无机材料学报 ›› 2019, Vol. 34 ›› Issue (7): 741-747.DOI: 10.15541/jim20180439 CSTR: 32189.14.10.15541/jim20180439

张晓阳,彭海波( ),刘枫飞,赵彦,孙梦利,管明,张冰焘,杜鑫,袁伟,王铁山(

),刘枫飞,赵彦,孙梦利,管明,张冰焘,杜鑫,袁伟,王铁山( )

)

收稿日期:2018-09-18

修回日期:2018-11-15

出版日期:2019-07-20

网络出版日期:2019-06-26

作者简介:张晓阳(1994-), 男, 硕士研究生. E-mail:1843558514@qq.com

基金资助:

ZHANG Xiao-Yang,PENG Hai-Bo( ),LIU Feng-Fei,ZHAO Yan,SUN Meng-Li,GUAN Ming,ZHANG Bing-Tao,DU Xin,YUAN Wei,WANG Tie-Shan(

),LIU Feng-Fei,ZHAO Yan,SUN Meng-Li,GUAN Ming,ZHANG Bing-Tao,DU Xin,YUAN Wei,WANG Tie-Shan( )

)

Received:2018-09-18

Revised:2018-11-15

Published:2019-07-20

Online:2019-06-26

Supported by:摘要:

研究辐照导致硼硅酸盐玻璃机械性能的影响, 对高放废物的长期安全处置具有重要的意义。本工作采用0.3 MeV的P离子、4 MeV的Kr离子、5 MeV的Xe离子以及8 MeV的Au离子分别辐照硼硅酸盐玻璃, 利用纳米压痕技术表征了辐照前后样品的硬度和模量。结果表明: 硼硅酸盐玻璃的硬度和模量在一定范围内会随着辐照剂量的增大而减小, 辐照达到0.1 dpa时硬度和模量变化趋于饱和, 此时硬度下降了35%, 模量下降了18%; 而且不同种类的离子辐照对硼硅酸盐玻璃的硬度和模量造成的变化趋势基本相同。使用掠入射X射线衍射仪对样品晶态结构进行了分析, 发现辐照后硼硅酸盐玻璃仍保持非晶状态。利用Raman光谱对辐照后样品的微观结构的变化进行了表征, 发现辐照会导致玻璃网络结构发生改变, 玻璃的聚合度下降, 无序度增加。本工作还证明了离子辐照导致玻璃机械性能变化的主要因素是离子在样品中的核能量沉积导致玻璃结构的改变。

中图分类号:

张晓阳, 彭海波, 刘枫飞, 赵彦, 孙梦利, 管明, 张冰焘, 杜鑫, 袁伟, 王铁山. 多种重离子辐照对硼硅酸盐玻璃机械性能的影响[J]. 无机材料学报, 2019, 34(7): 741-747.

ZHANG Xiao-Yang, PENG Hai-Bo, LIU Feng-Fei, ZHAO Yan, SUN Meng-Li, GUAN Ming, ZHANG Bing-Tao, DU Xin, YUAN Wei, WANG Tie-Shan. Mechanical Properties of Borosilicate Glass with Different Irradiation of Heavy Ions[J]. Journal of Inorganic Materials, 2019, 34(7): 741-747.

| Ion | Energy/MeV | Range/μm | Fluence /(ions?cm2) | Electronic deposited energy/(keV?cm3) | Nuclear deposited energy/(keV?cm3) | Dose/dpa |

