无机材料学报 ›› 2023, Vol. 38 ›› Issue (8): 885-892.DOI: 10.15541/jim20230026 CSTR: 32189.14.10.15541/jim20230026

所属专题: 【信息功能】介电、铁电、压电材料(202506)

收稿日期:2023-01-16

修回日期:2023-02-09

出版日期:2023-08-20

网络出版日期:2023-03-17

通讯作者:

李 端, 副研究员. E-mail: duan_li_2016@163.com作者简介:李俊生(1982-), 男, 副研究员. E-mail: charlesljs@163.com

基金资助:

LI Junsheng( ), ZENG Liang, LIU Rongjun, WANG Yanfei, WAN Fan, LI Duan(

), ZENG Liang, LIU Rongjun, WANG Yanfei, WAN Fan, LI Duan( )

)

Received:2023-01-16

Revised:2023-02-09

Published:2023-08-20

Online:2023-03-17

Contact:

LI Duan, associate professor. E-mail: duan_li_2016@163.comAbout author:LI Junsheng (1982-), male, associate professor. E-mail: charlesljs@163.com

Supported by:摘要:

AB(O,N)3型钙钛矿氮氧化物是一类新型功能陶瓷材料, 具有独特的介电/磁/光催化等性能, 在能源存储与转化领域应用前景广阔, 但传统制备工艺耗时长且产物纯度较低。本研究以尿素为氮源、金属氧化物为前驱体, 采用无压放电等离子烧结设备一步合成了钙钛矿氮氧化物SrTa(O,N)3陶瓷粉体, 并实现了快速致密化。深入研究了升温速率和合成温度对粉体组成与微观形貌的影响, 并对优化后制备的陶瓷块体进行了介电性能表征。结果表明, 较高的升温速率和适中的合成温度有利于氮化反应的充分进行, 在100 ℃/min和1000 ℃下制得的SrTa(O,N)3粉体纯度最高, 氧氮化物相含量约97%, 粒径分布区间为100~300 nm, Sr、Ta、O、N 四种元素分布均匀。较优的致密化工艺为烧结温度1300 ℃、升温速率300 ℃/min、保温时间1 min, 经烧结制得的SrTa(O,N)3陶瓷试片致密度可达94%以上, 且纯度很高, 该材料在300 Hz时的介电常数高达8349, 介电损耗为10-4量级, 优于文献报道值。本研究制备的SrTa(O,N)3陶瓷的高介电常数与致密度和纯度的调控密不可分, 这是因为气孔和杂质会降低材料介电常数, 高致密度和高纯度是SrTa(O,N)3氧氮化物陶瓷获得优异介电性能的关键。

中图分类号:

李俊生, 曾良, 刘荣军, 王衍飞, 万帆, 李端. 锶钽氧氮化物功能陶瓷的高效合成、致密化及介电性能研究[J]. 无机材料学报, 2023, 38(8): 885-892.

LI Junsheng, ZENG Liang, LIU Rongjun, WANG Yanfei, WAN Fan, LI Duan. Functional Strontium Tantalum Oxynitride Ceramics: Efficient Synthesis, Densification and Dielectric Performance[J]. Journal of Inorganic Materials, 2023, 38(8): 885-892.

| Sample | Synthesis temperature /℃ | Heating rate /(℃·min-1) | Composition/% (in atomic) | O/N | |||

|---|---|---|---|---|---|---|---|

| Sr | Ta | O | N | ||||

| STON-1000-10 | 1000 | 10 | 9.19 | 11.05 | 61.51 | 18.25 | 3.37 |

| STON-800-100 | 800 | 100 | 14.59 | 7.74 | 57.10 | 20.57 | 2.78 |

| STON-900-100 | 900 | 100 | 12.60 | 10.98 | 50.24 | 26.18 | 1.92 |

| STON-1000-100 | 1000 | 100 | 11.74 | 11.92 | 47.83 | 28.51 | 1.68 |

| STON-1100-100 | 1100 | 100 | 10.63 | 13.02 | 44.86 | 31.49 | 1.42 |

| STON-1200-100 | 1200 | 100 | 10.11 | 13.50 | 44.17 | 32.22 | 1.37 |

表1 样品合成条件(升温制度)及元素含量

Table 1 Synthesis conditions (heating strategy) and element content

| Sample | Synthesis temperature /℃ | Heating rate /(℃·min-1) | Composition/% (in atomic) | O/N | |||

