无机材料学报 ›› 2023, Vol. 38 ›› Issue (12): 1405-1412.DOI: 10.15541/jim20230164 CSTR: 32189.14.10.15541/jim20230164

所属专题: 【信息功能】功能晶体(202506)

李一村1( ), 郝晓斌1, 代兵1(

), 郝晓斌1, 代兵1( ), 文东岳1, 朱嘉琦1, 耿方娟1, 乐卫平2, 林伟群2(

), 文东岳1, 朱嘉琦1, 耿方娟1, 乐卫平2, 林伟群2( )

)

收稿日期:2023-04-04

修回日期:2023-05-23

出版日期:2023-08-31

网络出版日期:2023-08-31

通讯作者:

代 兵, 教授. E-mail: daibinghit@vip.126.com;作者简介:李一村(1996-), 男, 博士研究生. E-mail: 741624995@qq.com

基金资助:

LI Yicun1( ), HAO Xiaobin1, DAI Bing1(

), HAO Xiaobin1, DAI Bing1( ), WEN Dongyue1, ZHU Jiaqi1, GENG Fangjuan1, YUE Weiping2, LIN Weiqun2(

), WEN Dongyue1, ZHU Jiaqi1, GENG Fangjuan1, YUE Weiping2, LIN Weiqun2( )

)

Received:2023-04-04

Revised:2023-05-23

Published:2023-08-31

Online:2023-08-31

Contact:

DAI Bing, professor. E-mail: daibinghit@vip.126.com;About author:LI Yicun (1996-), male, PhD candidate. E-mail: 741624995@qq.com

Supported by:摘要:

微波等离子体化学气相沉积(Microwave plasma chemical vapor deposition, MPCVD)技术是制备大尺寸、高品质单晶金刚石的理想途径, 然而MPCVD单晶金刚石生长过程的复杂性与晶体生长需求的多样性难以对生长过程进行优化设计。针对此问题, 本研究提出了一种基于等离子体诊断技术的MPCVD单晶金刚石生长的系统性设计方法, 采用等离子体成像和光谱分析对微波等离子体进行量化诊断。并利用自主研发的MPCVD设备, 研究了腔室压力-微波功率-等离子体性状-衬底温度间的物理耦合特性和量化关系, 得到了不同参数下的等离子体有效长轴尺寸、基团浓度和分布、能量密度等数据, 以实验观测数据为基础拟合得到了单晶金刚石生长工艺图谱。根据此工艺图谱, 可以通过选择生长温度和所需生长面积来选取工艺参数, 且通过实验验证, 表明此图谱具有较强的指导意义, 预测参数误差小于5%。同时根据该图谱的预测, 研究了不同等离子体能量密度下的单晶金刚石生长情况, 在较低功率下(2600 W)也得到了较高的能量密度(148.5 W/cm3), 含碳前驱体的浓度也高于其他工艺条件, 因而获得了较高的生长速率(8.9 μm/h)。此套方法体系可以针对不同单晶金刚石生长需求进行有效的等离子体调控和工艺优化。

中图分类号:

李一村, 郝晓斌, 代兵, 文东岳, 朱嘉琦, 耿方娟, 乐卫平, 林伟群. 基于等离子体诊断的MPCVD单晶金刚石生长优化设计[J]. 无机材料学报, 2023, 38(12): 1405-1412.

LI Yicun, HAO Xiaobin, DAI Bing, WEN Dongyue, ZHU Jiaqi, GENG Fangjuan, YUE Weiping, LIN Weiqun. Optimization Design of MPCVD Single Crystal Diamond Growth Based on Plasma Diagnostics[J]. Journal of Inorganic Materials, 2023, 38(12): 1405-1412.

