无机材料学报 ›› 2017, Vol. 32 ›› Issue (4): 400-406.DOI: 10.15541/jim20160341 CSTR: 32189.14.10.15541/jim20160341

谢佳苗, 王峰会

收稿日期:2016-05-25

修回日期:2016-07-11

出版日期:2017-04-20

网络出版日期:2017-03-24

基金资助:XIE Jia-Miao, WANG Feng-Hui

Received:2016-05-25

Revised:2016-07-11

Published:2017-04-20

Online:2017-03-24

Supported by:摘要:

为了降低固体氧化物燃料电池在制备和工作过程中产生的热应力, 提高电池的电化学性能, 在电池中引入功能梯度层可以有效减小电池各层之间材料参数的差异, 从而缓解各层之间的热失配应力。本研究将阳极功能层引入燃料电池中, 通过阳极功能层子层数目和非线性梯度成分指数n控制各子层材料属性的变化情况, 研究了燃料电池在800℃下的热应力分布。结果表明: 选取适当的指数n和阳极功能层的分层数目可以明显降低阳极层的最大拉应力和电解质层的最大压应力。

中图分类号:

谢佳苗, 王峰会. 基于热应力分析的固体氧化物燃料电池阳极功能层优化设计[J]. 无机材料学报, 2017, 32(4): 400-406.

XIE Jia-Miao, WANG Feng-Hui. Thermal Stress Analysis of Solid Oxide Fuel Cell with Anode Functional Layer[J]. Journal of Inorganic Materials, 2017, 32(4): 400-406.

| T | NiO-YSZ | YSZ | LSM | NiO | |

|---|---|---|---|---|---|

| E/GPa | 20℃ | 127.3 | 215 | 110 | 110 |

| 800℃ | 105.5 | 185 | 118 | 90 | |

| $\mu $ | 20℃ | 0.33 | 0.308 | 0.36 | 0.34 |

| 800℃ | 0.33 | 0.313 | 0.36 | 0.34 | |

| CTE /×10-6 | 20℃ | 11.77 | 7.6 | 9.8 | 13.0 |

| 800℃ | 12.42 | 10.5 | 11.8 | 13.0 | |

| 1400℃ | 12.50 | 10.5 | 11.8 | 13.1 |

表1 电极、电解质等的材料属性[19-21]

Table 1 Material properties of electrodes and electrolyte[19-21]

