Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (12): 1384-1390.DOI: 10.15541/jim20240241

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Xianke( ), ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili(

), ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili( )

)

Received:2024-05-13

Revised:2024-05-29

Published:2024-06-24

Online:2024-06-24

Contact:

TANG Huili, professor. E-mail: tanghl@tongji.edu.cnAbout author:LI Xianke (1999-), male, Master candidate. E-mail: va142857@163.com

Supported by:CLC Number:

LI Xianke, ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili. High-quality Indium-doped Gallium Oxide Single Crystal Growth by Floating Zone Method[J]. Journal of Inorganic Materials, 2024, 39(12): 1384-1390.

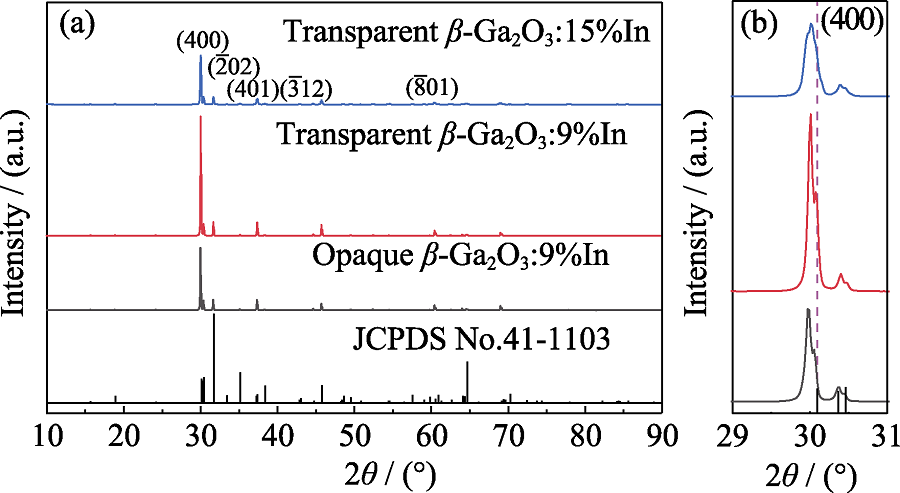

Fig. 2 XRD patterns of β-Ga2O3:In crystal powders (a) XRD patterns in the range of 2θ=10°-90°; (b) XRD diffraction peak of (400) crystal surface at 2θ=30.095°

Fig. 3 Optical microscope morphologies of bubble defects in opaque β-Ga2O3:9%In (a) Long strip bubble; (b) Short strip bubble; (c) Spherical bubble; (d) Short strip bubble