|---|---|---|---|---|---|---|

| Xe26+ | 5 | 1.9 | 6.1×1011 | 7.20×1018 | 3.99×1019 | 1×10-3 |

| 1.8×1012 | 2.12×1019 | 1.18×1020 | 3×10-3 | |||

| 3.6×1012 | 4.25×1019 | 2.35×1020 | 6×10-3 | |||

| 6.1×1012 | 7.20×1019 | 3.99×1020 | 1×10-2 | |||

| 1.8×1013 | 2.12×1020 | 1.18×1021 | 3×10-2 | |||

| 6.1×1013 | 7.20×1020 | 3.99×1021 | 0.1 | |||

| 3.0×1014 | 3.54×1021 | 1.96×1022 | 0.5 | |||

| 6.1×1014 | 7.20×1021 | 3.99×1022 | 1.0 | |||

| Kr17+ | 4 | 2.4 | 3.0×1011 | 2.80×1018 | 9.68×1018 | 2.05×10-4 |

| 1.0×1012 | 9.34×1018 | 3.23×1019 | 6.83×10-4 | |||

| 3.0×1012 | 2.80×1019 | 9.68×1019 | 2.05×10-3 | |||

| 6.0×1012 | 5.61×1019 | 1.94×1020 | 4.10×10-3 | |||

| 1.0×1013 | 9.34×1019 | 3.23×1020 | 6.83×10-3 | |||

| 3.0×1013 | 2.80×1020 | 9.68×1020 | 2.05×10-2 | |||

| 1.0×1014 | 9.34×1020 | 3.23×1021 | 6.83×10-2 | |||

| 5.0×1014 | 4.67×1021 | 1.61×1022 | 3.41×10-1 | |||

| P+ | 0.3 | 0.4 | 4.0×1011 | 1.21×1018 | 3.24×1018 | 2.26×10-4 |

| 1.4×1012 | 4.25×1018 | 1.14×1019 | 7.95×10-4 | |||

| 4.0×1012 | 1.21×1019 | 3.24×1019 | 2.26×10-3 | |||

| 8.0×1012 | 2.43×1019 | 6.49×1019 | 4.52×10-3 | |||

| 1.4×1013 | 4.25×1019 | 1.14×1020 | 7.95×10-3 | |||

| 4.0×1013 | 1.21×1020 | 3.24×1020 | 2.26×10-2 | |||

| 1.4×1014 | 4.25×1020 | 1.14×1021 | 7.95×10-2 | |||

| 7.0×1014 | 2.13×1021 | 5.68×1021 | 3.94×10-1 | |||

| Au | 8 | 2.0 | 1.14×1012 | 2.14×1019 | 1.39×1020 | 2.65×10-3 |

| 3.79×1012 | 7.11×1019 | 4.62×1020 | 8.85×10-3 | |||

| 7.57×1012 | 1.42×1020 | 9.23×1020 | 1.77×10-2 | |||

| 1.14×1013 | 2.14×1020 | 1.39×1021 | 2.65×10-2 | |||

| 3.79×1013 | 7.11×1020 | 4.62×1021 | 8.85×10-2 | |||

| 1.40×1014 | 2.63×1021 | 1.71×1022 | 3.26×10-1 |

表1 重离子辐照硼硅酸盐玻璃剂量表

Table 1 Doses of heavy ions for the irradiation

| Ion | Energy/MeV | Range/μm | Fluence /(ions?cm2) | Electronic deposited energy/(keV?cm3) | Nuclear deposited energy/(keV?cm3) | Dose/dpa |

