无机材料学报 ›› 2022, Vol. 37 ›› Issue (12): 1289-1294.DOI: 10.15541/jim20220320 CSTR: 32189.14.10.15541/jim20220320

李汪国1( ), 刘佃光1(

), 刘佃光1( ), 王珂玮2, 马百胜2, 刘金铃3

), 王珂玮2, 马百胜2, 刘金铃3

收稿日期:2022-06-07

修回日期:2022-08-09

出版日期:2022-12-20

网络出版日期:2022-08-26

通讯作者:

刘佃光, 副教授. E-mail: dianguang@swjtu.edu.cn作者简介:李汪国(1997-), 男, 硕士研究生. E-mail: 1648155341@qq.com

基金资助:

LI Wangguo1( ), LIU Dianguang1(

), LIU Dianguang1( ), WANG Kewei2, MA Baisheng2, LIU Jinling3

), WANG Kewei2, MA Baisheng2, LIU Jinling3

Received:2022-06-07

Revised:2022-08-09

Published:2022-12-20

Online:2022-08-26

Contact:

LIU Dianguang, associate professor. E-mail: dianguang@swjtu.edu.cnAbout author:LI Wangguo (1997-), male, Master candidate. E-mail: 1648155341@qq.com

Supported by:摘要:

闪烧技术是一种温度场与电场耦合的烧结技术, 具有低温快速传质的特性, 在高熵陶瓷的合成上具有显著的优势。本研究通过闪烧法合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比。在室温, 电场强度为50 V/cm, 电流密度为300 mA/mm2条件下闪烧, 物相转变的时间仅为10 s。闪烧试样最高相对密度为94%, 比传统烧结试样最高密度提高了22.8%。闪烧试样的最高硬度5.05 GPa, 比传统烧结试样高3.95 GPa。当频率<2 Hz时, 闪烧试样的介电常数比传统烧结试样高一个数量级。闪烧试样性能的提高, 一方面与临界电场加速传质, 提高材料致密度有关; 另一方面与临界电场引入额外的缺陷有关。

中图分类号:

李汪国, 刘佃光, 王珂玮, 马百胜, 刘金铃. 闪烧合成高熵氧化物陶瓷(MgCoNiCuZn)O的性能[J]. 无机材料学报, 2022, 37(12): 1289-1294.

LI Wangguo, LIU Dianguang, WANG Kewei, MA Baisheng, LIU Jinling. High Entropy Oxide Ceramics (MgCoNiCuZn)O: Flash Sintering Synthesis and Properties[J]. Journal of Inorganic Materials, 2022, 37(12): 1289-1294.