| T | NiO-YSZ | YSZ | LSM | NiO | |

|---|---|---|---|---|---|

| E/GPa | 20℃ | 127.3 | 215 | 110 | 110 |

| 800℃ | 105.5 | 185 | 118 | 90 | |

| $\mu $ | 20℃ | 0.33 | 0.308 | 0.36 | 0.34 |

| 800℃ | 0.33 | 0.313 | 0.36 | 0.34 | |

| CTE /×10-6 | 20℃ | 11.77 | 7.6 | 9.8 | 13.0 |

| 800℃ | 12.42 | 10.5 | 11.8 | 13.0 | |

| 1400℃ | 12.50 | 10.5 | 11.8 | 13.1 |

| Layer | AFL | NiO volume fraction | ||

|---|---|---|---|---|

| n=2 | n=1 | n=0.5 | ||

| 1 | AFL1 | 20% | 40% | 56% |

| 2 | AFL1 | 5% | 20% | 40% |

| AFL2 | 45% | 60% | 69% | |

| 3 | AFL1 | 2.5% | 13% | 32% |

| AFL2 | 20% | 40% | 56% | |

| AFL3 | 55% | 66% | 73% | |

| 4 | AFL1 | 1.3% | 10% | 27% |

| AFL2 | 11.3% | 30% | 49% | |

| AFL3 | 31.0% | 50% | 63% | |

| AFL4 | 61.0% | 70% | 75% | |

| 5 | AFL1 | 1% | 8% | 25% |

| AFL2 | 7% | 24% | 43% | |

| AFL3 | 20% | 40% | 56% | |

| AFL4 | 39% | 56% | 66% | |

| AFL5 | 65% | 72% | 76% | |

表2 各AFL子层中NiO的体积分数

Table 2 Volume fraction of NiO in AFL sublayers

| Layer | AFL | NiO volume fraction | ||

|---|---|---|---|---|

| n=2 | n=1 | n=0.5 | ||

| 1 | AFL1 | 20% | 40% | 56% |

| 2 | AFL1 | 5% | 20% | 40% |

