Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (9): 925-932.DOI: 10.15541/jim20210720

• RESEARCH ARTICLE • Next Articles

AN Wenran( ), HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang(

), HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang( )

)

Received:2021-11-22

Revised:2022-01-19

Published:2022-09-20

Online:2022-02-14

Contact:

CAO Xueqiang, professor. E-mail: xcao@whut.edu.cnAbout author:AN Wenran (1996-), female, Master candidate. E-mail: anwenran1019@126.com

Supported by:CLC Number:

AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating[J]. Journal of Inorganic Materials, 2022, 37(9): 925-932.

| Coating | Spray distance/mm | Power/kW | Current/A | Plasma gas Ar/H2/slpm* | Gun velocity/(mm∙s-1) | Feeding rate/(g∙min-1) |

|---|---|---|---|---|---|---|

| LMA | 100 | 42 | 620 | 35/12 | 800 | 35 |

Table 1 Parameters of air plasma spraying

| Coating | Spray distance/mm | Power/kW | Current/A | Plasma gas Ar/H2/slpm* | Gun velocity/(mm∙s-1) | Feeding rate/(g∙min-1) |

|---|---|---|---|---|---|---|

| LMA | 100 | 42 | 620 | 35/12 | 800 | 35 |

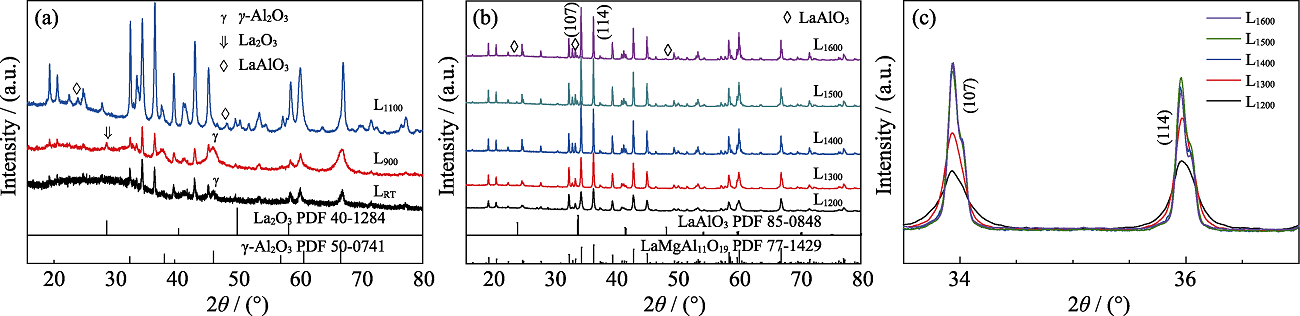

Fig. 3 XRD patterns of LMA coatings after heat-treatement at different temperatures (a) Lrt, L900, L1100; (b) L1200, L1300, L1400, L1500, and L1600; (c) Local magnification XRD patterns at 2θ between 33.5°-37° of (b)

