Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (2): 205-214.DOI: 10.15541/jim20240269

Special Issue: 【结构材料】陶瓷基复合材料(202512)

• Research Letter • Previous Articles Next Articles

LUAN Xingang1( ), HE Dianwei1, TU Jianyong2(

), HE Dianwei1, TU Jianyong2( ), CHENG Laifei1

), CHENG Laifei1

Received:2024-06-03

Revised:2024-09-03

Published:2025-02-20

Online:2024-09-23

Contact:

LUAN Xingang, professor. E-mail: xgluan@nwpu.edu.cn;Supported by:CLC Number:

LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism[J]. Journal of Inorganic Materials, 2025, 40(2): 205-214.

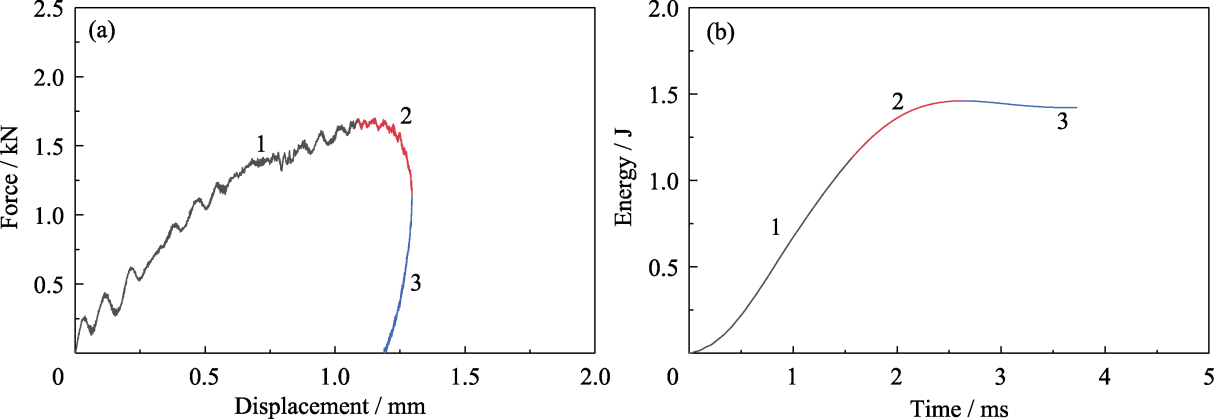

Fig. 2 Impact response of a 3D sample subjected to 1.5 J impact (a) Displacement-load curve; (b) Energy-time curve. Colorful figures are available on website

| Sample | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|

| 2D | 1.0 | 96.93 | 1.123 | Broken | |

| 1.5 | 96.01 | 1.379 | Broken | ||

| 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1.5 | 96.98 | 1.155 | Unbroken | |

| 1.5(1)* | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5(2)* | 80.55 | 0.724 | Broken | ||

| 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3.0 | 91.54 | 1.873 | Broken |

Table 1 Energy absorption of sample

| Sample | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|

| 2D | 1.0 | 96.93 | 1.123 | Broken | |

| 1.5 | 96.01 | 1.379 | Broken | ||

| 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1.5 | 96.98 | 1.155 | Unbroken | |

| 1.5(1)* | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5(2)* | 80.55 | 0.724 | Broken | ||

| 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3.0 | 91.54 | 1.873 | Broken |

Fig. 3 Macroscopic morphology of samples From left to right, 2D-1.0J, 2D-1.5J, 2D-2.0J, 3D-1.5J, 3D-2×1.5J (broken), 3D-2×1.5J (unbroken), 3D-3.0J (broken), and 3D-3.0J (unbroken)