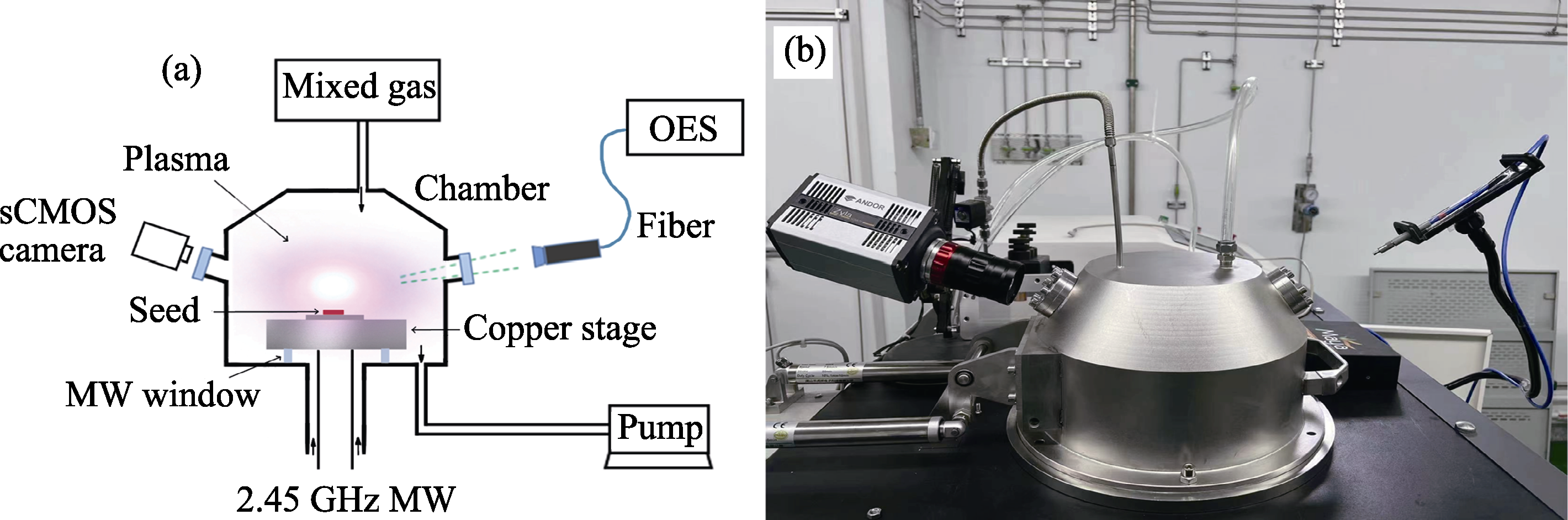

图1 HITLH-2450M金刚石生长系统及等离子体诊断系统

Fig. 1 HITLH-2450M diamond growth system and plasma diagnostic system (a) Diagrammatic sketch; (b) Photograph of the system

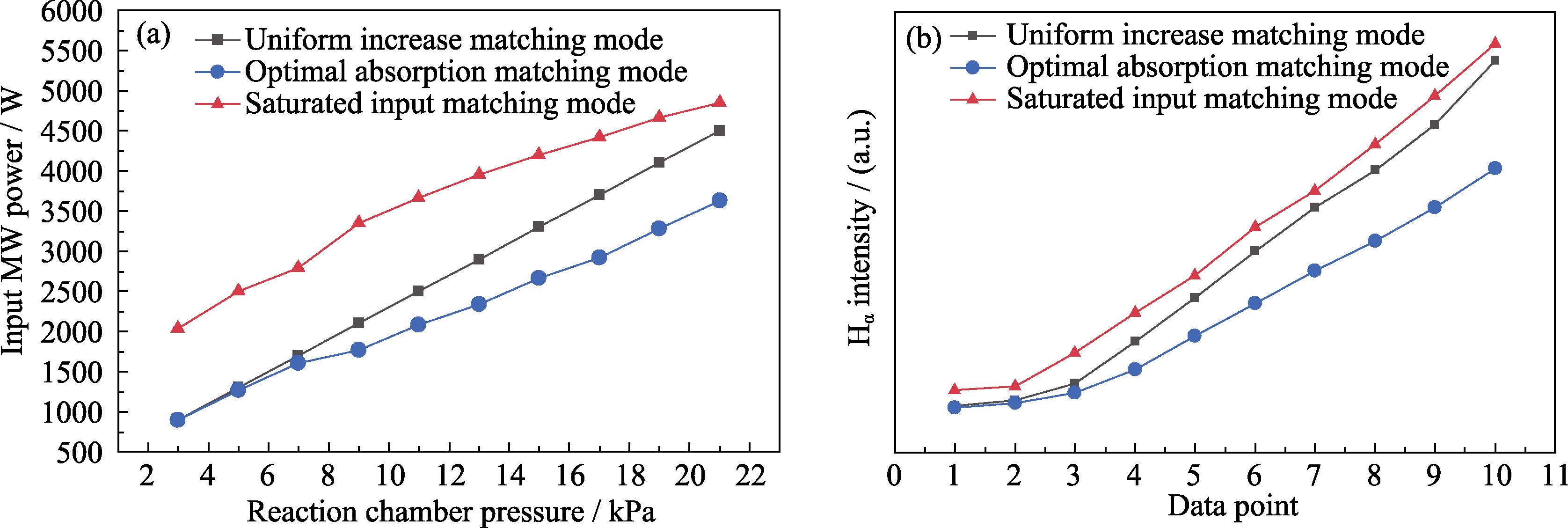

图2 三种匹配模式下, 压力-功率参数曲线(a)和等离子体核心Hα谱线强度变化(b)

Fig. 2 Pressure-microwave power parameter curves (a) and Hα intensity of plasma central region (b) under three matching modes The abscissa in (b) corresponds to the 10 parameter observation points in (a)

