Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (7): 817-825.DOI: 10.15541/jim20250060

• RESEARCH ARTICLE • Previous Articles Next Articles

WEI Zhifan( ), CHEN Guoqing(

), CHEN Guoqing( ), ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong

), ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong

Received:2025-02-17

Revised:2025-03-20

Published:2025-07-20

Online:2025-03-25

Contact:

CHEN Guoqing, professor. E-mail: gqchen@dlut.edu.cnAbout author:WEI Zhifan (1993-), male, PhD. E-mail: 424380067@qq.com

Supported by:CLC Number:

WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure[J]. Journal of Inorganic Materials, 2025, 40(7): 817-825.

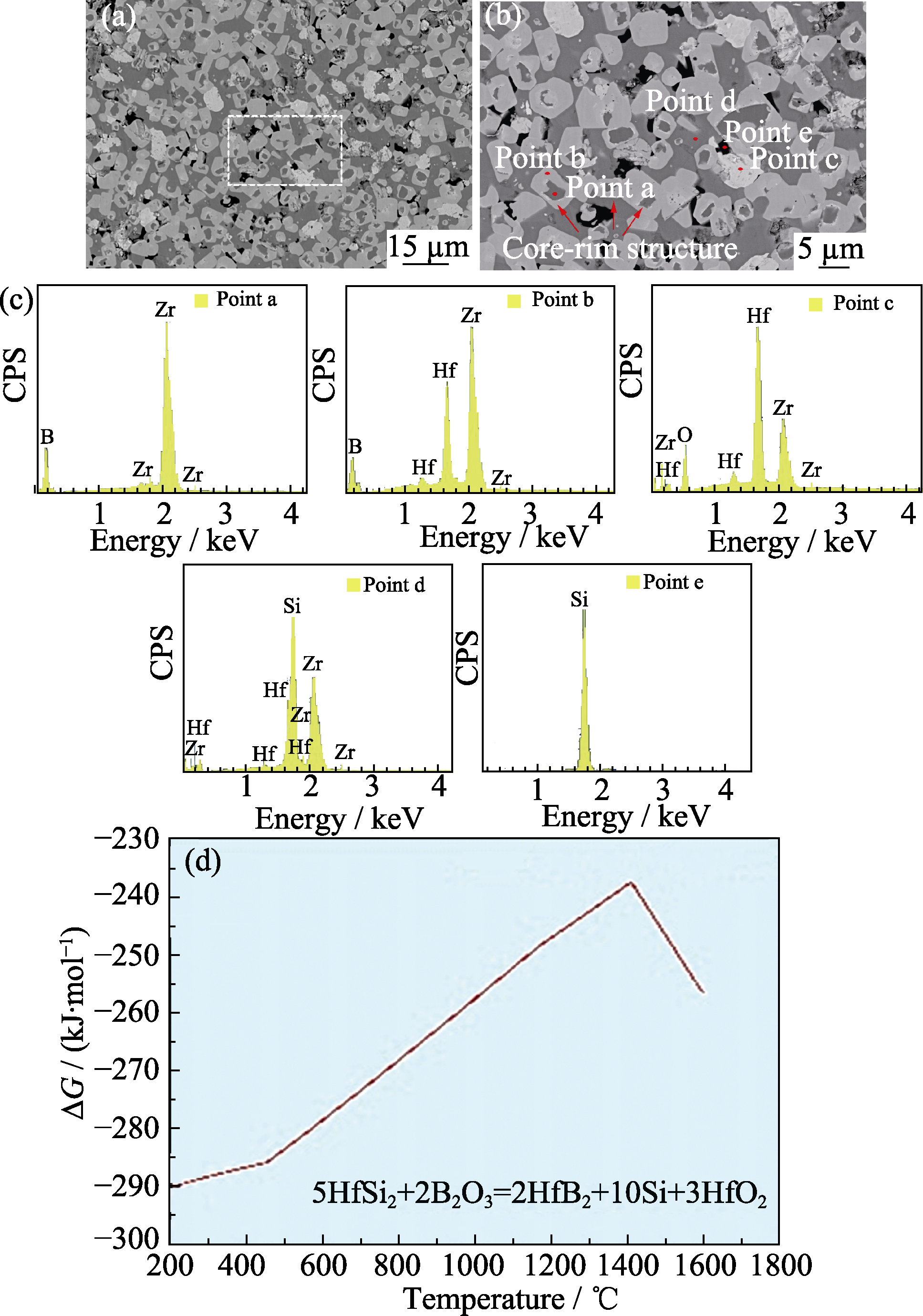

Fig. 3 (a) Microstructure and (b) partial enlarged microstructure of ZrB2-HfSi2 ceramic; (c) EDS results of ZrB2-HfSi2 ceramic; (d) Gibbs free energy of the reaction (6)

