Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (3): 287-293.DOI: 10.15541/jim20140397

• Orginal Article • Previous Articles Next Articles

ZHANG Xiao-Feng1, 2, ZHOU Ke-Song1, 2, SONG Jin-Bing2, DENG Chun-Ming2, NIU Shao-Peng1, 2, DENG Zi-Qian2

Received:2014-08-11

Revised:2014-09-29

Published:2015-03-20

Online:2015-03-06

About author:ZHANG Xiao-Feng. E-mail: zxf200808@126.com

CLC Number:

ZHANG Xiao-Feng, ZHOU Ke-Song, SONG Jin-Bing, DENG Chun-Ming, NIU Shao-Peng, DENG Zi-Qian. Deposition and CMAS Corrosion Mechanism of 7YSZ Thermal Barrier Coatings Prepared by Plasma Spray-Physical Vapor Deposition[J]. Journal of Inorganic Materials, 2015, 30(3): 287-293.

| Materials | Power /kW | Ar /slpm | N2 /slpm | Feed rate /(g?min-1) | Carrier Gas Ar /nlpm | Stand-off distance/mm | Pre-heating temperature/℃ | Chamber pressure /Pa |

|---|---|---|---|---|---|---|---|---|

| 7YSZ | 127 | 35 | 60 | 2×9 | 16 | 950 | 850 | 150 |

Table 1 Coating parameters of 7YSZ thermal barrier prepared by PS-PVD

| Materials | Power /kW | Ar /slpm | N2 /slpm | Feed rate /(g?min-1) | Carrier Gas Ar /nlpm | Stand-off distance/mm | Pre-heating temperature/℃ | Chamber pressure /Pa |

