无机材料学报 ›› 2022, Vol. 37 ›› Issue (10): 1079-1086.DOI: 10.15541/jim20220039 CSTR: 32189.14.10.15541/jim20220039

任培安( ), 汪聪, 訾鹏, 陶奇睿, 苏贤礼(

), 汪聪, 訾鹏, 陶奇睿, 苏贤礼( ), 唐新峰(

), 唐新峰( )

)

收稿日期:2022-01-24

修回日期:2022-03-04

出版日期:2022-10-20

网络出版日期:2022-04-07

通讯作者:

唐新峰, 教授. E-mail: tangxf@whut.edu.cn;作者简介:任培安(1996-), 男, 硕士研究生. E-mail: renpeian@whut.edu.cn

基金资助:

REN PeiAn( ), WANG Cong, ZI Peng, TAO Qirui, SU Xianli(

), WANG Cong, ZI Peng, TAO Qirui, SU Xianli( ), TANG Xinfeng(

), TANG Xinfeng( )

)

Received:2022-01-24

Revised:2022-03-04

Published:2022-10-20

Online:2022-04-07

Contact:

TANG Xinfeng, professor. E-mail: tangxf@whut.edu.cn;About author:REN Peian (1996-), male, Master candidate. E-mail: renpeian@whut.edu.cn

Supported by:摘要:

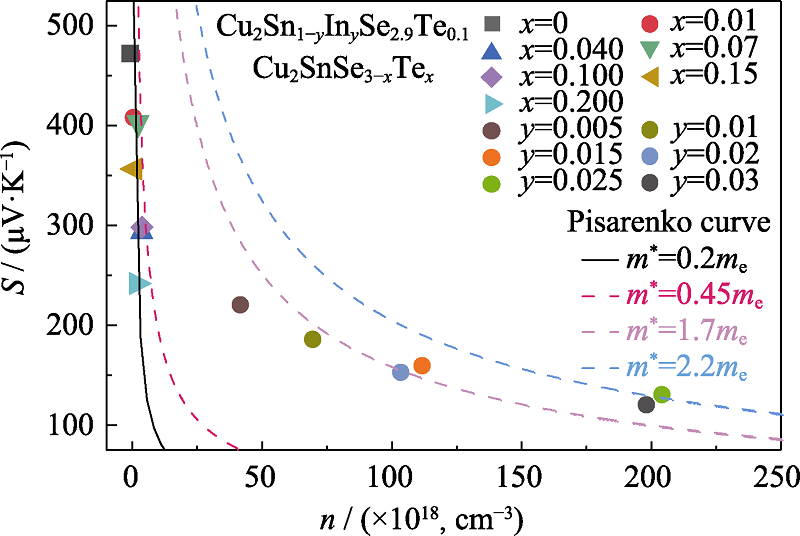

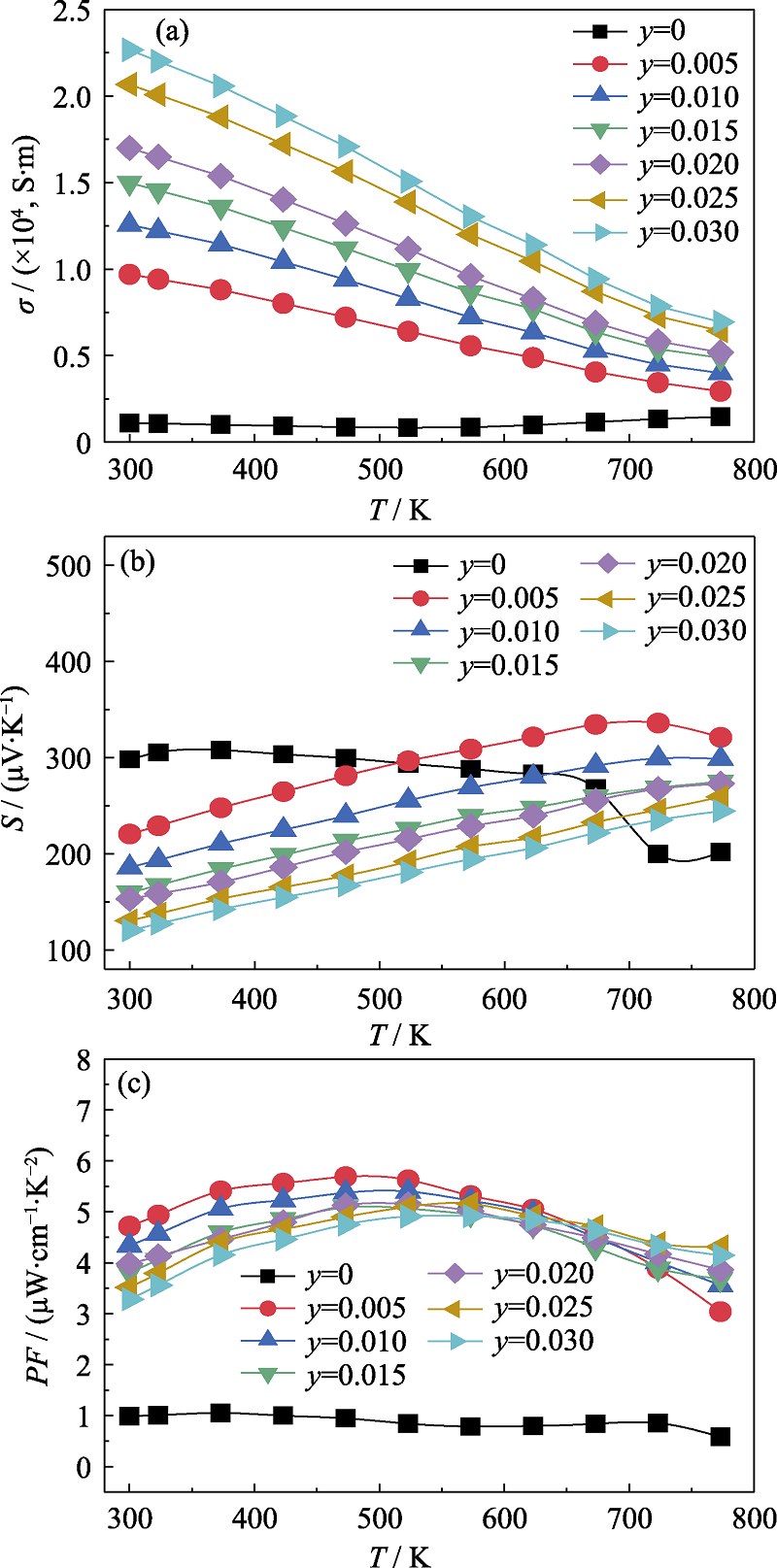

Cu2SnSe3基化合物作为一种绿色环保的新型热电材料, 近年受到了研究者的广泛关注。然而, 本征Cu2SnSe3基化合物载流子浓度低、电性能较差。为优化Cu2SnSe3化合物的电热输运性能, 本研究采用熔融、退火结合放电等离子烧结技术制备了一系列Cu2SnSe3-xTex (x=0~0.2)和Cu2Sn1-yInySe2.9Te0.1 (y=0.005~0.03)样品, 研究了Te固溶和In掺杂对材料电热输运性能的影响。Te在Cu2SnSe3-xTex (x=0~0.2)化合物中的固溶度为0.10, Te固溶显著增加了材料的载流子有效质量, 从本征Cu2SnSe3样品的0.2me增加到Cu2SnSe2.9Te0.1样品的0.45me, 显著提高了材料的功率因子, Cu2SnSe2.99Te0.01样品在300 K下获得最大功率因子为1.37 μW·cm-1·K-2。为了进一步提高材料的电传输性能, 本研究以Cu2SnSe2.9Te0.1为基体并选取In在Sn位掺杂。In掺杂将Cu2SnSe3基化合物的载流子浓度从5.96×1018 cm-3 (Cu2SnSe2.9Te0.1)显著提高到2.06×1020 cm-3 (Cu2Sn0.975In0.025Se2.9Te0.1)。调控载流子浓度促进了材料多价带参与电传输, 材料的电导率和载流子有效质量显著增加, 功率因子得到大幅度提升, 在473 K下Cu2Sn0.995In0.005Se2.9Te0.1化合物获得最大功率因子为5.69 μW·cm-1·K-2。由于电输运行性能显著提升和晶格热导率降低, Cu2Sn0.985In0.025Se2.9Te0.1样品在773 K下获得最大ZT为0.4, 较本征Cu2SnSe3样品提高了4倍。