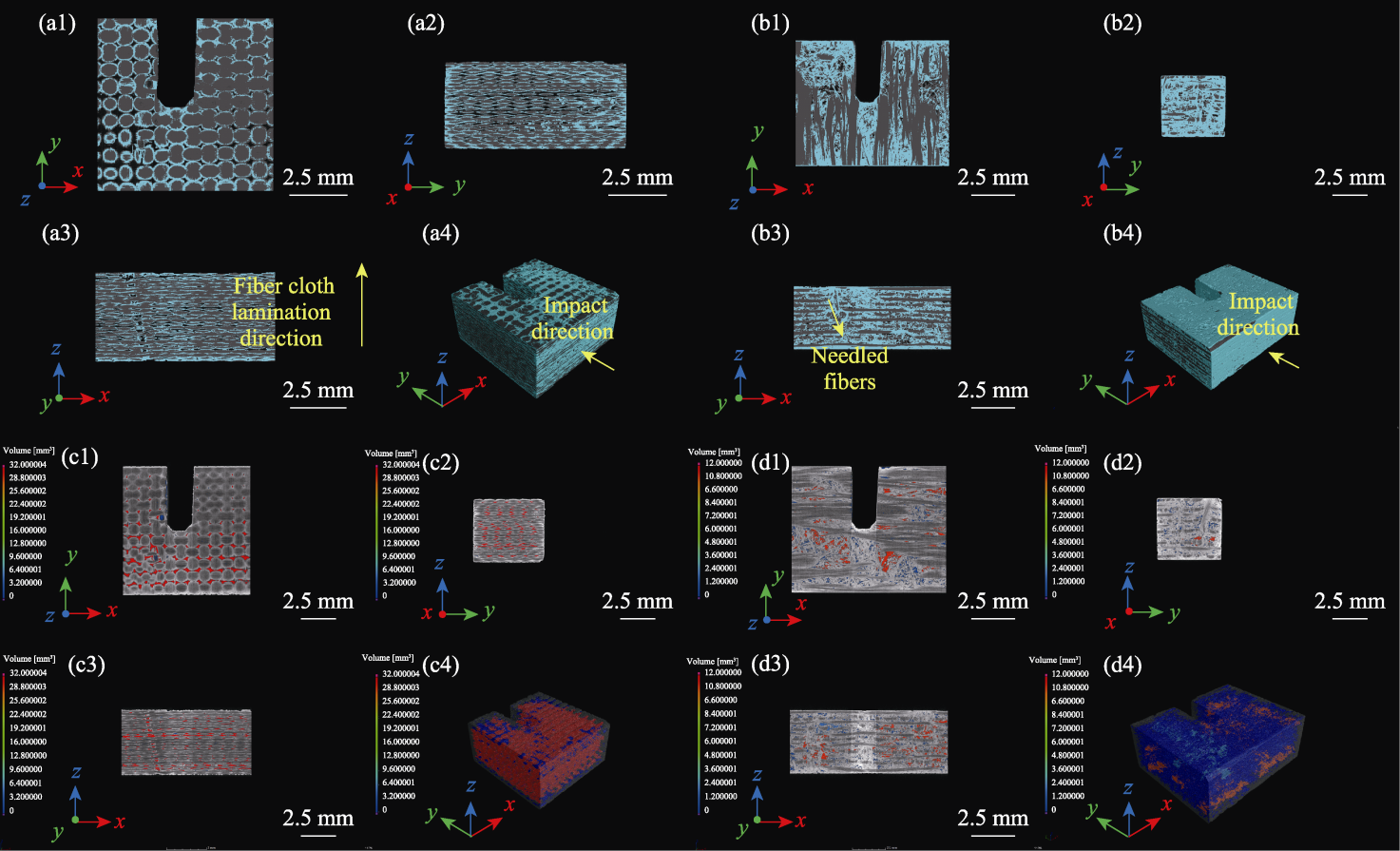

Fig. 4 Phase and pore analyses of samples using CT technique before impact (Grey for C-fiber bundles, light blue for SiC matrix, red for large pores, dark blue for small pores) Phase (a) and pore (c) analyses of the 2D C/SiC composite: (a1, c1) XY plane, (a2, c2) YZ plane, (a3, c3) XZ plane, and (a4, c4) stereogram; Phase (b) and pore (d) analyses of the 3D C/SiC composite: (b1, d1) XY plane, (b2, d2) YZ plane, (b3, d3) XZ plane, and (b4, d4) stereogram. Colorful figures are available on website