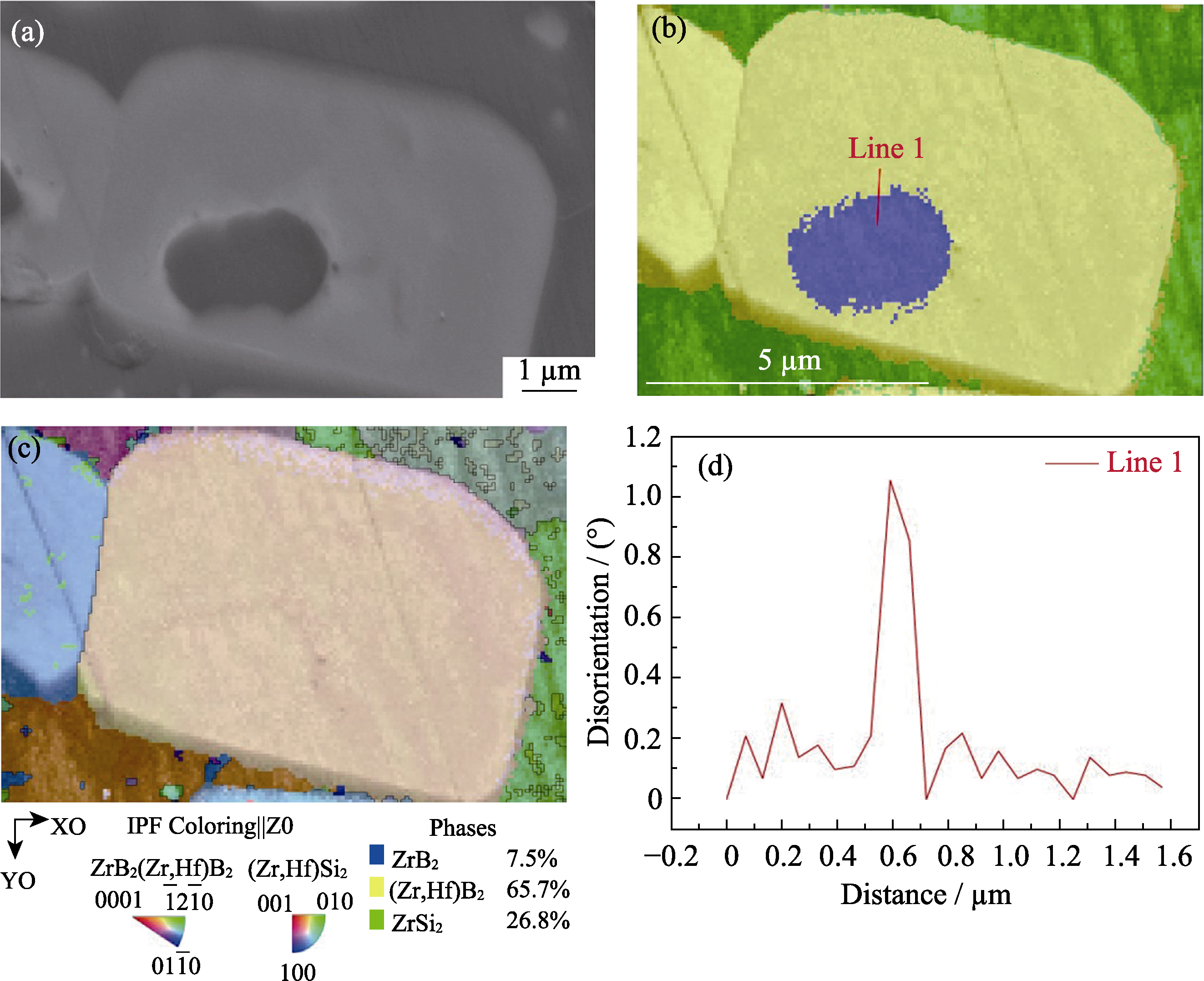

Fig. 4 EBSD analysis diagrams of ZrB2-HfSi2 ceramic with core-rim structure (a) Core-rim structure microstructure; (b) Phase distribution of core-rim structure; (c) IPF of core-rim structure; (d) Orientation angle difference of interface position