中图分类号:

任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰. Te与In共掺杂对Cu2SnSe3热电性能的影响[J]. 无机材料学报, 2022, 37(10): 1079-1086.

REN PeiAn, WANG Cong, ZI Peng, TAO Qirui, SU Xianli, TANG Xinfeng. Effect of Te and In Co-doping on Thermoelectric Properties of Cu2SnSe3 Compounds[J]. Journal of Inorganic Materials, 2022, 37(10): 1079-1086.

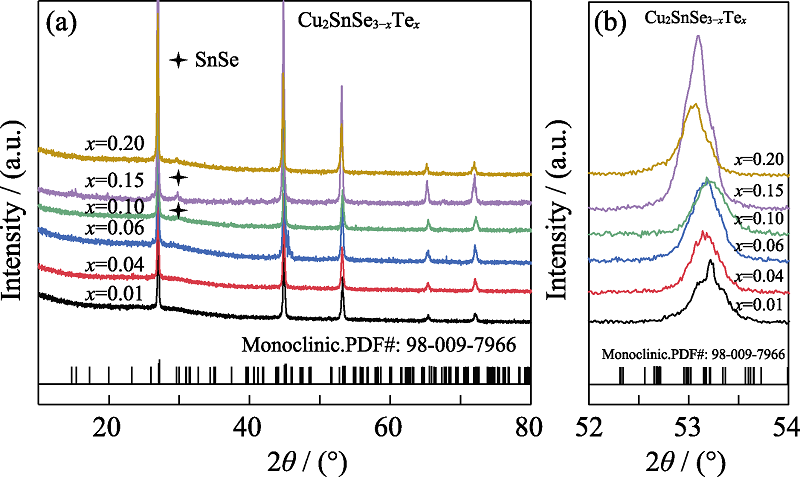

图1 烧结后Cu2SnSe3-xTex样品的粉末XRD图谱(a)以及在2θ=53°附近的放大图(b)

Fig. 1 Powder XRD patterns of Cu2SnSe3-xTex samples after PAS sintering (a) and corresponding enlarge view near 2θ=53° (b)

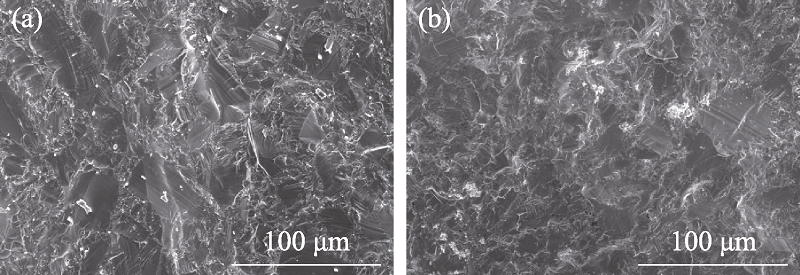

图2 Cu2SnSe3 (a)与Cu2SnSe2.9Te0.1 (b)的自由断裂面场发射扫描电镜照片

Fig. 2 Field emission scanning electron microscopies of freshly fractured surfaces of samples Cu2SnSe3 (a) and Cu2SnSe2.9Te0.1 (b)