|---|---|---|---|---|---|---|

| Xe26+ | 5 | 1.9 | 6.1×1011 | 7.20×1018 | 3.99×1019 | 1×10-3 |

| 1.8×1012 | 2.12×1019 | 1.18×1020 | 3×10-3 | |||

| 3.6×1012 | 4.25×1019 | 2.35×1020 | 6×10-3 | |||

| 6.1×1012 | 7.20×1019 | 3.99×1020 | 1×10-2 | |||

| 1.8×1013 | 2.12×1020 | 1.18×1021 | 3×10-2 | |||

| 6.1×1013 | 7.20×1020 | 3.99×1021 | 0.1 | |||

| 3.0×1014 | 3.54×1021 | 1.96×1022 | 0.5 | |||

| 6.1×1014 | 7.20×1021 | 3.99×1022 | 1.0 | |||

| Kr17+ | 4 | 2.4 | 3.0×1011 | 2.80×1018 | 9.68×1018 | 2.05×10-4 |

| 1.0×1012 | 9.34×1018 | 3.23×1019 | 6.83×10-4 | |||

| 3.0×1012 | 2.80×1019 | 9.68×1019 | 2.05×10-3 | |||

| 6.0×1012 | 5.61×1019 | 1.94×1020 | 4.10×10-3 | |||

| 1.0×1013 | 9.34×1019 | 3.23×1020 | 6.83×10-3 | |||

| 3.0×1013 | 2.80×1020 | 9.68×1020 | 2.05×10-2 | |||

| 1.0×1014 | 9.34×1020 | 3.23×1021 | 6.83×10-2 | |||

| 5.0×1014 | 4.67×1021 | 1.61×1022 | 3.41×10-1 | |||

| P+ | 0.3 | 0.4 | 4.0×1011 | 1.21×1018 | 3.24×1018 | 2.26×10-4 |

| 1.4×1012 | 4.25×1018 | 1.14×1019 | 7.95×10-4 | |||

| 4.0×1012 | 1.21×1019 | 3.24×1019 | 2.26×10-3 | |||

| 8.0×1012 | 2.43×1019 | 6.49×1019 | 4.52×10-3 | |||

| 1.4×1013 | 4.25×1019 | 1.14×1020 | 7.95×10-3 | |||

| 4.0×1013 | 1.21×1020 | 3.24×1020 | 2.26×10-2 | |||

| 1.4×1014 | 4.25×1020 | 1.14×1021 | 7.95×10-2 | |||

| 7.0×1014 | 2.13×1021 | 5.68×1021 | 3.94×10-1 | |||

| Au | 8 | 2.0 | 1.14×1012 | 2.14×1019 | 1.39×1020 | 2.65×10-3 |

| 3.79×1012 | 7.11×1019 | 4.62×1020 | 8.85×10-3 | |||

| 7.57×1012 | 1.42×1020 | 9.23×1020 | 1.77×10-2 | |||

| 1.14×1013 | 2.14×1020 | 1.39×1021 | 2.65×10-2 | |||