| AFL2 | 45% | 60% | 69% | |

| 3 | AFL1 | 2.5% | 13% | 32% |

| AFL2 | 20% | 40% | 56% | |

| AFL3 | 55% | 66% | 73% | |

| 4 | AFL1 | 1.3% | 10% | 27% |

| AFL2 | 11.3% | 30% | 49% | |

| AFL3 | 31.0% | 50% | 63% | |

| AFL4 | 61.0% | 70% | 75% | |

| 5 | AFL1 | 1% | 8% | 25% |

| AFL2 | 7% | 24% | 43% | |

| AFL3 | 20% | 40% | 56% | |

| AFL4 | 39% | 56% | 66% | |

| AFL5 | 65% | 72% | 76% | |

| Presented model | Experimental | Numerical analysis | |

|---|---|---|---|

| Max. compressive stresses of YSZ /MPa | 633.3 | 670[ | 608.46[ |

| Error | — | 5.8% | 3.9% |

表3 YSZ最大压应力结果对比

Table 3 Comparison results of the maximum compressive stresses of YSZ

| Presented model | Experimental | Numerical analysis | |

|---|---|---|---|

| Max. compressive stresses of YSZ /MPa | 633.3 | 670[ | 608.46[ |

| Error | — | 5.8% | 3.9% |

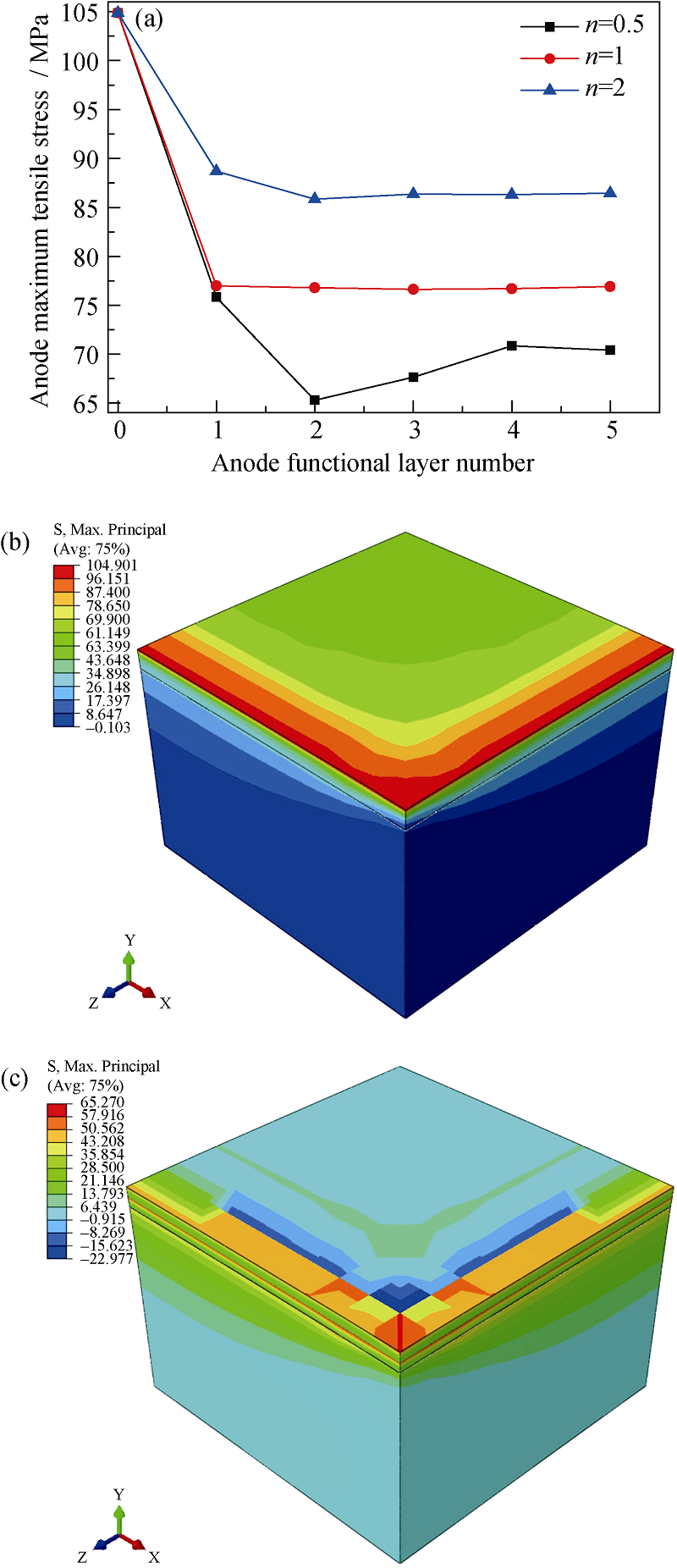

图6 阳极层的最大拉应力随AFL划分层数和指数n的变化情况(a)、未设置AFL的阳极应力云图(b)及n=0.5、AFL划分2层的应力云图(c)

Fig. 6 (a) Maximum tensile stresses of anode with the layers of AFL and the exponent n; (b) contour of anode without AFL; (c) contour of two layers of AFL (n=0.5)

