Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (10): 1091-1099.DOI: 10.15541/jim20240161

Special Issue: 【信息功能】介电、铁电、压电材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

JIANG Qiang1,2( ), SHI Lizhi1, CHEN Zhengran1, ZHOU Zhiyong1, LIANG Ruihong1(

), SHI Lizhi1, CHEN Zhengran1, ZHOU Zhiyong1, LIANG Ruihong1( )

)

Received:2024-04-02

Revised:2024-05-05

Published:2024-10-20

Online:2024-05-16

Contact:

LIANG Ruihong, professor. E-mail: liangruihong@mail.sic.ac.cnAbout author:JIANG Qiang (1997-), male, Master candidate. E-mail: jiangqiang2009@126.com

Supported by:CLC Number:

JIANG Qiang, SHI Lizhi, CHEN Zhengran, ZHOU Zhiyong, LIANG Ruihong. Preparation and Properties of Hard PZT Piezoelectric Ceramics Poled above Curie Temperature and Multilayer Actuators[J]. Journal of Inorganic Materials, 2024, 39(10): 1091-1099.

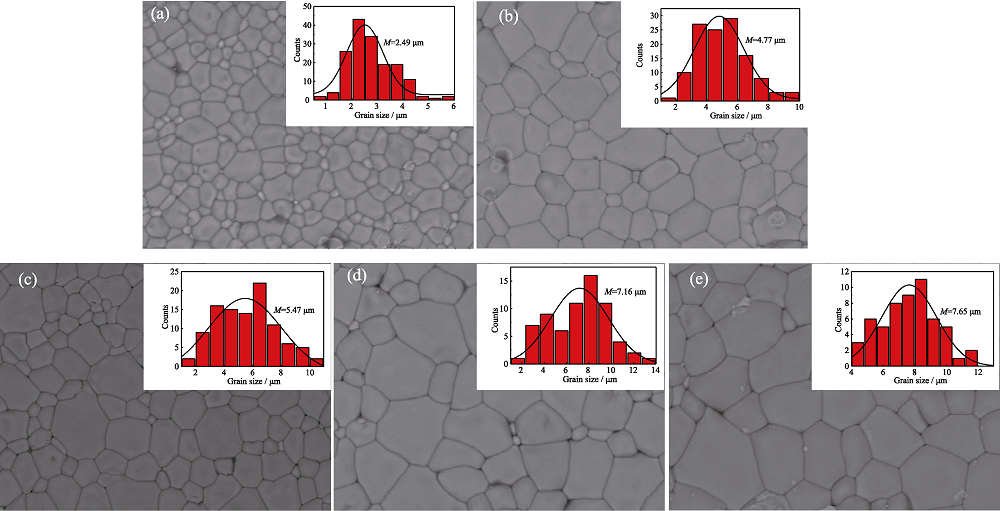

Fig. 3 Surface morphologies and distributions of grain sizes of PSN-PZT samples with different Li2CO3 additions (a) 0.05%; (b) 0.1%; (c) 0.2%; (d) 0.3%; (e) 0.5%. M: Mean particle diameter

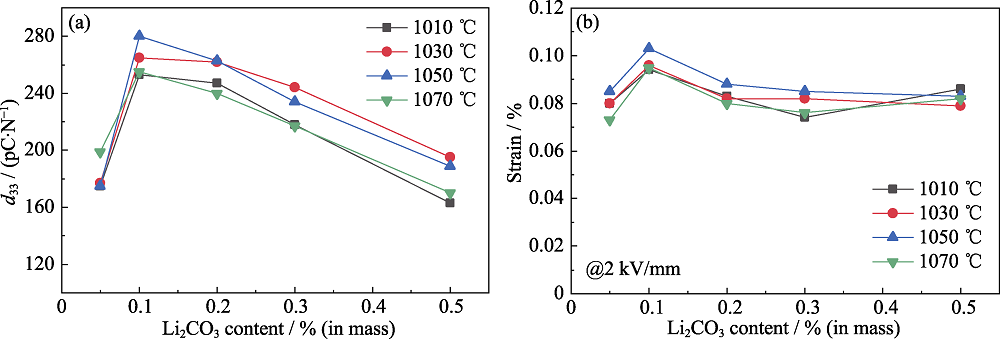

Fig. 4 Change of properties of PSN-PZT samples with Li2CO3 addition and sintering temperature (a) Piezoelectric coefficient d33; (b) Unipolar strain at 2 kV/mm

