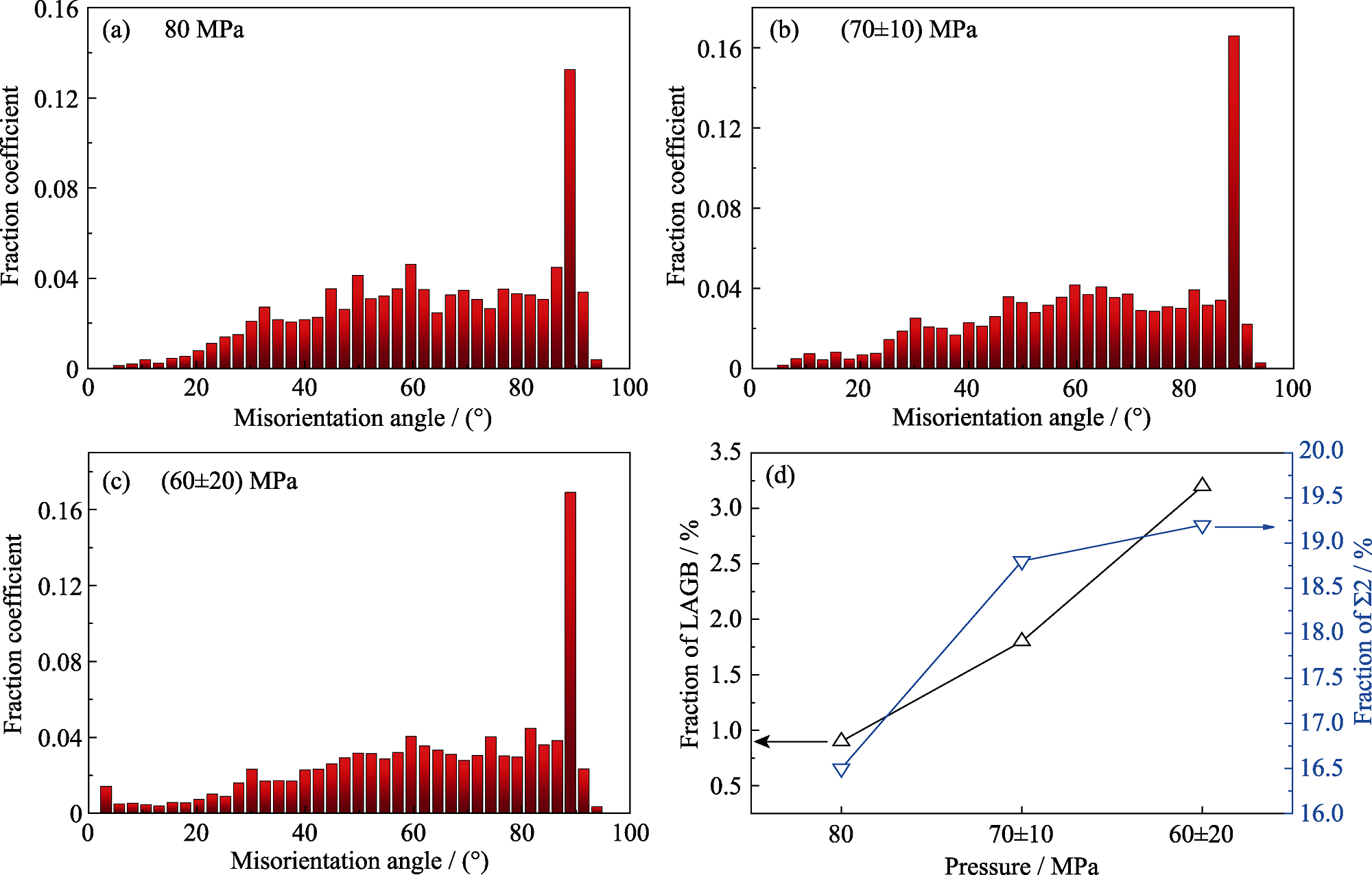

图6 不同压力振幅下WC样品的(a~c)晶粒取向差统计图及(d)小角晶界和Σ2晶界占比

Fig. 6 (a-c) Statistical diagrams of grain misorientation angle and (d) variation in fraction of low angle grain boundary (LAGB) and Σ2 grain boundary for WC samples prepared under different pressure amplitudes