|---|---|---|---|---|---|---|---|---|

| 7YSZ | 127 | 35 | 60 | 2×9 | 16 | 950 | 850 | 150 |

| Oxides | CaO | MgO | Al2O3 | SiO2 | Rest (Fe2O3, Na2O, K2O, etc) |

|---|---|---|---|---|---|

| Weight /wt% | 2 | 21 | 17 | 42 | 18 |

Table 2 Compositions of vermiculite obtained by XRF

| Oxides | CaO | MgO | Al2O3 | SiO2 | Rest (Fe2O3, Na2O, K2O, etc) |

|---|---|---|---|---|---|

| Weight /wt% | 2 | 21 | 17 | 42 | 18 |

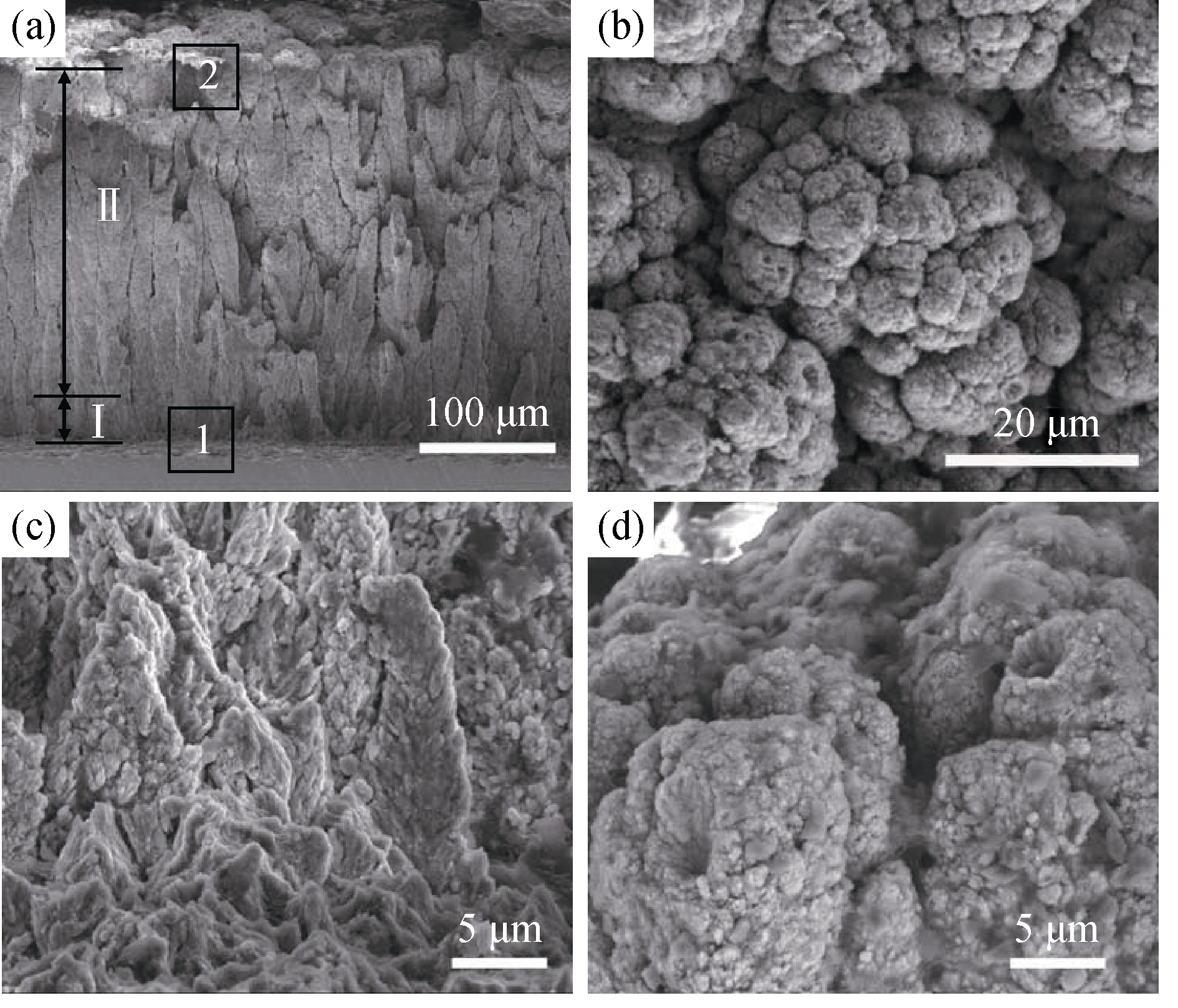

Fig. 2 Microstructures of 7YSZ coating prepared by PS-PVD (a) Cross-section view; (b) Surface; (c) Bottom view of cross-section area (1) and (d) Top view of cross-section area (2) in (a)

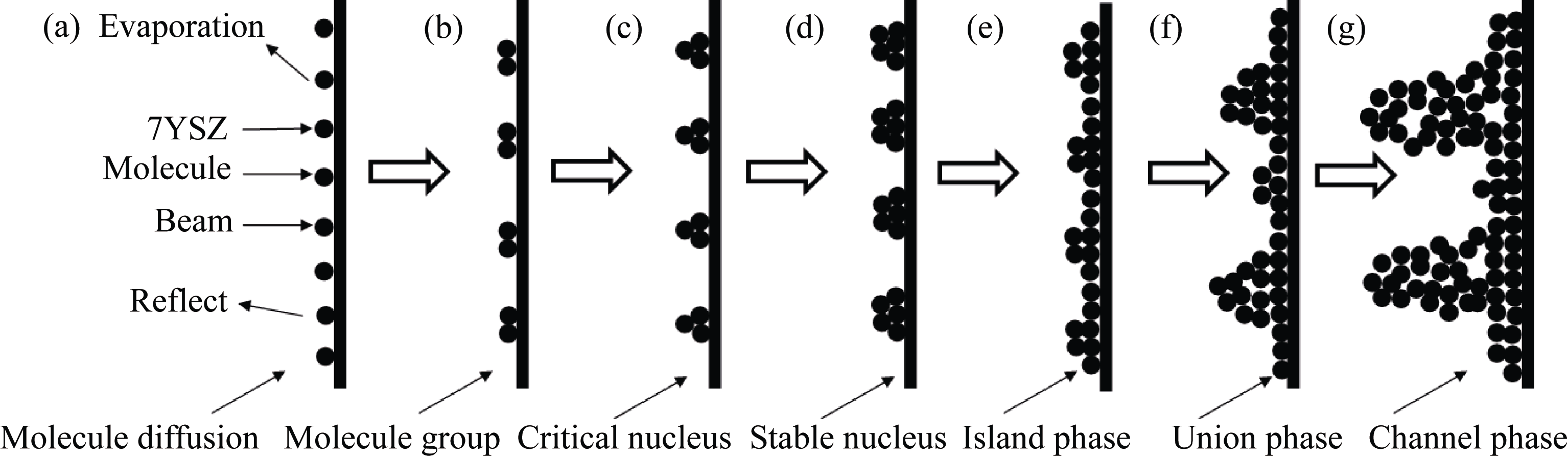

Fig. 3 Physical process of nucleus formation and grown (a) Molecule diffusion; (b) Molecule group; (c) Critical nucleus; (d) Stable nucleus; (e) Island phase; (f) Union phase; (g) Channel phase