|---|---|---|---|---|---|---|---|

| Sr | Ta | O | N | ||||

| STON-1000-10 | 1000 | 10 | 9.19 | 11.05 | 61.51 | 18.25 | 3.37 |

| STON-800-100 | 800 | 100 | 14.59 | 7.74 | 57.10 | 20.57 | 2.78 |

| STON-900-100 | 900 | 100 | 12.60 | 10.98 | 50.24 | 26.18 | 1.92 |

| STON-1000-100 | 1000 | 100 | 11.74 | 11.92 | 47.83 | 28.51 | 1.68 |

| STON-1100-100 | 1100 | 100 | 10.63 | 13.02 | 44.86 | 31.49 | 1.42 |

| STON-1200-100 | 1200 | 100 | 10.11 | 13.50 | 44.17 | 32.22 | 1.37 |

图5 不同合成温度所得产物的光学与SEM照片

Fig. 5 Optical and SEM images of the products obtained at different synthesis temperatures (a) 800 ℃; (b) 900 ℃; (c) 1000 ℃; (d) 1100 ℃; (e) 1200 ℃

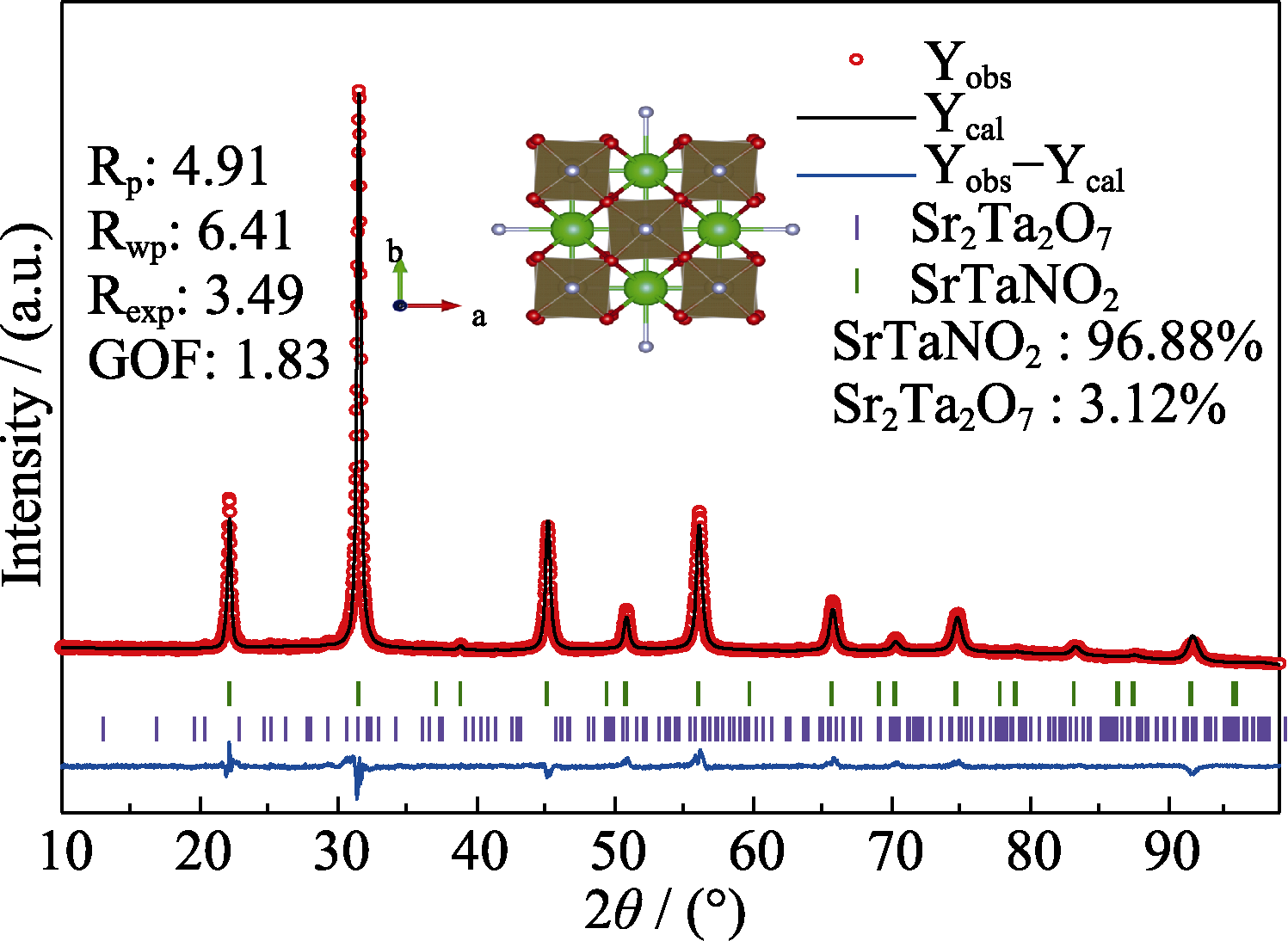

图6 SrTa(O,N)3粉体X射线衍射的Rietveld精修谱图

Fig. 6 Rietveld refinement of XRD pattern for SrTa(O,N)3 Vertical marks indicate the standard Bragg position for SrTaNO2 (upper) and Sr2Ta2O7 (lower)

图7 优化合成制得SrTa(O,N)3粉体的SEM照片和EDS元素分布图

Fig. 7 SEM image and EDS mappings of SrTa(O,N)3 powder prepared under optimized conditions (a) SEM image; (b) Sr; (c) Ta; (d) O; (e) N