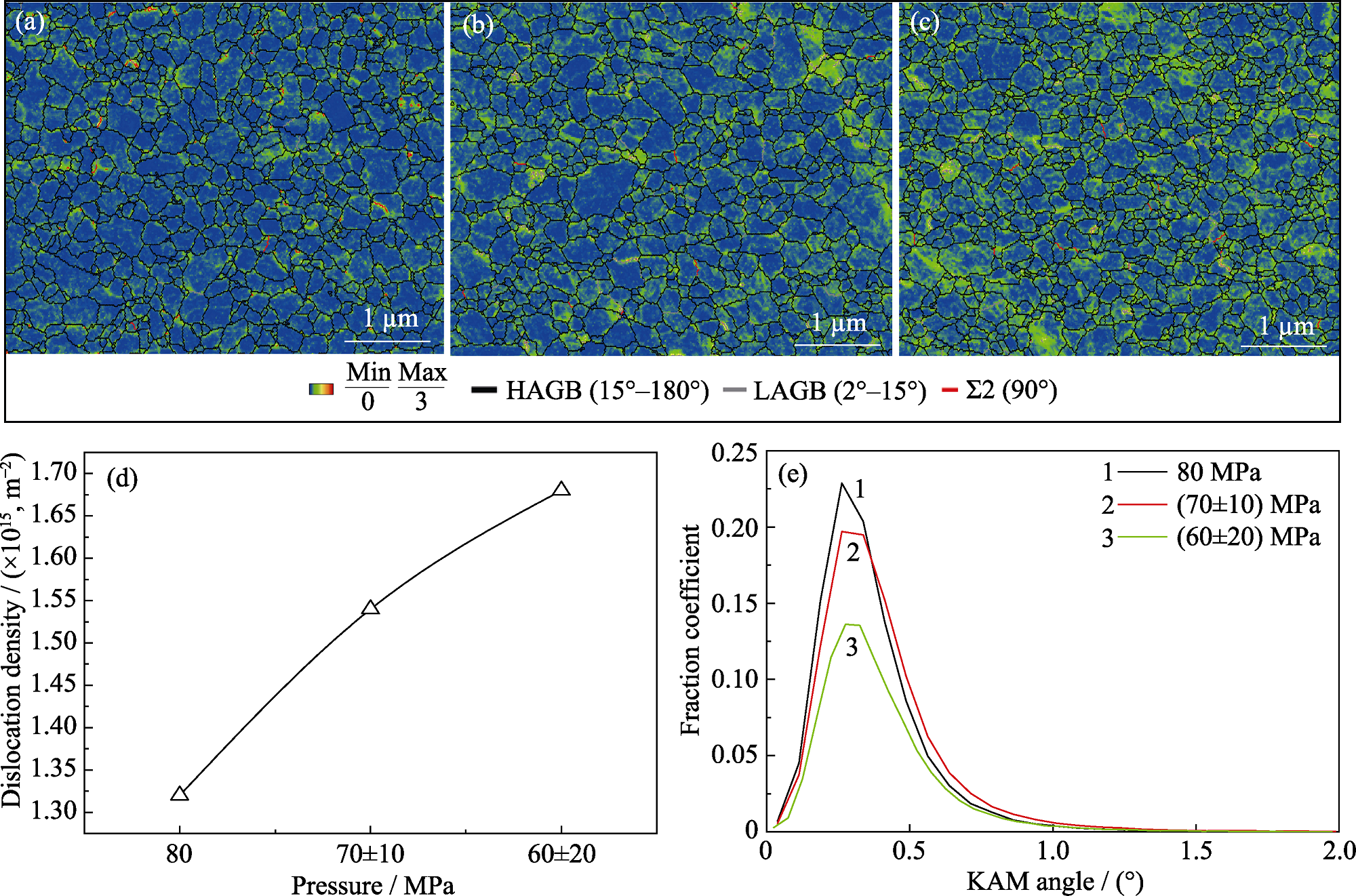

图7 不同压力振幅下WC样品的(a~c)KAM图、(d)位错密度和(e)KAM角分布统计图

Fig. 7 (a-c) KAM maps, (d) dislocation densities, and (e) statistical diagrams of KAM angle for WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa. HAGB: high angle grain boundary. Colorful figures are available on website