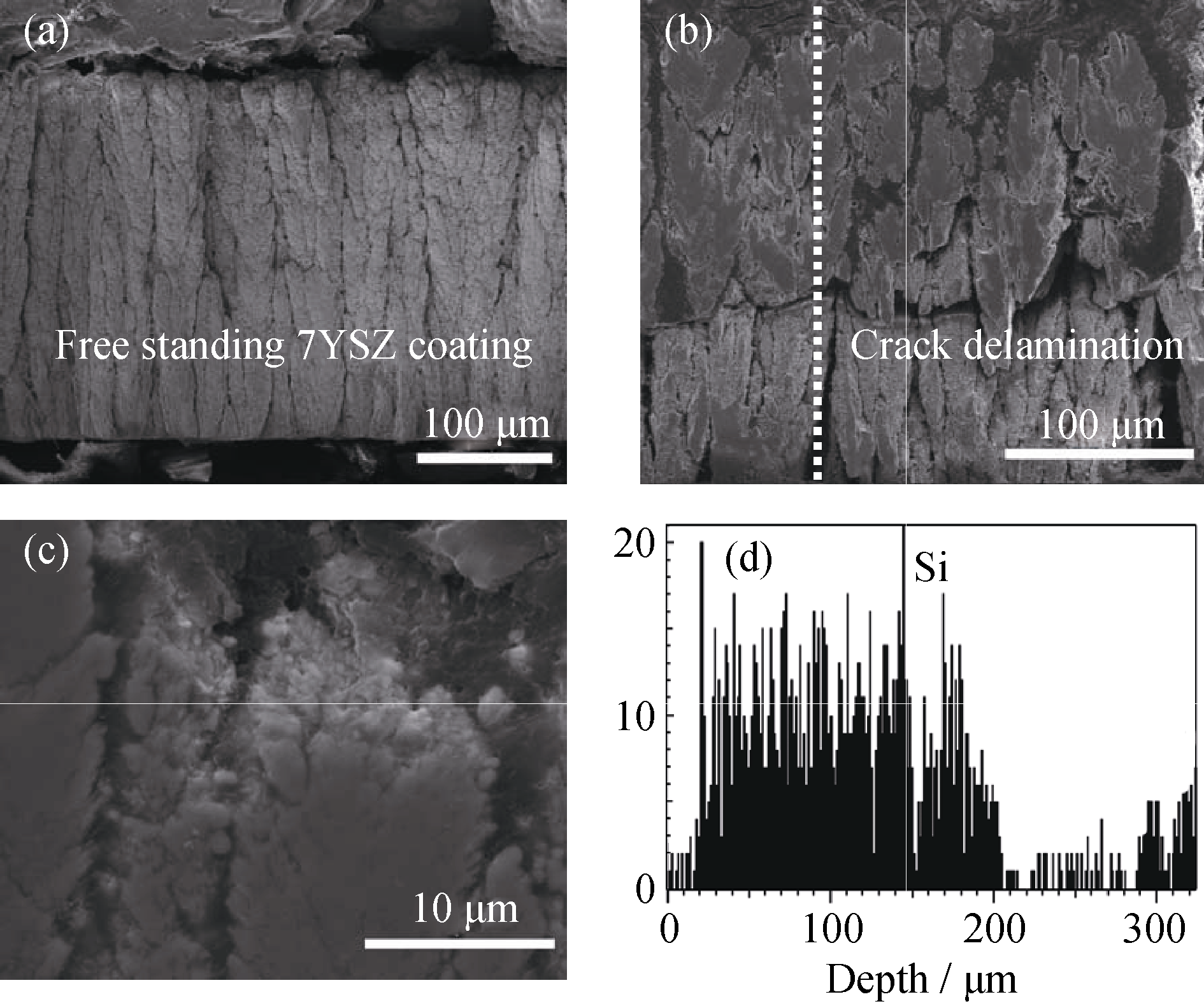

Fig. 5 Corrosion of columnar 7YSZ coating (a) Before corrosion; (b) After corrosion at 1200℃ for 24 h; (c) Enlarged coating tip in Fig. b, and (d) EDS spectra of Si in Fig. b