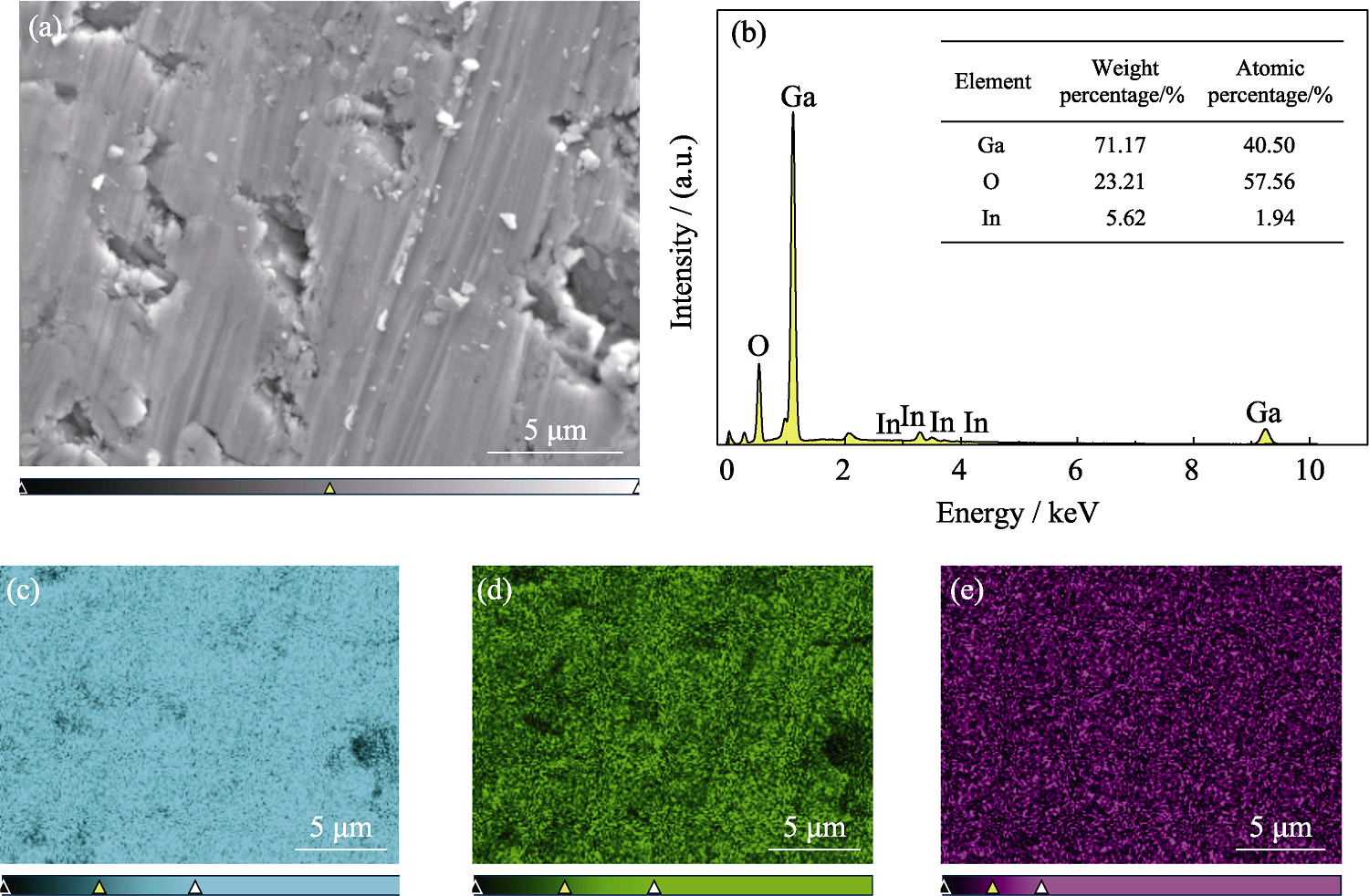

Fig. 4 SEM image, EDS pattern and corresponding elemental mappings of the opaque β-Ga2O3:9%In crystal (a) SEM image; (b) EDS pattern and elemental contents; (c-e) Elemental mappings of (c) Ga, (d) O and (e) In