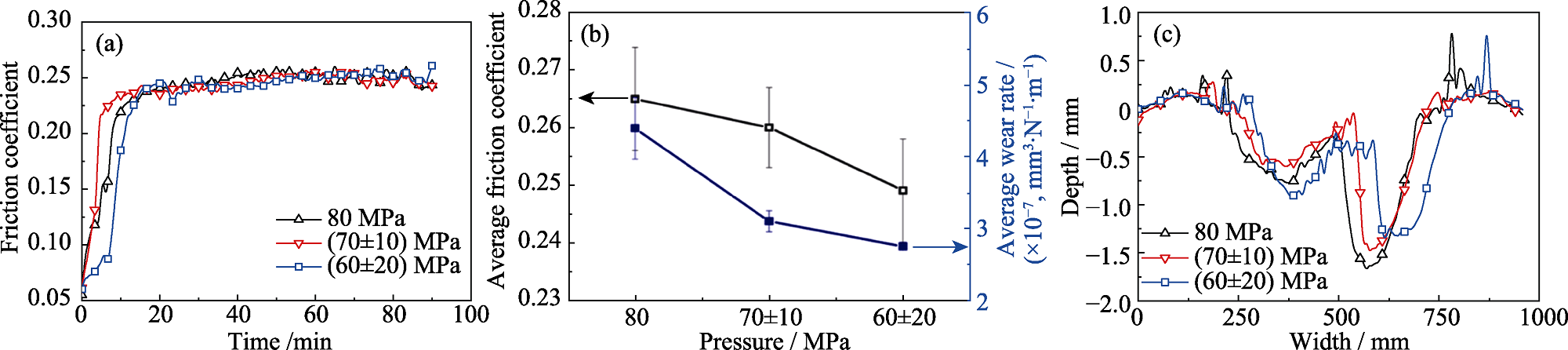

图8 不同压力振幅下制备的WC样品的摩擦磨损性能

Fig. 8 Tribological properties of WC samples prepared under different pressure amplitudes (a) Friction coefficient as a function of time; (b) Average friction coefficient and wear rate vs. pressure; (c) Wear scar depth vs. width