| Label | E/(V·cm-1) | J/(mA·mm-2) | Tf/℃ | t | Te/℃ |

|---|---|---|---|---|---|

| F1 | 50 | 150 | 300 | 60 s | 990 |

| F2 | 50 | 200 | 300 | 60 s | 1060 |

| F3 | 50 | 250 | 300 | 60 s | 1100 |

| F4 | 50 | 300 | 300 | 60 s | 1130 |

| C1 | - | - | 990 | 2 h | - |

| C2 | - | - | 1060 | 2 h | - |

| C3 | - | - | 1100 | 2 h | - |

| C4 | - | - | 1130 | 2 h | - |

表1 闪烧和传统烧结的实验参数

Table 1 Experimental parameters of flash sintering and conventional sintering

| Label | E/(V·cm-1) | J/(mA·mm-2) | Tf/℃ | t | Te/℃ |

|---|---|---|---|---|---|

| F1 | 50 | 150 | 300 | 60 s | 990 |

| F2 | 50 | 200 | 300 | 60 s | 1060 |

| F3 | 50 | 250 | 300 | 60 s | 1100 |

| F4 | 50 | 300 | 300 | 60 s | 1130 |

| C1 | - | - | 990 | 2 h | - |

| C2 | - | - | 1060 | 2 h | - |

| C3 | - | - | 1100 | 2 h | - |

| C4 | - | - | 1130 | 2 h | - |

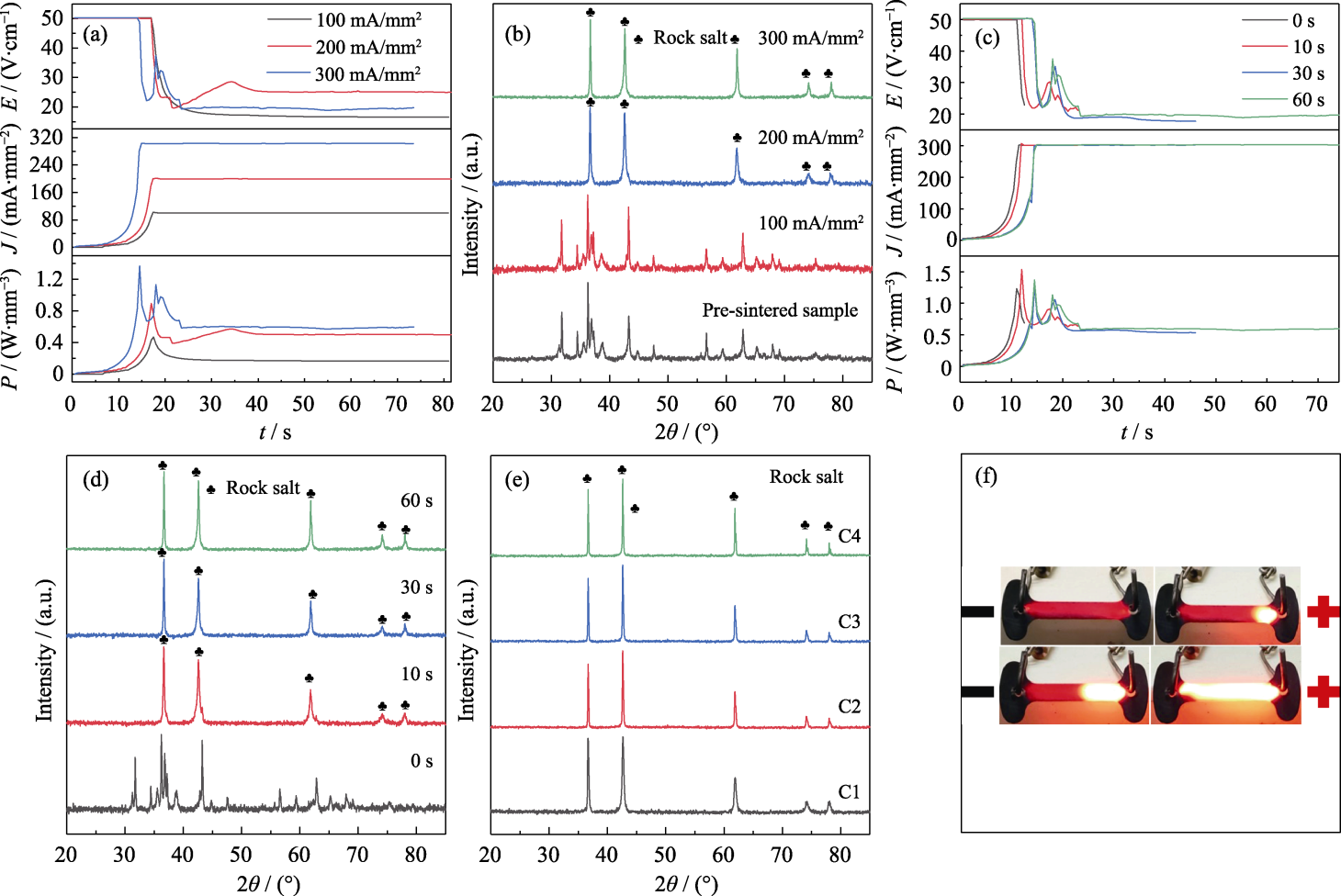

图1 不同条件下的闪烧曲线、闪烧样品和传统烧结样品的XRD图谱以及闪烧样品保温阶段的照片

Fig. 1 Flash sintering curves, XRD patterns of samples and pictures of flash sintered sample in the stable stage Flash sintering curves (a) and XRD patterns at room temperature (b) of samples flash sintered at electric field strength of 50 V/cm, holding time of 60 s, and current densities of 100, 200 and 300 mA/mm2, respectively; Flash sintering curves (c) and XRD patterns at room temperature (d) of samples flash sintered at electric field strength of 50 V/cm, current density of 300 mA/mm2, holding time of 0, 10, 30, 60 s; (e) XRD patterns of conventional sintered samples C1-C4; (f) Photos of flash sintered samples in the stable stage; The holding time referrs to the time during the stable stage of flash sintering; Colorful figures are available on website