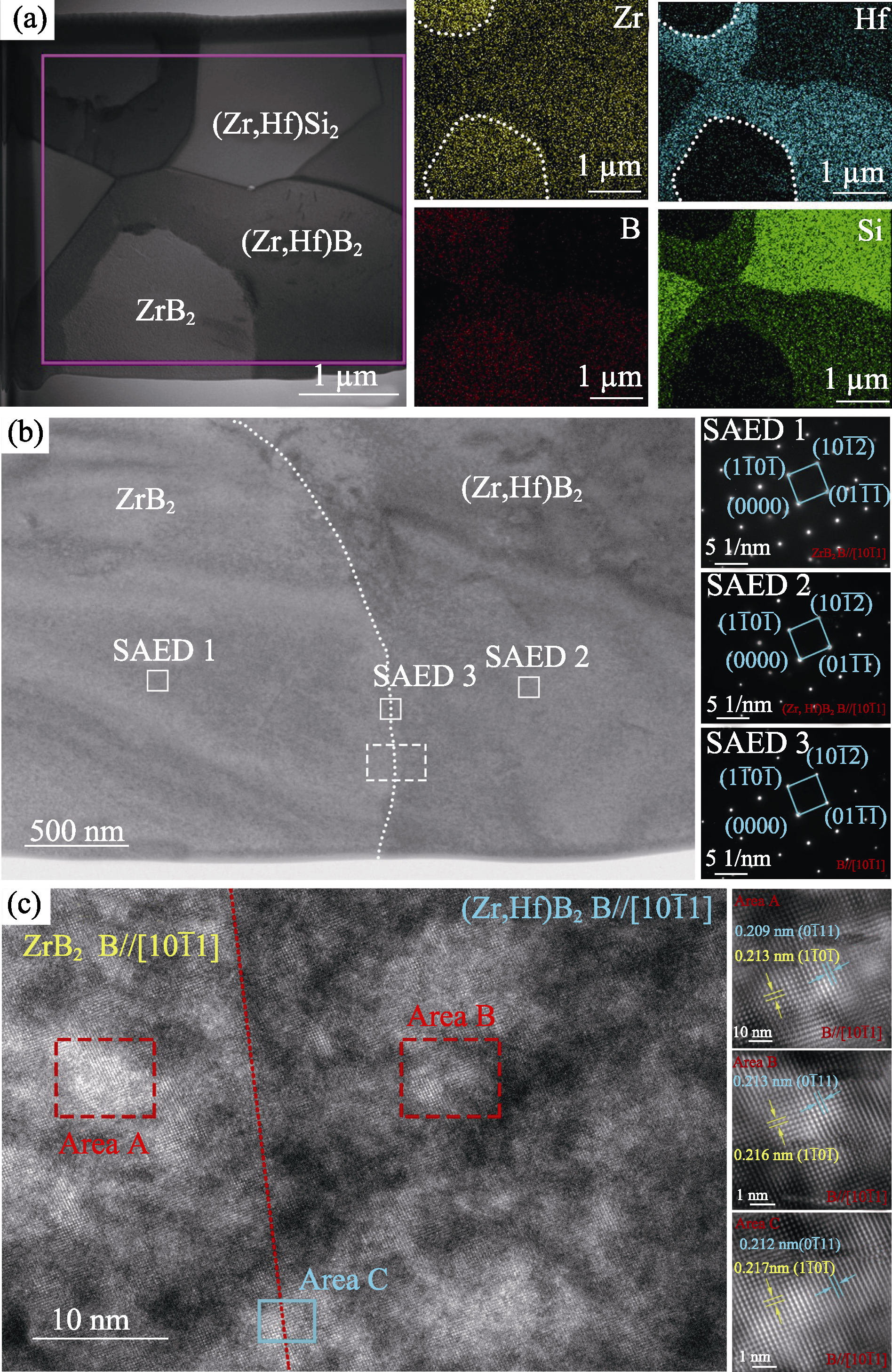

Fig. 5 (a) STEM image and element distribution of ZrB2-HfSi2 ceramic; (b) Microstructure at the interface of core-rim structure and SAED patterns; (c) HRTEM images of the selected interface position in Fig. 5(b)