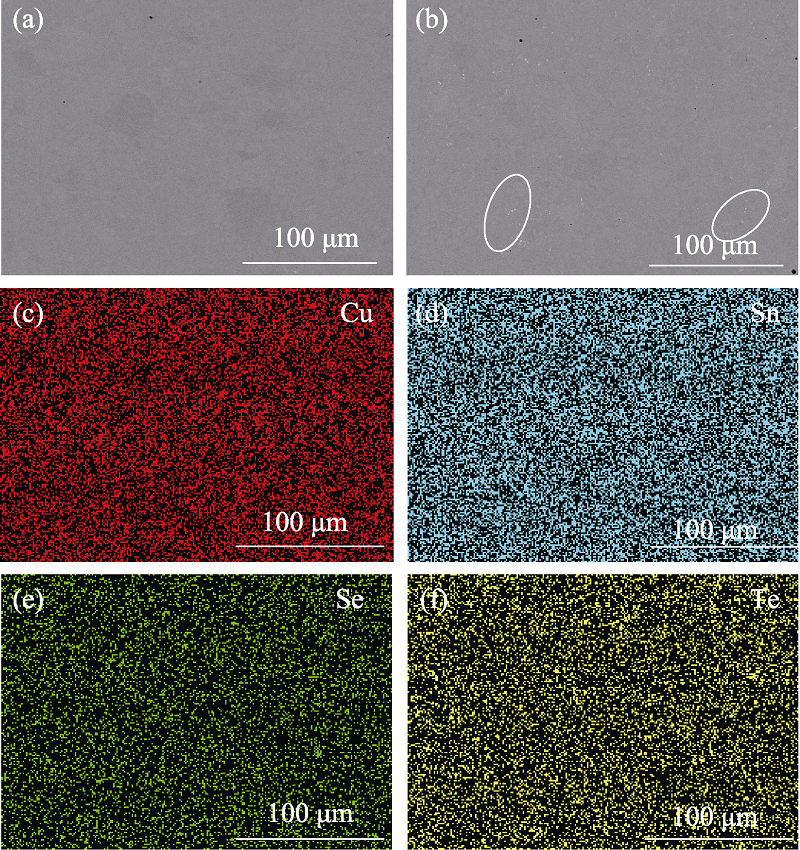

图3 Cu2SnSe2.9Te0.1 (a)与Cu2SnSe2.85Te0.15 (b)抛光面处的背散射电子图像及 Cu2SnSe2.9Te0.1样品的元素面分布图(c~f)

Fig. 3 Backscattered electron images of the polished surfaces for samples Cu2SnSe2.9Te0.1 (a) and Cu2SnSe2.85Te0.15 (b) with elemental distribution mappings of Cu2SnSe2.9Te0.1(c-f)