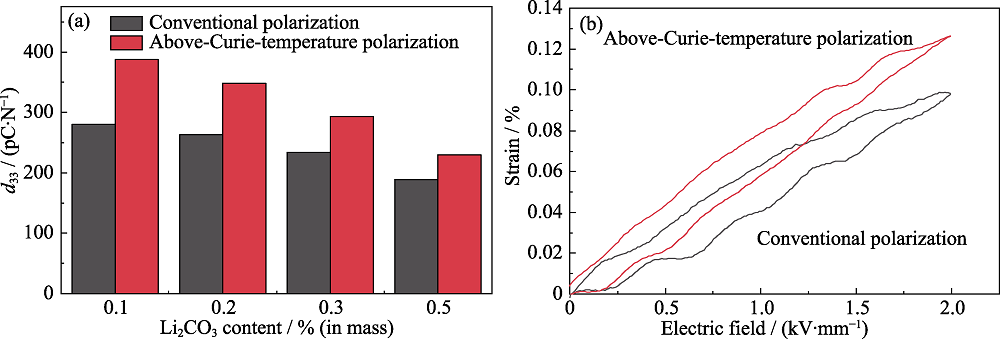

Fig. 6 Properties of PSN-PZT samples with different Li2CO3 additions under conventional polarization and above-Curie-temperature polarization (a) Piezoelectric coefficient d33; (b) Unipolar strain

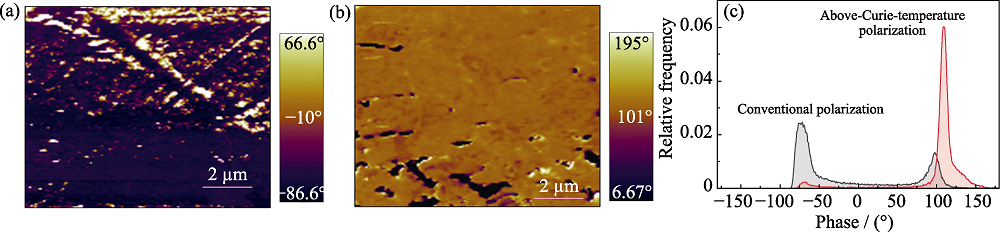

Fig. 7 Diagrams of domain structures (a, b) of PSN-PZT samples under conventional polarization (a) and above-Curie-temperature polarization (b), and their corresponding distributions of phases (c)

| Sample | Sintering temperature/℃ | d33/(pC·N-1) | kp | tanδ/% | Strain/%@2 kV/mm | Ref. |

|---|---|---|---|---|---|---|

| PSN-PZT-MnCO3-Li2CO3 | 1050 | 388 | 0.66 | 0.30 | 0.13 | This Work |

| PZT | 1250 | 210 | 0.52 | 1.2 | - | [ |

| PZT-Mn | 1230 | 180 | 0.62 | 0.80 | - | [ |

| PMS-PZT | 1240 | 374 | 0.60 | 0.41 | - | [ |

| PZT4 | >1200 | 289 | 0.70 | 0.4 | 0.02 | [ |

| PZT-PbO-WO3 | ~1100 | - | 0.25 | 0.35 | - | [ |

| PZT-ZnO | 1150 | 240 | 0.50 | 1.2 | - | [ |

| PBaSrZT-LiBiO2-CuO-MnCO3 | 900 | 255 | 0.58 | 0.58 | - | [ |

Table 1 Comparison of properties between piezoelectric ceramics in this work and literatures

| Sample | Sintering temperature/℃ | d33/(pC·N-1) | kp | tanδ/% | Strain/%@2 kV/mm | Ref. |

