Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (9): 938-946.DOI: 10.15541/jim20180529

• RESEARCH PAPER • Previous Articles Next Articles

FAN Jia-Feng1,2,ZHANG Xiao-Feng1,2( ),ZHOU Ke-Song1,2(

),ZHOU Ke-Song1,2( ),LIU Min2,DENG Chang-Guang2,DENG Chun-Ming2,NIU Shao-Peng2,DENG Zi-Qian2

),LIU Min2,DENG Chang-Guang2,DENG Chun-Ming2,NIU Shao-Peng2,DENG Zi-Qian2

Received:2018-11-09

Revised:2019-01-11

Published:2019-09-20

Online:2019-05-22

Supported by:CLC Number:

FAN Jia-Feng,ZHANG Xiao-Feng,ZHOU Ke-Song,LIU Min,DENG Chang-Guang,DENG Chun-Ming,NIU Shao-Peng,DENG Zi-Qian. Influence of Al-modification on CMAS Corrosion Resistance of PS-PVD 7YSZ Thermal Barrier Coatings[J]. Journal of Inorganic Materials, 2019, 34(9): 938-946.

| Materials | Power/kW | Ar/nlpm | N2/nlpm | Feed rate/ (g·min-1) | Carrier gas Ar/nlpm | Stand-off distance/mm | Pre-heating temperature/℃ | Chamber pressure/Pa |

|---|---|---|---|---|---|---|---|---|

| 7YSZ | 127 | 35 | 60 | 2×9 | 16 | 950 | 900 | 1.5 |

Table 1 Parameters of 7YSZ ceramic coating prepared by PS-PVD

| Materials | Power/kW | Ar/nlpm | N2/nlpm | Feed rate/ (g·min-1) | Carrier gas Ar/nlpm | Stand-off distance/mm | Pre-heating temperature/℃ | Chamber pressure/Pa |

|---|---|---|---|---|---|---|---|---|

| 7YSZ | 127 | 35 | 60 | 2×9 | 16 | 950 | 900 | 1.5 |

| Oxides | CaO | MgO | Al2O3 | SiO2 |

|---|---|---|---|---|

| Weight/wt% | 37.1 | 3.5 | 7.1 | 52.3 |

Table 2 Composition of CMAS powders

| Oxides | CaO | MgO | Al2O3 | SiO2 |

|---|---|---|---|---|

| Weight/wt% | 37.1 | 3.5 | 7.1 | 52.3 |

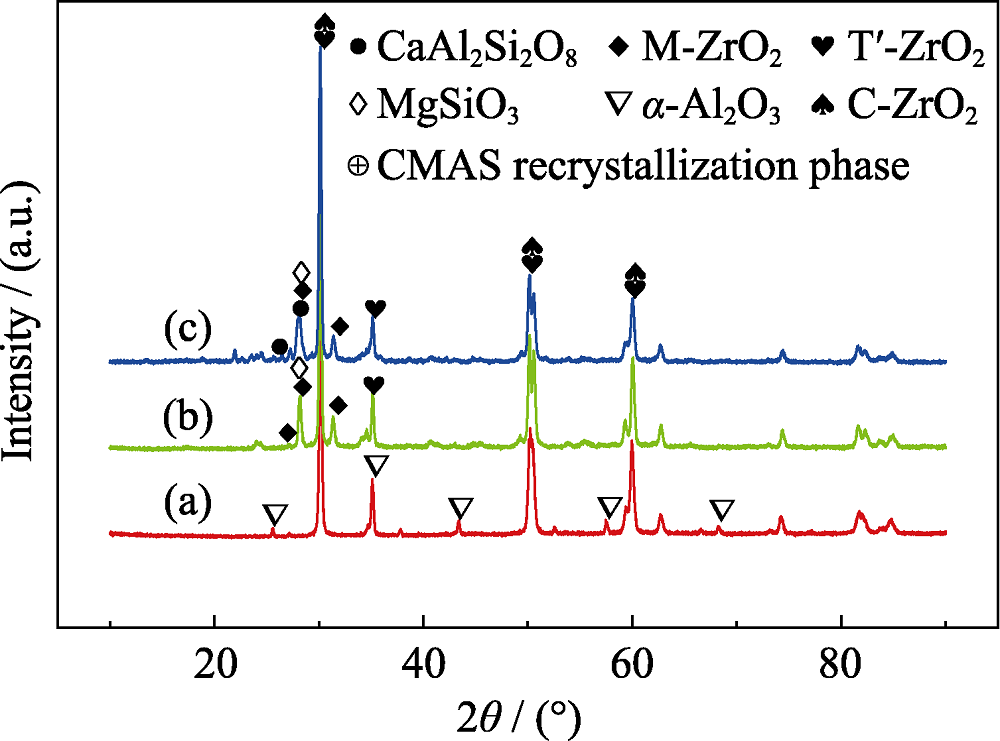

Fig. 9 XRD patterns of the surface of 7YSZ TBCs (a) Al-modified coating; (b) As-sprayed coating after corrosion; (c) Al- modified coating after corrosion

