Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (6): 693-698.DOI: 10.15541/jim20180028

• Orginal Article • Previous Articles

ZHENG Guo-Yuan1,2, LI Jia-Cheng1, SONG Li-Xin1, ZHANG Tao1

Received:2018-01-18

Published:2018-06-20

Online:2018-05-24

About author:ZHENG Guo-Yuan (1992–), male, candidate of Master degree. E-mail: weloveapple@126.com

CLC Number:

ZHENG Guo-Yuan, LI Jia-Cheng, SONG Li-Xin, ZHANG Tao. Simulation on Potassium Ion Concentration Profile of Engineered Stress Profile Glass by FDTD Method[J]. Journal of Inorganic Materials, 2018, 33(6): 693-698.

| Batch Code | First-step process (Salt 1) | Second-step process (Salt 2) |

|---|---|---|

| P0 | - | - |

| P1 | 450℃, 42 h | 400℃, 15 min |

| P2 | 450℃, 42 h | 400℃, 30 min |

| P3 | 450℃, 42 h | 400℃, 1 h |

| P4 | 450℃, 42 h | 400℃, 2 h |

| D1 | 450℃, 42 h | - |

| D2 | - | 400℃, 12 h |

| D3 | - | 350℃, 12 h |

Table 1 The various treatments of the samples

| Batch Code | First-step process (Salt 1) | Second-step process (Salt 2) |

|---|---|---|

| P0 | - | - |

| P1 | 450℃, 42 h | 400℃, 15 min |

| P2 | 450℃, 42 h | 400℃, 30 min |

| P3 | 450℃, 42 h | 400℃, 1 h |

| P4 | 450℃, 42 h | 400℃, 2 h |

| D1 | 450℃, 42 h | - |

| D2 | - | 400℃, 12 h |

| D3 | - | 350℃, 12 h |

| Temperature/℃ | 450 | 400 | 350 |

|---|---|---|---|

| D/(m2•s-1) | 2.27×10-14 | 4.25×10-15 | 9.63×10-16 |

Table 2 Diffusion coefficients at 450℃, 400℃ and 350℃

| Temperature/℃ | 450 | 400 | 350 |