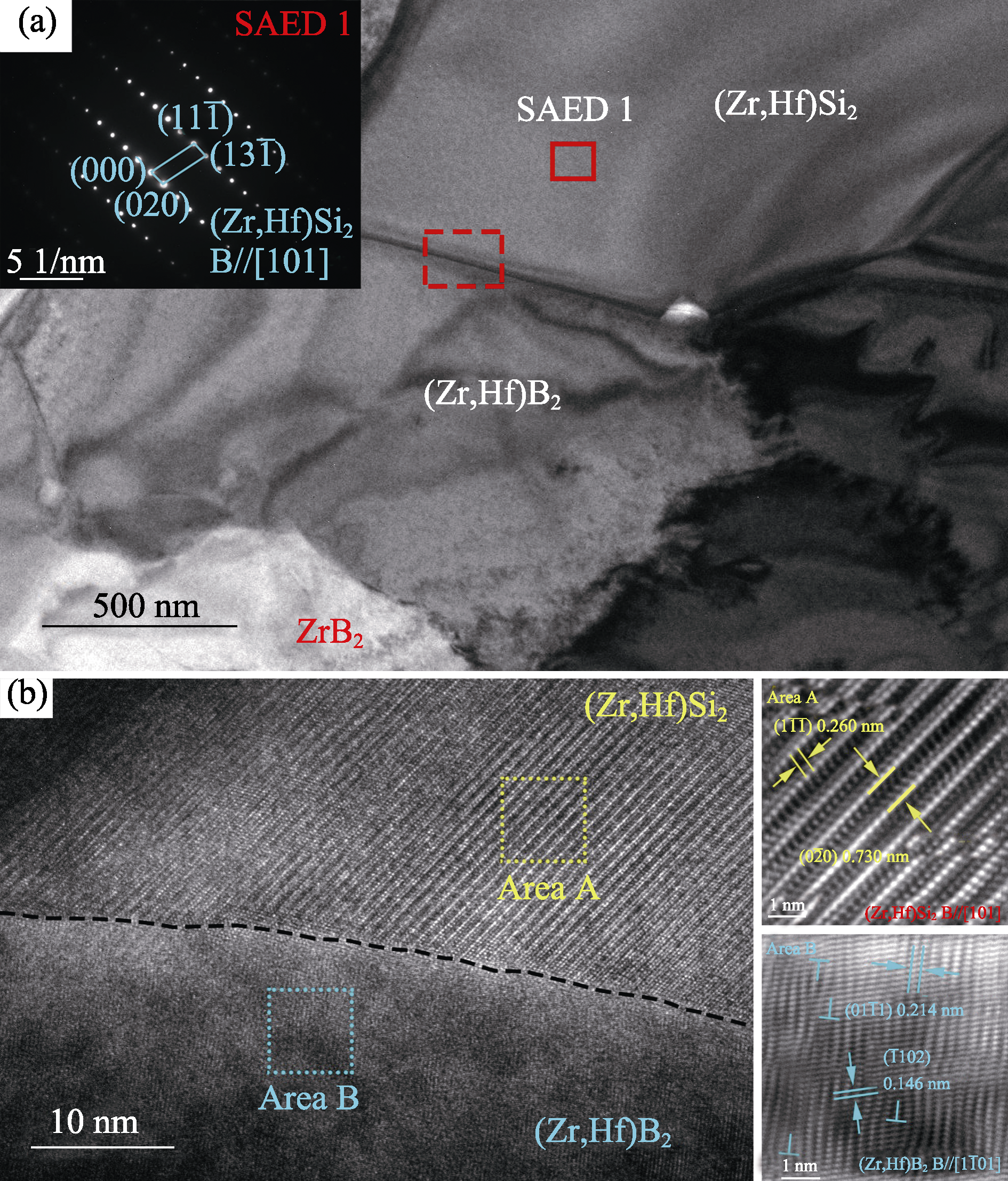

| Crystalline plane | Plane spacing measured/ theoretical value | Crystalline plane | Plane spacing measured/ theoretical value | Mismatch ratio measured/theoretical value | Interface |