| 3.79×1013 | 7.11×1020 | 4.62×1021 | 8.85×10-2 | |||

| 1.40×1014 | 2.63×1021 | 1.71×1022 | 3.26×10-1 |

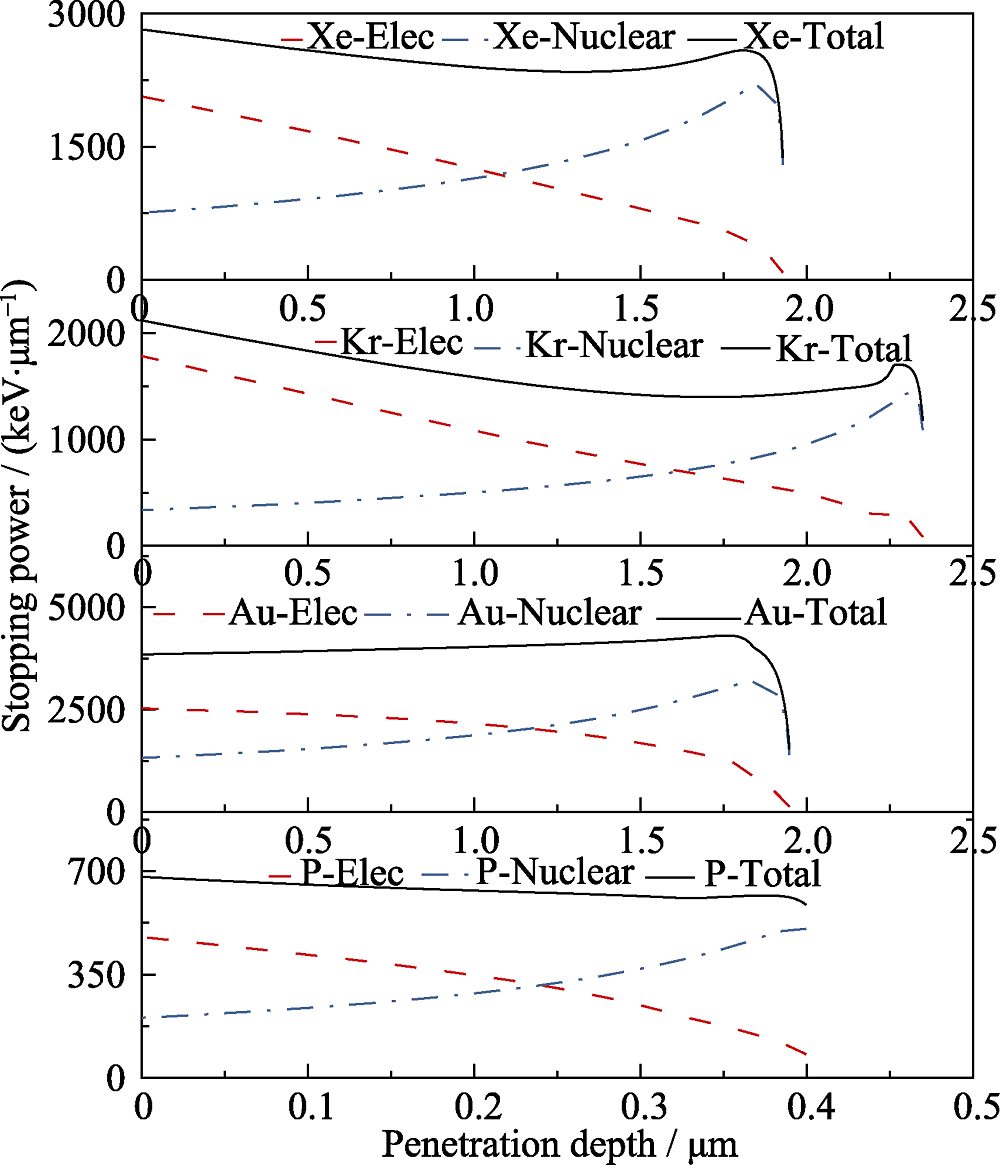

图1 重离子辐照硼硅酸盐玻璃电子能损、核能损以及总能损分布曲线

Fig. 1 Electronic energy loss, nuclear energy loss and total energy loss distribution curves of borosilicate glass with irradiation of heavy ions

| Measurement | Vmax/% | t/dpa |

|---|---|---|

| Hardness | -35.23 | 0.00715 |

| Modulus | -17.70 | 0.01378 |

表2 玻璃样品性能的拟合参数

Table 2 Properties fitting of glass samples

| Measurement | Vmax/% | t/dpa |

|---|---|---|

| Hardness | -35.23 | 0.00715 |

| Modulus | -17.70 | 0.01378 |

| [1] |

WEBER W J, EWING R C, ANGELL C A , et al. Radiation effects in glasses used for immobilization of high-level waste and plutonium disposition. Journal of Materials Research, 1997,12(8):1948-1978.

DOI URL |

| [2] |

JANTZEN C, KAPLAN D, BIBLER N , et al. Performance of a buried radioactive high level waste (HLW) glass after 24 years. Journal of Nuclear Materials, 2008,378(3):244-256.

DOI URL |

| [3] | WADE B . The management of radioactive wastes. Physics in Technology, 1982,13(3):112. |

| [4] | PEUGET S, FARES T, MAUGERI E A , et al. Effect of 10 B(n, α) 7 Li irradiation on the structure of a sodium borosilicate glass. Nuclear Instruments & Methods in Physics Research, 2014,327(1):22-28. |

| [5] |

BONFILS J D, PEUGET S, PANCZER G , et al. Effect of chemical composition on borosilicate glass behavior under irradiation. Journal of Non-Crystalline Solids, 2010,356(6):388-393.