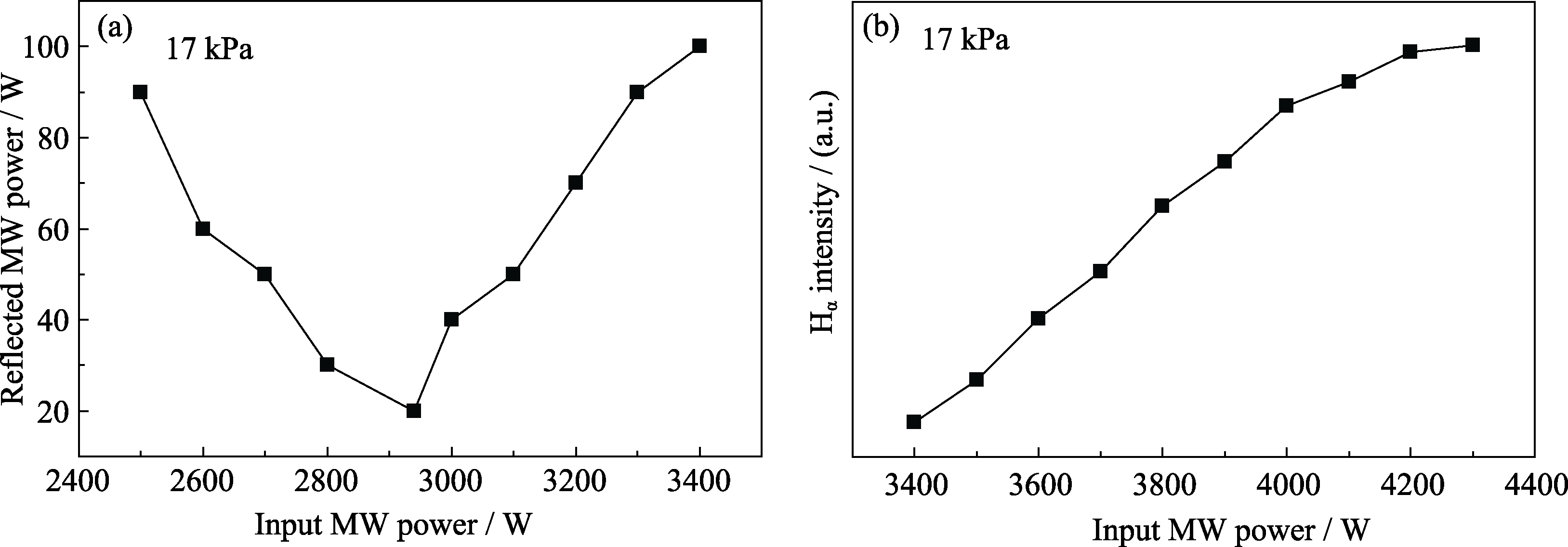

图3 一定压力下, 反射功率随输入功率的变化曲线(a)和等离子体核心Hα谱线强度随输入功率变化曲线(b)

Fig. 3 At a certain pressure, change of reflected power (a) and change of Hα intensity (b) with input power The data at 17 kPa are selected for display, and the variation trend is similar under the other pressures

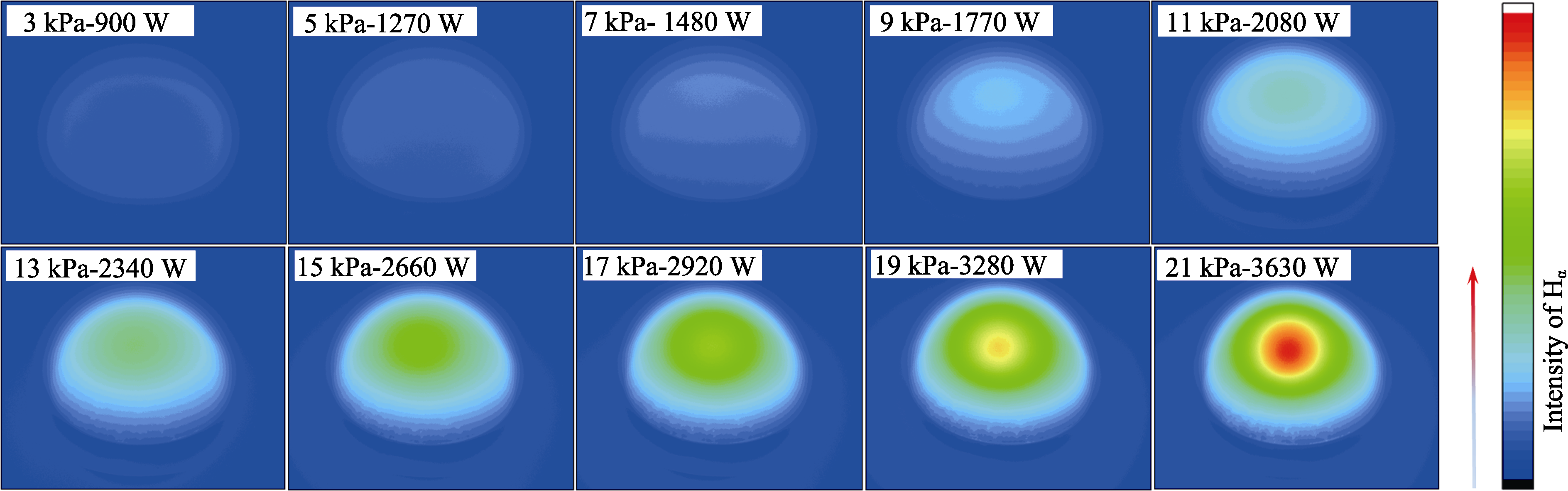

图4 最佳吸收匹配模式下各观测参数点等离子体中的原子氢浓度分布(其他模式下分布规律变化情况类似)

Fig. 4 Atomic hydrogen concentration distributions in plasma at various observation parameter points under optimal absorption matching mode with similar distribution pattern changes in other modes

