Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 981-988.DOI: 10.15541/jim20250038

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Fuping1,2( ), CHU Jiabao1,2, QIU Haibo1,2, DANG Wei1,2(

), CHU Jiabao1,2, QIU Haibo1,2, DANG Wei1,2( ), LI Chenxi1,2, ZHAO Kang1,2, TANG Yufei1,2

), LI Chenxi1,2, ZHAO Kang1,2, TANG Yufei1,2

Received:2025-01-25

Revised:2025-03-18

Published:2025-09-20

Online:2025-03-25

Contact:

DANG Wei, lecturer. E-mail:wdang@xaut.edu.cn

About author:LI Fuping (1985-), male, associate professor. E-mail: lifp@xaut.edu.cn

Supported by:CLC Number:

LI Fuping, CHU Jiabao, QIU Haibo, DANG Wei, LI Chenxi, ZHAO Kang, TANG Yufei. Compressive Resilience Mechanism of SiO2 Nanofibre Aerogels[J]. Journal of Inorganic Materials, 2025, 40(9): 981-988.

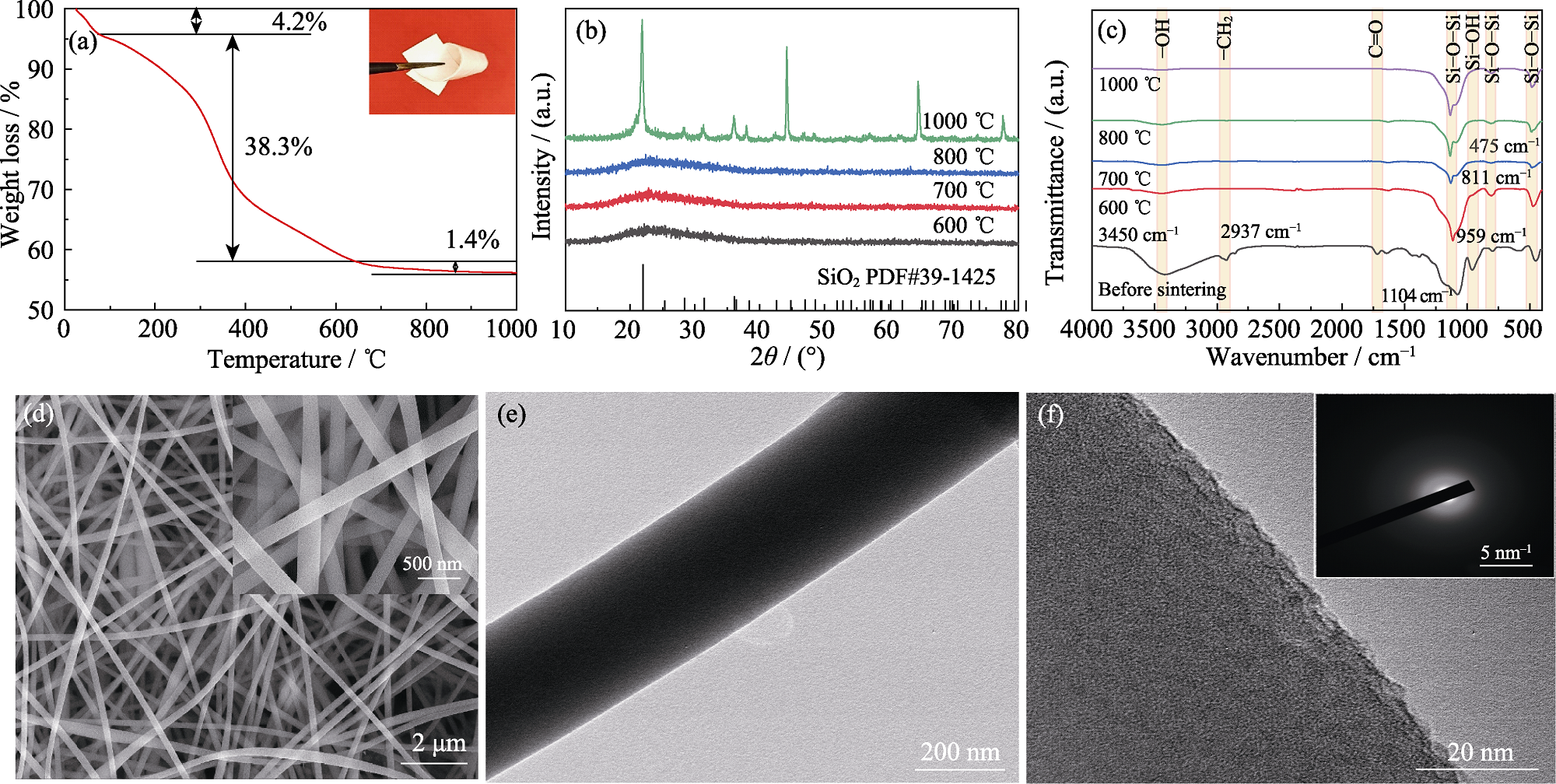

Fig. 1 (a) TG curve of precursor membrane; (b, c) XRD patterns (b) and FT-IR spectra (c) of SiO2 nanofiber membrane; (d-f) SEM image (d), TEM image (e), HRTEM image and corresponding SEAD pattern (f) of SiO2 nanofiber membrane sintered at 700 ℃