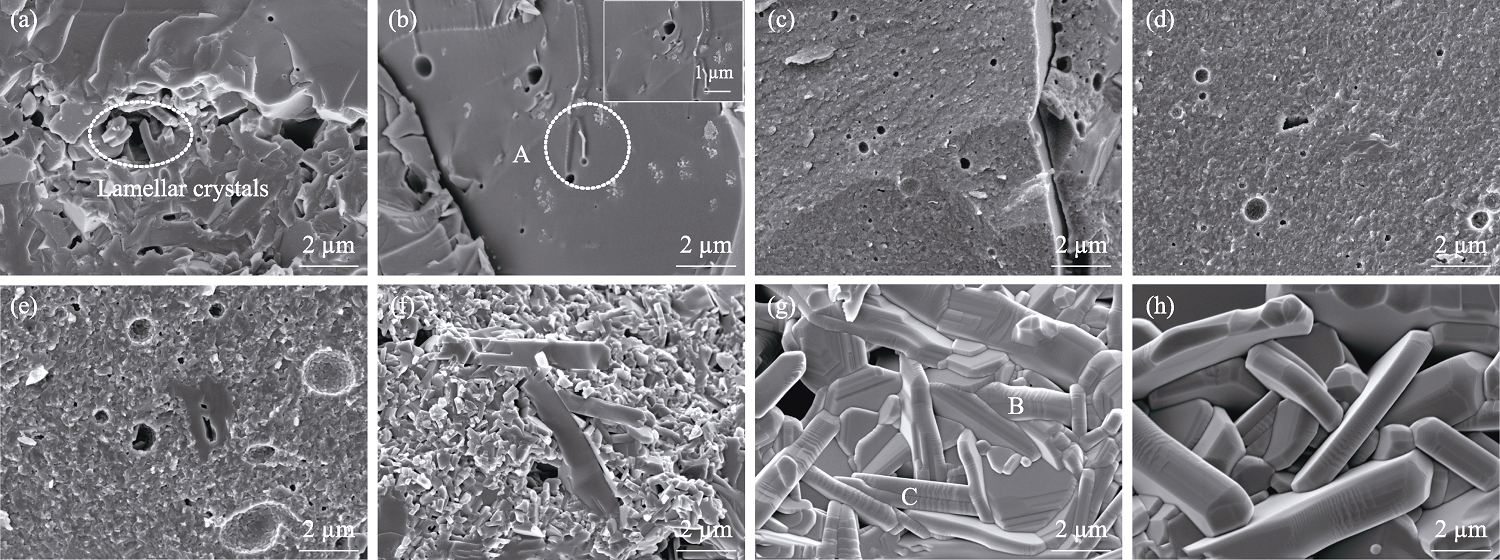

Fig. 4 Fractured cross-section morphologies of LMA coatings after heat-treatement at different temperatures (a) Lrt; (b) L900; (c) L1100; (d) L1200; (e) L1300; (f) L1400; (g) L1500; (h) L1600

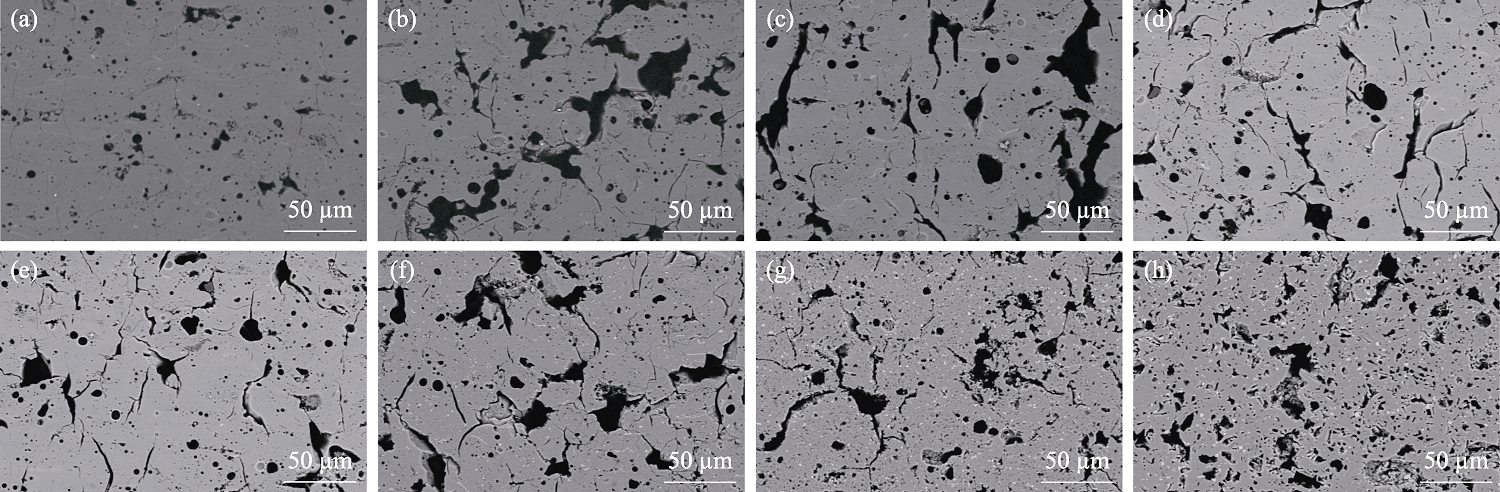

Fig. 6 Cross-sectional morphologies of LMA coatings after heat-treatement at different temperatures (a) Lrt; (b) L900; (c) L1100; (d) L1200; (e) L1300; (f) L1400; (g) L1500; (h) L1600