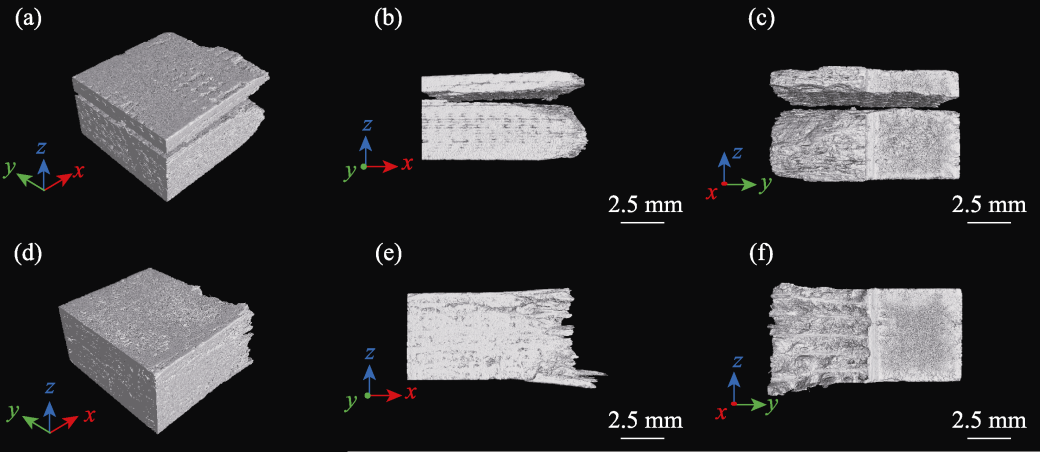

Fig. 6 CT photographs of the appearance of fractured C/SiC samples after impact 2 D C/SiC composite: (a) stereoscopic view, (b) YZ plane, and (c) XZ plane;3D C/SiC composite: (d) stereoscopic view, (e) YZ plane, and (f) XZ plane