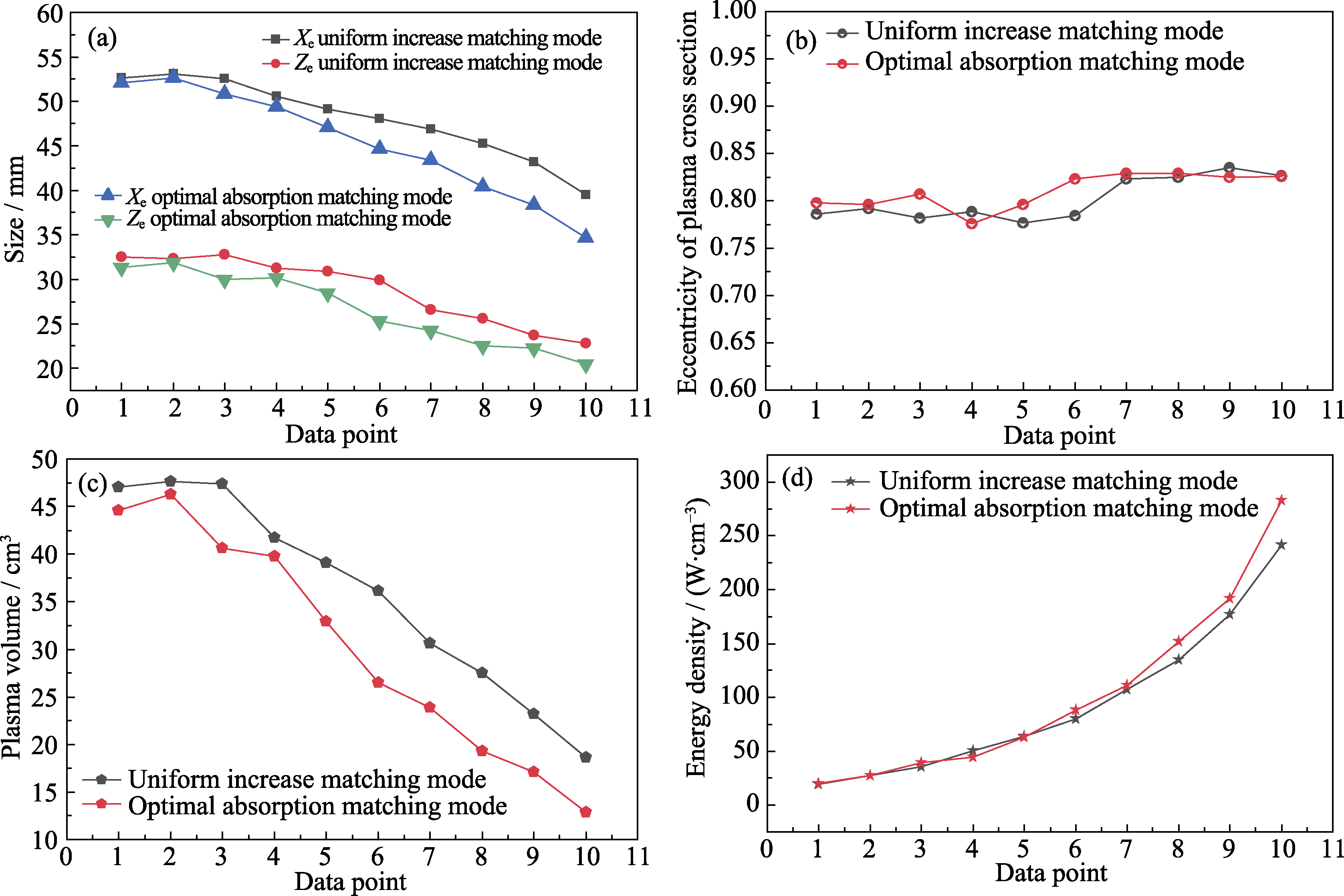

图5 均匀增长与最佳吸收匹配下的等离子体量化分析

Fig. 5 Quantitative analysis of plasma in uniform increase and optimal absorption matching mode (a) Sizes of major axis and minor axis; (b) Eccentricity; (c) Volume; (d) Energy density