|---|---|---|---|---|---|

| (1¯10¯1)ZrB2 | 0.213/0.216 nm | (1¯10¯1)(Zr,Hf)B2 | 0.216/0.215 nm | 1.4%/0.4% | Common lattice interface |

| (01¯1¯1)ZrB2 | 0.209/0.216 nm | (01¯1¯1)(Zr,Hf)B2 | 0.213/0.215 nm | 1.9%/0.4% | Common lattice interface |

| (01¯11)(Zr,Hf)B2 | 0.214/0.215 nm | (0¯20)(Zr,Hf)Si2 | 0.730/0.734 nm | 228.5%/243.4% | Noncommon lattice interface |

| (¯1102)(Zr,Hf)B2 | 0.146/0.148 nm | (1¯1¯1)(Zr,Hf)Si2 | 0.260/0.258 nm | 78.1%/74.3% | Noncommon lattice interface |

Table 1 Measured and theoretical values of the interplanar spacing and misfit ratio

| Crystalline plane | Plane spacing measured/ theoretical value | Crystalline plane | Plane spacing measured/ theoretical value | Mismatch ratio measured/theoretical value | Interface |

|---|---|---|---|---|---|

| (1¯10¯1)ZrB2 | 0.213/0.216 nm | (1¯10¯1)(Zr,Hf)B2 | 0.216/0.215 nm | 1.4%/0.4% | Common lattice interface |

| (01¯1¯1)ZrB2 | 0.209/0.216 nm | (01¯1¯1)(Zr,Hf)B2 | 0.213/0.215 nm | 1.9%/0.4% | Common lattice interface |

| (01¯11)(Zr,Hf)B2 | 0.214/0.215 nm | (0¯20)(Zr,Hf)Si2 | 0.730/0.734 nm | 228.5%/243.4% | Noncommon lattice interface |

| (¯1102)(Zr,Hf)B2 | 0.146/0.148 nm | (1¯1¯1)(Zr,Hf)Si2 | 0.260/0.258 nm | 78.1%/74.3% | Noncommon lattice interface |

Fig. 6 (a) Microstructure at the interface of (Zr,Hf)Si2/ (Zr,Hf)B2 and SAED patterns; (b) HRTEM images of the selected interface position in Fig. 6(a)