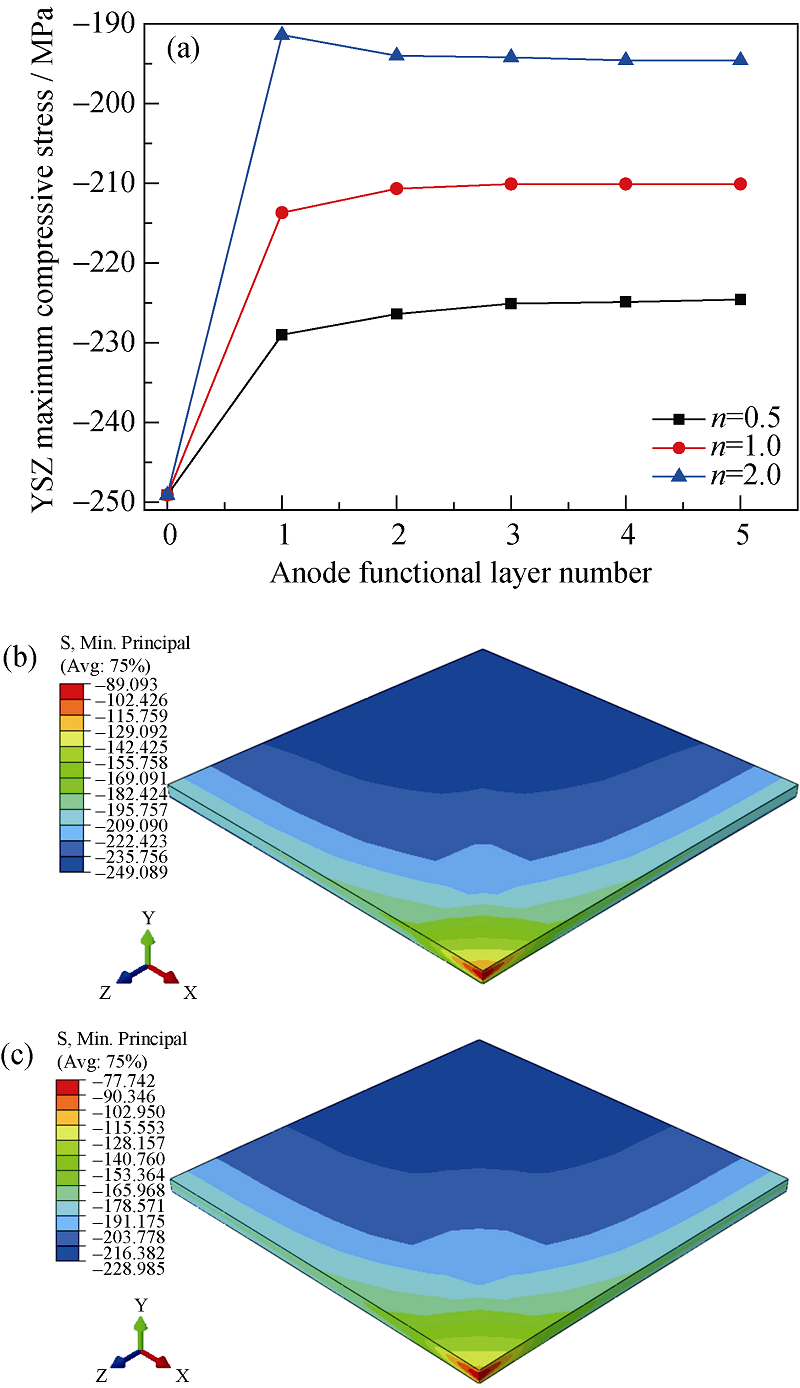

图7 YSZ的最大压应力随AFL划分层数和指数n的变化情况(a)、未设置AFL的YSZ应力云图(b)及n=0.5、AFL划分1层的应力云图(c)

Fig. 7 (a) Maximum compressive stresses of YSZ with the layers of AFL and the exponent n, (b) contour of YSZ without the AFL and (c) contour of YSZ with two layers of the AFL (n=0.5)

| [1] | LAURENCIN J, DELETTE G, LEFEBVRE-JORD F, et al.A numerical tool to estimate SOFC mechanical degradation: case of the planar cell configuration. J. Eur. Ceram. Soc., 2008, 28(9): 1857-1869. |

| [2] | DUAN Z S, YANG M, YAN A Y, et al.Ba0.5Sr0.5Co0.8Fe0.2O3-δ as a cathode for IT-SOFCs with a GDC interlayer. J. Power Sources, 2006, 160(1): 57-64. |

| [3] | CHEN X, LIN Z Z, YIN C, et al.Theoretical prediction of the growth and surface structure of platinum nanoparticles. Acta Phys. Sin., 2012, 61(7): 076801. |

| [4] | SELÇUK A, MERERE G, ATKINSON A. The influence of electrodes on the strength of planar zirconia solid oxide fuel cells. J. Mater. Sci., 2001, 36(5): 1173-1182. |

| [5] | LIANG L J, LI K, YAN D, et al.Mechanical property and deformation behavior of SOFCs. J. Inorg. Mater., 2015, 30(6): 633-638. |

| [6] | CHEN X, YANG J, PU J, et al.Finite element analysis of thermal stresses in planar SOFCs. J. Inorg. Mater., 2007, 22(2): 339-343. |

| [7] | 彭晓领. 组元磁化法制备ZrO2/Ni梯度功能材料研究. 浙江: 浙江大学博士学位论文, 2008. |

| [8] | ERDOGAN F, WU B H.Crack Problems in FGM layers under thermal stresses. J. Therm. Stresses, 1996, 19(3): 237-265. |

| [9] | LEE Y D, ERDOGAN F.Residual/thermal stresses in FGM and laminated thermal barrier coatings. Int. J. Fracture, 1995, 69(2): 145-165. |

| [10] | ZHA S W, ZHANG Y L, LIU M L.Functionally graded cathodes fabricated by Sol-Gel/slurry coating for honeycomb SOFCs. Solid State Ionics, 2005, 176(1/2): 25-31. |

| [11] | JIANG T Z, WANG Z H, REN B Y, et al.Compositionally continuously graded cathode layers of (Ba0.5Sr0.5)(Fe0.91Al0.09)O3-δ-Gd0.1Ce0.9O2 by wet powder spraying technique for solid oxide fuel cells. J. Power Sources, 2014, 247: 858-864. |