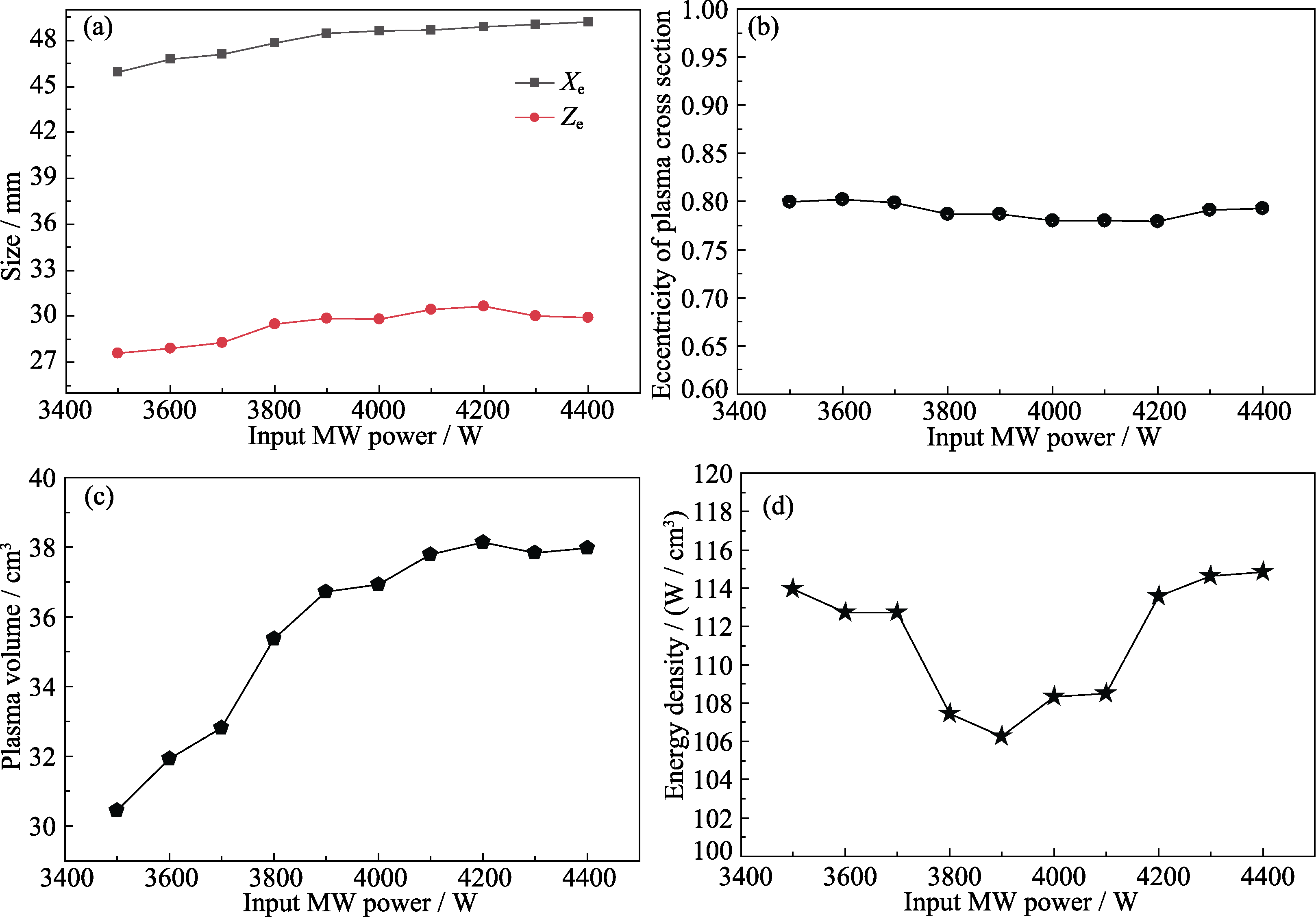

图6 恒定压力条件下等离子体长轴和短轴(a)、离心率(b)、体积(c)以及能量密度(d)随输入功率的变化曲线(选取气压为16 kPa的数据作为展示, 其余参数点变化趋势类似)

Fig. 6 Changes in plasma major axis and minor axis (a), eccentricity (b), volume (c), and energy density (d) with input power under constant pressure with data at 16 kPa showing the selected display, and variation trends being similar under different pressures

图7 MPCVD单晶金刚石生长工艺预测图谱

Fig. 7 Prediction map of MPCVD single crystal diamond growth process HITLH-2450M system, seed at 0.5 mm in thickness, under the conditions of 20 ℃ water-cooling, 9-17 kPa pressure, and 1600-4200 W microwave power

| Parameter | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Preset growth temperature/℃ | 850 | 850 | 850 |

| Preset major axis/mm | 48 | 42 | 53 |

| Predicted pressure- microwave power | 14.2 kPa- 3140 W | 15.6 kPa- 2600 W | 12.8 kPa- 3500 W |

| Actual growth temperature/℃ | 867 | 860 | 835 |

| Actual major axis/mm | 47.5 | 41.2 | 52.8 |

| Energy density/ (W·cm-3) | 121.3 | 148.5 | 115.2 |

| Growth rate/(μm·h-1) | 8.5 | 8.9 | 8.2 |

表1 根据工艺预测谱图选取的参数点及实际的单晶金刚石生长参数

Table 1 Parameter points selection based on the predicted map and growth parameters of actual single crystal diamond

| Parameter | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Preset growth temperature/℃ | 850 | 850 | 850 |

| Preset major axis/mm | 48 | 42 | 53 |

| Predicted pressure- microwave power | 14.2 kPa- 3140 W | 15.6 kPa- 2600 W | 12.8 kPa- 3500 W |