| [1] | FENG QIANG, TONG JINYAN, ZHENG YUNRONG, et al.Service induced degradation and rejuvenation of gas turbine blades.Materials China, 2012, 31(12): 21-34. |

| [2] | ZHENG LEI, GUO HONGBO, PENG HUI, et al.New generation thermal barrier coatings for ultrahigh temperature applications.Journal Aeronautical Materials, 2012, 32(6): 14-24. |

| [3] | HUANG XU, LI ZHENXI, HUANG HAO.et al.Recent development of new high-temperature titanium alloys for high thrust-weight ratio aero-engines.Materials China, 2011, 30(6): 21-27. |

| [4] | GUO HONG-BO, GONG SHENG-KAI, XU HUI-BING.Progress in thermal barrier coatings for advanced aero-engines.Materials China, 2009, 28(9/10): 18-27. |

| [5] | STRANGEMAN T, RAYBOULD D, JAMEEL A, et al.Damage mechanisms, life prediction, and development of EB-PVD thermal barrier coatings for turbine airfoils.Surf. Coat. Technol., 2007, 202(4-7): 658-664. |

| [6] | GUO HONG-BO, PENG LI-QUAN, GONG SHENG-KAI, et al.Progress in EB-PVD thermal barrier coatings.Thermal Spray Technol., 2009, 1(2): 7-14. |

| [7] | DORIER J L, GINDRAT M, HOLLENSTEIN C, et al.Plasma Jet Properties in a New Spraying Process at Low Pressure for Large Area Thin Film Deposition. Thermal Spray Conf., Singapore, 2001, 5: 759-64. |

| [8] | NIESSEN K V, GINDRAT M, REFLE A.Vapor phase deposition using plasma spray-PVD.Journal Thermal Spray Technol., 2010, 19(1/2): 502-509. |

| [9] | HOSPACH A, MAUER G, VABEN R, et al.Columnar-structured thermal barrier coatings (TBCs) by thin film low-pressure plasma spraying (LPPS-TF).Journal Thermal Spray Technol., 2010, 20(1/2): 116-120. |

| [10] | REFKE A, GINDRAT M, VON K.LPPS Thin Film: A Hybrid Coating Technology Between Thermal Spray and PVD For Functional Thin Coatings and Large Area Applications. Proceedings of the International Thermal Spray Conf., Beijing, 2007, 1: 705-710. |

| [11] | HALL A, DAI J, XIAO T.Low Pressure Plasma Spray-thin Film at San-dia National Laboratories. Proceedings of the International Spray, Las Vegas, 2009, 5: 725-728. |

| [12] | HARDER B.PS-PVD processing varies coating architecture with processing parameter.Advanced Material & Processes, 2011, 51: 9-11. |

| [13] | SHINOZAWA A, EGUCHI K, KAMBARA M, et al.Feather- like structured YSZ coatings at fast rates by plasma spray physical vapor deposition.Journal Thermal Spray Technol., 2010, 19(1-2): 190-197. |

| [14] | MAUER G, VABEN R.Plasma sprayed-PVD: plasma characterristic and impact on coating properties.Journal Physicals: conference series, 2012, 406: 012005-012017. |

| [15] | HUA JIAJIE, ZHANG LIPENG, LIU ZIWEI, et al.Progress of research on the failure mechanism of thermal barrier coatings.Journal Inorganic Materials, 2012, 27(7): 680-686. |

| [16] | DREXLER J M, ORTIZ A L, PADTURE N P.Composition effect of thermal barrier coating ceramic on their interaction with molten Ca-Mg-Al-Silicate (CMAS) glass.Acta Materialia, 2012, 60(15): 5437-5447. |

| [17] | DREXLER J M, GLEDHILL A D, SHINODA K, et al.Jet engine coatings for resisting volcanic ash damage.Advanced Materials, 2011, 23(21): 2419-2424. |