| Sample | Heating rate/ (℃·min-1) | Sintering temperature/℃ | Dwell time/min | Density/ (g·cm-3) | Relative density/% | Open porosity/% | (Open porosity/ Total porosity)/% |

|---|---|---|---|---|---|---|---|

| STON-SPS-1 | 300 | 1100 | 1 | 5.69 | 70.94 | 3.12 | 10.77 |

| STON-SPS-2 | 300 | 1200 | 1 | 6.30 | 78.54 | 7.54 | 35.28 |

| STON-SPS-3 | 300 | 1250 | 0 | 6.93 | 86.40 | 4.37 | 21.90 |

| STON-SPS-4 | 300 | 1250 | 1 | 7.13 | 88.89 | 0.43 | 3.89 |

| STON-SPS-5 | 300 | 1250 | 3 | 7.24 | 90.26 | 0.57 | 5.88 |

| STON-SPS-6 | 200 | 1300 | 1 | 7.37 | 91.88 | 0.69 | 8.53 |

| STON-SPS-7 | 300 | 1300 | 1 | 7.55 | 94.13 | 0.55 | 9.52 |

| STON-SPS-8 | 300 | 1400 | 1 | 7.67 | 95.62 | 0.49 | 11.53 |

表2 不同SPS工艺所得氧氮化物陶瓷的密度及孔隙率(100 MPa)

Table 2 Density and porosity of oxynitride ceramics prepared by different SPS processes (100 MPa)

| Sample | Heating rate/ (℃·min-1) | Sintering temperature/℃ | Dwell time/min | Density/ (g·cm-3) | Relative density/% | Open porosity/% | (Open porosity/ Total porosity)/% |