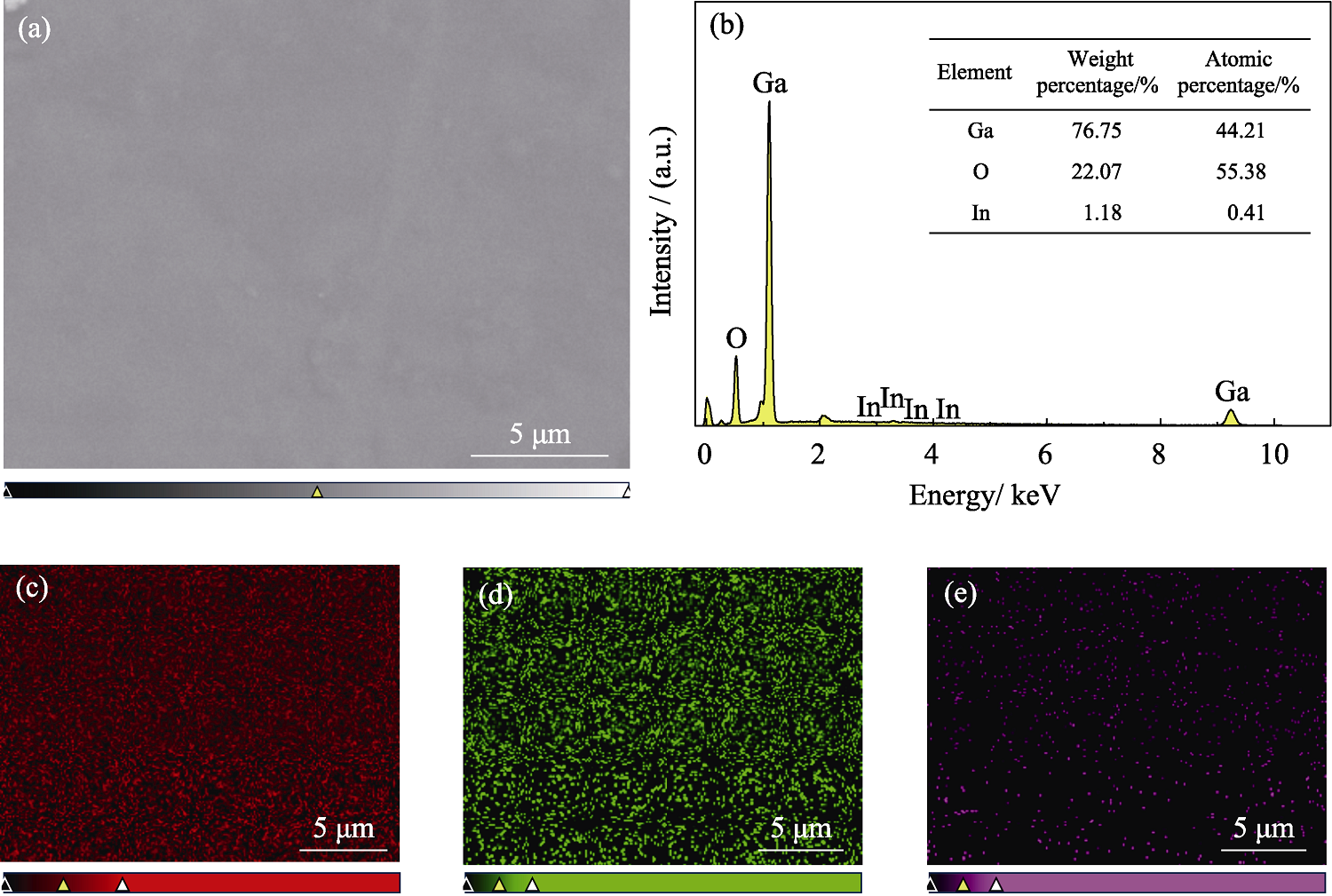

Fig. 6 SEM image, EDS pattern and corresponding elemental mappings of transparent β-Ga2O3:9%In crystal (a) SEM image; (b) EDS pattern and elemental contents; (c-e) Elemental mappings of (c) Ga, (d) O and (e) In

| Element | β-Ga2O3:9%In | β-Ga2O3:15%In |

|---|---|---|

| In | 1.76 | 1.87 |

| Si | 0.01 | 0.03 |

| Al | 0.01 | 0.01 |

| Fe | 0.01 | 0 |

| Mg | 0.02 | 0.02 |

Table 1 ICP-AES testing of transparent β-Ga2O3:9%In and β-Ga2O3:15%In crystals (%, in mass)

| Element | β-Ga2O3:9%In | β-Ga2O3:15%In |

|---|---|---|

| In | 1.76 | 1.87 |

| Si | 0.01 | 0.03 |

| Al | 0.01 | 0.01 |

| Fe | 0.01 | 0 |

| Mg | 0.02 | 0.02 |

Fig. 7 Absorption spectra and optical bandgaps of UID β-Ga2O3 and β-Ga2O3:In crystals (a) Absorption spectra of UID β-Ga2O3, opaque β-Ga2O3:9%In, transparent β-Ga2O3:9%In and transparent β-Ga2O3:15%In crystals; (b) Optical bandgap fitting of UID β-Ga2O3, transparent β-Ga2O3:9%In and transparent β-Ga2O3:15%In crystals

| [1] | ZHANG J, LI B, XIA C, et al. Growth and spectral characterization of β-Ga2O3 single crystals. Journal of Physics and Chemistry of Solids, 2006, 67(12): 2448. |

| [2] | TIPPINS H H. Optical absorption and photoconductivity in the band edge of β-Ga2O3. Physical Review, 1965, 140(1A): A316. |

| [3] | MATSUMOTO T, AOKI M, KINOSHITA A, et al. Absorption and reflection of vapor grown single crystal platelets of β-Ga2O3. Japanese Journal of Applied Physics, 1974, 13(10): 1578. |

| [4] | RICCI F, BOSCHI F, BARALDI A, et al. Theoretical and experimental investigation of optical absorption anisotropy in β-Ga2O3. Journal of Physics: Condensed Matter, 2016, 28(22): 224005. |

| [5] | ONUMA T, SAITO S, SASAKI K, et al. Valence band ordering in β-Ga2O3 studied by polarized transmittance and reflectance spectroscopy. Japanese Journal of Applied Physics, 2015, 54(11): 112601. |

| [6] | HE N, TANG H, LIU B, et al. Ultra-fast scintillation properties of β-Ga2O3 single crystals grown by floating zone method. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2018, 888: 9. |

| [7] | GALAZKA Z, GANSCHOW S, SEYIDOV P, et al. Two inch diameter, highly conducting bulk β-Ga2O3 single crystals grown by the Czochralski method. Applied Physics Letters, 2022, 120(15): 152101. |