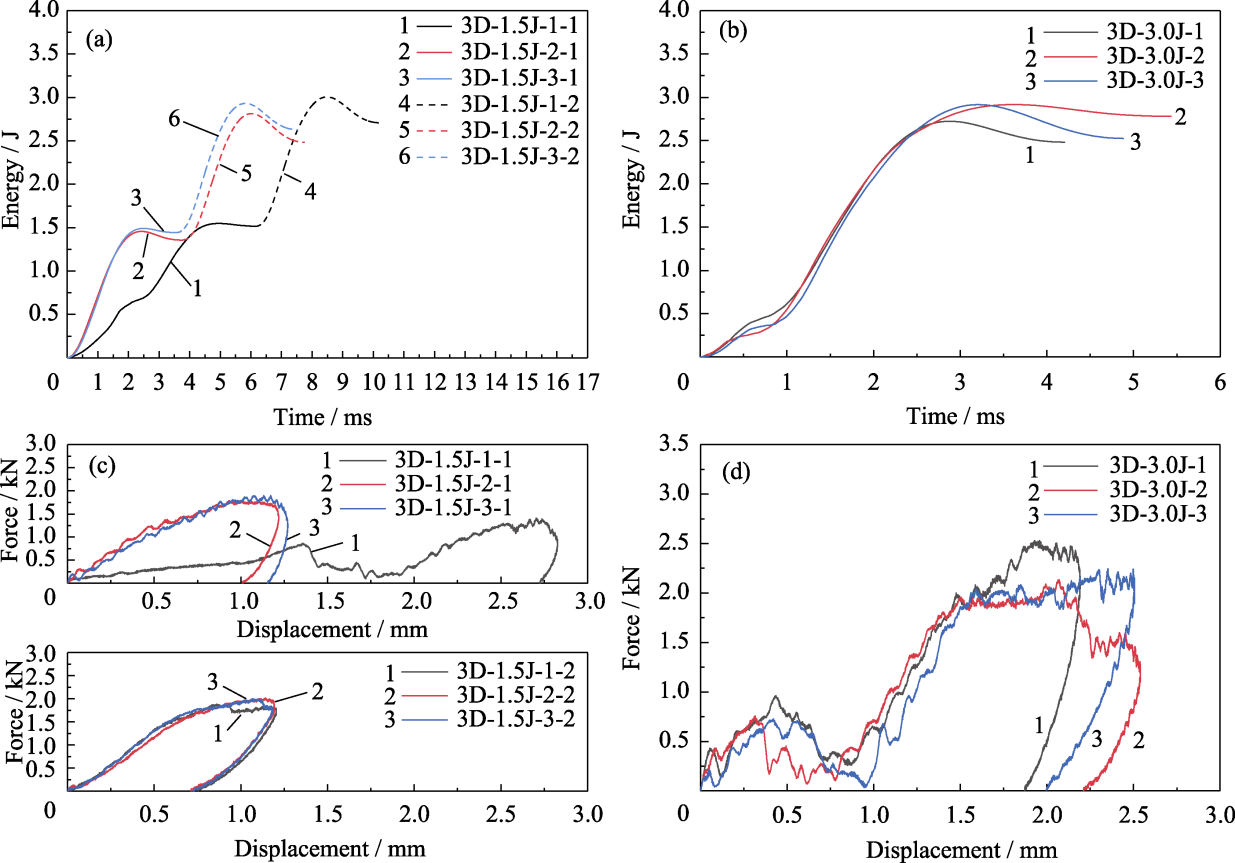

Fig. 8 Energy-time curves and displacement-load curves of 3D C/SiC composite with different impact energies Energy-time: (a) 2×1.5 J and (b) 3.0 J; Displacement-load: (c) 2×1.5 J and (d) 3.0 J

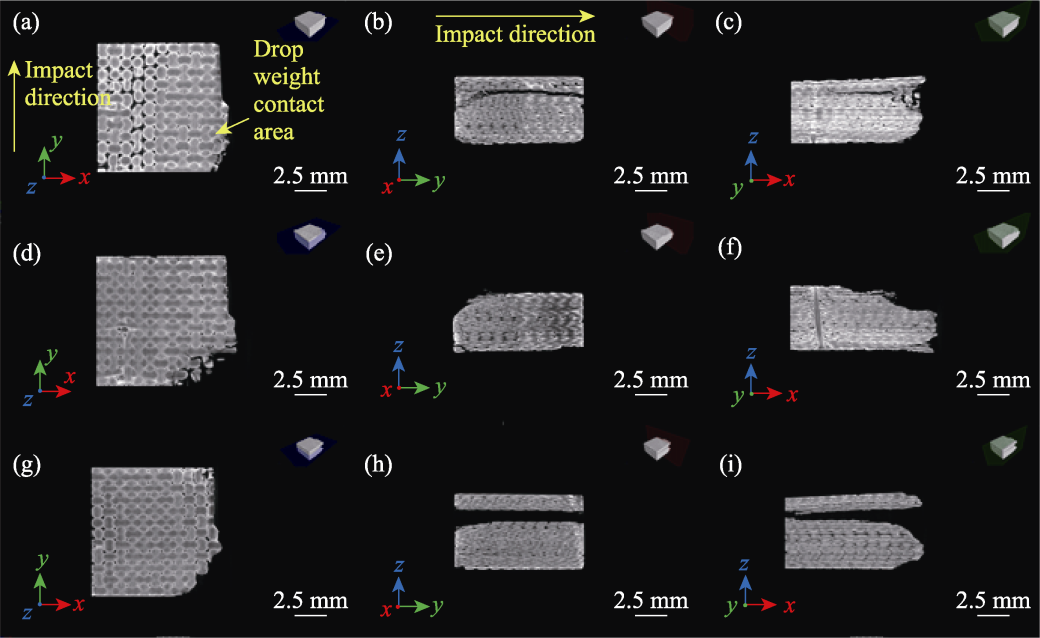

Fig. 9 CT scan results of 3D C/SiC composite after impact XY plane: (a) 1.5 J, (d) 3.0 J, and (g) 2×1.5 J; YZ plane: (b) 1.5 J, (e) 3.0 J, and (h) 2×1.5 J; XZ plane: (c) 1.5 J, (f) 3.0 J, and (i) 2×1.5 J