|---|---|---|---|

| D/(m2•s-1) | 2.27×10-14 | 4.25×10-15 | 9.63×10-16 |

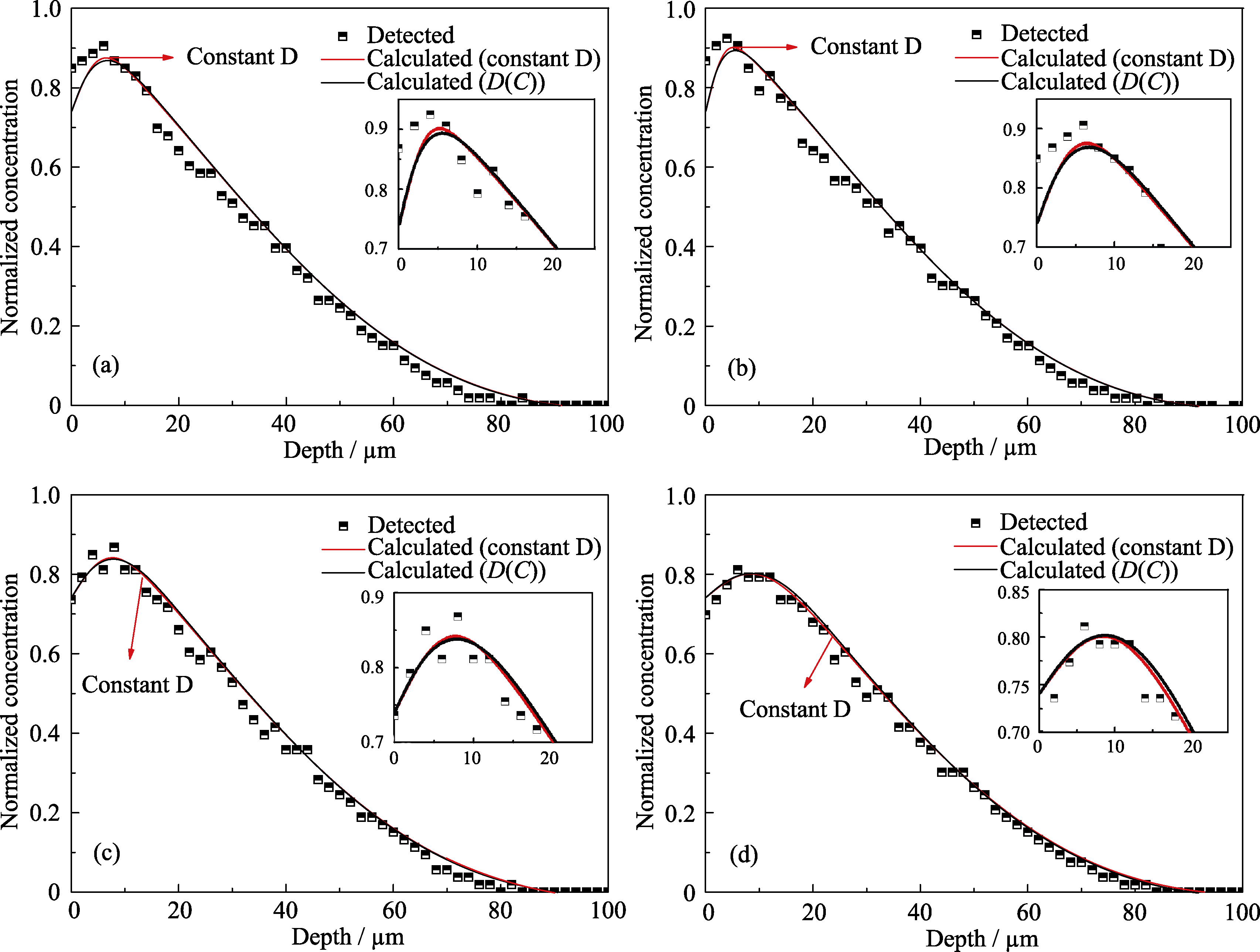

Fig. 5 Measured and calculated K+ profiles in two-step ion-exchanged glass with different processing time of the second step(a) 15 min; (b) 30 min; (c) 1 h; (d) 2 h

| Code | Simulation result*1 | Bend strength (16 pieces) | Variation coefficient*2 | Weibull modulus | |

|---|---|---|---|---|---|

| Peak value | g/µm-1 | ||||

| P0 | - | - | 100.32 MPa | 18.0% | 8.38 |

| D1 | - | - | 471.28 MPa | 5.28% | 22.98 |

| P1 | 0.90129 | 0.031292 | 469.16 MPa | 4.05% | 28.34 |

| P2 | 0.86847 | 0.019208 | 468.88 MPa | 2.08% | 54.51 |

| P3 | 0.83794 | 0.012338 | 460.61 MPa | 2.55% | 45.43 |

| P4 | 0.80203 | 0.007056 | 430.86 MPa | 2.74% | 42.32 |

Table 3 The relation between peak value, general gradient g (numerical simulation results) and strength property of the ESP glass

| Code | Simulation result*1 | Bend strength (16 pieces) | Variation coefficient*2 | Weibull modulus | |

|---|---|---|---|---|---|

| Peak value | g/µm-1 | ||||

| P0 | - | - | 100.32 MPa | 18.0% | 8.38 |

| D1 | - | - | 471.28 MPa | 5.28% | 22.98 |

| P1 | 0.90129 | 0.031292 | 469.16 MPa | 4.05% | 28.34 |

| P2 | 0.86847 | 0.019208 | 468.88 MPa | 2.08% | 54.51 |

| P3 | 0.83794 | 0.012338 | 460.61 MPa | 2.55% | 45.43 |

| P4 | 0.80203 | 0.007056 | 430.86 MPa | 2.74% | 42.32 |

| [1] | LAWN B R.Fracture of Brittle Solids. Cambridge, UK: Cambridge Univ. Press, 1993. |