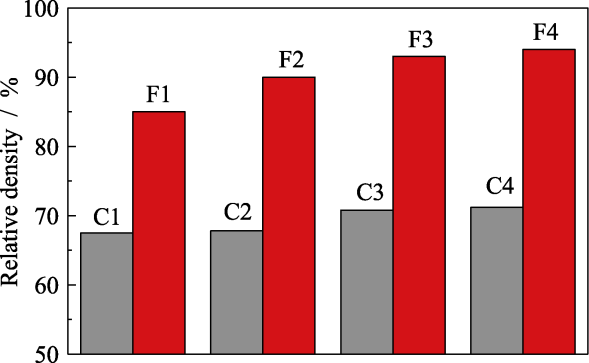

图2 在300 ℃保温60 s, 不同电流密度下闪烧试样的密度, 以及在对应温度下传统烧结试样的密度

Fig. 2 Densities of samples flash sintered at different current densities at 300 ℃ with holding time of 60 s, and of samples conventionally sintered at the corresponding temperatures

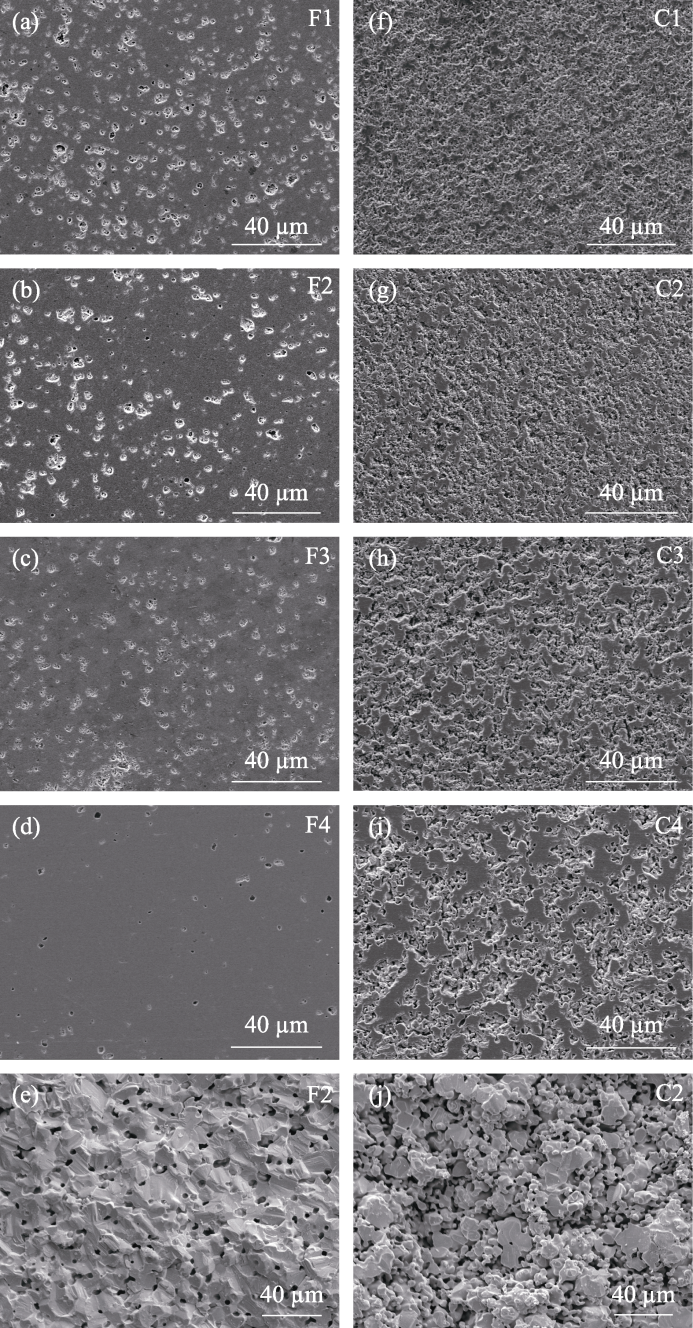

图3 不同电流密度闪烧样品以及相应温度传统烧结样品微观结构对比

Fig. 3 Comparison of microstructures of flash sintered samples with different current densities and