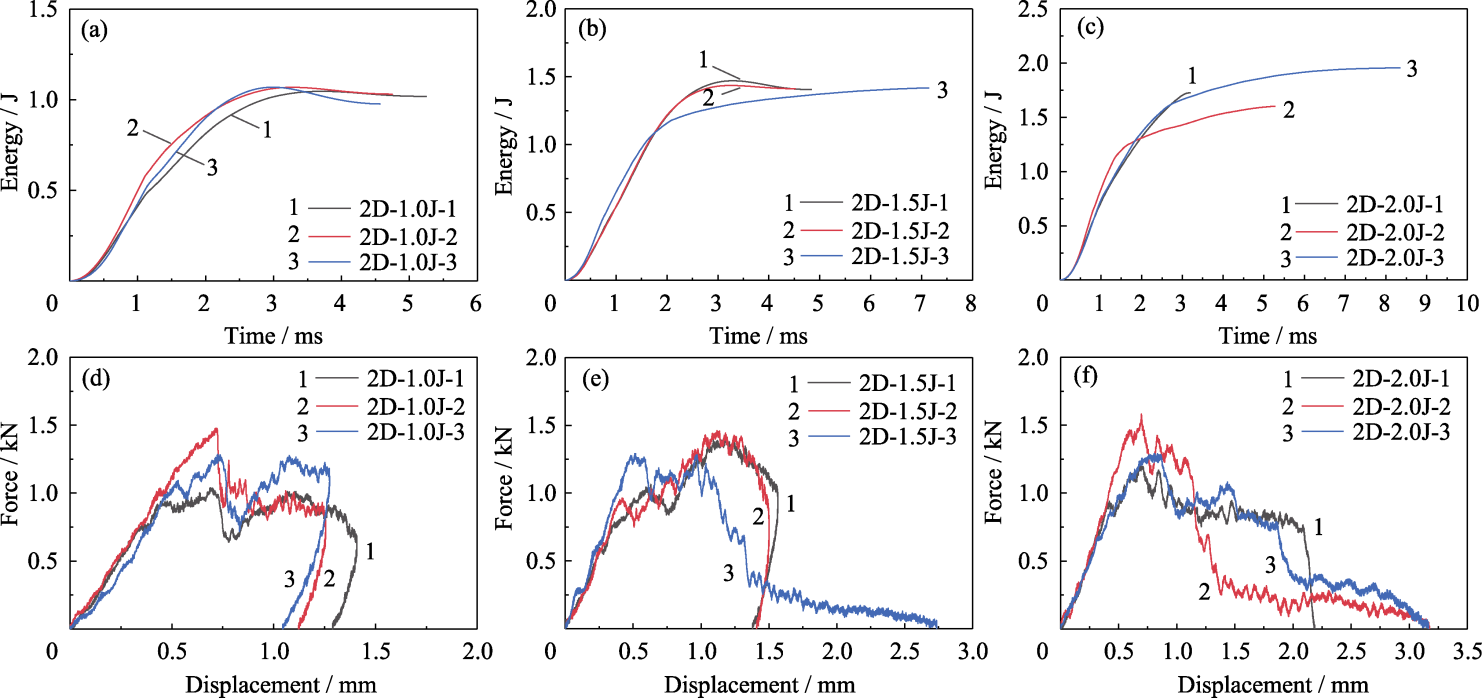

Fig. 10 Energy-time curves (a-c) and displacement-load (d-f) curves of 2D C/SiC composite with different impact energies of 1.0 J (a, d), 1.5 J (b, e), and 2.0 J (c, f)