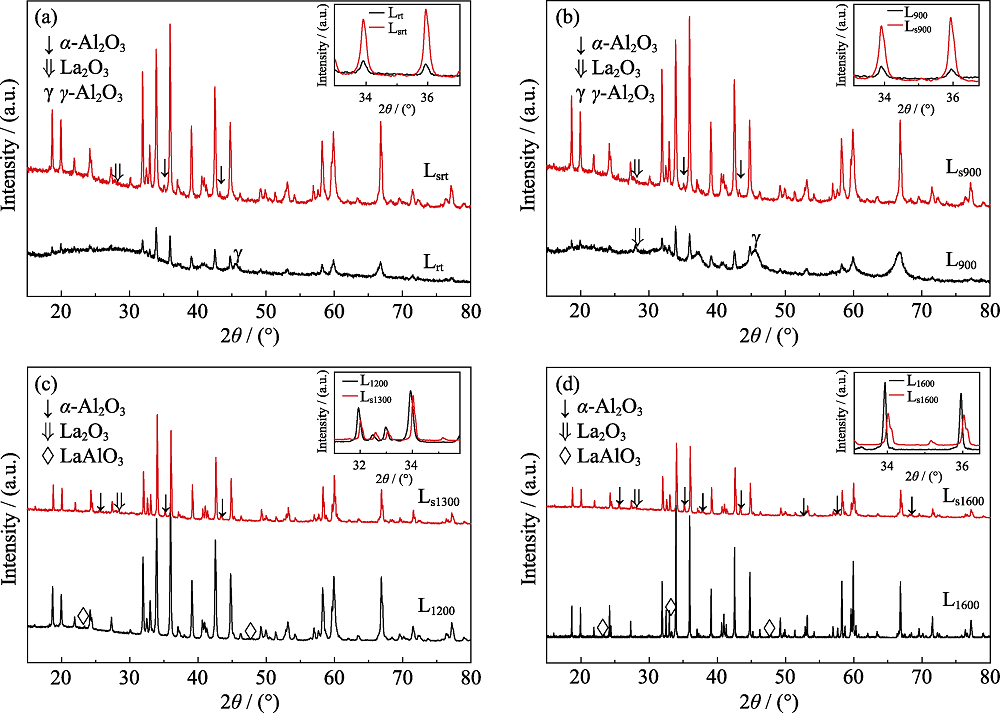

Fig. 10 Comparisons of XRD patterns of coatings before and after thermal shock (a) Lrt and Lsrt; (b) L900 and Ls900; (c) L1300 and Ls1300; (d) L1600 and Ls1600