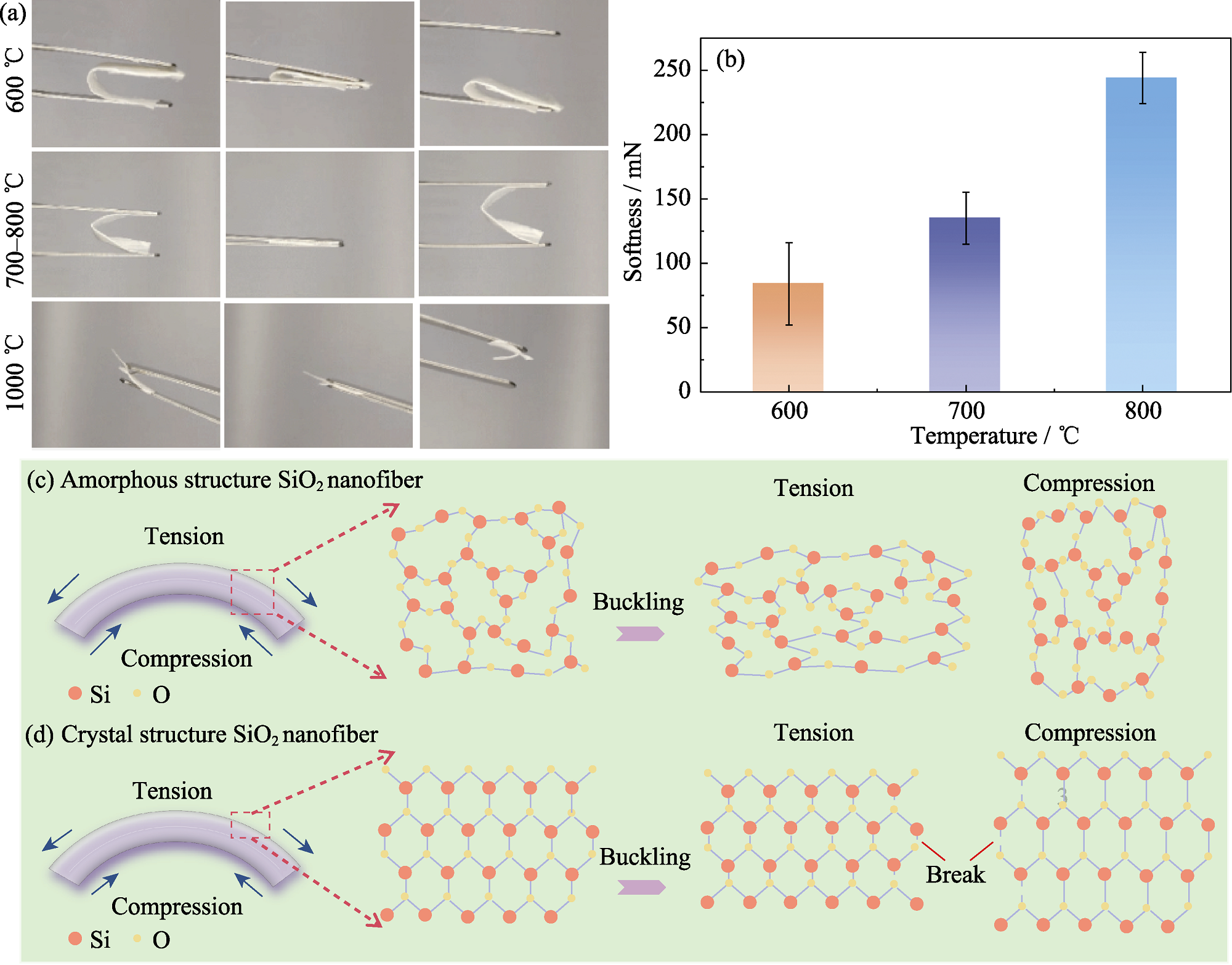

Fig. 2 (a, b) Flexibility of SiO2 nanofiber membrane; (c, d) Schematic diagrams for buckling deformation of SiO2 nanofiber with different structures Colorful figures are available on website