conventional sintered samples at corresponding temperatures (a-e) Microstructures of flash sintered samples; (f-j) Microstructures of conventional sintered samples

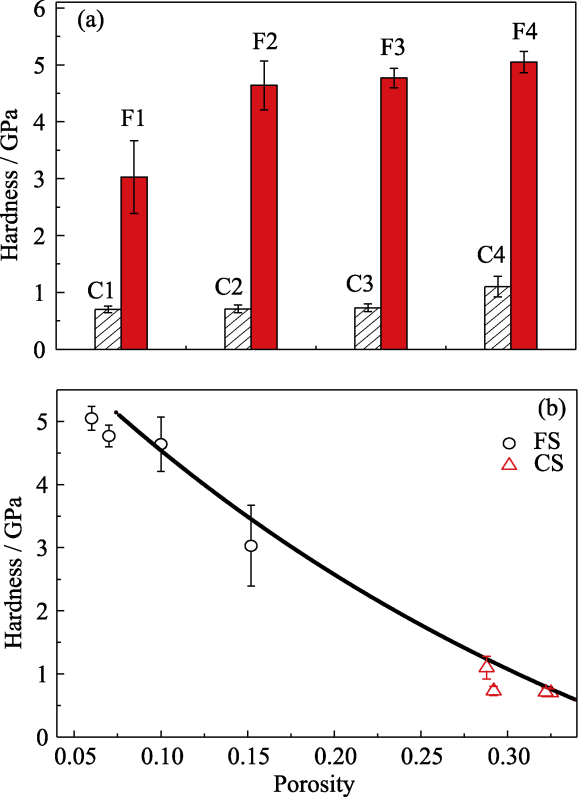

图4 闪烧试样和传统烧结试样的硬度(a)及其硬度随气孔率的变化曲线(b)

Fig. 4 Hardness (a) and plot of hardness as a function of porosity(b) of flash sintered and conventional sintered samples

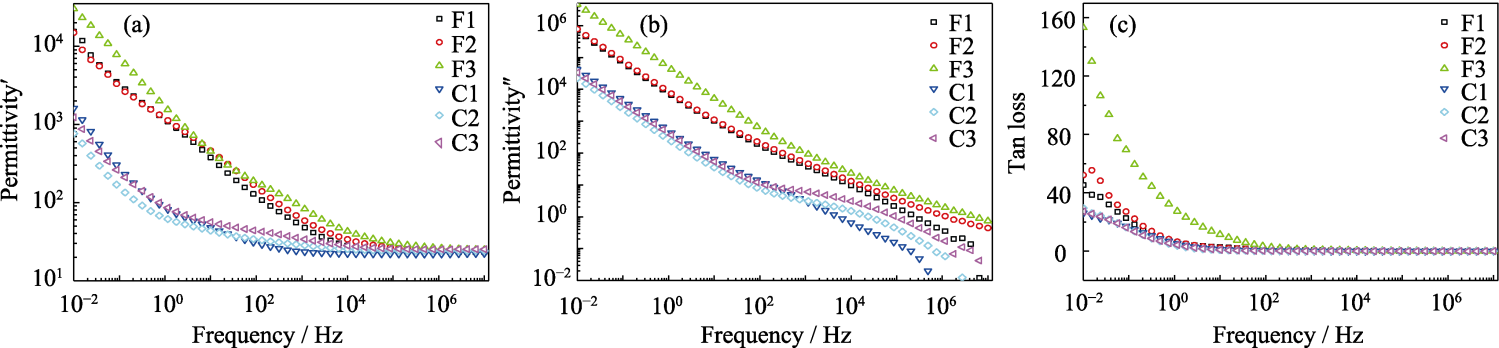

图5 不同电流密度下闪烧试样以及相应温度下传统烧结试样的介电常数的实部(a)与虚部(b)以及介电损耗(c)