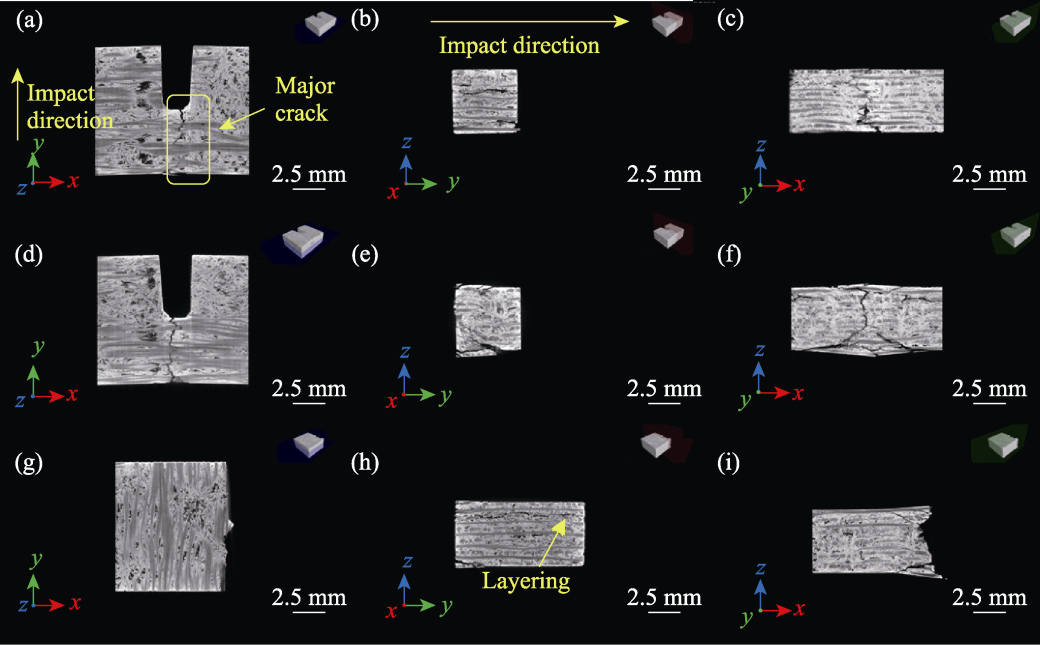

Fig. 11 CT scan results of 2D C/SiC composite after impact XY plane: (a) 1.0, (d) 1.5, and (g) 2.0 J; YZ plane: (b) 1.0, (e) 1.5, and (h) 2.0 J; XZ plane: (c) 1.0, (f) 1.5, and (i) 2.0 J

| Sample | Number | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|---|

| 2D | 1 | 1.0 | 97.69 | 1.289 | Broken | |

| 2 | 1.0 | 96.93 | 1.123 | Broken | ||

| 3 | 1.0 | 92.13 | 1.045 | Broken | ||

| 1 | 1.5 | 96.01 | 1.379 | Broken | ||

| 2 | 1.5 | 98.58 | 1.410 | Broken | ||

| 3 | 1.5 | 93.67 | 2.737* | Broken | ||

| 1 | 2.0 | 80.79 | 3.175 | Broken | ||

| 2 | 2.0 | 98.69 | 3.166 | Broken | ||

| 3 | 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1 | 1.5 | 91.35 | 2.277 | Unbroken | |

| 2 | 1.5 | 97.58 | 1.188 | Unbroken | ||

| 3 | 1.5 | 96.98 | 1.155 | Unbroken | ||

| 1 | 1.5 | 98.15 | 89.72 | 2.725* | Unbroken | |

| 1.5 | 80.88 | 0.754 | Broken | |||

| 2 | 1.5 | 93.60 | 86.01 | 1.008 | Unbroken | |

| 1.5 | 78.36 | 0.712 | Unbroken | |||

| 3 | 1.5 | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5 | 80.55 | 0.724 | Broken | |||

| 1 | 3.0 | 95.73 | 2.212 | Unbroken | ||

| 2 | 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3 | 3.0 | 91.54 | 1.873 | Broken |

Table S1 Impact energy absorption for all samples

| Sample | Number | Impact energy/J | Er/% | Etr/% | Δh/mm | Case of sample fracture |