| [18] | WU J, GUO H B, GAO Y Z, et al.Microstructure and thermo- physical properties of yttria-stabilized zirconia coatings with CMAS deposits.J. Euro. Ceram. Soc., 2011, 31(10): 1881-1888. |

| [19] | 杨邦朝, 王文生, 薄膜物理与技术. 成都: 电子科技大学出版社, 1993: 144-165. |

| [20] | MAUER G, HOSPACH A, VABEN R, Process development and coating characteristics of plasma spray-PVD. Surf. Coat. Technol., 207, 220: 219-224. |

| [21] | MAUER G, JARLIGO M O, REZANKA S, et al. Novel opportunities for thermal spray by PS-PVD.Surf. Coat. Technol., DOI: 10.1016/j. surfcoat. 2014.06.002. |

| [22] | 唐伟忠. 薄膜材料制备原理、技术及应用. 2003, 北京: 冶金工业出版社, 2003: 162-222. |

| [23] | THORNTON J A.Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings.J. Vacuum Sci. Technol., 1974, 11(4): 666-670. |

| [24] | MAUER G, HOSPACH A, ZOTOV N, VABEN R.Process conditions and microstructures of ceramic coatings by gas phase deposition based on plasma spraying.Journal Thermal Spray Technol., 2013, 22(2/3): 83-89. |

| [25] | MERCER C, FAULHABER S, EVANS A G, et al.R. A delamination mechanism for thermal barrier coatings subject to calcium-magnesium-alumino-silicate (CMAS) infiltration.Acta Materialia, 2005, 53(4): 1029-1039. |

| [26] | HE QING, LIU XINJI, LIU BO, et al.Influence of CMAS infiltration on microstructure of plasma-sprayed YSZ thermal barrier coating.China Surface Engineering, 2012, 25(4): 42-47. |

| [27] | CHEN X.Calcium-Magnesium-Alumina-Silicate (CMAS) delamination mechanisms in EB-PVD thermal barrier coatings.Surf. Coat. Technol., 2006, 200(11): 3418-3427. |

| [28] | KRAMER S, YANG J, LEVI C G, et al.C A. Thermochem.ical interaction of thermal barrier coatings with molten CaO-MgO- Al2O3-SiO2.J. Am. Ceram. Soc., 2006, 89(10): 3167-3175. |

| [29] | PENG H, WANG L, GUO H B, et al.Degradation of EB-PVD thermal barrier coatings caused by CMAS deposits.Progress in Natural Science: Materials International, 2012, 22(5): 461-467. |

| [1] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [2] | LI Liuyuan, HUANG Kaiming, ZHAO Xiuyi, LIU Huichao, WANG Chao. Influence of RE-Si-Al-O Glass Phase on Microstructure and CMAS Corrosion Resistance of High Entropy Rare Earth Disilicates [J]. Journal of Inorganic Materials, 2024, 39(7): 793-802. |

| [3] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [4] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [5] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [6] | LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274. |

| [7] | FAN Jia-Feng,ZHANG Xiao-Feng,ZHOU Ke-Song,LIU Min,DENG Chang-Guang,DENG Chun-Ming,NIU Shao-Peng,DENG Zi-Qian. Influence of Al-modification on CMAS Corrosion Resistance of PS-PVD 7YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2019, 34(9): 938-946. |

| [8] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, NIU Shao-Peng, XU Shi-Ming. Preparation of Si/Mullite/Yb2SiO5 Environment Barrier Coating (EBC) by Plasma Spray-Physical Vapor Deposition (PS-PVD) [J]. Journal of Inorganic Materials, 2018, 33(3): 325-330. |

| [9] |

GUAN Yong-Jun,XIA Yuan.

Electrochemical Impedance Spectroscopy of PEO Coating on Aluminum Alloy in NaCl Solution [J]. Journal of Inorganic Materials, 2008, 23(4): 784-788. |

| [10] | XIE Zhi-Yong,HUANG Qi-Zhong,SHU Zhe-An,ZHANG Fu-Qin,HUANG Bo-Yun. Preparation of C/C Composites by CVI with Multi-factor Coupling Physical Fields and Deposition Mechanism [J]. Journal of Inorganic Materials, 2005, 20(5): 1201-1207. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||