Fig. 5 Real (a) and imaginary (b) parts of the dielectric constants, and tangent loss of flash sintered samples at different current densities and conventional sintered samples at the corresponding temperatures (c)

| [1] |

XIANG H, XING Y, DAI F, et al. High-entropy ceramics: present status, challenges, and a look forward. Journal of Advanced Ceramics, 2021, 10: 385-441.

DOI URL |

| [2] |

ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015, 6: 8485.

DOI PMID |

| [3] |

WANG Q, SARKAR A, LI Z, et al. High entropy oxides as anode material for Li-ion battery applications: a practical approach. Electrochemistry Communications, 2019, 100: 121-125.

DOI URL |

| [4] |

BĖRARDAN D, FRANGER S, DRAGOE D, et al. Colossal dielectric constant in high entropy oxides. Physica Status Solidi (RRL)- Rapid Research Letters, 2016, 10: 328-333.

DOI URL |

| [5] |

BĖRARDAN D, FRANGER S, MEENA A K, et al. Room temperature lithium superionic conductivity in high entropy oxides. Journal of Materials Chemistry A, 2016, 4: 9536-9541.

DOI URL |

| [6] |

QIU N, CHEN H, YANG Z, et al. A high entropy oxide (Mg0.2Co0.2Ni0.2Cu0.2Zn0.2O) with superior lithium storage performance. Journal of Alloys and Compounds, 2019, 777: 767-774.

DOI URL |

| [7] |

CHEN J, LIU W, LIU J, et al. Stability and compressibility of cation-doped high-entropy oxide MgCoNiCuZnO5. The Journal of Physical Chemistry C, 2019, 123: 17735-17744.

DOI URL |

| [8] | BRAUN J L, ROST C M, LIM M, et al. Charge-induced disorder controls the thermal conductivity of entropy-stabilized oxides. Adv. Mater., 2018, 30: e1805004. |

| [9] | HONG W, CHEN F, SHEN Q, et al. Microstructural evolution and mechanical properties of (Mg,Co,Ni,Cu,Zn)O high-entropy ceramics. Journal of the American Ceramic Society, 2019, 102: 2228-2237. |

| [10] |

CHEN H, LIN W, ZHANG Z, et al. Mechanochemical synthesis of high entropy oxide materials under ambient conditions: dispersion of catalysts via entropy maximization. ACS Materials Letters, 2019, 1: 83-88.

DOI URL |

| [11] |

CHEN H, FU J, ZHANG P, et al. Entropy-stabilized metal oxide solid solutions as CO oxidation catalysts with high-temperature stability. Journal of Materials Chemistry A, 2018, 6: 11129-11133.

DOI URL |

| [12] |

DUPUY A D, WANG X, SCHOENUNG J M. Entropic phase transformation in nanocrystalline high entropy oxides. Materials Research Letters, 2018, 7: 60-67.

DOI URL |

| [13] | LIU J, SHAO G, LIU D, et al. Design and synthesis of chemically complex ceramics from the perspective of entropy. Materials Today Advances, 2020, 8: 1-12. |

| [14] |

LIU D, PENG X, LIU J, et al. Ultrafast synthesis of entropy- stabilized oxide at room temperature. Journal of the European Ceramic Society, 2020, 40: 2504-2508.

DOI URL |

| [15] |

YOON B, AVILA V, RAJ R, et al. Reactive flash sintering of the entropy-stabilized oxide Mg0.2Ni0.2Co0.2Cu0.2Zn0.2O. Scripta Materialia, 2020, 181: 48-52.