|---|---|---|---|---|---|---|---|

| STON-SPS-1 | 300 | 1100 | 1 | 5.69 | 70.94 | 3.12 | 10.77 |

| STON-SPS-2 | 300 | 1200 | 1 | 6.30 | 78.54 | 7.54 | 35.28 |

| STON-SPS-3 | 300 | 1250 | 0 | 6.93 | 86.40 | 4.37 | 21.90 |

| STON-SPS-4 | 300 | 1250 | 1 | 7.13 | 88.89 | 0.43 | 3.89 |

| STON-SPS-5 | 300 | 1250 | 3 | 7.24 | 90.26 | 0.57 | 5.88 |

| STON-SPS-6 | 200 | 1300 | 1 | 7.37 | 91.88 | 0.69 | 8.53 |

| STON-SPS-7 | 300 | 1300 | 1 | 7.55 | 94.13 | 0.55 | 9.52 |

| STON-SPS-8 | 300 | 1400 | 1 | 7.67 | 95.62 | 0.49 | 11.53 |

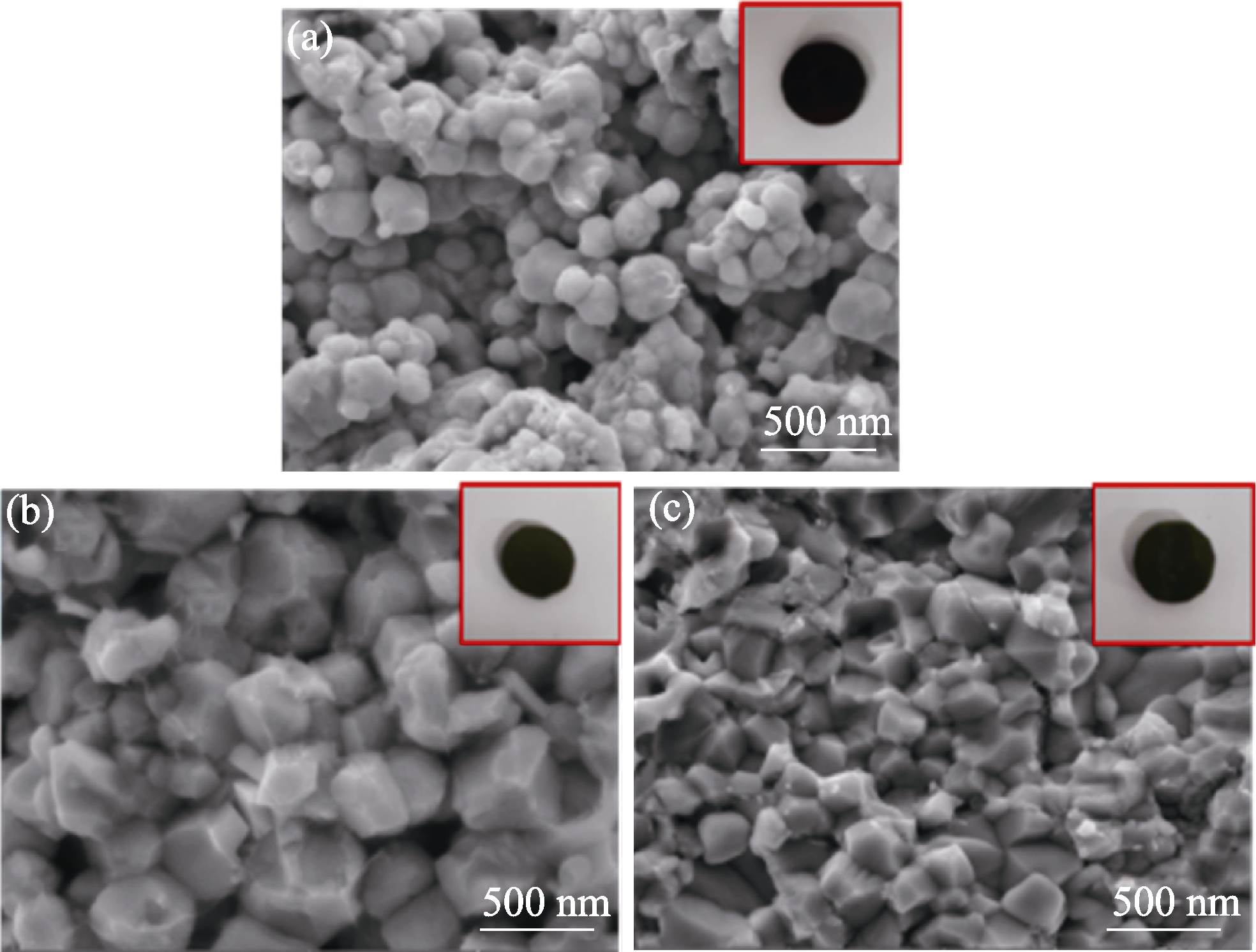

图9 SPS烧结所得SrTa(O,N)3块体的SEM和光学照片

Fig. 9 SEM and optical images of SrTa(O,N)3 bulk obtained by SPS process (a) STON-SPS-1; (b) STON-SPS-4; (c) STON-SPS-7