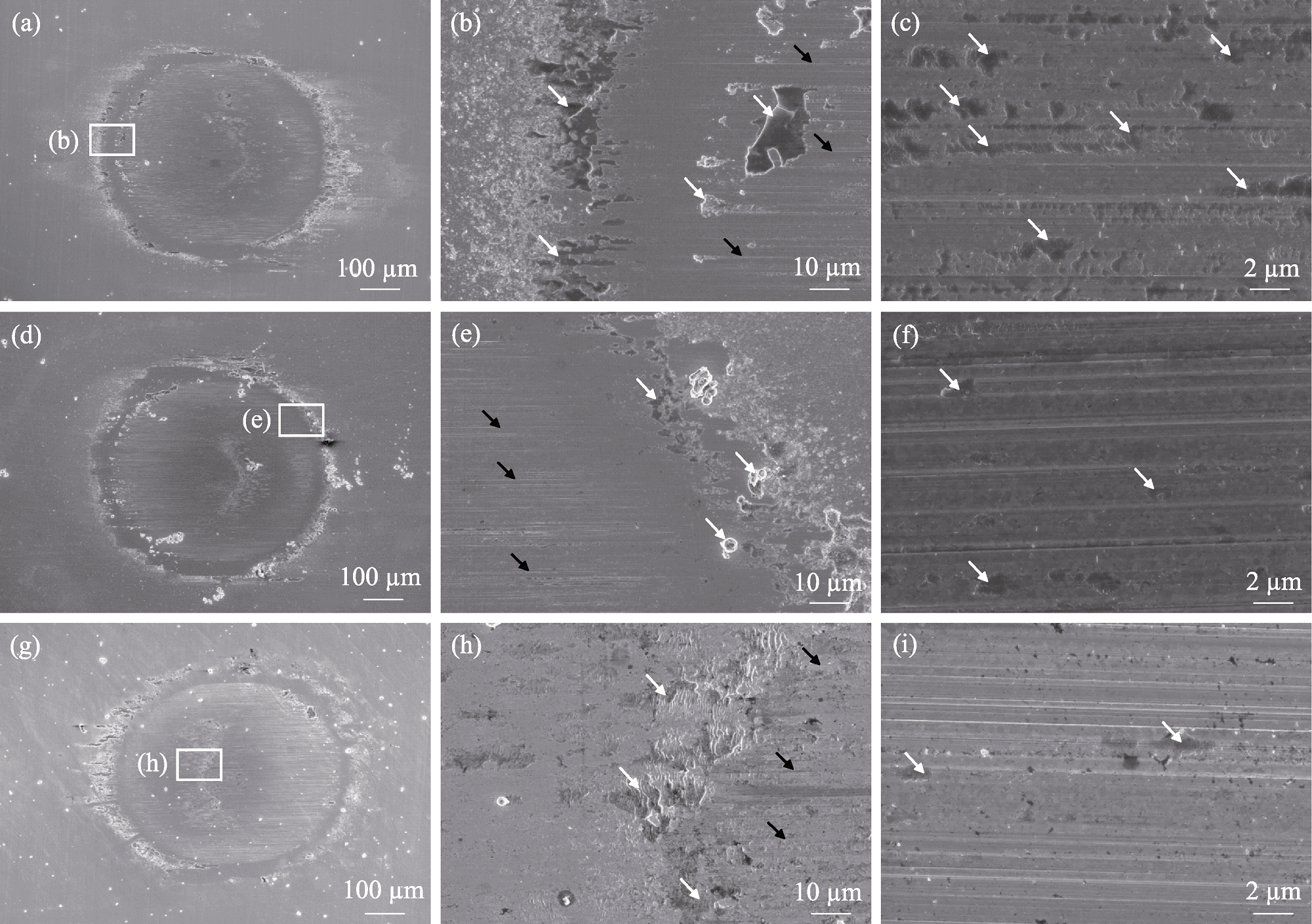

图9 不同压力振幅下制备的WC样品的磨痕形貌

Fig. 9 Wear scar morphologies of WC samples prepared under different pressure amplitudes (a-c) 80 MPa; (d-f) (70±10) MPa; (g-i) (60±20) MPa