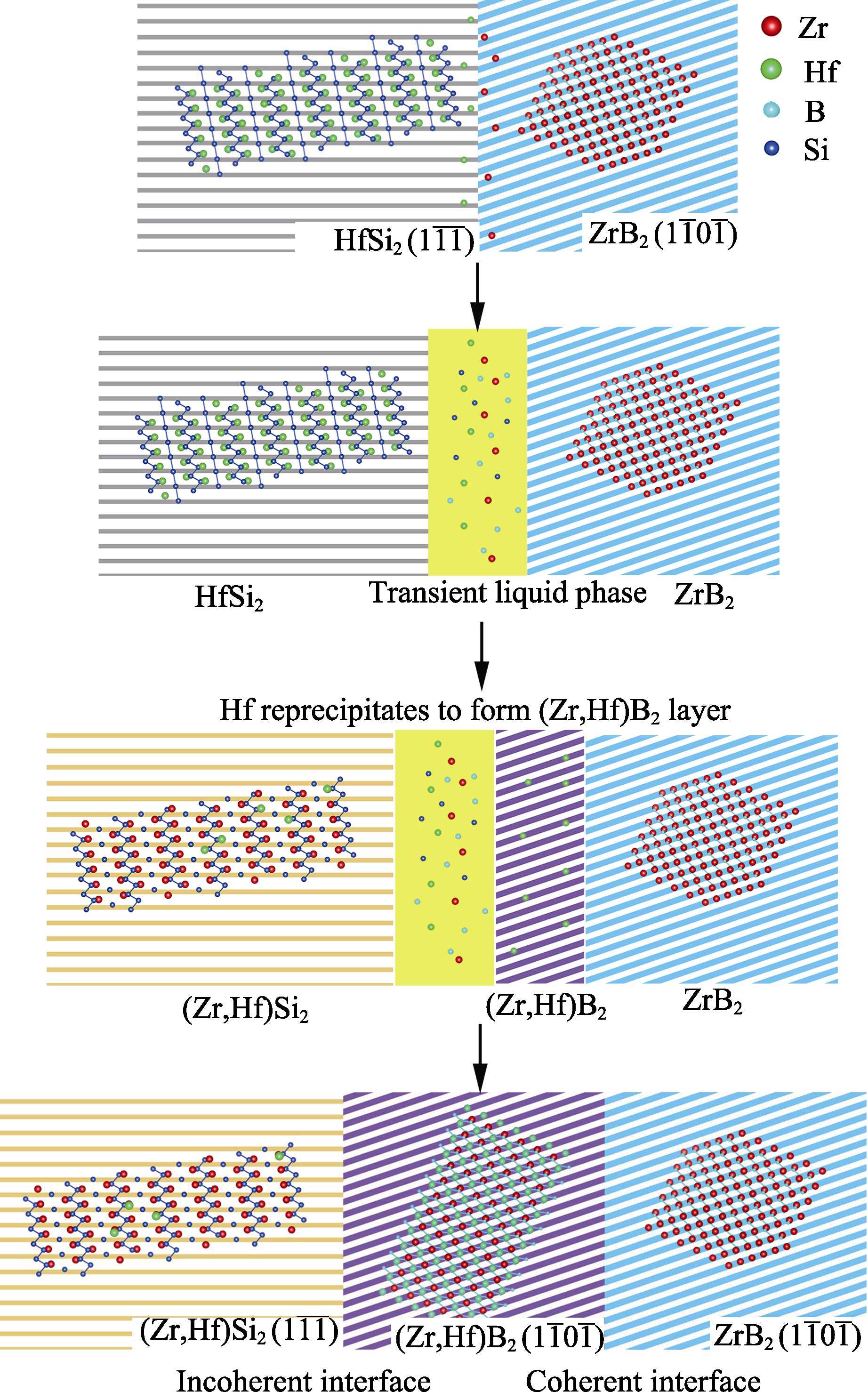

Fig. 7 Formation mechanism diagram of core-rim structure interface in ZrB2-HfSi2 During the initial stage, the surface of ZrB2 melts, and Hf partially dissolves in the transient liquid phase to form a core. During the middle stage, Hf solute diffuses through the transient liquid phase to the surface of the unmelted ZrB2 nucleus, and then precipitates to form a high Hf solubility (Zr,Hf)B2 peripheral layer. During the later stage, the remaining Zr-rich transient liquid phase precipitates to form (Zr,Hf)Si2 phase, and finally forms the hierarchical relationship of ZrB2-(Zr,Hf)B2-(Zr,Hf)Si2.