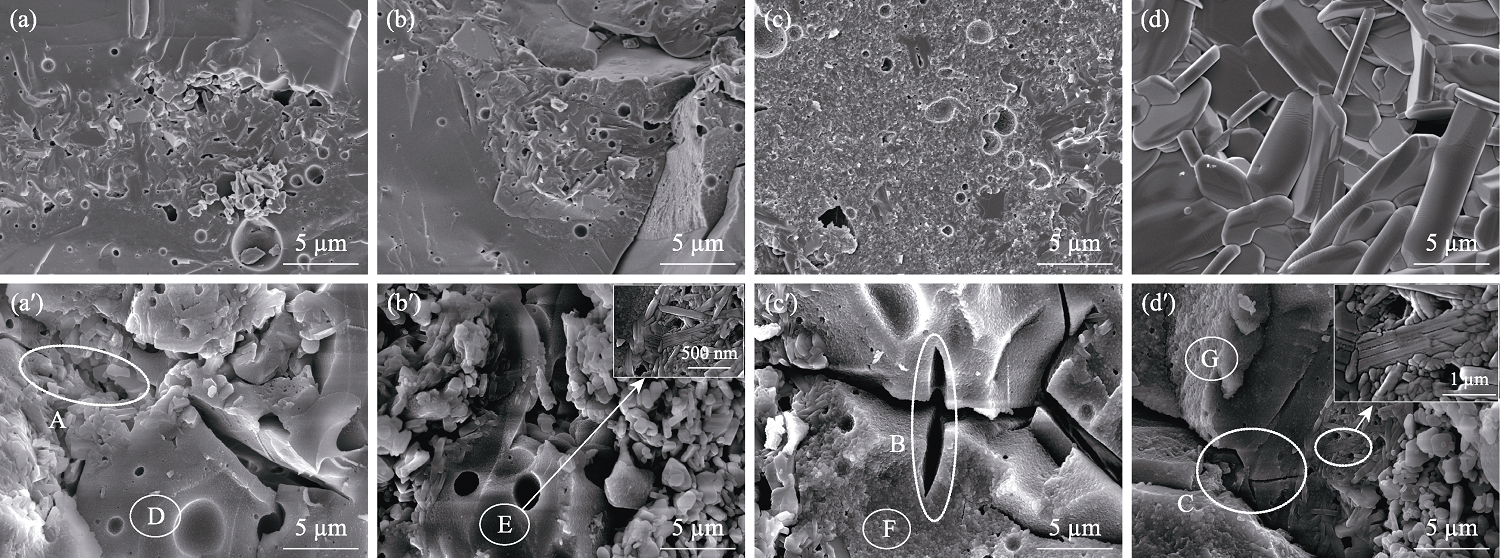

Fig. 11 Fractured cross-sectional morphologies of coatings before and after thermal shock (a) Lrt; (a′) Lsrt; (b) L900; (b′) Ls900; (c) L1300; (c′) Ls1300; (d) L1600; (d′) Ls1600

| HV/GPa | Lrt | L900 | L1300 | L1600 |

|---|---|---|---|---|

| Before | 6.61 | 6.56 | 11.08 | 6.76 |

| After | 10.12 | 10.89 | 12.07 | 11.01 |

Table 2 Vickers hardness of coatings before and after thermal shock

| HV/GPa | Lrt | L900 | L1300 | L1600 |

|---|---|---|---|---|

| Before | 6.61 | 6.56 | 11.08 | 6.76 |

| After | 10.12 | 10.89 | 12.07 | 11.01 |

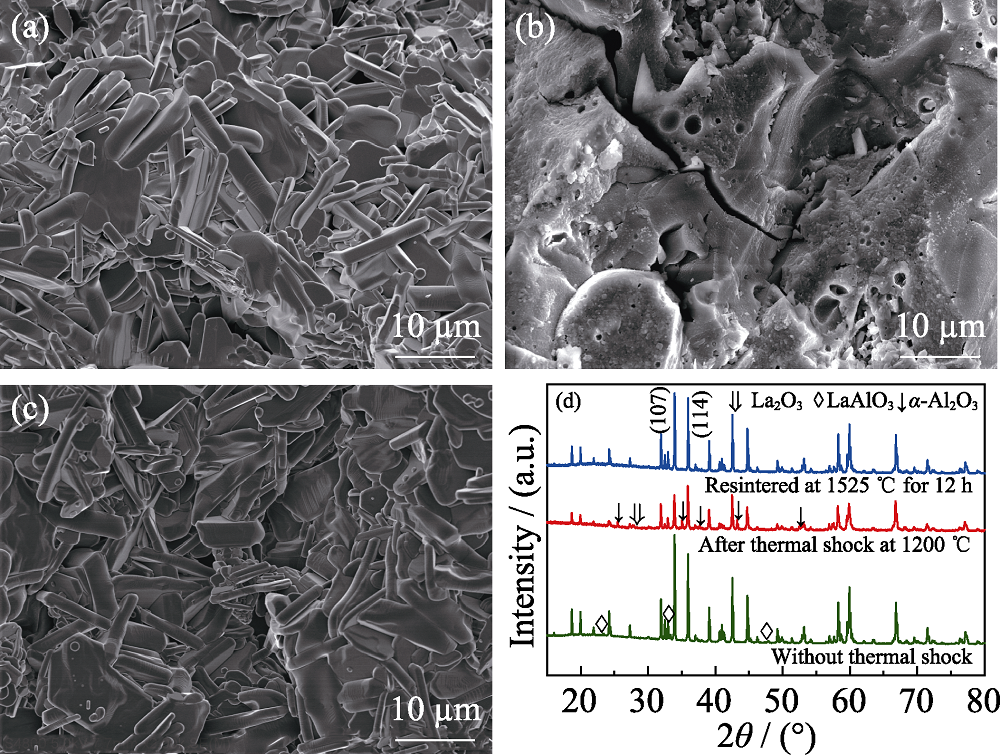

Fig. 12 (a-c) Fractured cross-section morphologies and (d) XRD patterns of L1600 heat-treatement at different conditions (a) L1600; (b) Ls1600; (c) Ls1600-1525

| [1] |

CAO X Q, VASSEN R, STOEVER D. Ceramic materials for thermal barrier coatings. Journal of the European Ceramic Society, 2004, 24(1): 1-10.

DOI URL |

| [2] |

CLARKE D R, OECHSNER M, PADTURE N P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891-902.