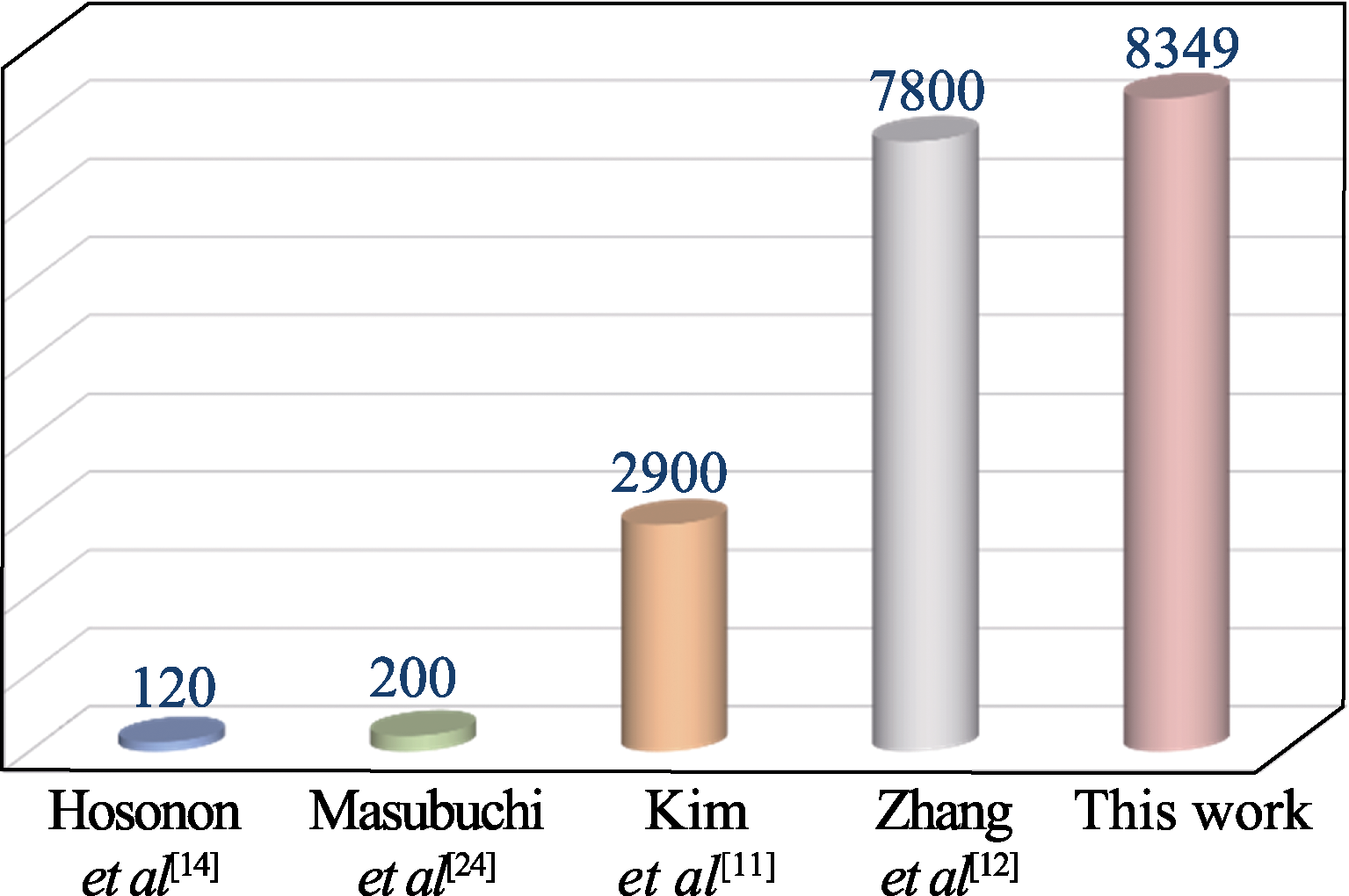

图11 本工作制备的SrTa(O,N)3陶瓷低频介电常数与文献报道值比较[11-12,14,24]