| [1] | SEBASTIAN M, THOMAS D, HEIKO G ,et al. Method and process development of advanced atmospheric plasma spraying for thermal barrier coatings. Journal of Thermal Spray Technology, 2012,21(3):400-408. |

| [2] | LIN F, JIANG X L . Research progress on plasma spraying. Journal of Functional Materials, 2003,34(3):254-257. |

| [3] | QIN Q, MAO Z J, LIU Z F . Application and future prospect of high-temperature alloy in aero-engine industry. Tool Engineering, 2017,51(9):3-6. |

| [4] | EVANS A G, MUMM D R, HUTCHINSON J W ,et al. Mechanisms controlling the durability of thermal barrier coatings. Progress in Materials Science, 2001,46(5):505-553. |

| [5] | CLARKE D R, LEVI C G . Materials design for the next generation thermal barrier coatings. Annual Review of Materials Research, 2003,33(1):383-417. |

| [6] | WU R T, OSAWA M, YOKOKAWA T ,et al. Degradation mechanisms of an advanced jet engine service-retired TBC component. Journal of Solid Mechanics and Materials Engineering, 2010,4(2):119-130. |

| [7] | GUO S Q, FENG Y B, HE Y ,et al. Materials and fabrication technique of thermal barrier coatings for future aeroengines. Surface Technology, 2012,41(5):119-123. |

| [8] | STRANGEMAN T, RAYBOULD D, JAMEEL A ,et al. Damage mechanisms, life prediction, and development of EB-PVD thermal barrier coatings for turbine airfoils. Surface and Coatings Technology, 2007,202(4-7):658-664. |

| [9] | GUO H B, PENG L Q, GONG S K , et al. Progress in EB-PVD thermal barrier coatings. Thermal Spray Technology, 2009,1(2):7-14. |

| [10] | MAUER G, HOSPACH A VAßEN R, . Process development and coating characteristics of plasma spray-PVD. Surface and Coatings Technology, 2013,220(15):219-224. |

| [11] | HOSPACH A, MAUER G, VAßEN R , et al. Columnar-structured thermal barrier coatings (TBCs) by thin film low-pressure plasma spraying (LPPS-TF). Journal of Thermal Spray Technology, 2011,20(1):116-120. |

| [12] | NIESSEN K V, GINDRAT M, REFLE A . Vapor phase deposition using plasma spray-PVD. Journal of Thermal Spray Technology, 2010,19(1/2):502-509. |

| [13] | MAUER G., JARLIGO M O, REZANKA S ,et al. Novel opportunities for thermal spray by PS-PVD. Surface and Coatings Technology, 2015,268:52-57. |

| [14] | KRäMER S, YANG J, LEVI C G ,et al. Thermochemical interaction of thermal barrier coatings with molten CaO-MgO-Al2O3- SiO2( CMAS) deposits. Journal of the American Ceramic Society, 2006,89(10):3167-3175. |

| [15] | DAROLIA R . Thermal barrier coatings technology: critical review, progress update, remaining challenges and prospects. International Materials Reviews, 2013,58(6):315-348. |

| [16] | LEVI C G, HUTCHINSON J W, VIDAL-SÉTIF M H , et al. Environmental degradation of thermal-barrier coatings by molten deposits. Materials Research Society Bulletin, 2012,37(10):932-941. |

| [17] | ZHANG X F, ZHOU K S, SONG J B ,et al. Deposition and CMAS corrosion mechanism of 7YSZ thermal barrier coatings prepared by plasma spray-physical vapor deposition. Journal of Inorganic Materials, 2015,30(3):287-293. |

| [18] | WANG W Z, FANG H J, HUANG J B . Research status on cracking of thermal barrier coating against CMAS corrosion. Surface Technology, 2018,47(8):23-29. |