| [8] | UEDA Y, IGARASHI T, KOSHI K, et al. Two-inch Fe-doped β-Ga2O3 (010) substrates prepared using vertical bridgman method. Japanese Journal of Applied Physics, 2023, 62: SF1006. |

| [9] | TANG H, HE N, ZHANG H, et al. Inhibition of volatilization and polycrystalline cracking, and the optical properties of β-Ga2O3 grown by the EFG method. CrystEngComm, 2020, 22(5): 924. |

| [10] | LI Z, CHEN J, TANG H, et al. Band gap engineering in β-Ga2O3 for a high-performance X-ray detector. ACS Applied Electronic Materials, 2021, 3(10): 4630. |

| [11] | ZHANG C, TANG H, LI J, et al. Boltzmann thermometer with broadband emission in Mn4+-doped β-Ga2O3 crystals. Journal of Luminescence, 2024, 267: 120334. |

| [12] | XIAO H, SHAO G, SAI Q, et al. Wide Bandgap engineering of β-(Al, Ga)2O3 mixed crystals. Journal of Inorganic Materials, 2016, 31(11): 1258. |

| [13] | KPKUBUN Y, ABE T, NAKAGOMI S. Sol-Gel prepared (Ga1-xInx)2O3 thin films for solar-blind ultraviolet photodetectors. Physica Status Solidi (a), 2010, 207(7): 1741. |

| [14] | SEACAT S, LYONS J L, PEELAERS H. Properties of orthorhombic Ga2O3 alloyed with In2O3 and Al2O3. Applied Physics Letters, 2021, 119(4): 042104. |

| [15] | SHAIK E B, KAMAL C S, SRINIVASU K, et al. Optical insights of indium-doped β-Ga2O3 nanoparticles and its luminescence mechanism. Journal of Materials Science: Materials in Electronics, 2020, 31(8): 6185. |

| [16] | LIN T, XIE C, YANG S, et al. Investigation on the bandgap- adjustable (Ga1-xInx)2O3 film prepared by magnetron sputtering. ACS Applied Electronic Materials, 2024, 6(3): 1858. |

| [17] | SUN S M, LIU W J, WANG Y P, et al. Band alignment of In2O3/ β-Ga2O3 interface determined by X-ray photoelectron spectroscopy. Applied Physics Letters, 2018, 113(3): 031603. |

| [18] | TANG H, WU Q, LUO P, et al. Growth and property of In:Ga2O3 oxide semiconductor single crystal. Journal of Inorganic Materials, 2017, 32(6): 621. |

| [19] | GALAZKA Z, UECKER R, IRMSCHER K, et al. Melt growth, characterization and properties of bulk In2O3 single crystals. Journal of Crystal Growth, 2013, 362: 349. |

| [20] | OSHIMA T, FUJITA S. Properties of Ga2O3-based (InxGa1-x)2O3 alloy thin films grown by molecular beam epitaxy. Physica Status Solidi (c), 2008, 5(9): 3113. |

| [21] | ZHANG F, SAITO K, TANAKA T, et al. Wide bandgap engineering of (GaIn)2O3 films. Solid State Communications, 2014, 186: 28. |

| [22] | ZHANG F, SUN J, LI H, et al. Band-gap tunable (GaxIn1-x)2O3 layer grown by magnetron sputtering. Frontiers of Information Technology & Electronic Engineering, 2021, 22(10): 1370. |

| [23] | VASYLTSIV V I, RYM Y I, ZAKHARKO Y M. Optical absorption and photoconductivity at the band edge of β-Ga2-xInxO3. Physica Status Solidi (b), 1996, 195(2): 653. |

| [24] | WU Q, TANG H, SU L, et al. Growth and properties of β-Ga2O3:In single crystal by optical floating zone method. Journal of the Chinese Ceramic Society, 2017, 45(4): 548. |

| [25] | LI Z, TANG H, LI Y, et al. Enhanced scintillation performance of β-Ga2O3 single crystals by Al3+ doping and its physical mechanism. Applied Physics Letters, 2022, 121(10): 102102. |

| [26] | TANG H, HE N, ZHU Z, et al. Temperature-dependence of X-ray excited luminescence of β-Ga2O3 single crystals. Applied Physics Letters, 2019, 115(7): 071904. |

| [27] | VARLEY J B, WEBER J R, JANOTTI A, et al. Oxygen vacancies and donor impurities in β-Ga2O3. Applied Physics Letters, 2010, 97(14): 142106. |

| [28] | WANG V, XIAO W, KANG L J, et al. Sources of n-type conductivity in GaInO3. Journal of Physics D: Applied Physics, 2015, 48(1): 015101. |