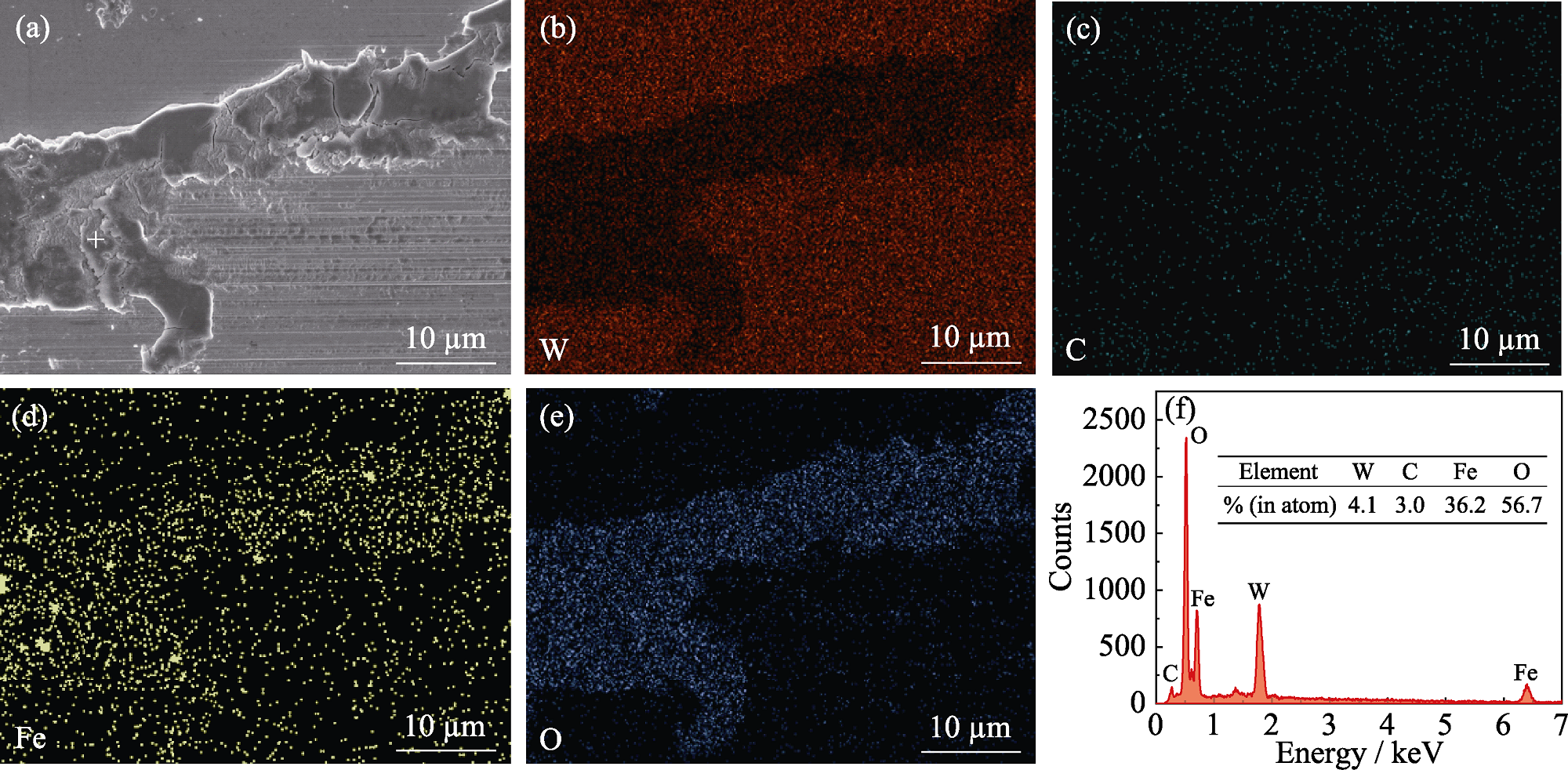

图10 压力振幅为10 MPa时WC样品磨痕表面黏着物的形貌和成分分析

Fig. 10 Morphology and element characterization of adhesive phase of WC sample prepared under pressure amplitude of 10 MPa (a) SEM image; (b-e) EDS mappings corresponding to (a); (f) EDS spectrum corresponding to point in (a) marked with + symbol

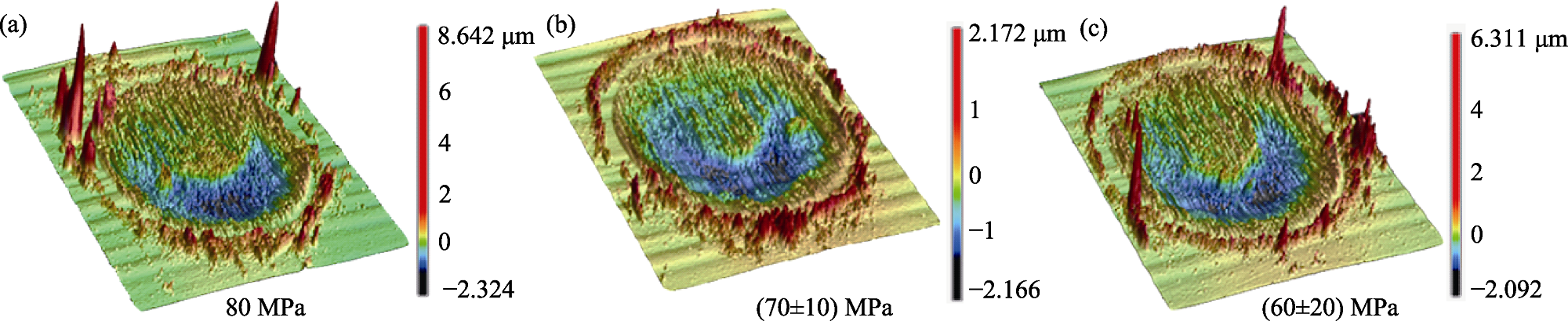

图S2 不同压力振幅下WC样品的三维磨痕形貌

Fig. S2 Three-dimensional surface topographies of WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa

| [1] | SUN J L, ZHAO J, HUANG Z F, et al. A review on binderless tungsten carbide: development and application. Nano-Micro Letters, 2020, 12: 162. |

| [2] | REN X Y, MIAO H Z, PENG Z J. A review of cemented carbides for rock drilling: an old but still tough challenge in geo-engineering. International Journal of Refractory Metals and Hard Materials, 2013, 39: 61. |

| [3] | KORNAUS K, RACZKA M, GUBERNAT A, et al. Pressureless sintering of binderless tungsten carbide. Journal of the European Ceramic Society, 2017, 37(15): 4567. |

| [4] | GUBERNAT A, RUTKOWSKI P, GRABOWSKI G, et al. Hot pressing of tungsten carbide with and without sintering additives. International Journal of Refractory Metals and Hard Materials, 2014, 43: 193. |

| [5] | ANDERSON K P, WOLLMERSHAUSER J A, RYOU H, et al. Nanostructural effects beyond Hall-Petch: towards superhard tungsten carbide. Acta Materialia, 2024, 275: 120004. |