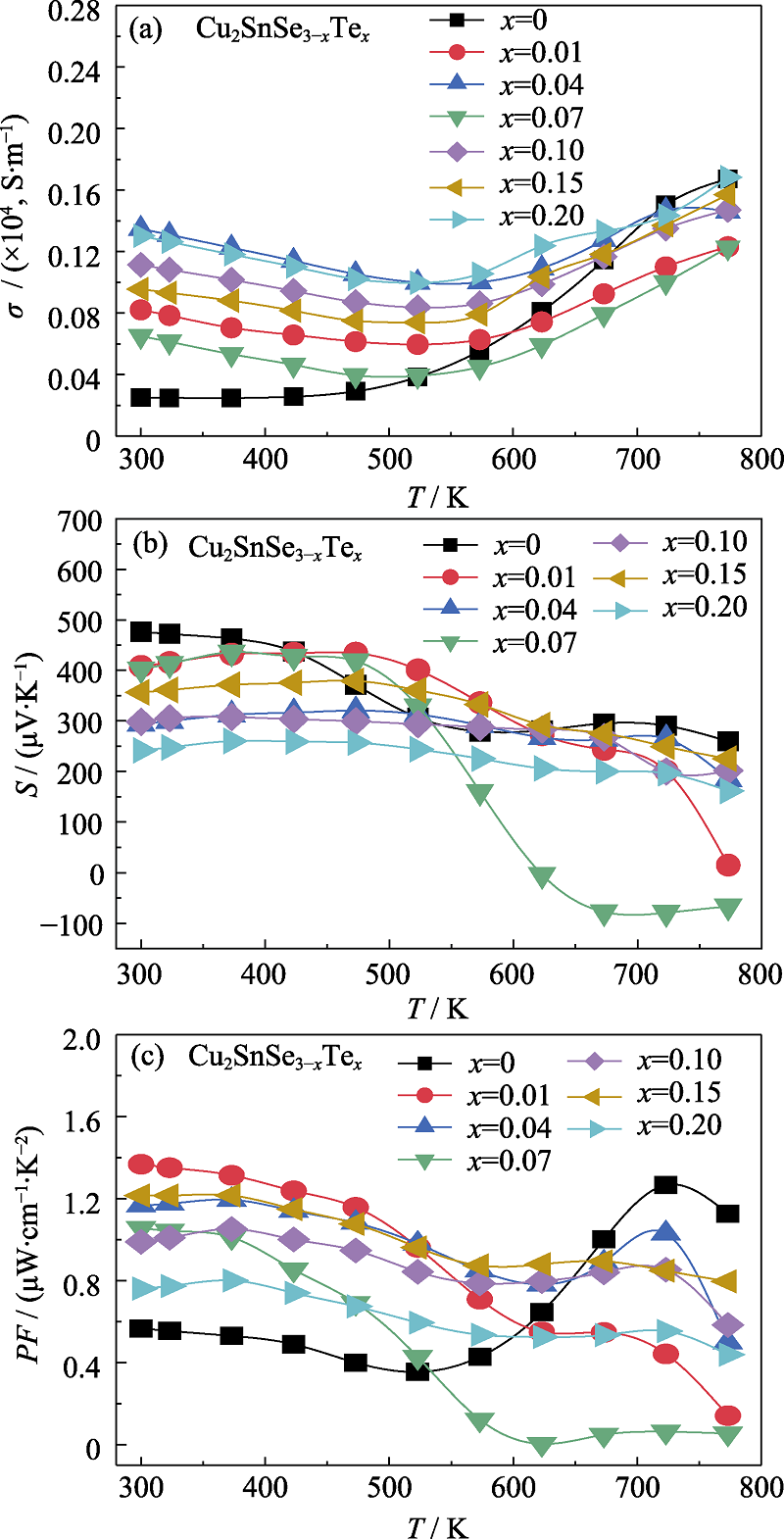

图4 Cu2SnSe3-xTex化合物的电导率(a)、Seebeck系数(b)和功率因子(c)随温度的变化曲线

Fig. 4 Temperature dependent electrical conductivity (a), Seebeck coefficient (b) and power factor (c) of Cu2SnSe3-xTex samples

| Sample | σ/(×104, S·m-1) | S/ (μV·K-1) | n/(×1017, cm-3) | μ/(cm2· V-1·s-1) |

|---|---|---|---|---|

| Cu2SnSe3 | 0.02 | 472.18 | 6.25 | 24.92 |

| Cu2SnSe2.99Te0.01 | 0.08 | 408.07 | 24.34 | 21.04 |

| Cu2SnSe2.96Te0.04 | 0.13 | 294.12 | 53.77 | 15.68 |

| Cu2SnSe2.93Te0.07 | 0.07 | 402.62 | 40.29 | 10.14 |

| Cu2SnSe2.9Te0.1 | 0.11 | 298.21 | 59.63 | 11.67 |

| Cu2SnSe2.85Te0.15 | 0.10 | 356.49 | 21.27 | 27.98 |

| Cu2SnSe2.8Te0.2 | 0.13 | 241.73 | 24.05 | 21.64 |

表1 Cu2SnSe3-xTex在室温下的电导率(σ)、Seebeck系数(S)、载流子浓度(n)以及载流子迁移率(μ)