|---|---|---|---|---|---|---|

| 2D | 1 | 1.0 | 97.69 | 1.289 | Broken | |

| 2 | 1.0 | 96.93 | 1.123 | Broken | ||

| 3 | 1.0 | 92.13 | 1.045 | Broken | ||

| 1 | 1.5 | 96.01 | 1.379 | Broken | ||

| 2 | 1.5 | 98.58 | 1.410 | Broken | ||

| 3 | 1.5 | 93.67 | 2.737* | Broken | ||

| 1 | 2.0 | 80.79 | 3.175 | Broken | ||

| 2 | 2.0 | 98.69 | 3.166 | Broken | ||

| 3 | 2.0 | 89.08 | 2.458 | Broken | ||

| 3D | 1 | 1.5 | 91.35 | 2.277 | Unbroken | |

| 2 | 1.5 | 97.58 | 1.188 | Unbroken | ||

| 3 | 1.5 | 96.98 | 1.155 | Unbroken | ||

| 1 | 1.5 | 98.15 | 89.72 | 2.725* | Unbroken | |

| 1.5 | 80.88 | 0.754 | Broken | |||

| 2 | 1.5 | 93.60 | 86.01 | 1.008 | Unbroken | |

| 1.5 | 78.36 | 0.712 | Unbroken | |||

| 3 | 1.5 | 96.98 | 88.11 | 1.155 | Unbroken | |

| 1.5 | 80.55 | 0.724 | Broken | |||

| 1 | 3.0 | 95.73 | 2.212 | Unbroken | ||

| 2 | 3.0 | 87.15 | 1.997 | Unbroken | ||

| 3 | 3.0 | 91.54 | 1.873 | Broken |

| [1] | ZHAO G C, JIANG Z G, QU Z L, et al. Fracture characteristics and in-situ damage mechanism of PIP-C/SiC composites to various temperatures and loading velocities. Engineering Fracture Mechanics, 2023, 286: 109300. |

| [2] | YAO L J, LI Z S, CHENG Q Y, et al. Damage behavior of 2D C/SiC composites under low velocity impact. Journal of Inorganic Materials, 2010, 25(3): 311. |

| [3] | YIN D Z, DENG Y F, MA Y Z, et al. Effect of SiC content on the mechanical behaviour of a three-dimensional needled C/SiC composite. Ceramics International, 2021, 47(17): 25067. |

| [4] | LI Y, XIAO P, SHI Y, et al. Mechanical behavior of LSI based C/C-SiC composites subjected to flexural loadings. Composites Part A, 2017, 95: 315. |

| [5] | NIU Z B, CHEN S A, LI Y, et al. A damage constitutive model for the nonlinear mechanical behavior of C/SiC composites during mechanical cyclical loading/unloading. Composites Part A: Applied Science and Manufacturing, 2022, 161: 107072. |

| [6] | ALMEIDA R S M, CHEN S A, BESSER B, et al. Fatigue behavior and damage analysis of PIP C/SiC composite. Journal of the European Ceramic Society, 2022, 42(13): 5391. |

| [7] | YAO L J, LYU P, BAI G D, et al. Influence of low velocity impact on oxidation performance of SiC coated C/SiC composites. Ceramics International, 2019, 45(16): 20470. |

| [8] | MEI H, YU C K, XU H R, et al. The effects of stitched density on low-velocity impact damage of cross-woven carbon fiber reinforced silicon carbide composites. Ceramics International, 2016, 42(1): 1762. |

| [9] | FRANKEL P G, WITHERS P J, PREUSS M, et al. Residual stress fields after FOD impact on flat and aerofoil-shaped leading edges. Mechanics of Materials, 2012, 55: 130. |

| [10] | KHARGHANI N, SOARES C G. Behavior of composite laminates with embedded delaminations. Composite Structures, 2016, 150: 226. |

| [11] | SINGH A, MALL S. Tensile and fatigue behavior of oxide/oxide ceramic matrix composite with simulated foreign object damage in combustion environment. International Journal of Applied Ceramic Technology, 2017, 15(1): 16. |

| [12] | ESPINO N V. Prediction of foreign object debris/damage (FOD) type for elimination in the aeronautics manufacturing environment through logistic regression model. Texas: The University of Texas at El Paso, Master's thesis, 2013. |

| [13] | CHEN X. Foreign object damage on the leading edge of a thin blade. Mechanics of Materials, 2005, 37(4): 447. |

| [14] | DING J, HALL R F, BYRNE J, et al. Fatigue crack growth from foreign object damage under combined low and high cycle loading. Part I: experimental studies. International Journal of Fatigue, 2007, 29(7): 1339. |

| [15] | TRABANDT U, ESSER B, KOCH D, et al. Ceramic matrix composites life cycle testing under reusable launcher environmental conditions. International Journal of Applied Ceramic Technology, 2005, 2(2): 150. |

| [16] | MEI H, YU C K, XU Y W, et al. Effect of impact energy on damage resistance and mechanical property of C/SiC composites under low velocity impact. Materials Science and Engineering: A, 2017, 687: 141. |

| [17] | LIU B, AN Q J, ZHONG J G, et al. Study on notch sensitivity and failure of 3D needled C/SiC fracture toughness. Advances in Aeronautical Science and Engineering, 2022, 13(2): 85. |

| [18] |

PI H L, ZHANG B P, YU X M, et al. Damage characteristics of 2D C/SiC-ZrC composites under low velocity impact. Journal of Inorganic Materials, 2020, 35(12): 1327.