|---|---|---|---|---|---|---|

| PSN-PZT-MnCO3-Li2CO3 | 1050 | 388 | 0.66 | 0.30 | 0.13 | This Work |

| PZT | 1250 | 210 | 0.52 | 1.2 | - | [ |

| PZT-Mn | 1230 | 180 | 0.62 | 0.80 | - | [ |

| PMS-PZT | 1240 | 374 | 0.60 | 0.41 | - | [ |

| PZT4 | >1200 | 289 | 0.70 | 0.4 | 0.02 | [ |

| PZT-PbO-WO3 | ~1100 | - | 0.25 | 0.35 | - | [ |

| PZT-ZnO | 1150 | 240 | 0.50 | 1.2 | - | [ |

| PBaSrZT-LiBiO2-CuO-MnCO3 | 900 | 255 | 0.58 | 0.58 | - | [ |

| Sample | C/μF | tanδ/% |

|---|---|---|

| Hard PSN-PZT actuator | 0.32 | 0.45 |

| PMN-PZT actuator | 0.71 | 2.29 |

Table 2 Dielectric properties of the hard PSN-PZT and PMN-PZT actuators

| Sample | C/μF | tanδ/% |

|---|---|---|

| Hard PSN-PZT actuator | 0.32 | 0.45 |

| PMN-PZT actuator | 0.71 | 2.29 |

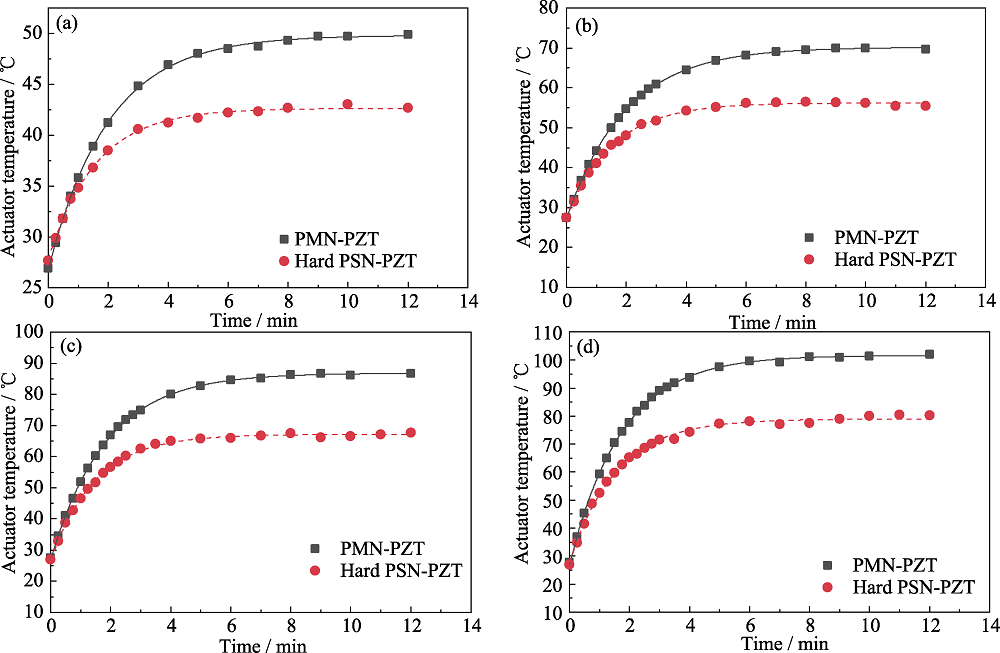

Fig. 10 Temperature rise of the hard PSN-PZT actuator and PMN-PZT actuator under 150 V driving voltage and various frequencies (a) 50 Hz; (b) 100 Hz; (c) 150 Hz; (d) 200 Hz

| [1] | TAKAHASHI S. Multilayer piezoelectric ceramic actuators and their applications. Japanese Journal of Applied Physics, 1985, 24: 41. |

| [2] | PRITCHARD J, BOWEN C R, LOWRIE F. Multilayer actuators. British Ceramic Transactions, 2001, 100(6): 265. |

| [3] | RANDALL C A, KELNBERGER A, YANG G Y, et al. High strain piezoelectric multilayer actuators—a material science and engineering challenge. Journal of Electroceramics, 2005, 14(3): 177. |

| [4] | SHERRIT S, JONES C M, ALDRICH J B, et al. Multilayer Piezoelectric Stack Actuator Characterization. SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, 2008: 53. |

| [5] | ŌHASHI J, FUDA Y F Y, OHNO T O T. Multilayer piezoelectric ceramic actuator with interdigital internal electrodes. Japanese Journal of Applied Physics, 1993, 32: 2412. |

| [6] | FURUKAWA T, ISHIDA K, FUKADA E. Piezoelectric properties in the composite systems of polymers and PZT ceramics. Journal of Applied Physics, 1979, 50(7): 4904. |

| [7] | BERLINCOURT D. Piezoelectric ceramics: characteristics and applications. Journal of the Acoustical Society of America, 1981, 70(6): 1586. |

| [8] | HOFFMANN M J, HAMMER M, ENDRISS A, et al. Correlation between microstructure, strain behavior, and acoustic emission of soft PZT ceramics. Acta Materialia, 2001, 49(7): 1301. |

| [9] | NGUYEN T N, THONG H C, ZHU Z X, et al. Hardening effect in lead-free piezoelectric ceramics. Journal of Materials Research, 2021, 36: 996. |

| [10] | WANG S F, DOUGHERTY J P, HUEBNER W, et al. Silver-palladium thick-film conductors. Journal of the American Ceramic Society, 1994, 77(12): 3051. |