Table 1 Electrical conductivities (σ), Seebeck coefficients (S), carrier concentrations (n) and carrier mobilities (μ) of Cu2SnSe3-xTex samples at room temperature

| Sample | σ/(×104, S·m-1) | S/ (μV·K-1) | n/(×1017, cm-3) | μ/(cm2· V-1·s-1) |

|---|---|---|---|---|

| Cu2SnSe3 | 0.02 | 472.18 | 6.25 | 24.92 |

| Cu2SnSe2.99Te0.01 | 0.08 | 408.07 | 24.34 | 21.04 |

| Cu2SnSe2.96Te0.04 | 0.13 | 294.12 | 53.77 | 15.68 |

| Cu2SnSe2.93Te0.07 | 0.07 | 402.62 | 40.29 | 10.14 |

| Cu2SnSe2.9Te0.1 | 0.11 | 298.21 | 59.63 | 11.67 |

| Cu2SnSe2.85Te0.15 | 0.10 | 356.49 | 21.27 | 27.98 |

| Cu2SnSe2.8Te0.2 | 0.13 | 241.73 | 24.05 | 21.64 |

图5 Cu2SnSe3-xTex与Cu2Sn1-yInySe2.9Te0.1样品的载流子浓度与Seebeck系数的关系曲线

Fig. 5 Relationship between carrier concentration and Seebeck coefficient for Cu2SnSe3-xTex and Cu2Sn1-yInySe2.9Te0.1 samples Colorful figure is available on website

图8 Cu2Sn1-yInySe2.9Te0.1化合物的电导率(a)、Seebeck系数(b)和功率因子(c)随温度的变化曲线

Fig. 8 Temperature dependent electrical conductivity (a), Seebeck coefficient (b) and power factor (c) for Cu2Sn1-yInySe2.9Te0.1 samples

| Sample | σ/(×104, S·m-1) | S/ (μV·K-1) | n/(×1019, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|

| Cu2SnSe2.9Te0.1 | 0.11 | 298.21 | 0.59 | 11.68 |

| Cu2Sn0.995In0.005Se2.9Te0.1 | 0.97 | 220.50 | 4.35 | 13.95 |

| Cu2Sn0.99In0.01Se2.9Te0.1 | 1.26 | 185.79 | 7.15 | 10.99 |

| Cu2Sn0.985In0.015Se2.9Te0.1 | 1.50 | 159.47 | 11.36 | 8.25 |

| Cu2Sn0.98In0.02Se2.9Te0.1 | 1.67 | 152.91 | 10.54 | 10.08 |

| Cu2Sn0.975In0.025Se2.9Te0.1 | 2.07 | 130.39 | 20.60 | 6.28 |

| Cu2Sn0.97In0.03Se2.9Te0.1 | 2.27 | 120.35 | 20.00 | 7.09 |

表2 Cu2Sn1-yInySe2.9Te0.1样品在室温下的电导率(σ)、Seebeck系数(S)、载流子浓度(n)以及载流子迁移率(μ)

Table 2 Electrical conductivities (σ), Seebeck coefficients (S), carrier concentrations (n) and carrier mobilities (μ) of Cu2Sn1-yInySe2.9Te0.1 samples at room temperature

| Sample | σ/(×104, S·m-1) | S/ (μV·K-1) | n/(×1019, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|

| Cu2SnSe2.9Te0.1 | 0.11 | 298.21 | 0.59 | 11.68 |

| Cu2Sn0.995In0.005Se2.9Te0.1 | 0.97 | 220.50 | 4.35 | 13.95 |

| Cu2Sn0.99In0.01Se2.9Te0.1 | 1.26 | 185.79 | 7.15 | 10.99 |

| Cu2Sn0.985In0.015Se2.9Te0.1 | 1.50 | 159.47 | 11.36 | 8.25 |

| Cu2Sn0.98In0.02Se2.9Te0.1 | 1.67 | 152.91 | 10.54 | 10.08 |

| Cu2Sn0.975In0.025Se2.9Te0.1 | 2.07 | 130.39 | 20.60 | 6.28 |

| Cu2Sn0.97In0.03Se2.9Te0.1 | 2.27 | 120.35 | 20.00 | 7.09 |

| [1] |

ZHOU W, YAMAMOTO K, MIURA A, et al. Seebeck-driven transverse thermoelectric generation. Nature Materials, 2021, 20(4): 463-467.

DOI PMID |

| [2] |

FREIRE L O, NAVARRETE L M, CORRALES B P, et al. Efficiency in thermoelectric generators based on Peltier cells. Energy Reports, 2021, 7: 355-361.