| [6] | SHON I J, KIM B R, DOH J M, et al. Properties and rapid consolidation of ultra-hard tungsten carbide. Journal of Alloys and Compounds, 2010, 489(1): L4. |

| [7] | KUMAR A K N, WATABE M, KUROKAWA K. The sintering kinetics of ultrafine tungsten carbide powders. Ceramics International, 2011, 37(7): 2643. |

| [8] | 邹芹, 李爽, 李艳国. 无粘结相WC硬质合金的研究进展. 硬质合金, 2021, 38(4): 297. |

| [9] | MAZO I, MOLINARI A, SGLAVO V M. Electrical resistance flash sintering of tungsten carbide. Materials & Design, 2022, 213: 110330. |

| [10] |

LIU J L, LIU D G, REN K, et al. Research progress on the flash sintering mechanism of oxide ceramics and its application. Journal of Inorganic Materials, 2022, 37(5): 473.

DOI |

| [11] | HUANG B, CHEN L D, BAI S Q. Bulk ultrafine binderless WC prepared by spark plasma sintering. Scripta Materialia, 2006, 54(3): 441. |

| [12] | ZHAO J F, HOLLAND T, UNUVAR C, et al. Sparking plasma sintering of nanometric tungsten carbide. International Journal of Refractory Metals & Hard Materials, 2009, 27(1): 130. |

| [13] | CHA S I, HONG S H. Microstructures of binderless tungsten carbides sintered by spark plasma sintering process. Materials Science and Engineering A, 2003, 356(1/2): 381. |

| [14] | LANTSEV E, MALEKHONOVA N, NOKHRIN A, et al. Influence of oxygen on densification kinetics of WC nanopowders during SPS. Ceramics International, 2021, 47(3): 4294. |

| [15] | MA D J, KOU Z L, LIU Y J, et al. Sub-micro binderless tungsten carbide sintering behavior under high pressure and high temperature. International Journal of Refractory Metals & Hard Materials, 2016, 54: 427. |

| [16] | GRASSO S, POETSCHKE J, RICHTER V, et al. Low-temperature spark plasma sintering of pure nano WC powder. Journal of the American Ceramic Society, 2013, 96(6): 1702. |

| [17] | XIE Z P, LI S, AN L N. A novel oscillatory pressure-assisted hot pressing for preparation of high-performance ceramics. Journal of the American Ceramic Society, 2014, 97(4): 1012. |

| [18] | ZHAO K, ZHONG W M, SUN M Y, et al. Sintering mechanism of pure B4C ceramic prepared by hot oscillating pressing and with excellent mechanical properties. Advanced Engineering Materials, 2024, 26(16): 2400695. |

| [19] | WANG K W, ZHAO K, LIU J L, et al. Interplay of microstructure and mechanical properties of WC-6Co cemented carbides by hot oscillating pressing method. Ceramics International, 2021, 47(14): 20731. |

| [20] | LIU D G, FAN J Y, ZHAO K, et al. Preparation of super-strong ZrO2 ceramics using dynamic hot forging. Journal of the European Ceramic Society, 2023, 43(2): 733. |

| [21] | ZHAO K, FENG P Z, TAN J, et al. A new route to fabricate high- performance binderless tungsten carbide: dynamic sinter forging. Journal of the American Ceramic Society, 2023, 106(6): 3343. |

| [22] | HE Z B, CHEN F, LIU D G, et al. Sintering behavior of simulating core FCM fuel via hot oscillatory pressing. Journal of Inorganic Materials, 2024, 39(5): 501. |

| [23] | 张渤涛, 姚曙, 范建业, 等. 电场辅助动态热锻制备超高韧3YSZ陶瓷. 粉末冶金材料科学与工程, 2024, 29(4): 290. |

| [24] | FOX R T, NILSSON R. Binderless tungsten carbide carbon control with pressureless sintering. International Journal of Refractory Metals & Hard Materials, 2018, 76: 82. |

| [25] | POETSCHKE J, RICHTER V, MICHAELIS A. Fundamentals of sintering nanoscaled binderless hardmetals. International Journal of Refractory Metals and Hard Materials, 2015, 49: 124. |

| [26] | PORZ L. 60 years of dislocations in ceramics: a conceptual framework for dislocation mechanics in ceramics. International Journal of Ceramic Engineering & Science, 2022, 4(4): 214. |