| [11] | GAO L, GUO H, ZHANG S, et al. Base metal co-fired multilayer piezoelectrics. Actuators, 2016, 5(1): 8. |

| [12] | CORKER D L, WHATMORE R W, RINGGAARD E, et al. Liquid-phase sintering of PZT ceramics. Journal of the European Ceramic Society, 2000, 20(12): 2039. |

| [13] | LEE J S, PARK E C, LEE S H, et al. Conduction analysis of Li2O doped 0.2[Pb(Mg1/3Nb2/3)]-0.8[PbTiO3-PbZrO3] ceramics fabricated by columbite precursor method. Materials Chemistry and Physics, 2005, 90(2/3): 381. |

| [14] | LEE J Y, CHOI J W, KANG M G, et al. Effect of CuO addition on sintering temperature and piezoelectric properties of 0.05Pb- (Al0.5Nb0.5)O3-0.95Pb(Zr0.52Ti0.48)O3+0.7wt.%Nb2O5+0.5wt.%MnO2 ceramics. Journal of Electroceramics, 2009, 23(2/3/4): 572. |

| [15] | AHN C W, NAHM S, RYU J, et al. Effects of CuO and ZnO additives on sintering temperature and piezoelectric properties of 0.41Pb(Ni1/3Nb2/3)O3-0.36PbTiO3-0.23PbZrO3 ceramics. Japanese Journal of Applied Physics, 2004, 43: 205. |

| [16] | ZENG Y, YAO F, ZHANG G, et al. Effects of Bi2O3-Li2CO3 additions on dielectric and pyroelectric properties of Mn doped Pb(Zr0.9Ti0.1)O3 thick films. Ceramics International, 2013, 39(4): 3709. |

| [17] | CHEN H, PU T, FAN S, et al. Enhanced electrical properties in low-temperature sintering PNN-PMW-PZT ceramics by Yb2O3 doping. Materials Research Bulletin, 2022, 146: 111576. |

| [18] | CHAO X, YANG Z, LI G, et al. Fabrication and characterization of low temperature sintering PMN-PZN-PZT step-down multilayer piezoelectric transformer. Sensors and Actuators A: Physical, 2008, 144(1): 117. |

| [19] | NIELSEN E R, RINGGAARD E, KOSEC M. Liquid-phase sintering of Pb(Zr,Ti)O3 using PbO-WO3 additive. Journal of the European Ceramic Society, 2002, 22(11): 1847. |

| [20] | YOO J, LEE C, JEONG Y, et al. Microstructural and piezoelectric properties of low temperature sintering PMN-PZT ceramics with the amount of Li2CO3 addition. Materials Chemistry and Physics, 2005, 90(2/3): 386. |

| [21] | DONNELLY N J, SHROUT T R, RANDALL C A. Properties of (1-x)PZT-xSKN ceramics sintered at low temperature using Li2CO3. Journal of the American Ceramic Society, 2008, 91(7): 2182. |

| [22] | PU T, CHEN H, XING J, et al. High piezoelectricity of low- temperature sintered Li2CO3-added PNN-PZT relaxor ferroelectrics. Journal of Materials Science: Materials in Electronics, 2022, 33(8): 4819. |

| [23] | GERMAN R M, SURI P, PARK S J. Liquid phase sintering. Journal of Materials Science, 2009, 44: 1. |

| [24] | PICHT G, KHANSUR N H, WEBBER K G, et al. Grain size effects in donor doped lead zirconate titanate ceramics. Journal of Applied Physics, 2020, 128(21): 214105. |

| [25] | RANDALL C A, WANG S F, LAUBSCHER D, et al. Structure property relationships in core-shell BaTiO3-LiF ceramics. Journal of Materials Research, 1993, 8(4): 871. |

| [26] | ZHANG Q, YUE Y, NIE R, et al. Achieving both high d33 and high TC in low-temperature sintering Pb(Ni1/3Nb2/3)O3-Pb(Mg1/2W1/2)O3-Pb- (Zr0.5Ti0.5)O3 ceramics using Li2CO3. Materials Research Bulletin, 2017, 85: 96. |

| [27] | DU G, LIANG R H, LI T, et al. Recent progress on defect dipoles characteristics in piezoelectric materials. Journal of Inorganic Materials, 2013, 28(2): 123. |

| [28] | LI B, BLENDELL J E, BOWMAN K J. Temperature-dependent poling behavior of lead-free BZT-BCT piezoelectrics. Journal of the American Ceramic Society, 2011, 94(10): 3192. |