DOI URL |

| [16] |

KUMAR A, SHARMA G, AFTAB A, et al. Flash assisted synthesis and densification of five component high entropy oxide (Mg, Co, Cu, Ni, Zn)O at 350 ℃ in 3 min. Journal of the European Ceramic Society, 2020, 40: 3358-3362.

DOI URL |

| [17] |

SARKAR A, DJENADIC R, USHARANI N J, et al. Nanocrystalline multicomponent entropy stabilised transition metal oxides. Journal of the European Ceramic Society, 2017, 37: 747-754.

DOI URL |

| [18] |

PARK J, CHEN I W. In situ thermometry measuring temperature flashes exceeding 1,700 ℃ in 8mol% Y2O3-stablized zirconia under constant-voltage heating. Journal of the American Ceramic Society, 2013, 96: 697-700.

DOI URL |

| [19] |

CHAIM R. On the kinetics of liquid-assisted densification during flash sintering of ceramic nanoparticles. Scripta Materialia, 2019, 158: 88-90.

DOI URL |

| [20] |

REN K, HUANG S, CAO Y, et al. The densification behavior of flash sintered BaTiO3. Scripta Materialia, 2020, 186: 362-365.

DOI URL |

| [21] |

JHA S K, CHARALAMBOUS H, WANG H, et al. In-situ observation of oxygen mobility and abnormal lattice expansion in ceria during flash sintering. Ceramics International, 2018, 44: 15362-15369.

DOI URL |

| [22] |

RAJ R. Joule heating during flash-sintering. Journal of the European Ceramic Society, 2012, 32: 2293-2301.

DOI URL |

| [23] |

NARAYAN J. A new mechanism for field-assisted processing and flash sintering of materials. Scripta Materialia, 2013, 69: 107-111.

DOI URL |

| [24] |

ZHANG Y, NIE J, CHAN J M, et al. Probing the densification mechanisms during flash sintering of ZnO. Acta Materialia, 2017, 125: 465-475.

DOI URL |

| [25] |

JI W, PARKER B, FALCO S, et al. Ultra-fast firing: effect of heating rate on sintering of 3YSZ, with and without an electric field. Journal of the European Ceramic Society, 2017, 37: 2547-2551.

DOI URL |

| [26] |

REN K, WANG Q, LIAN Y, et al. Densification kinetics of flash sintered 3mol% Y2O3 stabilized zirconia. Journal of Alloys and Compounds, 2018, 747: 1073-1077.

DOI URL |

| [27] |

COLOGNA M, PRETTE A L G, RAJ R. Flash-sintering of cubic yttria-stabilized zirconia at 750 ℃ for possible use in SOFC manufacturing. Journal of the American Ceramic Society, 2011, 94: 316-319.

DOI URL |

| [28] |

PARK H S, RUDD R E, CAVALLO R M, et al. Grain-size- independent plastic flow at ultrahigh pressures and strain rates. Physical Review Letters, 2015, 114: 065502.

DOI URL |

| [29] |

LI J, FAN J, YUAN Y, et al. Effect of oscillatory pressure on the sintering behavior of ZrO2 ceramic. Ceramics International, 2020, 46: 13240-13243.

DOI URL |

| [30] |

LIU D, ZHANG X, FAN J, et al. Sintering behavior and mechanical properties of alumina ceramics exposed to oscillatory pressure at different sintering stages. Ceramics International, 2021, 47: 23682-23685.

DOI URL |

| [31] |

REN K, XIA J, WANG Y. Grain growth kinetics of 3mol% yttria- stabilized zirconia during flash sintering. Journal of the European Ceramic Society, 2019, 39: 1366-1373.

DOI URL |

| [32] |

ZHAO R, HAN D, LU S, et al. Position-sensitive electric property of flash-sintered 3Y-TZP ceramics based on DC bias assisted impedance analysis. Ceramics International, 2022, 48: 2882-2885.

DOI URL |

| [33] |

YAO S, LIU D, LIU J, et al. Ultrafast preparation of Al2O3-ZrO2 multiphase ceramics with eutectic morphology via flash sintering. Ceramics International, 2021, 47: 31555-31560.