| [27] | ZHAO M J, ZHU Q Q, ZOU J, et al. Binderless nanocrystalline tungsten carbide with enhanced hardness induced by high-pressure sintering. Journal of the European Ceramic Society, 2024, 44(8): 4875. |

| [28] | DONG H F, LI B Z, LIU B B, et al. Extraordinary high- temperature mechanical properties in binder-free nanopolycrystalline WC ceramic. Journal of Materials Science & Technology, 2022, 97: 169. |

| [29] | WANG H B, LOU H Z, XING M, et al. Exploring the origin of wear in cemented carbides via molecular dynamics simulations. International Journal of Refractory Metals and Hard Materials, 2024, 118: 106476. |

| [30] | SALEM M N, DING K, RӦDEL J, et al. Thermally enhanced dislocation density improves both hardness and fracture toughness in single-crystal SrTiO3. Journal of the American Ceramic Society, 2023, 106: 1344. |

| [31] | XU H Y, JI W, GUO W M, et al. Enhanced mechanical properties and oxidation resistance of zirconium diboride ceramics via grain-refining and dislocation regulation. Advanced Science, 2022, 9(6): 2104532. |

| [32] | MISHRA M, TANGPATJAROEN C, SZLUFARSKA I. Plasticity- controlled friction and wear in nanocrystalline SiC. Journal of the American Ceramic Society, 2014, 97(4): 1194. |

| [33] | FU L C, ZHOU L P. Effect of applied magnetic field on wear behavior of martensitic steel. Journal of Materials Research and Technology, 2019, 8(3): 2880. |

| [1] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [2] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [3] | 姜灵毅, 庞生洋, 杨超, 张悦, 胡成龙, 汤素芳. C/SiC-BN复合材料的制备及氧化行为[J]. 无机材料学报, 2024, 39(7): 779-786. |

| [4] | 薛轶凡, 李玮洁, 张中伟, 庞旭, 刘愚. 碳纤维布表面PyC界面相微观结构及均匀性的工艺调控[J]. 无机材料学报, 2024, 39(4): 399-408. |

| [5] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [6] | 李建波, 田震, 蒋全伟, 于砺锋, 康慧君, 曹志强, 王同敏. 不同元素掺杂对CaTiO3微观结构及热电性能的影响[J]. 无机材料学报, 2023, 38(12): 1396-1404. |

| [7] | 吴东江, 赵紫渊, 于学鑫, 马广义, 由竹琳, 任冠辉, 牛方勇. Al2O3-TiCp复相陶瓷激光定向能量沉积直接增材制造[J]. 无机材料学报, 2023, 38(10): 1183-1192. |

| [8] | 吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280. |

| [9] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [10] | 张俊敏, 陈小武, 廖春景, 郭斐宇, 杨金山, 张翔宇, 董绍明. SiCf/SiC复合材料的RMI制备方法以及微观结构和性能优化[J]. 无机材料学报, 2021, 36(10): 1103-1110. |

| [11] | 朱丹阳, 钱康, 陈肖朴, 胡泽望, 刘欣, 李晓英, 潘裕柏, MIHÓKOVÁ Eva, NIKL Martin, 李江. 热等静压烧结制备细晶粒Ce,Y:SrHfO3闪烁陶瓷[J]. 无机材料学报, 2021, 36(10): 1118-1124. |

| [12] | 吴小军,杨杰,郑蕊,张兆甫,杨毅. 烧蚀型面结构对CVI+HPIC工艺制备针刺C/C喉衬等离子烧蚀性能的影响[J]. 无机材料学报, 2020, 35(6): 654-660. |

| [13] | 董丽佳, 郭筱洁, 李雪, 陈朝贵, 金阳, AHMED Alsaedi, TASAWAr Hayat, 赵轻舟, 盛国栋. 不同pH条件下硫化钼纳米片吸附Cd(II)的微观机制研究[J]. 无机材料学报, 2020, 35(3): 293-300. |

| [14] | 徐维民, 李世波, 胡树郡, 姜吉鹏, 于文波, 周洋. ZrC/Cr2AlC复合材料的微观结构及力学性能研究[J]. 无机材料学报, 2020, 35(1): 61-64. |

| [15] | 焦思怡, 葛万银, 殷立雄, 徐美美, 常哲, 张荔. 新型二维TiSe2纳米片的可控合成及其生长机理[J]. 无机材料学报, 2019, 34(8): 834-838. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||