| [19] | YANG S J, PENG H, GUO H B . Failure and protection of thermal barrier coating under CMAS attack. Journal of Aeronautical Materials, 2018,38(2):43-51. |

| [20] | GANG Y X, BAI Y, LIU K , et al. Corrosion failure mechanism of thermal barrier coatings after infiltration of CMAS deposits and countermeasure study. Rare Metal Materials and Engineering, 2017, 46(1):282-288. |

| [21] | MOHAN P, YAO B, PATTERSON T ,et al. Electrophoretically deposited alumina as protective overlay for thermal barrier coatings against CMAS degradation. Surface and Coatings Technology, 2009,204(6/7):797-801. |

| [22] | AYGUN A, VASILIEV A L, PADTURE N P ,et al. Novel thermal barrier coatings that are resistant to high-temperature attack by glassy deposits. Acta Materialia, 2007,55(20):6734-6745. |

| [23] | GUO L, GUO H B, PENG H ,et al. Thermophysical properties of Yb2O3 doped Gd2Zr2O7 and thermal cycling durability of (Gd0.9Yb0.1)2Zr2O7/YSZ thermal barrier coatings. Journal of the European Ceramic Society, 2014,34(5):1255-1263. |

| [24] | ZHANG X F, ZHOU K S, LIU M ,et al. Thermal shock analysis of surface Al-modified 7YSZ nano-thermal barrier coating. Journal of Inorganic Materials, 2017,32(9):973-979. |

| [25] | ZHANG X F . In-situ Synthsis of Al and ZrO2 to Improve the Properties of Thermal Barrier Coating. Guangzhou: PhD thesis of South China University of Technology, 2016. |

| [26] | ZHANG X F, ZHOU K S, LIU M ,et al. Enhanced properties of Al-modified EB-PVD 7YSZ thermal barrier coatings. Ceramics International, 2016,42(12):13969-13975. |

| [27] | DREXLER J M, ORTIZ A L, PADTURE N P . Composition effects of thermal barrier coating ceramics on their interaction with molten Ca-Mg-Al-silicate (CMAS) glass. Acta Materialia, 2012,60(15):5437-5447. |

| [28] | ZHANG X F, ZHOU K S, XU W ,et al. In situ synthesis of α-alumina layer at top yttrium-stabilized zirconia thermal barrier coatings for oxygen barrier. Ceram Int., 2014,40(8):12703-12708. |

| [29] | SONG X W, YU H T, NIU X Q ,et al. Progress in rare earth oxides doped ZrO2-based ceramic materials for thermal barrier coatings. Journal of Inner Mongolia University of Science and Technology, 2009,28(3):287-292. |

| [30] | 陈肇友 . 相图与耐火材料. 北京: 冶金工业出版社, 2014: 91-96. |

| [31] | 胡赓祥, 蔡珣, 戎咏华 . 材料科学基础, 3版. 上海: 上海交通大学出版社, 2010: 136-138. |

| [32] | HOWARD R E, LIDIARD A B . Matter transport in solids. Reports on Progress in Physics, 1964,27:161-162. |

| [1] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [2] | LI Liuyuan, HUANG Kaiming, ZHAO Xiuyi, LIU Huichao, WANG Chao. Influence of RE-Si-Al-O Glass Phase on Microstructure and CMAS Corrosion Resistance of High Entropy Rare Earth Disilicates [J]. Journal of Inorganic Materials, 2024, 39(7): 793-802. |

| [3] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [4] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [5] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, NIU Shao-Peng, XU Shi-Ming. Preparation of Si/Mullite/Yb2SiO5 Environment Barrier Coating (EBC) by Plasma Spray-Physical Vapor Deposition (PS-PVD) [J]. Journal of Inorganic Materials, 2018, 33(3): 325-330. |

| [6] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, DENG Chang-Guang, CHEN Huan-Tao. Thermal Shock Analysis of Surface Al-modified 7YSZ Nano-thermal Barrier Coatin [J]. Journal of Inorganic Materials, 2017, 32(9): 973-979. |

| [7] | ZHANG Xiao-Feng, ZHOU Ke-Song, SONG Jin-Bing, DENG Chun-Ming, NIU Shao-Peng, DENG Zi-Qian. Deposition and CMAS Corrosion Mechanism of 7YSZ Thermal Barrier Coatings Prepared by Plasma Spray-Physical Vapor Deposition [J]. Journal of Inorganic Materials, 2015, 30(3): 287-293. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||