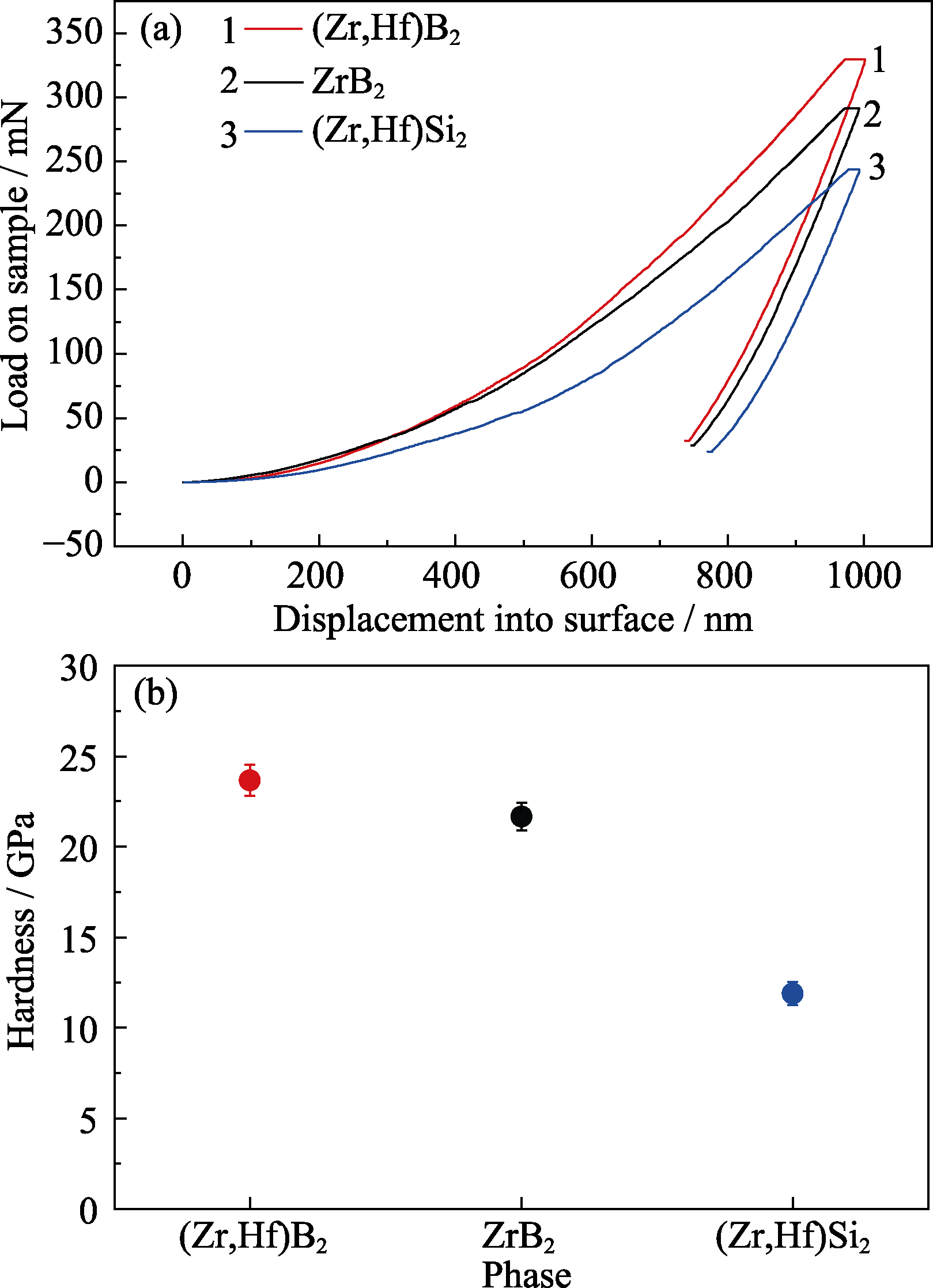

Fig. 9 (a) Load-displacement curves of ZrB2, (Zr,Hf)B2 and (Zr,Hf)Si2 in nano indentation experiment; (b) Hardnesses of ZrB2, (Zr,Hf)B2 and (Zr,Hf)Si2 in the microstructures