DOI URL |

| [3] | CLARKE D R, PHILLPOT S R. Thermal barrier coating materials. Materials Today, 2005, 8(6): 22-29. |

| [4] |

EVANS A G, CLARKE D R, LEVI C G. The influence of oxides on the performance of advanced gas turbines. Journal of the European Ceramic Society, 2008, 28(7): 1405-1419.

DOI URL |

| [5] | MAO W G, LUO J M, DAI C Y, et al. Effect of heat treatment on deformation and mechanical properties of 8mol% yttria-stabilized zirconia by berkovich nanoindentation. Applied Surface Science, 2015, 338: 92-98. |

| [6] |

ZHOU X, HE L M, CAO X Q, et al. La2(Zr0.7Ce0.3)2O7 thermal barrier coatings prepared by electron beam-physical vapor deposition that are resistant to high temperature attack by molten silicate. Corrosion Science, 2016, 115(16): 143-151.

DOI URL |

| [7] |

ZHOU F F, WANG Y, CUI Z Y, et al. Thermal cycling behavior of nanostructured 8YSZ, SZ/8YSZ and 8CSZ/8YSZ thermal barrier coatings fabricated by atmospheric plasma spraying. Ceramics International, 2017, 43(5): 4102-4111.

DOI URL |

| [8] |

HUANG L L, MENG H M, TANG J. Crystallization behavior of plasma-sprayed lanthanide magnesium hexaaluminate coatings. International Journal of Minerals, Metallurgy and Materials, 2014, 21(12): 1247-1253.

DOI URL |

| [9] |

LU H R, WANG C A, ZHANG C G, et al. Thermo-physical properties of rare-earth hexaaluminates LnMgAl11O19 (Ln: La, Pr, Nd, Sm, Eu and Gd) magnetoplumbite for advanced thermal barrier coatings. Journal of the European Ceramic Society, 2015, 35(4): 1297-1306.

DOI URL |

| [10] |

KINGERY W D, MCQUARRIE M C. Thermal conductivity: i, concepts of measurement and factors affecting thermal conductivity of ceramic materials. Journal of the American Ceramic Society, 1954, 37(2): 67-72.

DOI URL |

| [11] | LIU H Z, OUYANG J H, LIU Z G, et al. Microstructure, thermal shock resistance and thermal emissivity of plasma sprayed LaMAl11O19 (M=Mg, Fe) coatings for metallic thermal protection systems. Applied Surface Science, 2013, 217: 52-59. |

| [12] |

CAO X Q, ZHANG Y F, ZHANG J F, et al. Failure of the plasma-sprayed coating of lanthanum hexaluminate. Journal of the European Ceramic Society, 2008, 28(10): 1979-1986.

DOI URL |

| [13] |

SUN J B, WANG J S, ZHOU X, et al. Thermal cycling behavior of the plasma-sprayed coating of lanthanum hexaaluminate. Journal of the European Ceramic Society, 2018, 38(4): 1919-1929.

DOI URL |

| [14] |

ZENG J Y, SUN J B, LIANG P P, et al. Heat-treated lanthanum magnesium hexaaluminate coatings exposed to molten calcium- magnesium-alumino-silicate. Ceramics International, 2019, 45(9): 11723-11733.

DOI URL |

| [15] | SUN J B, WANG J S, DONG S J, et al. Effect of heat treatment on microstructure and property of plasma-sprayed lanthanum hexaaluminate coating. Journal of Alloys and Compounds, 2018, 739: 856-865. |

| [16] |

CHAO C Y, REN Z H, ZHU Y H, et al. Self-templated synthesis of single-crystal and single-domain ferroelectric nanoplates. Angewandte Chemie International Edition, 2012, 51(37): 9283-9287.

DOI URL |

| [17] |

SUN J B, WANG J S, ZHOU X, et al. Microstructure and thermal cycling behavior of plasma-sprayed LaMgAl11O19 coatings. Ceramics International, 2018, 44(5): 5572-5580.

DOI URL |

| [18] |

DOMINGUEZ C, CHEVALIER J, TORRECILLAS R, et al. Microstructure development in calcium hexaluminate. Journal of the European Ceramic Society, 2001, 21(3): 381-387.

DOI URL |

| [19] | SUN X M, DU L Z, LAN H, et al. Study on thermal shock behavior of YSZ abradable sealing coating prepared by mixed solution precursor plasma spraying. Surface & Coatings Technology, 2020, 397: 126045. |

| [20] |

ZHOU X, SONG W J, YUAN J Y, et al. Thermophysical properties and cyclic lifetime of plasma sprayed SrAl12O19 for thermal barrier coating applications. Journal of the American Ceramic Society, 2020, 103(10): 5599-5611.