| [12] | MCCOPPIN J, BARNEY I, MUKHOPADHYAY S, et al.Compo-sitional control of continuously graded anode functional layer. J. Power Sources, 2012, 215: 160-163. |

| [13] | WANG Y S, GROSS D. Analysis of a crack in a functionally gradient interface layer under static and dynamic loading. Key Eng. Mater., 2000, 183-187: 331-336. |

| [14] | WANG Y S, HUANG G Y, GROSS D.On the mechanical modeling of functionally graded interracial zone with a griffith crack: anti-plane deformation. J. Appl. Mech.-T. ASME, 2003, 70(5): 676-680. |

| [15] | HUANG G Y, WANG Y S, YU S W.A new multi-layered model for in-plane fracture analysis of functionally graded materials (FGMS). Chin. J. Theor. Appl. Mech., 2005, 37(1): 1-8. |

| [16] | MÜLLER A C, HERBSTRITT D, IVERS-TIFFÉE E. Development of a multilayer anode for solid oxide fuel cells. Solid State Ionics, 2002, 152-153: 537-542. |

| [17] | KONG J R, SUN K N, ZHOU D, et al.Ni-YSZ gradient anodes for anode-supported SOFCs. J. Power Sources, 2007, 166(2): 337-342. |

| [18] | ANANDAKUMAR G, Li N, VERMA A, et al.Thermal stress and probability of failure analyses of functionally graded solid oxide fuel cells. J. Power Sources, 2010, 195(19): 6659-6670. |

| [19] | NAKAJO A, WUILLENIN Z, HERLE J V, et al.Simulation of thermal stresses in anode-supported solid oxide fuel cell stacks. Part I: Probability of failure of the cells. J. Power Sources, 2009, 193(1): 203-215. |

| [20] | CLAGUE R, MARQUIS A J, BRANDON N P.Finite element and analytical stress analysis of a solid oxide fuel cell. J. Power Sources, 2012, 210(15): 224-232. |

| [21] | JIANG W C, LUO Y, ZHANG W Y, et al. Effect of temperature fluctuation on creep and failure probability for planar solid oxide fuel cell. J. Fuel Cell Sci. Tech.-T. ASME, 2015, 12(5): 051004- 1-10. |

| [22] | KIN J H, PAULINO G H.Isoparametric graded finite elements for nonhomogeneous isotropic and orthotropic materials. J. Appl. Mech., 2002, 69(4): 502-514. |

| [23] | HIRANO T, WAKASHIMA K.Mathematical modeling and design. MRS Bull., 1995, 20(1): 40-42. |

| [24] | GIANNAKOPOULOS A E, SURESH S, FINOT M, et al.Elastoplastic analysis of thermal cycling: layered materials with compositional gradients. Acta Metal. Mater., 1995, 43(4): 1335-1354. |

| [25] | WILLIAMSON R L, RABIN B H, DRAKE J T.Finite element analysis of thermal residual stresses at graded ceramic-metal interfaces. Part I. Model description and geometrical effects. J. Appl. Phys., 1993, 74(2): 1310. |

| [26] | AMADA S.Hierarchical functionally gradient structures of bamboo, barley, and corn. MRS Bull., 1995, 20(1): 35-36. |

| [27] | TEIXEIRA V. Numerical analysis of the influence of coating porosity and substrate elastic properties on the residual stresses in high temperature graded coatings. Surf. Coat. Tech., 2001, 146-147(2): 79-84. |

| [28] | HSIEH C L, TUAN W H.Elastic and thermal expansion behavior of two-phase composites. Mat. Sci. Eng. A-Struct., 2006, 425(1/2): 349-360. |

| [29] | YAKABE H, BABA Y, SAKURAI T, et al.Evaluation of the residual stress for anode-supported SOFCs. J. Power Sources, 2004, 135(1/2): 9-16. |