| [2] | GRIFFITH A A.The phenomona of rupture and flow in solid.Phil. Trans. R. Soc. Lond. A, 1920, 221(4): 163-190. |

| [3] | WEIBULL W.A statistical distribution function of wide applicability.J. Appl. Mech.-Trans. ASME, 1951, 18(3): 293-297. |

| [4] | DENG B, JIANG D.Determination of the weibull parameters from the mean value and the coefficient of variation of the measured strength for brittle ceramics.Journal of Advanced Ceramics, 2017, 6(2): 149-156. |

| [5] | RAO M P, SANCHEZ-HERENCIA A J, BELTZ G E,et al. Laminar ceramics that exhibit a threshold strength. Science, 1999, 286(5437): 102-105. |

| [6] | FILLERY S P, LANGE F F.Ion-exchanged glass laminates that exhibit a threshold strength.J. Am. Ceram. Soc., 2007, 90(8): 2502-2509. |

| [7] | FAIR G E, LANGE F F.Ceramic composites with three-dimensional architectures designed to produce a threshold strength - I. Processing.J. Am. Ceram. Soc., 2005, 88(5): 1158-1164. |

| [8] | FAIR G E, HE M Y, MCMEEKING R M,et al., Ceramic composites with three-dimensional architectures designed to produce a threshold strength - II. Mechanical observations. J. Am. Ceram. Soc., 2005, 88(7): 1879-1885. |

| [9] | KARLSSON S, JONSON B, STALHANDSKE C.The technology of chemical glass strengthening - a review.Glass Technol.-Eur. J. Glass Sci. Technol. Part A, 2010, 51: 41-54. |

| [10] | VARSHNEYA A K.Chemical strengthening of glass: lessons learned and yet to be learned.Int. J. Appl. Glass Sci., 2010, 1: 131-142. |

| [11] | TANDON R, GREEN D J.Crack stability and t-curves due to macroscopic residual compressive stress profiles.J. Am. Ceram. Soc., 1991, 74(8): 1981-1986. |

| [12] | GREEN D J, TANDON R, SGLAVO V M.Crack arrest and multiple cracking in class through the use of designed residual stress profiles.Science, 1999, 283(5406): 1295-1297. |

| [13] | SGLAVO V M, LARENTIS L, GREEN D J.Flaw-insensitive ion-exchanged glass: I, Theoretical aspects.J. Am. Ceram. Soc., 2001, 84(8): 1827-1831. |

| [14] | SGLAVO V M, GREEN D J.Flaw-insensitive ion-exchanged glass: II, Production and mechanical performance.J. Am. Ceram. Soc., 2001, 84(8): 1832-1838. |

| [15] | GREEN D J.Critical parameters in the processing of engineered stress profile glasses.J. Non-Cryst. Solids, 2003, 316(1): 35-41. |

| [16] | ABRAMS M B, GREEN D J.Prediction of crack propagation and fracture in residually stressed glass as a function of the stress profile and flaw size distribution.J. Eur. Ceram. Soc., 2006, 26(13): 2677-2684. |

| [17] | COOK R F, CLARKE D R.Fracture stability, r-curves and strength variability.Acta Metall., 1988, 36(3): 555-562. |

| [18] | SHETTY D K, WANG J S.Crack stability and strength distribution of ceramics that exhibit rising crack-growth-resistance (r-curve) behavior.J. Am. Ceram. Soc., 1989, 72(7): 1158-1162. |

| [19] | VARSHNEYA A K.Mechanical model to simulate buildup and relaxation of stress during glass chemical strengthening.J. Non-Cryst. Solids, 2016, 433: 28-30. |

| [20] | SHEN J W, GREEN D J.Prediction of stress profiles in ion exchanged glasses.J. Non-Cryst. Solids, 2004, 344(1/2): 79-87. |