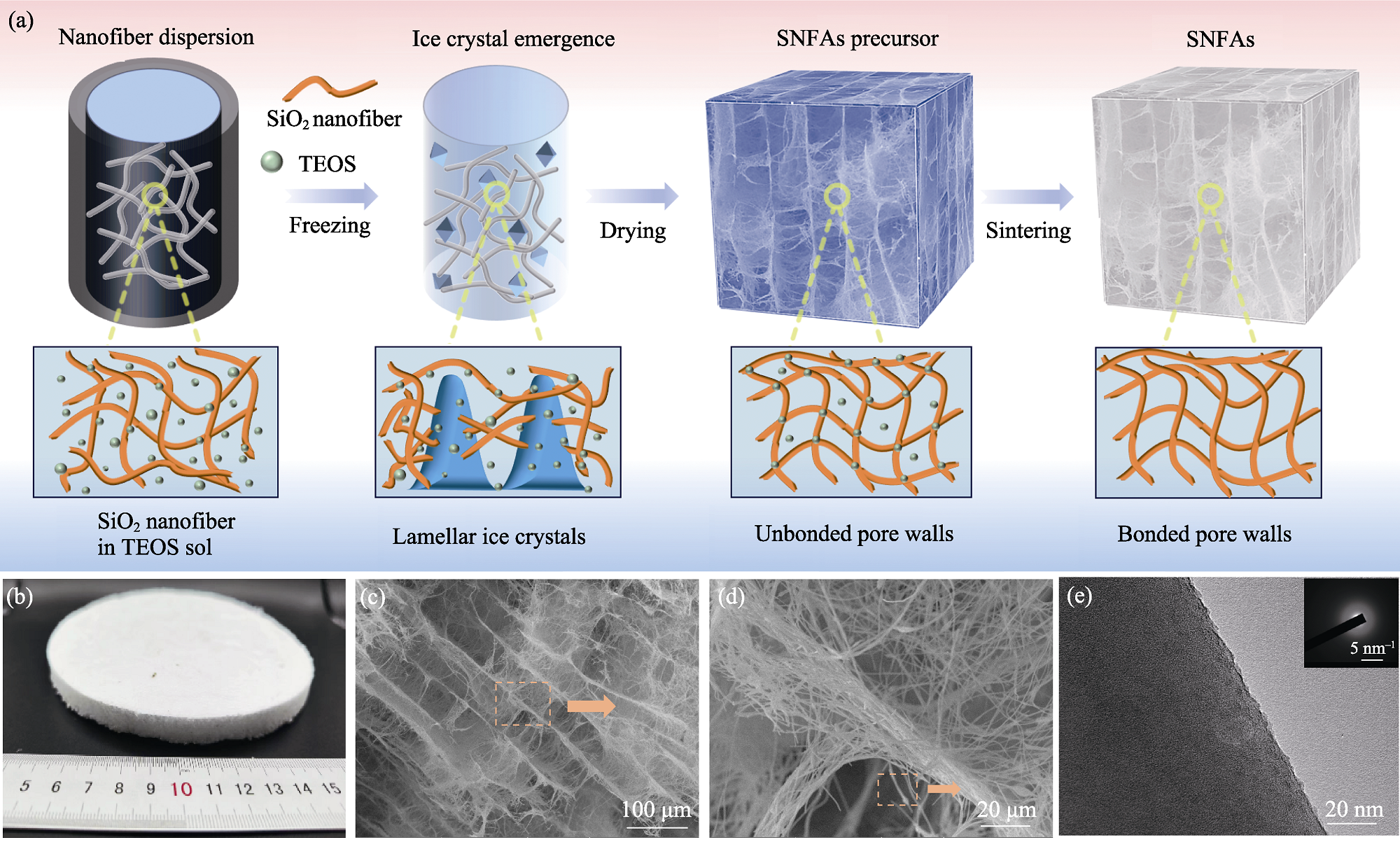

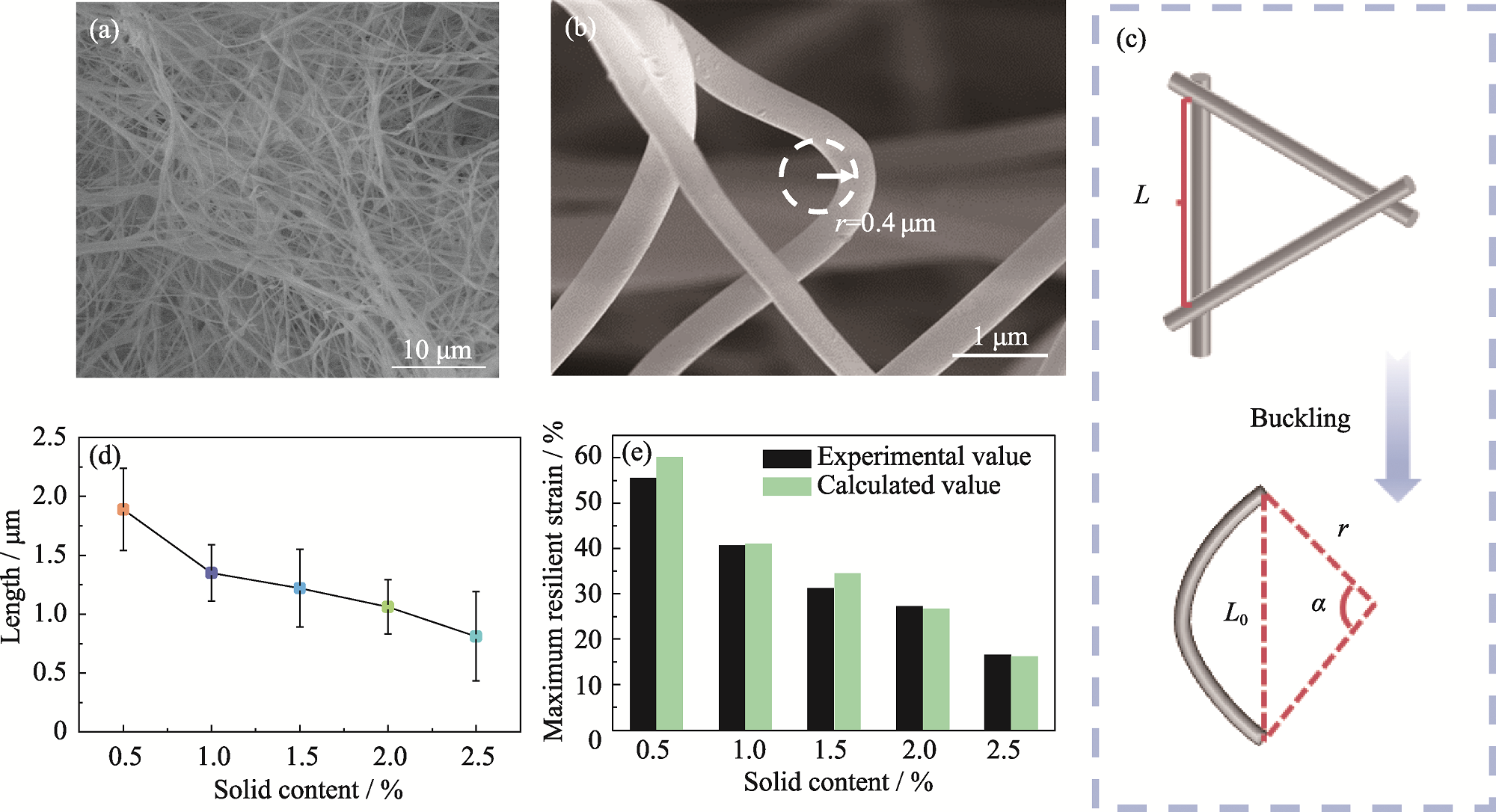

Fig. 3 (a) Fabrication process of SiO2 nanofiber aerogels; (b-e) Digital photo (b) and microstructures (c-e) of SiO2 nanofiber aerogels fabricated with 1.5% solid content and sintered at 700 ℃