| Actual growth temperature/℃ | 867 | 860 | 835 |

| Actual major axis/mm | 47.5 | 41.2 | 52.8 |

| Energy density/ (W·cm-3) | 121.3 | 148.5 | 115.2 |

| Growth rate/(μm·h-1) | 8.5 | 8.9 | 8.2 |

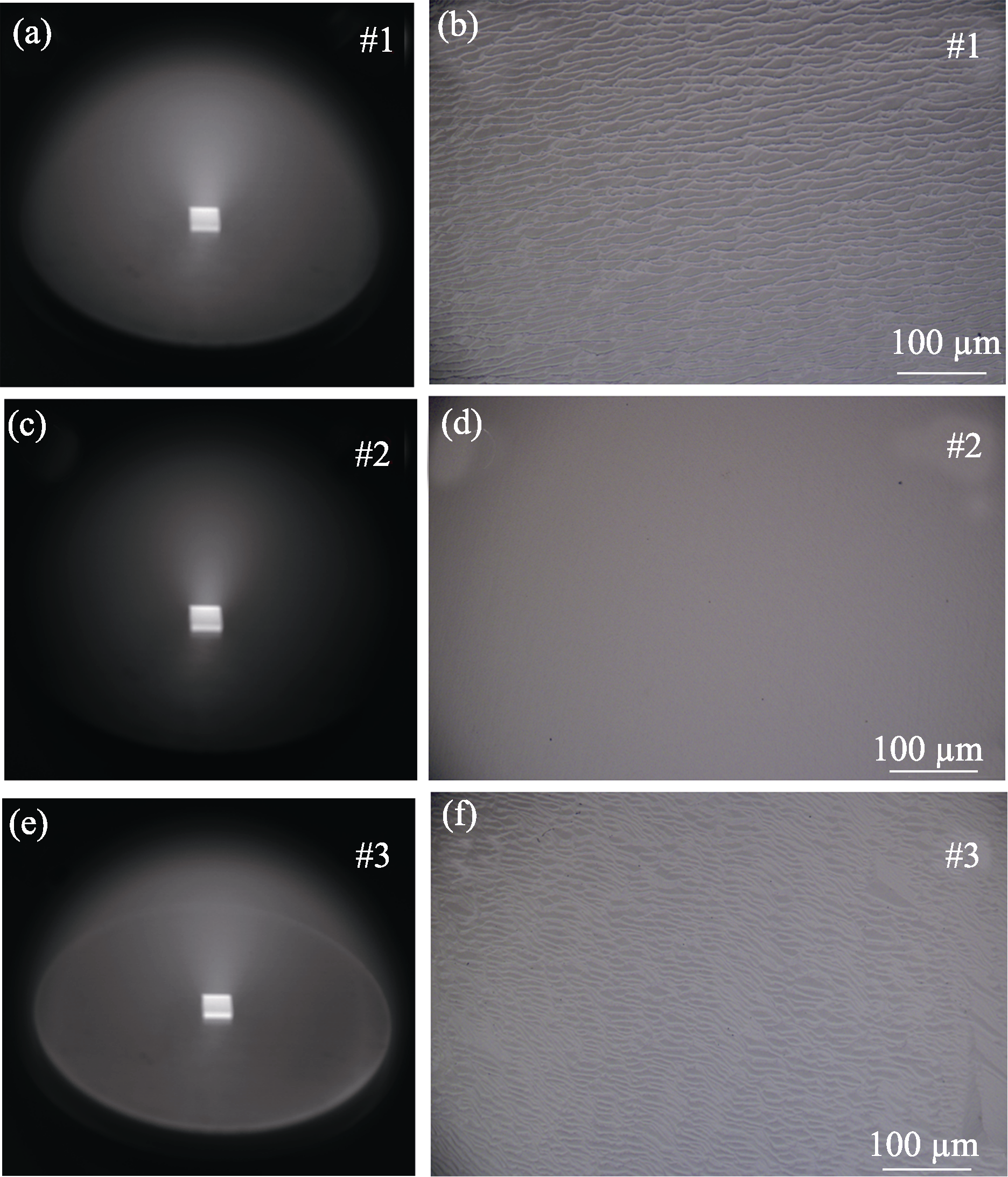

图8 三个实验样品的等离子体生长环境照片(加装Hα滤镜)以及生长10 h后的表面光学显微形貌

Fig. 8 Photos of plasma growth environment of three samples (with Hα filter) and the surface optical micrographs after 10 h of growth (a, b) Sample 1; (c, d) Sample 2; (e, f) Sample 3