DOI URL |

| [6] | WEBER W J. Models and mechanisms of irradiation-induced amorphization in ceramics. Nuclear Instruments & Methods in Physics Research, 2000, 166-167(99):98-106. |

| [7] | ABBAS A, SERRUYS Y, GHALEB D , et al. Evolution of nuclear glass structure under α-irradiation. Nuclear Instruments & Methods in Physics Research, 2000, 166-167(166):445-450. |

| [8] | OLLIER N, BOIZOT B, REYNARD B , et al. Beta irradiation borosilicate glasses: the role of the mixed alkali effect. Nuclear Inst & Methods in Physics Research B, 2006,218(1):176-182. |

| [9] | ZHANG G F, WANG T S, YANG K J , et al. Raman spectra and nano-indentation of Ar-irradiated borosilicate glass. Nuclear Instruments & Methods in Physics Research, 2013,316(12):218-221. |

| [10] | YANG K J, WANG T S, ZHANG G F , et al. Study of irradiation damage in borosilicate glass induced by He ions and electrons. Nuclear Inst & Methods in Physics Research B, 2013,307(6):541-544. |

| [11] |

LUO S, LI L, TANG B , et al. Synroc immobilization of high level waste (HLW) bearing a high content of sodium. Waste Management, 1998,18(1):55-59.

DOI URL |

| [12] |

DELAYE J M, PEUGET S, BUREAU G , et al. Molecular dynamics simulation of radiation damage in glasses. Journal of Non-Crystalline Solids, 2011,357(14):2763-2768.

DOI URL |

| [13] |

JOSLIN D L, OLIVER W C . A new method for analyzing data from continuous depth-sensing microindentation tests. Journal of Materials Research, 1990,5(1):123-126.

DOI URL |

| [14] | ROUTBORT J L, MATZKE H . The effect of composition and radiation on the fracture of a nuclear waste glass. Materials Science & Engineering, 1983,58(2):229-237. |

| [15] | 莫志深, 张宏放 . 晶态聚合物结构和X射线衍射. 北京: 科学出版社, 2003: 360-361. |

| [16] | PEUGET S, NOËL P Y, LOUBET J L , et al. Effects of deposited nuclear and electronic energy on the hardness of R7T7-type containment glass. Nuclear Instruments & Methods in Physics Research, 2006,246(2):379-386. |

| [17] | PENG H, SUN M, LIU F , et al. Potential effect on the interaction of highly charged ion with graphene. Nuclear Instruments & Methods in Physics Research, 2017,407:291-296. |

| [18] |

MANARA D, GRANDJEAN A, NEUVILLE D . Advances in understanding the structure of borosilicate glasses: a Raman spectroscopy study. American Mineralogist, 2009,94(5/6):777-784.

DOI URL |

| [19] |

BOIZOT B, AGNELLO S, REYNARD B , et al. Raman spectroscopy study of β-irradiated silica glass. Journal of Non-Crystalline Solids, 2003,325(1/2/3):22-28.

DOI URL |

| [20] |

PENG H B, SUN M L, YANG K J , et al. Effect of irradiation on hardness of borosilicate glass. Journal of Non-Crystalline Solids, 2016,443:143-147.

DOI URL |

| [21] |

KARAKURT G, ABDELOUAS A, GUIN J P , et al. Understanding of the mechanical and structural changes induced by alpha particles and heavy ions in the French simulated nuclear waste glass. Journal of Nuclear Materials, 2016,475:243-254.

DOI URL |

| [22] |

MIR A H, MONNET I, TOULEMONDE M , et al. Mono and sequential ion irradiation induced damage formation and damage recovery in oxide glasses: stopping power dependence of the mechanical properties. Journal of Nuclear Materials, 2016,469:244-250.

DOI URL |

| [23] | MIR A H, TOULEMONDE M, JEGOU C , et al. Understanding and simulating the material behavior during multi-particle irradiations. Scientific Reports, 2016, 6: 30191-1-11. |

| [24] |

KIEU L H, KILYMIS D, DELAYE J M , et al. Discussion on the structural origins of the fracture toughness and hardness changes in rapidly quenched borosilicate glasses: a molecular dynamics study. Procedia Materials Science, 2014,7:262-271.