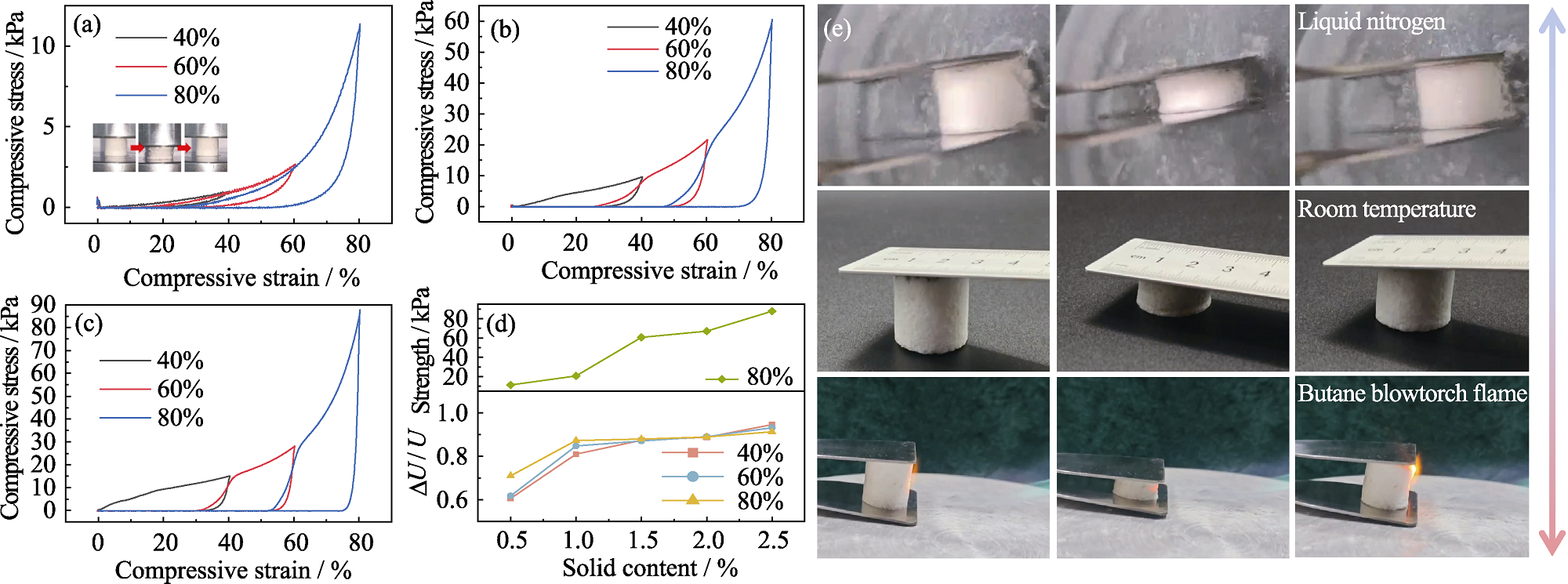

Fig. 5 Compressive mechanical properties of SiO2 nanofiber aerogels (a-c) Stress-strain curves of SiO2 nanofiber aerogels fabricated with solid contents of (a) 0.5%, (b) 1.5% and (c) 2.5%; (d) Effect of solid content on the compressive strength and energy loss coefficients (ΔU/U); (e) Resilience of SiO2 nanofiber aerogels under liquid nitrogen, room temperature and butane blowtorch flame. Colorful figures are available on website

Fig. 6 Compressive resilience mechanism of SiO2 fiber aerogels (a) Pore wall of SiO2 nanofiber aerogels; (b) Minimum curve radius of single SiO2 nanofiber during buckling; (c) Buckling deformation of nanofiber; (d) Effective nanofiber length of SiO2 nanofiber aerogels fabricated with different solid contents; (e) Comparison of experimental and calculated values of resilience for SiO2 nanofiber aerogels

| [1] | ZHAN W, CHEN L, KONG Q H, et al. The synthesis and polymer reinforced mechanical properties of SiO2 aerogels: a review. Molecules, 2023, 28(14): 5534. |

| [2] |

LUO Y, XIA S H, NIU B, et al. Preparation and high temperature inorganic transformation of flexible silicone aerogels. Journal of Inorganic Materials, 2022, 37(12): 1281.