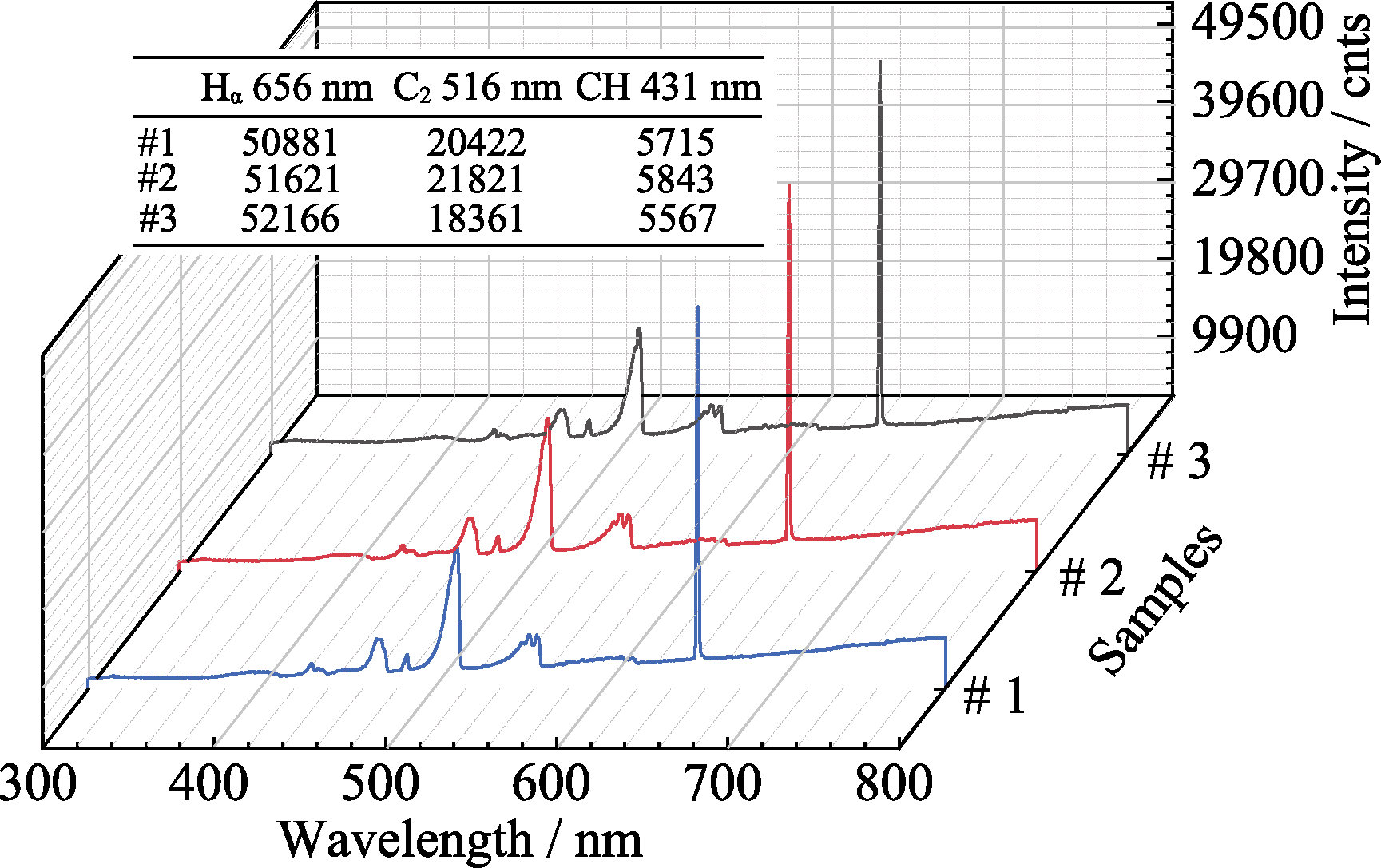

图9 单晶金刚石样品生长过程中的等离子体发射光谱

Fig. 9 Plasma emission spectra in the growth of single crystal diamond #1, # 2 and # 3 correspond to samples 1, 2, and 3, respectively

| [1] | ARNAULT J, SAADA S, RALCHENKO V. CVD grown single crystal diamond: a review. Physica Status Solidi (RRL)-Rapid Research Letters, 2022, 16: 2100354. |

| [2] | ZHENG Y, CHENGMING L I, LIU J, et al. Chemical vapor deposited diamond with versatile grades: from gemstone to quantum electronics. Frontiers of Materials Science, 2022, 16: 220590. |

| [3] | LIU K, ZHANG S, RALCHENKO V, et al. Tailoring of typical color centers in diamond for photonics. Advanced Materials, 2021, 33: 2000891. |

| [4] | LIU K, ZHANG S, LIU B J, et al. Investigating the energetic band diagrams of oxygen-terminated CVD grown e6 electronic grade diamond. Carbon, 2020, 169: 440. |

| [5] |

MOKUNO Y, CHAYAHARA A, YAMADA H. Synthesis of large single crystal diamond plates by high rate homoepitaxial growth using microwave plasma CVD and lift-off process. Diamond and Related Materials, 2008, 17(4/5): 415.

DOI URL |

| [6] | YAN C S, VOHRA Y K, MAO H K et al. Very high growth rate chemical vapor deposition of single-crystal diamond. Proceedings of the National Academy of Sciences of the United States of America, 2002, 99(20): 12523. |

| [7] | MUEHLE M, ASMUSSEN J, BECKER M F, et al. Extending microwave plasma assisted CVD SCD growth to pressures of 400 Torr. Diamond and Related Materials, 2017, 79: 150. |

| [8] | LIANG Q, CHIN C Y, LAI J, et al. Enhanced growth of high quality single crystal diamond by microwave plasma assisted chemical vapor deposition at high gas pressures. Applied Physics Letters, 2009, 94(2): 12523. |

| [9] |

ACHARD J, TALLAIRE A, SUSSMANN R, et al. The control of growth parameters in the synthesis of high-quality single crystalline diamond by CVD. Journal of Crystal Growth, 2005, 284(3/4): 396.

DOI URL |

| [10] |

TALLAIRE A, ACHARD J, SILVA F, et al. Homoepitaxial deposition of high-quality thick diamond films: effect of growth parameters. Diamond and Related Materials, 2005, 14(3): 249.

DOI URL |

| [11] | SILVA F, ACHARD J, BRINZA O, et al. High quality, large surface area, homoepitaxial MPACVD diamond growth. Diamond & Related Materials, 2009, 18(5): 683. |

| [12] | GICQUEL A, SILVA F, ROND C, et al. Ultrafast deposition of diamond by plasma-enhanced CVD. Comprehensive Hard Materials, 2014, 3: 217. |

| [13] |

YAMADA H, CHAYAHARA A, MOKUNO Y, et al. Modeling and numerical analyses of microwave plasmas for optimizations of a reactor design and its operating conditions. Diamond and Related Materials, 2005, 14(11): 1776.

DOI URL |

| [14] | YAMADA H, CHAYAHARA A, MOKUNO Y. Simplified description of microwave plasma discharge for chemical vapor deposition of diamond. Journal of Applied Physics, 2007, 101: 063302. |

| [15] | SU J J, LI Y F, LI X L, et al. A novel microwave plasma reactor with a unique structure for chemical vapor deposition of diamond films. Diamond and Related Materials, 2014, 42: 28. |

| [16] | FÜNER M, WILD C, KOIDL P. Simulation and development of optimized microwave plasma reactors for diamond deposition. Surface & Coatings Technology, 1999, 116-119: 853. |

| [17] | LI Y F, SU J J, LIU Y Q, et al. Design of a new TM021 mode cavity type MPCVD reactor for diamond film deposition. Diamond and Related Materials, 2014, 44: 88. |

| [18] |

SILVA F, HASSOUNI K, BONNIN X, et al. Microwave engineering of plasma-assisted CVD reactors for diamond deposition. Journal of Physics Condensed Matter, 2009, 21(36): 364202.