Fig. 11 Dielectric constants at low frequency ranges of SrTa(O,N)3 ceramic bulk in this work and literatures[11-12,14,24]

| [1] | MARCHAND R, PASTUSZAK R, LAURENT Y, et al. Structure cristalline de Nd2AlO3N. Détermination de L Ordre oxygène-azote par diffraction de neutrons. Revue Dechimie Minerale, 1982, 19(6): 684. |

| [2] | MARCHAND R, PORS F, LAURENT Y. Préparation et caractérisation de nouveaux oxynitrures à structure perovskite. Revue Internationale des Hautes Températures et des Réfractaires, 1986, 23(1): 11. |

| [3] |

ZHANG X, LIU X, YAN J, et al. Preparation and property of high entropy (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 perovskite ceramics. Journal of Inorganic Materials, 2021, 36(4): 379.

DOI URL |

| [4] |

LI S, SONG G, ZHANG Y, et al. Preparation and physical property of BTO-based multiferroic Ceramics. Journal of Inorganic Materials, 2022, 37(1): 79.

DOI URL |

| [5] |

FUERTES A. Metal oxynitrides as emerging materials with photocatalytic and electronic properties. Materials Horizons, 2015, 2(5): 453.

DOI URL |

| [6] | AGUIAR R. Synthesis, Properties and Applications of AB(O,N)3 Oxynitride Perovskites. Augsburg: University of Augsburg PhD Thesis, 2009. |

| [7] | LI W. Formability, Synthesis and Properties of Perovskite-type Oxynitrides. Darmstadt: Technische Universität Darmstadt PhD Thesis, 2015. |

| [8] |

EBBINGHAUS S G, AGUIAR R, WEIDENKAFF A, et al. Topotactical growth of thick perovskite oxynitride layers by nitridation of single crystalline oxides. Solid State Sciences, 2008, 10(6): 709.

DOI URL |

| [9] |

SEO J, NISHIYAMA H, YAMADA T, et al. Visible-light- responsive photoanodes for highly active, stable water oxidation. Angewandte Chemie International Edition, 2018, 57(28): 8396.

DOI URL |

| [10] | LI D, ZENG L, LI B, et al. Rapid synthesis of dielectric tantalum- based oxynitrides. Materials and Design, 2020, 187: 108416. |

| [11] | KIM Y I, WOODWARD P M, BABA-KISHI K Z, et al. Characterization of the structural, optical, and dielectric properties of oxynitride perovskites AMO2N (A=Sr, Ba, Ca; M=Ta, Nb). Materials Chemistry, 2004, 16(7): 1267. |

| [12] |

ZHANG Y R, MASUBUCHI Y, MOTOHASHI T, et al. Hot isostatic press sintering and dielectric properties of SrTaO2N ceramics. Ceramics International, 2013, 39(3): 3377.

DOI URL |

| [13] |

CHEN D, HABU D, MASUBUCHI Y, et al. Partial nitrogen loss in SrTaO2N and LaTiO2N oxynitride perovskites. Solid State Sciences, 2016, 54(1): 2.

DOI URL |

| [14] |

HOSONO A, MASUBUCHI Y, KIKKAWA S, et al. Sintering behavior of dielectric SrTaO2N under high pressure of nitrogen. Ceramics International, 2017, 43(2): 2737.

DOI URL |

| [15] |

RACHEL A, EBBINGHAUS S G, GÜNGERICH M, et al. Tantalum and niobium perovskite oxynitrides: synthesis and analysis of the thermal behaviour. Thermochim Acta, 2006, 438(1): 134.

DOI URL |

| [16] |

CLARKE S J, HARDSTONE K A, MICHIE C W, et al. Rosseinsky. High-temperature synthesis and structures of perovskite and n=1 Ruddlesden-popper tantalum oxynitrides. Chemistry of Materials, 2002, 14(6): 2664.

DOI URL |

| [17] |

SUN S K, MOTOHASHI T, MASUBUCHI Y, et al. Direct synthesis of SrTaO2N from SrCO3/Ta3N5 involving CO evolution. Journal of the European Ceramic Society, 2014, 34(16): 4451.

DOI URL |

| [18] | LI D, ZHANG C R, LI B, et al. Research progress in preparation of nitride ceramic materials by urea process. Aerospace Material Technology, 2011, 41(5): 1. |

| [19] |

WANG M H, ZHONG H B, FAN Y C, et al. Spark plasma sintering of bioactive Ca2MgSi2O7 Ceramics. Journal of Inorganic Materials, 2017, 32(8): 825.