DOI URL |

| [25] | CHEN L, WANG T S, ZHANG G F , et al. XPS and Raman studies of electron irradiated sodium silicate glass. Chinese Physics B, 2013, 22(12): 126101-1-6. |

| [26] | YUAN W, PENG H, SUN M , et al. Structural origin of hardness decrease in irradiated sodium borosilicate glass. Journal of Chemical Physics, 2017, 147(23): 234502-1-6. |

| [27] |

KILYMIS D A, DELAYE J M . Nanoindentation studies of simplified nuclear glasses using molecular dynamics. Journal of Non-Crystalline Solids, 2014,401(1430):147-153.

DOI URL |

| [28] | PENG H B, LIU F F, ZHANG B T , et al. Comparative studies of irradiation effects in borosilicate glass and fused silica irradiated by energetic Xe ions. Acta Physica Sinica, 2018, 67(3): 038101- 1-8. |

| [1] | 王月月, 黄佳慧, 孔红星, 李怀珠, 姚晓红. 载银放射状介孔二氧化硅的制备及其在牙科树脂中的应用[J]. 无机材料学报, 2025, 40(1): 77-83. |

| [2] | 岳仔豪, 杨小兔, 张正亮, 邓瑞翔, 张涛, 宋力昕. Pb2+对掺杂硼硅酸盐玻璃中CsPbBr3钙钛矿量子点发光性能的影响[J]. 无机材料学报, 2024, 39(4): 449-456. |

| [3] | 杨平军, 李铁虎, 李昊, 党阿磊. 石墨烯对环氧树脂泡沫炭石墨化、电导率和力学性能的影响[J]. 无机材料学报, 2024, 39(1): 107-112. |

| [4] | 罗淑文, 马名生, 刘峰, 刘志甫. Ca-B-Si体系LTCC材料腐蚀行为及腐蚀机理[J]. 无机材料学报, 2023, 38(5): 553-560. |

| [5] | 孙小凡, 陈小武, 靳喜海, 阚艳梅, 胡建宝, 董绍明. 低温反应熔渗工艺制备AlN-SiC复相陶瓷及其性能研究[J]. 无机材料学报, 2023, 38(10): 1223-1229. |

| [6] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [7] | 庞力斌, 王德平. 介孔硼硅酸盐玻璃微球药物载体的制备及其性能表征[J]. 无机材料学报, 2022, 37(7): 780-786. |

| [8] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [9] | 冯明星, 王斌, 徐鹏宇, 涂兵田, 王皓. 基于键价模型的MgAl2O4透明陶瓷热机械性能预测[J]. 无机材料学报, 2021, 36(10): 1067-1073. |

| [10] | 张舟, 王皓, 涂兵田, 徐鹏宇, 王为民, 傅正义. Mg0.27Al2.58O3.73N0.27透明陶瓷机械性能评价[J]. 无机材料学报, 2018, 33(9): 1006-1010. |

| [11] | 聂恒昌, 王永龄, 贺红亮, 王根水, 董显林. 多孔PZT95/5铁电陶瓷材料研究进展[J]. 无机材料学报, 2018, 33(2): 153-161. |

| [12] | 王 卡, 万 康, 张 静, 陈 林, 陈 琼, 常永勤, 龙 毅. 立方相Y掺杂ZrO2纳米晶薄膜的制备与辐照效应研究[J]. 无机材料学报, 2015, 30(6): 593-598. |

| [13] | 曾 涛, 白 杨, 沈喜训, 王保峰, 董显林, 周志勇. 多孔PZT95/5铁电陶瓷的机械性能和铁电性能研究[J]. 无机材料学报, 2014, 29(7): 758-762. |

| [14] | 李伟信, 白明敏, 陆 颖, 饶平根. Al2O3/Steel-epoxy层状复合材料的制备和性能[J]. 无机材料学报, 2013, 28(4): 453-459. |

| [15] | 宋永忠,翟更太,史景利,李贵生,郭全贵,宋进仁,刘 朗. 中间相沥青制备高密度高强度炭/石墨材料[J]. 无机材料学报, 2008, 23(3): 519-524. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||