DOI URL |

| [19] | BOLSHAKOV A P, RALCHENKO V G, SHU G Y, et al. Single crystal diamond growth by MPCVD at subatmospheric pressures. Materials Today Communications, 2020, 25: 101635. |

| [20] | GICQUEL A, DERKAOUI N, ROND C, et al. Quantitative analysis of diamond deposition reactor efficiency. Chemical Physics, 2012, 398: 239. |

| [21] | LOBAEV M A, BOGDANOV S A, RADISHEV D B, et al. Method of power density determination in microwave discharge, sustained in hydrogen-methane gas mixture. Diamond & Related Materials, 2016, 66: 177. |

| [22] | BUSHUEV E V, YUROV V YU, BOLSHAKOV A P, et al. Express in situ measurement of epitaxial CVD diamond film growth kinetics. Diamond and Related Materials, 2017, 72: 61. |

| [23] |

ACHARD J, SILVA F, BRINZA O, et al. Coupled effect of nitrogen addition and surface temperature on the morphology and the kinetics of thick CVD diamond single crystals. Diamond and Related Materials, 2007, 16(4-7): 685.

DOI URL |

| [24] | WANG X, DUAN P, CAO Z, et al. Homoepitaxy growth of single crystal diamond under 300 torr pressure in the MPCVD system. Materials, 2019, 12: 3953. |

| [25] | MUCHNIKOV A B, VIKHAREV A L, GORBACHEV A M, et al. Homoepitaxial single crystal diamond growth at different gas pressures and MPACVD reactor configurations. Diamond and Related Materials, 2010, 19(5/6): 43. |

| [1] | 李家琪, 李小松, 李煊赫, 朱晓兵, 朱爱民. 暖等离子体合成过渡金属掺杂氧化锰析氧电催化剂[J]. 无机材料学报, 2024, 39(7): 835-844. |

| [2] | 卢灏, 许晟瑞, 黄永, 陈兴, 徐爽, 刘旭, 王心颢, 高源, 张雅超, 段小玲, 张进成, 郝跃. 等离子体增强原子层沉积AlN外延单晶GaN研究[J]. 无机材料学报, 2024, 39(5): 547-553. |

| [3] | 杨志亮, 杨鏊, 刘鹏, 陈良贤, 安康, 魏俊俊, 刘金龙, 吴立枢, 李成明. 热管理用3英寸硅衬底金刚石薄膜的制备[J]. 无机材料学报, 2024, 39(3): 283-290. |

| [4] | 邱海洋, 苗广潭, 李辉, 栾奇, 刘国侠, 单福凯. 等离子体处理对突触晶体管长程塑性的影响[J]. 无机材料学报, 2023, 38(4): 406-412. |

| [5] | 李一村, 刘雪冬, 郝晓斌, 代兵, 吕继磊, 朱嘉琦. 等离子体聚集装置下的高能量密度单晶金刚石快速生长研究[J]. 无机材料学报, 2023, 38(3): 303-309. |

| [6] | 王潇, 朱智杰, 吴之怡, 张城城, 陈志杰, 肖梦琦, 李超然, 何乐. 钴等离激元超结构粉体催化剂的制备及其光热催化应用[J]. 无机材料学报, 2022, 37(1): 22-28. |

| [7] | 董梦悦, 徐卫卫, 赵静, 底兰波, 张秀玲. 制备方法对Ru/γ-Al2O3与等离子体共活化CO2甲烷化反应的影响[J]. 无机材料学报, 2020, 35(5): 567-572. |

| [8] | 郑雪, 江睿, 李谦, 王伟哲, 徐智谋, 彭静. 类阳极氧化铝纳米结构LED的研究[J]. 无机材料学报, 2020, 35(5): 561-566. |

| [9] | 韩杰敏, 王梅, 仝召民, 马一飞. 基于石墨烯森林电极的摩擦纳米发电机[J]. 无机材料学报, 2019, 34(8): 839-843. |

| [10] | 邹溪, 晋云霞, 孔钒宇, 王勇禄, 张益彬, 邵建达. 多层介质膜脉宽压缩光栅清洗方法研究[J]. 无机材料学报, 2019, 34(12): 1285-1289. |

| [11] | 李晓萍, 李跃军, 曹铁平, 孙大伟, 王霞, 席啸天. 简易合成Bi/Bi2MoO6/TiO2复合纳米纤维及其增强的可见光催化性能[J]. 无机材料学报, 2019, 34(11): 1193-1199. |

| [12] | 陈文波, 陈伦江, 刘川东, 程昌明, 童洪辉, 朱海龙. 射频热等离子体制备球形氧化铝粉末的数值模拟及实验研究[J]. 无机材料学报, 2018, 33(5): 550-556. |

| [13] | 严世胜, 彭鸿雁, 赵志斌, 潘孟美, 羊大立, 阿金华, 叶国林, 王崇太, 郭心玮. 掺氮金刚石电极性能及其氧化降解硝基苯研究[J]. 无机材料学报, 2018, 33(5): 565-569. |

| [14] | 李大川, 赵华玉, 钟兴华, 陶顺衍. 大气等离子体喷涂的单片层研究进展[J]. 无机材料学报, 2017, 32(6): 571-580. |

| [15] | 余洁意, 黄 昊, 高 见, 周 雷, 高 嵩, 董星龙, 全 燮. 直流电弧等离子体制备纳米SiC及其催化特性[J]. 无机材料学报, 2017, 32(4): 351-356. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||