DOI URL |

| [21] |

TARASI F, MEDRAJ M, DOLATABADI A, et al. High- temperature performance of alumina-zirconia composite coatings containing amorphous phases. Advanced Functional Materials, 2011, 21(21): 4143-4151.

DOI URL |

| [22] |

CHEN X L, ZHANG Y F, ZHONG X H, et al. Thermal cycling behaviors of the plasma sprayed thermal barrier coatings of hexaluminates with magnetoplumbite structure. Journal of the European Ceramic Society, 2010, 30(7): 1649-1657.

DOI URL |

| [23] | 杨晓洁, 常雪婷, 范润华. 快速多重旋转碾压诱导Ti-6Al-4V 表面纳米晶及性能研究. 表面技术, 2021, 50(5): 177-183. |

| [24] |

ARAI Y, INOUE R, KAKISAWA H. Anisotropic crack propagation behavior for the silicon-bond coat layer in a multilayer coated system. International Journal of Applied Ceramic Technology, 2021, 18(3): 947-956.

DOI URL |

| [25] |

SONG X M, SUHONEN T, SUN C, et al. Microstructures, microhardness, and crystallization behaviors of amorphous Al2O3- YSZ coatings prepared by air plasma spraying. Surface Review and Letters, 2015, 22(4): 1550047.

DOI URL |

| [1] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [2] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [3] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [4] | ZHU Yong, GU Jun, YU Tao, HE Haitong, YAO Rui. Synthesis and Property of Platinum-cobalt Alloy Nano Catalyst [J]. Journal of Inorganic Materials, 2021, 36(3): 299-305. |

| [5] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [6] | Bo-Le MA, Wen MA, Wei HUANG, Yu BAI, Rui-Ling JIA, Hong-Ying DONG. Thermophysical Property of Single-phase Strontium Zirconate Co-doped with Double Rare-earth Oxides as a Thermal Barrier Coating Material [J]. Journal of Inorganic Materials, 2019, 34(4): 394-400. |

| [7] | WANG Lin, DING Kun-Ying, LIN Xiao-Ping, LI Ze, ZHENG Run-Guo, YANG Lian-Wei. Defect Evolution and Microcracks of 8YSZ Double-layer Thermal Barrier Coatings by Water Immersion Ultrasound Macroscopic Detection [J]. Journal of Inorganic Materials, 2019, 34(12): 1265-1271. |

| [8] | QU Jing-Jing, WEI Xing, LIU Fei, YUAN Chang-Lai, CHEN Guo-Hua, HUANG Xian-Pei. Heat-treatment on Crystallization and Dielecty Property of Mg-Al-Si-Ti-B Glass-ceramics [J]. Journal of Inorganic Materials, 2018, 33(12): 1309-1315. |

| [9] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, DENG Chang-Guang, CHEN Huan-Tao. Thermal Shock Analysis of Surface Al-modified 7YSZ Nano-thermal Barrier Coatin [J]. Journal of Inorganic Materials, 2017, 32(9): 973-979. |

| [10] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [11] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [12] | LI Jian, CHEN Bao-Rong, ZHOU Hong-Ming. Effects of Washing and Heat-treatment on Structure and Electrochemical Charge/Discharge Property of LiNi0.8Co0.15Al0.05O2 Powder [J]. Journal of Inorganic Materials, 2016, 31(7): 773-778. |

| [13] | MA Rong-Bin, CHENG Xu-Dong, ZOU Jun, LI Qing-Yu, HUANG Xia. Toughness and Thermal Shock of SiC Fiber/Yttria-stabilized-zirconia Composite Thick Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2016, 31(2): 190-194. |

| [14] | ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, HAN Tao, Song Jin-Bing, LIU-Min. Erosion Failure Mechanism and Model Establishment of Thermal Barrier Coatings Based on Roughness [J]. Journal of Inorganic Materials, 2014, 29(3): 294-300. |

| [15] | YANG Bin, LI Lin-Yan, FAN Min-Guang, LI Bin, XU Sheng-Ming, WANG Jian-Long, LIN Xu-Ping. Synthesis and Thermophysical Properties of (La1-xMgx)2Ce2O7-x [J]. Journal of Inorganic Materials, 2014, 29(12): 1301-1305. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||