| [29] | VÍLLORA E G, YAMAGA M, INOUE T, et al. Optical spectroscopy study on β-Ga2O3. Japanese Journal of Applied Physics, 2002, 41: L622. |

| [30] | ISLAM M M, RANA D, HERNANDEZ A, et al. Study of trap levels in β-Ga2O3 by thermoluminescence spectroscopy. Journal of Applied Physics, 2019, 125(5): 055701. |

| [1] | CAI Hao, WANG Qihang, ZOU Zhaoyong. Crystallization Pathway of Monohydrocalcite via Amorphous Calcium Carbonate Regulated by Magnesium Ion [J]. Journal of Inorganic Materials, 2024, 39(11): 1275-1282. |

| [2] | HAO Yongxin, QIN Juan, SUN Jun, YANG Jinfeng, LI Qinglian, HUANG Guijun, XU Jingjun. Impact of Crucible Bottom Shape on the Growth of Congruent Lithium Niobate Crystals by Czochralski Method [J]. Journal of Inorganic Materials, 2024, 39(10): 1167-1174. |

| [3] | QIN Juan, LIANG Dandan, SUN Jun, YANG Jinfeng, HAO Yongxin, LI Qinglian, ZHANG Ling, XU Jingjun. Flat Shoulder Congruent Lithium Niobate Crystals Grown by the Czochralski Method [J]. Journal of Inorganic Materials, 2023, 38(8): 978-986. |

| [4] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [5] | YANG Jiaxue, LI Wen, WANG Yan, ZHU Zhaojie, YOU Zhenyu, LI Jianfu, TU Chaoyang. Spectroscopic and Yellow Laser Features of Dy3+: Y3Al5O12 Single Crystals [J]. Journal of Inorganic Materials, 2023, 38(3): 350-356. |

| [6] | WU Zhen, LI Huifang, ZHANG Zhonghan, ZHANG Zhen, LI Yang, LAN Jianghe, SU Liangbi, WU Anhua. Growth and Characterization of CeF3 Crystals for Magneto-optical Application [J]. Journal of Inorganic Materials, 2023, 38(3): 296-302. |

| [7] | QI Xuejun, ZHANG Jian, CHEN Lei, WANG Shaohan, LI Xiang, DU Yong, CHEN Junfeng. Macroscopic Defects of Large Bi12GeO20 Crystals Grown Using Vertical Bridgman Method [J]. Journal of Inorganic Materials, 2023, 38(3): 280-287. |

| [8] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| [9] | ZHANG Chaoyi, TANG Huili, LI Xianke, WANG Qingguo, LUO Ping, WU Feng, ZHANG Chenbo, XUE Yanyan, XU Jun, HAN Jianfeng, LU Zhanwen. Research Progress of ScAlMgO4 Crystal: a Novel GaN and ZnO Substrate [J]. Journal of Inorganic Materials, 2023, 38(3): 228-242. |

| [10] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [11] | WANG Haidong, WANG Yan, ZHU Zhaojie, LI Jianfu, LAKSHMINARAYANA Gandham, TU Chaoyang. Crystal Growth and Structural, Optical, and Visible Fluorescence Traits of Dy3+-doped SrGdGa3O7 Crystal [J]. Journal of Inorganic Materials, 2023, 38(12): 1475-1482. |

| [12] | MING Yue, HU Yue, MEI Anyi, RONG Yaoguang, HAN Hongwei. Application of Lead Acetate Additive for Printable Perovskite Solar Cell [J]. Journal of Inorganic Materials, 2022, 37(2): 197-203. |

| [13] | XU Jiayue, LI Zhichao, PAN Yunfang, ZHOU Ding, WEN Feng, MA Wenjun. Research Progress of Hyperstoichiometric UO2 Crystals [J]. Journal of Inorganic Materials, 2020, 35(11): 1183-1192. |

| [14] | Rong-Hui LI, Yi-Zheng JIA, Nan-Nan HU. 3D Hierarchical Flower Like Alumina Nanomaterials: Preparation and Arsenic Removal Performance [J]. Journal of Inorganic Materials, 2019, 34(5): 553-559. |

| [15] | WANG Dong-Hai, XUE Yan-Yan, LI Na, ZHOU Shi-Ming, XU Xiao-Dong, LI Dong-Zhen, XU Jun, WANG Qing-Guo. Micro-tube Sapphire Crystal Grown by the Edge-defined-film Fed Method [J]. Journal of Inorganic Materials, 2019, 34(12): 1290-1294. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||