| [30] | FAN P F, LI G J, ZENG Y K, et al.Numerical study on thermal stresses of a planar solid oxide fuel cell. Int. J. Therm. Sci., 2014, 77: 1-10. |

| [1] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [2] | 渠吉发, 王旭, 张维轩, 张康喆, 熊永恒, 谭文轶. 掺杂改性NaYTiO4增强固体氧化物燃料电池阳极抗硫中毒性能[J]. 无机材料学报, 2025, 40(5): 489-496. |

| [3] | 薛柯, 蔡长焜, 谢满意, 李舒婷, 安胜利. 固体氧化物燃料电池Pr1+xBa1-xFe2O5+δ阴极材料的制备及电化学性能研究[J]. 无机材料学报, 2025, 40(4): 363-371. |

| [4] | 张婧慧, 陆晓彤, 毛海雁, 田亚州, 张山林. 烧结助剂对BaZr0.1Ce0.7Y0.2O3-δ电解质烧结行为及电导率的影响[J]. 无机材料学报, 2025, 40(1): 84-90. |

| [5] | 潘建隆, 马官军, 宋乐美, 郇宇, 魏涛. 燃料还原法原位制备高稳定性/催化活性SOFC钴基钙钛矿阳极[J]. 无机材料学报, 2024, 39(8): 911-919. |

| [6] | 叶梓滨, 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江. 阳极支撑型锥管串接式直接碳固体氧化物燃料电池组的制备及性能[J]. 无机材料学报, 2024, 39(7): 819-827. |

| [7] | 张琨, 王宇, 朱腾龙, 孙凯华, 韩敏芳, 钟秦. LaNi0.6Fe0.4O3阴极接触材料导电特性调控及其对SOFC电化学性能的影响[J]. 无机材料学报, 2024, 39(4): 367-373. |

| [8] | 陈正鹏, 金芳军, 李明飞, 董江波, 许仁辞, 徐韩昭, 熊凯, 饶睦敏, 陈创庭, 李晓伟, 凌意瀚. 双钙钛矿Sr2CoFeO5+δ阴极材料的制备及其中温固体氧化物燃料电池性能研究[J]. 无机材料学报, 2024, 39(3): 337-344. |

| [9] | 薛顶喜, 伊炳尧, 李国君, 马帅, 刘克勤. 功能梯度阳极固体氧化物燃料电池热应力数值模拟研究[J]. 无机材料学报, 2024, 39(11): 1189-1196. |

| [10] | 郭天民, 董江波, 陈正鹏, 饶睦敏, 李明飞, 李田, 凌意瀚. 中温固体氧化物燃料电池的高熵双钙钛矿阴极材料: 兼容性与活性研究[J]. 无机材料学报, 2023, 38(6): 693-700. |

| [11] | 樊帅, 金天, 张山林, 雒晓涛, 李成新, 李长久. Li2O烧结助剂对固体氧化物燃料电池LSGM电解质烧结特性及离子电导率的影响[J]. 无机材料学报, 2022, 37(10): 1087-1092. |

| [12] | 曹丹,周明扬,刘志军,颜晓敏,刘江. 阳极支撑质子导体电解质固体氧化物燃料电池的制备及其性能研究[J]. 无机材料学报, 2020, 35(9): 1047-1052. |

| [13] | 夏天, 孟燮, 骆婷, 占忠亮. 固体氧化物燃料电池LaxSr2-3x/2Fe1.5Ni0.1Mo0.4O6-δ阳极性能研究[J]. 无机材料学报, 2020, 35(5): 617-622. |

| [14] | 李凯, 李霄, 李箭, 谢佳苗. 基于应力分析Ni-Fe合金支撑固体氧化物燃料电池结构稳定性研究[J]. 无机材料学报, 2019, 34(6): 611-617. |

| [15] | 汪维, 苑莉莉, 丘倩媛, 周明扬, 刘美林, 刘江. 流延法制备单片式直接碳固体氧化物燃料电池组及其性能研究[J]. 无机材料学报, 2019, 34(5): 509-514. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||