DOI |

| [3] |

潘月磊, 程旭东, 闫明远, 等. 二氧化硅气凝胶及其在保温隔热领域应用进展. 化工进展, 2023, 42(1): 297.

DOI |

| [4] | YI Z H, ZHANG X, YAN L W, et al. Super-insulated, flexible, and high resilient mullite fiber reinforced silica aerogel composites by interfacial modification with nanoscale mullite whisker. Composites Part B, 2022, 230: 109549. |

| [5] | 石小靖, 张瑞芳, 何松, 等. 玻璃纤维增韧SiO2气凝胶复合材料的制备及隔热性能. 硅酸盐学报, 2016, 44(1): 129. |

| [6] |

ZHANG X S, WANG B, WU N, et al. Micro-nano ceramic fibers for high temperature thermal insulation. Journal of Inorganic Materials, 2021, 36(3): 245.

DOI |

| [7] | SU L, NIU M, LI M, et al. Engineering the mechanical properties of resilient ceramic aerogels. Journal of the American Ceramic Society, 2023, 107(3): 1468. |

| [8] | LIU C, WANG S, WANG N, et al. From 1D nanofibers to 3D nanofibrous aerogels: a marvellous evolution of electrospun SiO2 nanofibers for emerging applications. Nano-Micro Letters, 2022, 14: 194 |

| [9] | 沈晓冬, 吴晓栋, 孔勇, 等. 气凝胶纳米材料的研究进展. 中国材料进展, 2018, 37(9): 671. |

| [10] |

SI Y, WANG X Q, DOU L Y, et al. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Science Advances, 2018, 4(4): 8925.