DOI URL |

| [3] |

BELL L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science, 2008, 321(5895): 1457-1461.

DOI PMID |

| [4] |

YANG D W, LUO T T, SU X X, et al. Unveiling the intrinsic low thermal conductivity of BiAgSeS through entropy engineering in SHS kinetic process. Journal of Inorganic Materials, 2021, 36(9): 991-998.

DOI |

| [5] |

CHEN B Q, CHEN L D, ZHANG Q H. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019, 34(3): 279-293.

DOI URL |

| [6] |

ELSHEIKH M H, SHNAWAH D A, SABRI M F M, et al. A review on thermoelectric renewable energy: principle parameters that affect their performance. Renewable and Sustainable Energy Reviews, 2014, 30: 337-355.

DOI URL |

| [7] |

SHEN J J, FANG T, FU T Z, et al. Lattice thermal conductivity in thermoelectric materials. Journal of Inorganic Materials, 2019, 34(3): 260-268.

DOI URL |

| [8] |

LIU W, YANG L, CHEN Z, et al. Promising and eco-friendly Cu2X-based thermoelectric materials: progress and applications. Advanced Materials, 2020, 32(8): 1905703.

DOI URL |

| [9] |

ZHOU X Y, LIU Y, ZHANG C, et al. Optimization of thermoelectric transport properties of Nb-doped Mo1-xWxSeTe solid solutions. Journal of Inorganic Materials, 2020, 35(12): 1373-7379.

DOI URL |

| [10] |

YANG X, SU X L, YAN Y G, et al. Structures and thermoelectric properties of (GeTe)nBi2Te3. Journal of Inorganic Materials, 2021, 36(1): 75-80.

DOI URL |

| [11] |

SHUAI J, SUN Y, TAN X, et al. Manipulating the Ge vacancies and Ge precipitates through Cr doping for realizing the high- performance GeTe thermoelectric material. Small, 2020, 16(13): 1906921.

DOI URL |

| [12] | HONG M, ZHENG K, LYV W, et al. Computer-aided design of high-efficiency GeTe-based thermoelectric devices. Energy & Environmental Science, 2020, 13: 1856-1864. |

| [13] |

SU X, WEI P, LI H, et al. Multi-scale microstructural thermoelectric materials: transport behavior, non-equilibrium preparation, and applications. Advanced Materials, 2017, 29(20): 1602013.

DOI URL |

| [14] |

HUANG L, LU J, MA D, et al. Facile in situ solution synthesis of SnSe/rGo nanocomposites with enhanced thermoelectric performance. Journal of Materials Chemistry A, 2020, 8(3): 1394-1402.

DOI URL |

| [15] |

YANG Q Y, QIU P F, SHI X, et al. Application of entropy engineering in thermoelectrics. Journal of Inorganic Materials, 2021, 36(4): 347-354.

DOI |

| [16] |

SHI X, XI L, FAN J, et al. Cu-Se bond network and thermoelectric compounds with complex diamondlike structure. Chemistry of Materials, 2010, 22(22): 6029-6031.

DOI URL |

| [17] |

MING H, ZHU G, ZHU C, et al. Boosting thermoelectric performance of Cu2SnSe3 via comprehensive band structure regulation and intensified phonon scattering by multidimensional defects. ACS Nano, 2021, 15: 10532-10541.

DOI URL |

| [18] | DENG T, XING T, BROD M K, et al. Discovery of high- performance thermoelectric copper chalcogenide using modified diffusion-couple high-throughput synthesis and automated histogram analysis technique. Energy & Environmental Science, 2020, 13(9): 3041-3053. |

| [19] |

SIYAR M, CHO J Y, YOUN Y, et al. Effect of annealing temperature on the phase transition, band gap and thermoelectric properties of Cu2SnSe3. Journal of Materials Chemistry C, 2018, 6(7): 1780-1788.

DOI URL |

| [20] |

FAN J, SCHNELLE W, ANTONYSHYN I, et al. Structural evolvement and thermoelectric properties of Cu3-xSnxSe3 compounds with diamond-like crystal structures. Dalton Transactions, 2014, 43(44): 16788-16794.