DOI URL |

| [34] |

HOMES C C, VOGT T, SHAPIRO S M, et al. Optical response of high-dielectric-constant perovskite-related oxide. Science, 2001, 293: 673-676.

PMID |

| [35] | 许静. 有机改性SiC晶须/PVDF复合薄膜的制备及介电性能研究. 西安: 西安建筑科技大学硕士学位论文, 2018. |

| [36] |

LIU D, WANG K, ZHAO K, et al. Creep behavior of zirconia ceramics under a strong DC field. Scripta Materialia, 2022, 214: 114654.

DOI URL |

| [37] |

MA B, ZHU Y, WANG K, et al. Microstructure and dielectric property of flash sintered SiO2-coated BaTiO3 ceramics. Scripta Materialia, 2019, 170: 1-5.

DOI URL |

| [1] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [2] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| [3] | 李俊生, 曾良, 刘荣军, 王衍飞, 万帆, 李端. 锶钽氧氮化物功能陶瓷的高效合成、致密化及介电性能研究[J]. 无机材料学报, 2023, 38(8): 885-892. |

| [4] | 杜剑宇, 葛琛. 光电人工突触研究进展[J]. 无机材料学报, 2023, 38(4): 378-386. |

| [5] | 谢兵, 蔡金峡, 王铜铜, 刘智勇, 姜胜林, 张海波. 高储能密度聚合物基多层复合电介质的研究进展[J]. 无机材料学报, 2023, 38(2): 137-147. |

| [6] | 刘金铃, 刘佃光, 任科, 王一光. 氧化物陶瓷闪烧机理及其应用研究进展[J]. 无机材料学报, 2022, 37(5): 473-480. |

| [7] | 梁汉琴, 尹金伟, 左开慧, 夏咏锋, 姚冬旭, 曾宇平. 添加BaTiO3的热压烧结Si3N4陶瓷的力学和介电性能[J]. 无机材料学报, 2021, 36(5): 535-540. |

| [8] | 王义良, 艾云龙, 杨书伟, 梁炳亮, 郑振环, 欧阳晟, 何文, 陈卫华, 刘长虹, 张建军, 刘智勇. M3O4(M=FeCoCrMnMg)高熵氧化物粉体的简易制备及超电容性能研究[J]. 无机材料学报, 2021, 36(4): 425-430. |

| [9] | 张丰年, 郭猛, 苗洋, 高峰, 成楚飞, 程富豪, 刘宇峰. 高熵陶瓷(Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ的制备及烧结行为[J]. 无机材料学报, 2021, 36(4): 372-378. |

| [10] | 樊文琪, 宋雪梅, 黄怡玲, 常程康. CMAS对YSZ涂层腐蚀引起的结构变化及其相变分布[J]. 无机材料学报, 2021, 36(10): 1059-1066. |

| [11] | 喻瑛, 杜红亮, 杨泽田, 靳立, 屈绍波. 无铅块体陶瓷的电卡效应: 现状与挑战[J]. 无机材料学报, 2020, 35(6): 633-646. |

| [12] | 刘小根,包亦望,万德田,孙与康. 硫化镍引发钢化玻璃自爆的临界尺寸及影响[J]. 无机材料学报, 2020, 35(2): 211-216. |

| [13] | 徐东, 朱钰方, 郑元义, 罗宇, 陈航榕. 可注射磁性液固相变材料用于骨肉瘤的磁共振成像与低温磁热治疗研究[J]. 无机材料学报, 2020, 35(11): 1277-1282. |

| [14] | 韩刘洋, 郭少波, 闫世光, RÉMIENSDenis, 王根水, 董显林. Pb0.3CaxSr0.7-xTiO3陶瓷的室温电卡效应[J]. 无机材料学报, 2019, 34(9): 1011-1014. |

| [15] | 张晓晨, 王雪梅, 王春雷. 烧结方式对(K,Na,Li)(Nb,Sb,Ta)O3压电陶瓷的微观结构和物理性能的影响[J]. 无机材料学报, 2019, 34(7): 721-726. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||