DOI URL |

| [20] |

LI D, LI W, FASEL C, et al. Sinterability of the oxynitride LaTiO2N with perovskite-type structure. Journal of Alloys and Compounds, 2014, 586: 567.

DOI URL |

| [21] | LI D, MORAES E G, GUO P, et al. Rapid sintering of silicon nitride foams decorated with one-dimensional nanostructures by intense thermal radiation. Science and Technology of Advanced Materials, 2014, 15(4): 045003. |

| [22] |

LI D, SHEN Z. Rapid sintering of ceramics with gradient porous structure by asymmetric thermal radiation. Journal of the American Ceramic Society, 2015, 98(12): 3631.

DOI URL |

| [23] |

HOSONO A, SUN S K, MASUBUCHI Y, et al. Additive sintering and post-ammonolysis of dielectric BaTaO2N oxynitride perovskite. Journal of the European Ceramic Society, 2016, 36(14): 3341.

DOI URL |

| [24] |

MASUBUCHI Y, KAWAMURA F, TANIGUCHI T, et al. High pressure densi-fication and dielectric properties of perovskite-type oxynitride SrTaO2N. Journal of the European Ceramic Society, 2015, 35(4): 1191.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [3] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [4] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| [5] | 渠吉发, 王旭, 张维轩, 张康喆, 熊永恒, 谭文轶. 掺杂改性NaYTiO4增强固体氧化物燃料电池阳极抗硫中毒性能[J]. 无机材料学报, 2025, 40(5): 489-496. |

| [6] | 吕昕怿, 相恒阳, 曾海波. 长程有序助力钙钛矿QLED高性能化[J]. 无机材料学报, 2025, 40(1): 111-112. |

| [7] | 瞿牡静, 张淑兰, 朱梦梦, 丁浩杰, 段嘉欣, 代恒龙, 周国红, 李会利. CsPbBr3@MIL-53纳米复合荧光粉的合成、性能及其白光LEDs应用[J]. 无机材料学报, 2024, 39(9): 1035-1043. |

| [8] | 肖梓晨, 何世豪, 邱诚远, 邓攀, 张威, 戴维德仁, 缑炎卓, 李金华, 尤俊, 王贤保, 林俍佑. 钙钛矿太阳能电池纳米纤维改性电子传输层研究[J]. 无机材料学报, 2024, 39(7): 828-834. |

| [9] | 刘焱, 覃显鹏, 甘霖, 周国红, 章天金, 王士维, 陈鹤拓. 亚微米球形Y2O3粉体及其透明陶瓷的制备[J]. 无机材料学报, 2024, 39(6): 691-696. |

| [10] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [11] | 陈甜, 罗媛, 朱刘, 郭学益, 杨英. 有机-无机共添加增强柔性钙钛矿太阳能电池机械弯曲及环境稳定性能[J]. 无机材料学报, 2024, 39(5): 477-484. |

| [12] | 于嫚, 高荣耀, 秦玉军, 艾希成. 上转换发光纳米材料对钙钛矿太阳能电池迟滞效应和离子迁移动力学的影响[J]. 无机材料学报, 2024, 39(4): 359-366. |

| [13] | 陈正鹏, 金芳军, 李明飞, 董江波, 许仁辞, 徐韩昭, 熊凯, 饶睦敏, 陈创庭, 李晓伟, 凌意瀚. 双钙钛矿Sr2CoFeO5+δ阴极材料的制备及其中温固体氧化物燃料电池性能研究[J]. 无机材料学报, 2024, 39(3): 337-344. |

| [14] | 刘锁兰, 栾福园, 吴子华, 寿春晖, 谢华清, 杨松旺. 原位生长钙钛矿太阳能电池共形氧化锡薄膜[J]. 无机材料学报, 2024, 39(12): 1397-1403. |

| [15] | 王煜, 熊浩, 黄孝坤, 江琳沁, 吴波, 黎健生, 杨爱军. 低剂量异辛酸亚锡调控两步法制备Sn-Pb混合钙钛矿太阳能电池[J]. 无机材料学报, 2024, 39(12): 1339-1347. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||