| [29] | DONG D, MURAKAMI K, KANEKO S, et al. Piezoelectric properties of PZT ceramics sintered at low temperature with complex-oxide additives. Journal of the Ceramic Society of Japan, 1993, 101(1178): 1090. |

| [30] | EYRAUD L, GUIFFARD B, LEBRUN L, et al. Interpretation of the softening effect in PZT ceramics near the morphotropic phase boundary. Ferroelectrics, 2006, 330(1): 51. |

| [31] | ZHU Z G, LI B S, LI G R, et al. Microstructure and piezoelectric properties of PMS-PZT ceramics. Materials Science and Engineering: B, 2005, 117(2): 216. |

| [32] | ZHANG S, LIM J B, LEE H J, et al. Characterization of hard piezoelectric lead-free ceramics. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2009, 56(8): 1523. |

| [33] | LI H B, LI Y, WANG D W, et al. Effects of ZnO nanoneedles addition on the mechanical and piezoelectric properties of hard PZT-based composites. Journal of Materials Science: Materials in Electronics, 2013, 24: 1463. |

| [34] | DU Z, ZHAO C, THONG H C, et al. Effect of MnCO3 on the electrical properties of PZT-based piezoceramics sintered at low temperature. Journal of Alloys and Compounds, 2019, 801: 27. |

| [35] | ZHENG J, TAKAHASHI S, YOSHIKAWA S, et al. Heat generation in multilayer piezoelectric actuators. Journal of the American Ceramic Society, 1996, 79(12): 3193. |

| [36] | YANG G, YUE Z X, LI L T. Research progress on the characteristics and mechanism of applied field-induced fatigue in piezoelectric ceramics. Journal of Inorganic Materials, 2007, 22(1): 1. |

| [1] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [2] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [3] | KE Xin, XIE Bingqing, WANG Zhong, ZHANG Jingguo, WANG Jianwei, LI Zhanrong, HE Huijun, WANG Limin. Progress of Interconnect Materials in the Third-generation Semiconductor and Their Low-temperature Sintering of Copper Nanoparticles [J]. Journal of Inorganic Materials, 2024, 39(1): 17-31. |

| [4] | FANG Ai-Hua, XIE Xiao-Ming, HUANG Fu-Qiang, JIANG Mian-Heng. High Upper Critical Field of Sm0.85Nd0.15FeAsO0.85F0.15 Superconductors by Mechanical Alloying Synthesis [J]. Journal of Inorganic Materials, 2012, 27(4): 439-444. |

| [5] | LI Yue-Ming,SONG Ting-Ting,YOU Yuan,HU Yuan-Yun,LIU Wei-Liang,TANG Chun-Bao. Research on Low-temperature Sintering of Ca0.3(Li1/2Sm1/2)0.7TiO3 Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2008, 23(6): 1293-1297. |

| [6] | LIU Xiang-Chun,ZHAO Li-Li,GAO Feng,YAN Xiao-Bin,TIAN Chang-Sheng. Phase Transition and Grain Growth Kinetics of V2O5 and B2O3 Doped Zinc Titanate Ceramics [J]. Journal of Inorganic Materials, 2006, 21(4): 885-892. |

| [7] | WU Jun,XIE Chang-Sheng,HUANG Kai-Jin,WANG Ai-Hua,WANG Wen-Yan. Low Temperature Sintering of Doped ZnO-V2O5 Varistors [J]. Journal of Inorganic Materials, 2004, 19(1): 239-243. |

| [8] | LUO Ling-Hong,ZHOU He-Ping,HUANG He-Ji,WANG Shao-Hong. Development of Dielectric Materials and Processing for Mulitilayer Chip Inductors [J]. Journal of Inorganic Materials, 2001, 16(6): 1032-1040. |

| [9] | Xu Xiao-Lei,LI Wen-Lan,ZHUANG Han-Rui,Xu Su-Ying,Li Min-Zhong. Low-Temperature Sintering of Y-Li-Ca-Doped AlN Ceramics [J]. Journal of Inorganic Materials, 1999, 14(1): 175-179. |

| [10] | HE Xin-Hua,XIONG Mao-Ren,LING Zhi-Yuan,QIU Qi-Chun. Low-Temperature Sintering of NiCuZn Ferrite for Multilayer-chip Inductor [J]. Journal of Inorganic Materials, 1999, 14(1): 71-77. |

| [11] | WU Yin,ZHOU Her-Ping,MIAO Wei-Guo,HAN Wei,XUE Hong-Lu. Characteristics of Low-Temperature Sintering of Shocked Aluminium Nitride Powder [J]. Journal of Inorganic Materials, 1998, 13(2): 229-233. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||