| [21] | VARSHNEYA A K, OLSON G A, KRESKI P K,et, al. Buildup and relaxation of stress in chemically strengthened glass. J. Non-Cryst. Solids, 2015, 427: 91-97. |

| [22] | SHIDFAR A, AZARY H.An inverse problem for a nonlinear diffusion equation.Nonlinear Anal.-Theory Methods Appl., 1997, 28(4): 589-593. |

| [23] | FATULLAYEV A.Determination of unknown coefficient in nonlinear diffusion equation.Nonlinear Anal.-Theory Methods Appl., 2001, 44(3): 337-344. |

| [24] | SHEN J W, GREEN D J, PANTANO C G.Control of concentration profiles in two step ion exchanged glasses.Phys. Chem. Glasses, 2003, 44(4): 284-292. |

| [25] | MEHRER H.Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-controlled Processes. Berlin Heidelberg: Springer-Verlag, 2007. |

| [26] | LI X Y, JIANG L B, WANG Y, et al. Correlation between K+-Na+ diffusion coefficient and flexural strength of chemically tempered aluminosilicate glass. J. Non-Cryst. Solids, 2017, 471: 72-81. |

| [27] | MATANO C.On the relation between diffusion-coefficients and concentrations of solid metals.Japanese Journal of Physics, 1933, 8: 109-113. |

| [1] | WANG Zhixiang, CHEN Ying, PANG Qingyang, LI Xin, WANG Genshui. Sintering Behaviour and Dielectric Properties of MnCO3-doped MgO-based Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 97-103. |

| [2] | LI Guangyu, YUE Yifan, WANG Bo, ZHANG Chengyu, SUO Tao, LI Yulong. Damage of 2D-SiC/SiC Composites under Projectile Impact and Tensile Properties after Impact [J]. Journal of Inorganic Materials, 2024, 39(5): 494-500. |

| [3] | SHEN Bin, ZHANG Xu, XIONG Huai, LI Haiyuan, XIE Xinglong. Preparation and Optical Properties of Sol-Gel SiO2 Antireflective Films [J]. Journal of Inorganic Materials, 2024, 39(5): 525-530. |

| [4] | GUAN Haoyang, ZHANG Li, JING Kaikai, SHI Weigang, WANG Jing, LI Mei, LIU Yongsheng, ZHANG Chengyu. Interfacial Mechanical Properties of the Domestic 3rd Generation 2.5D SiCf/SiC Composite [J]. Journal of Inorganic Materials, 2024, 39(3): 259-266. |

| [5] | WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo. Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates [J]. Journal of Inorganic Materials, 2024, 39(1): 51-60. |

| [6] | JIN Sai, LIU Xiaogen, QI Shuang, ZHAO Runchang, LI Zhijun. Fused Silica Glass: Laser-induced Damage on Bending Strength Weakening and Safety Design [J]. Journal of Inorganic Materials, 2023, 38(6): 671-677. |

| [7] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [8] | HUA Siheng, YANG Dongwang, TANG Hao, YUAN Xiong, ZHAN Ruoyu, XU Zhuoming, LYU Jianan, XIAO Yani, YAN Yonggao, TANG Xinfeng. Effect of Surface Treatment of n-type Bi2Te3-based Materials on the Properties of Thermoelectric Units [J]. Journal of Inorganic Materials, 2023, 38(2): 163-169. |

| [9] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [10] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [11] | YANG Yanguo, REN Haishen, HE Daihua, LIN Huixing. Effect of Cation Field Strength on Structure and High-temperature Properties of BaO-SiO2-Ln2O3 Glass-ceramic [J]. Journal of Inorganic Materials, 2023, 38(10): 1207-1215. |

| [12] | LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating [J]. Journal of Inorganic Materials, 2022, 37(4): 467-472. |

| [13] | LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing [J]. Journal of Inorganic Materials, 2022, 37(3): 310-316. |

| [14] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [15] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||