DOI |

| [19] | TITA V, DE CARVALHO J, VANDEPITTE D. Failure analysis of low velocity impact on thin composite laminates: experimental and numerical approaches. Composite Structures, 2008, 83(4): 413. |

| [20] | ZHAO D L, GUO T, FAN X M, et al. Effect of pyrolytic carbon interphase on mechanical properties of mini T800-C/SiC composites. Journal of Advanced Ceramics, 2021, 10(2): 219. |

| [21] |

LIU B, GAO Y D, TAN Z Y, et al. Low energy level impact damage on 2D C/SiC composites: experimental study. Acta Aeronautica et Astronautica Sinica, 2021, 42(2): 224202.

DOI |

| [1] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [2] | WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo. Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates [J]. Journal of Inorganic Materials, 2024, 39(1): 51-60. |

| [3] | SHI Weigang, ZHANG Chao, LI Mei, WANG Jing, ZHANG Chengyu. 2D-SiCf/SiC Interlaminar Mode I Fracture Testing and Characterization [J]. Journal of Inorganic Materials, 2024, 39(1): 45-50. |

| [4] | WANG Xueyao, WANG Wugang, LI Yingwei, PENG Qi, LIANG Ruihong. Correlation between Constitutive Behavior and Fracture Performance of PZT Ceramics [J]. Journal of Inorganic Materials, 2023, 38(7): 839-844. |

| [5] | WEI Tingting, GAO Xiguang, SONG Yingdong. Response of 2D SiC/SiC Composites Resistivity to Service Environments [J]. Journal of Inorganic Materials, 2022, 37(4): 420-426. |

| [6] | MA Delong, BAO Yiwang, WAN Detian, QIU Yan, ZHENG Dezhi, FU Shuai. Pre-crack and Fracture Toughness Evaluation of Ceramic Thin Plates [J]. Journal of Inorganic Materials, 2021, 36(7): 733-737. |

| [7] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [8] | LÜ Xiaoxu, JIANG Zhuyu, ZHOU Yiran, QI Zhe, ZHAO Wenqing, JIAO Jian. Effect of BN/SiC Multilayered Interphases on Mechanical Properties of SiC Fibers and Minicomposites by PIP [J]. Journal of Inorganic Materials, 2020, 35(10): 1099-1104. |

| [9] | ZHANG Zhao-Fu,SHA Jian-Jun,ZU Yu-Fei,DAI Ji-Xiang. ZrB2-SiC Composites Toughened by Interlocking Microstructure and Chopped Carbon Fiber [J]. Journal of Inorganic Materials, 2019, 34(9): 918-924. |

| [10] | ZHANG Biao, YANG Chang-An, SHI Pei. Synthesis of Graphene/Hydroxyapatite Composite Bioceramics via Plasma Activated Sintering [J]. Journal of Inorganic Materials, 2018, 33(12): 1355-1359. |

| [11] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [12] | ZHANG Zhi-Gang, YAO Guang-Chun, LUO Hong-Jie, ZHANG Xiao, MA Jun-Fei, XU Jian-Rong. Sintering Behavior and Properties of NiFe2O4 Ceramic Inert Anode Toughened by Adding NiFe2O4 Nanopowder [J]. Journal of Inorganic Materials, 2016, 31(7): 761-768. |

| [13] | MA Rong-Bin, CHENG Xu-Dong, ZOU Jun, LI Qing-Yu, HUANG Xia. Toughness and Thermal Shock of SiC Fiber/Yttria-stabilized-zirconia Composite Thick Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2016, 31(2): 190-194. |

| [14] | ZHAO Shuang, YANG Zi-Chun, ZHOU Xin-Gui. Fracture Behavior of SiC/SiC Composites with Different Interfaces [J]. Journal of Inorganic Materials, 2016, 31(1): 58-62. |

| [15] | LIANG Ling-Jiang, LI Kai, YAN Dong, MA Ben, YANG Jia-Jun, PU Jian, CHI Bo, LI Jian. Mechanical Property and Deformation Behavior of SOFCs [J]. Journal of Inorganic Materials, 2015, 30(6): 633-638. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||