DOI PMID |

| [11] | FENG Y, GUO Y S, LI X Y, et al. Continuous rapid fabrication of ceramic fiber sponge aerogels with high thermomechanical properties via a green and low-cost electrospinning technique. ACS Nano, 2024, 18: 19054. |

| [12] | WANG J H, LIU L P, DONG W L, et al. Ultra-high radial elastic aerogel fibers for thermal insulation textile. Journal of Advanced Materials Science, 2024: 2417873. |

| [13] | SU L, WANG H J, JIA S H, et al. Highly stretchable, crack- insensitive and compressible ceramic aerogel. ACS Nano, 2021, 15(11): 18354. |

| [14] | ZHANG X, LIU C, ZHANG X X, et al. Super strong, shear resistant, and highly elasticlamellar structured ceramic nanofibrous aerogels for thermal insulation. Journal of Materials Chemistry A, 2021, 9: 27415. |

| [15] |

XU B, LIANG H T, HU J, et al. Preparation of anisotropic polyimide aerogels for thermal protection with outstanding flexible resilience using the freeze-drying method. RSC Advances, 2024, 14(12): 8556.

DOI PMID |

| [16] | LI B, TIAN H Y, LI L, et al. Graphene-assisted assembly of electrically and magnetically conductive ceramic nanofibrous aerogels enable multifunctionality. Advanced Functional Materials, 2024, 34(22): 2314653. |

| [17] | JIANG J P, YAN L W, SONG M J, et al. Thermally insulated C/SiC/SiBCN composite ceramic aerogel with enhanced electromagnetic wave absorption performance. Ceramics International, 2025, 51(1): 17. |

| [18] | PATIL S P, PARAG S, BERND M. Mechanical properties and behavior of glass fiber-reinforced silica aerogel nanocomposites: Insights from all-atom simulations. Scripta Materialia, 2019, 177: 65. |

| [19] | 瑚佩, 姜勇刚, 张忠明, 等. 耐高温、高强度隔热复合材料研究进展. 材料导报, 2020, 34(7): 7082. |

| [20] | SHAHRIAR S M S, MCCARTHY D A, ANDRABI M S, et al. Mechanically resilient hybrid aerogels containing fibers of dual-scale sizes and knotty networks for tissue regeneration. Nature Communications, 2024, 15: 1080. |

| [21] |

PENG F, JIANG Y G, FENG J, et al. Research progress on alumina aerogel composites for high-temperature thermal insulation. Journal of Inorganic Materials, 2021, 36(7): 673.

DOI |

| [22] | XU W H, ZHU Y X, RAVICHANDRAN D, et al. Review of fiber-based three-dimensional printing for applications ranging from nanoscale nanoparticle alignment to macroscale patterning. ACS Applied Nano Materials, 2021, 4(8): 7538. |

| [23] | 吴晓栋, 宋梓豪, 王伟, 等. 气凝胶材料的研究进展. 南京工业大学学报(自然科学版), 2020, 42(4): 405. |

| [24] | WANG J, LIU X N, SHANG S S, et al. Novel biphasic high-entropy ceramic aerogels and their fiber composites with low thermal conductivity, high thermal stability and significant thermal insulation property. Journal of Alloys and Compounds, 2024, 1007: 176299. |

| [25] | XU B K, HE Q C, W Y Q, et al. Ultralight and efficient microwave absorption of SiC/SiO2 ceramic aerogels derived from biomass. Ceramics International, 2023, 49(18): 30125. |

| [26] | 吕双祺, 孙燕涛, 腾雪峰, 等. 陶瓷纤维增强SiO2气凝胶复合材料面内拉伸非均匀全场应变测量与分析. 复合材料学报, 2021, 38(7): 2336. |

| [27] | ZHANG K K, LIU L, WANG X, et al. Lightweight and superamphiphobic silanized cellulose-silica aerogels on green flexible thermal substrates. Chemical Engineering Journal, 2024, 502: 158238. |

| [28] | CHANG J M, ZHU Y W, LIU J, et al. Fabrication of elastic SiO2 aerogels with prominent mechanical strength and stability reinforced by SiO2 nanofibers and polyurethane for oil adsorption. Separation and Purification Technology, 2024, 341: 126914. |

| [29] | ZIMMERMANN G V M, ZATTERA J A. Silica aerogel reinforced with cellulose nanofibers. Journal of Porous Materials, 2021, 28(5): 1325. |