DOI URL |

| [21] |

DELGADO G, MORA A, MARCANO G, et al. Crystal structure refinement of the semiconducting compound Cu2SnSe3 from X-ray powder diffraction data. Materials Research Bulletin, 2003, 38(15): 1949-1955.

DOI URL |

| [22] |

CHOI S G, KANG J, LI J, et al. Optical function spectra and bandgap energy of Cu2SnSe3. Applied Physics Letters, 2015, 106(4): 043902.

DOI URL |

| [23] |

MARCANO G, RINCÓN C, DE CHALBAUD L, et al. Crystal growth and structure, electrical, and optical characterization of the semiconductor Cu2SnSe3. Journal of Applied Physics, 2001, 90(4): 1847-1853.

DOI URL |

| [24] |

XI L, ZHANG Y, SHI X, et al. Chemical bonding, conductive network, and thermoelectric performance of the ternary semiconductors Cu2SnX3 (X= Se, S) from first principles. Physical Review B, 2012, 86(15): 155201.

DOI URL |

| [25] | CHENG X, YANG D, SU X, et al. Synergistically enhanced thermoelectric performance of Cu2SnSe3-based composites via Ag doping balance. ACS Applied Materials & Interfaces, 2021, 13(46): 55178-55187. |

| [1] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| [2] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [3] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [4] | 鲁志强, 刘可可, 李强, 胡芹, 冯利萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰. p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能[J]. 无机材料学报, 2023, 38(11): 1331-1337. |

| [5] | 江润璐, 吴鑫, 郭昊骋, 郑琦, 王连军, 江莞. UiO-67基导电复合材料的制备及其热电性能研究[J]. 无机材料学报, 2023, 38(11): 1338-1344. |

| [6] | 程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730. |

| [7] | 刘丹, 赵亚欣, 郭锐, 刘艳涛, 张志东, 张增星, 薛晨阳. 退火条件对磁控溅射MgO-Ag3Sb-Sb2O4柔性薄膜热电性能的影响[J]. 无机材料学报, 2022, 37(12): 1302-1310. |

| [8] | 逯旭, 侯绩翀, 张强, 樊建锋, 陈少平, 王晓敏. Mg含量对Mg3(1+z)Sb2化合物热电传输性能的影响[J]. 无机材料学报, 2021, 36(8): 835-840. |

| [9] | 杨枭, 苏贤礼, 鄢永高, 唐新峰. (GeTe)nBi2Te3的结构与热电性能研究[J]. 无机材料学报, 2021, 36(1): 75-80. |

| [10] | 李周, 肖翀. 异层等价离子双掺杂策略优化BiCuSeO的热电性能[J]. 无机材料学报, 2019, 34(3): 294-300. |

| [11] | 胡慧珊, 杨君友, 辛集武, 李思慧, 姜庆辉. SnO的歧化反应对SnTe热电性能的优化[J]. 无机材料学报, 2019, 34(3): 315-320. |

| [12] | 黄志成, 姚瑶, 裴俊, 董金峰, 张波萍, 李敬锋, 尚鹏鹏. n型SnS热电材料的制备与性能研究[J]. 无机材料学报, 2019, 34(3): 321-327. |

| [13] | 檀小芳, 端思晨, 王泓翔, 吴庆松, 李苗苗, 刘国强, 徐静涛, 谈小建, 邵和助, 蒋俊. 多掺杂协同调控碲化锡热导率和功率因子提升热电性能[J]. 无机材料学报, 2019, 34(3): 335-340. |

| [14] | 刘虹霞, 李文, 张馨月, 李娟, 裴艳中. (Ag2Se)1-x(Bi2Se3)x的热电性能研究[J]. 无机材料学报, 2019, 34(3): 341-348. |

| [15] | 杨春利, 严 敏, 李 伟. In、Ta共掺对BaCeO3烧结性能及稳定性的影响[J]. 无机材料学报, 2016, 31(9): 955-960. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||