| [1] | YUAN Liping, WU Yuanbo, YU Jiajing, ZHANG Shiyan, SUN Yi, HU Yunchu, FAN Youhua. CNFs Aerogel Composite with Phosphomolybdic Acid Intercalated Hydrotalcite: Preparation and Thermal Insulation Performance [J]. Journal of Inorganic Materials, 2025, 40(4): 415-424. |

| [2] | MAO Aiqin, LU Wenyu, JIA Yanggang, WANG Ranran, SUN Jing. Flexible Piezoelectric Devices and Their Wearable Applications [J]. Journal of Inorganic Materials, 2023, 38(7): 717-730. |

| [3] | ZHANG Xiangsong, LIU Yetong, WANG Yongying, WU Zirui, LIU Zhenzhong, LI Yi, YANG Juan. Self-assembled Platinum-iridium Alloy Aerogels and Their Efficient Electrocatalytic Ammonia Oxidation Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 511-520. |

| [4] | LUO Yi, XIA Shuhai, NIU Bo, ZHANG Yayun, LONG Donghui. Preparation and High Temperature Inorganic Transformation of Flexible Silicone Aerogels [J]. Journal of Inorganic Materials, 2022, 37(12): 1281-1288. |

| [5] | PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(7): 673-684. |

| [6] | ZHANG Xiaoshan, WANG Bing, WU Nan, HAN Cheng, WU Chunzhi, WANG Yingde. Micro-nano Ceramic Fibers for High Temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(3): 245-256. |

| [7] | ZHANG Ze,WANG Xiaodong,SHEN Jun. Effect of Organic-inorganic Crosslinking Degree on the Mechanical and Thermal Properties of Aerogels [J]. Journal of Inorganic Materials, 2020, 35(4): 454-460. |

| [8] | LUO Yi,FENG Junzong,FENG Jian,JIANG Yonggang,LI Liangjun. Research Progress on Advanced Carbon Materials as Pt Support for Proton Exchange Membrane Fuel Cells [J]. Journal of Inorganic Materials, 2020, 35(4): 407-415. |

| [9] | LIU Fengqi, FENG Jian, JIANG Yonggang, LI Liangjun. Preparation and Application of Boron Nitride Aerogels [J]. Journal of Inorganic Materials, 2020, 35(11): 1193-1202. |

| [10] | DING Zhuofeng, YANG Yongqiang, LI Zaijun. Synthesis and Supercapacitor Performance of Histidine-functionalized Carbon Dots/Graphene Aerogel [J]. Journal of Inorganic Materials, 2020, 35(10): 1130-1136. |

| [11] | LYU Ziye, TANG Yiping, CAO Huazhen, ZHENG Guoqu, HOU Guangya. Effect of V Doping on Electrocatalytic Performance of Ni-Co-S on Bacterial Cellulose-derived Carbon Aerogel [J]. Journal of Inorganic Materials, 2020, 35(10): 1142-1148. |

| [12] | ZHU Zhao-Xian,WANG Fei,YAO Hong-Jun,DONG Jin-Xin,LONG Dong-Hui. High-temperature Insulation Property of Opacifier-doped Al2O3-SiO2 Aerogel/Mullite Fiber Composites [J]. Journal of Inorganic Materials, 2018, 33(9): 969-975. |

| [13] | WANG Yong, YU Yun, FENG Ai-Hu, JIANG Feng, HU Xue-Bing, SONG Li-Xin. Nafion Modified Graphene Aerogel with Hierarchical Porous Structures [J]. Journal of Inorganic Materials, 2018, 33(4): 469-474. |

| [14] | YANG Jing-Feng, WANG Qi-Hua, WANG Ting-Mei. Synthesis and Property of Alumina Aerogel [J]. Journal of Inorganic Materials, 2018, 33(3): 259-265. |

| [15] | HE Fei, LI Ya, LUO Jin, FANG Min-Han, HE Xiao-Dong. Development of SiO2/C and SiC/C Composites Featuring Aerogel Structures [J]. Journal of Inorganic Materials, 2017, 32(5): 449-458. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||