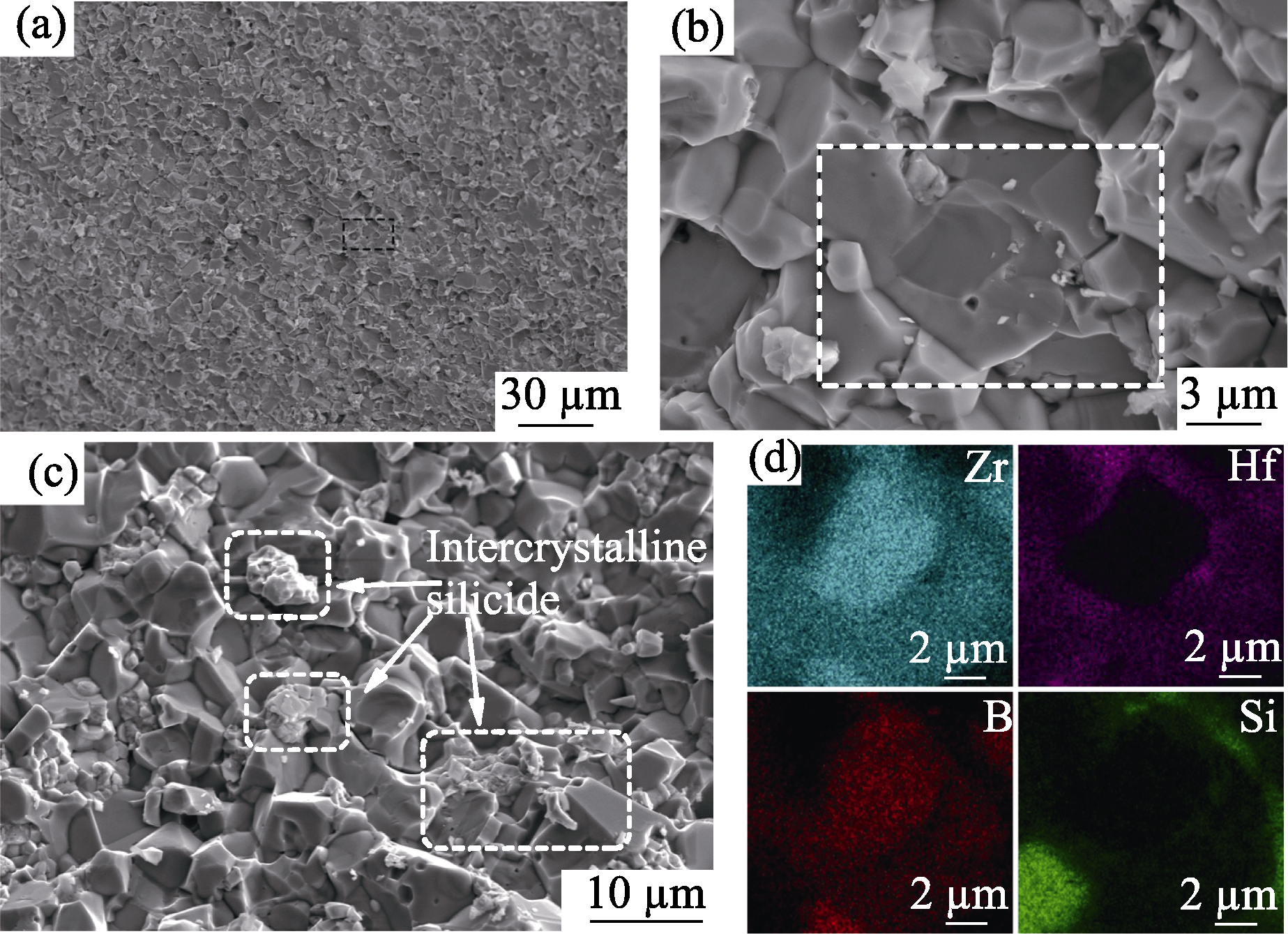

Fig. 10 (a) Fracture microstructure of ZrB2-HfSi2 ceramics; (b) Cleavage platform of core-rim structure; (c) Enlarged drawing of fracture and (d) corresponding EDS element distributions

| [1] | PARTHASARATHY T A, PETRY M D, CINIBULK M K, et al. Thermal and oxidation response of UHTC leading edge samples exposed to simulated hypersonic flight conditions. Journal of the American Ceramic Society, 2013, 96(3): 907. |

| [2] | FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017, 129: 94. |

| [3] | FAHRENHOLTZ W G, HILMAS G E, TALMY I G, et al. Refractory diborides of zirconium and hafnium. Journal of the American Ceramic Society, 2007, 90(5): 1347. |

| [4] | MONTEVERDE F, BELLOSI A, GUICCIARDI S. Processing and properties of zirconium diboride-based composites. Journal of the European Ceramic Society, 2002, 22(3): 279. |

| [5] | GOLLA B R, MUKHOPADHYAY A, BASU B, et al. Review on ultra-high temperature boride ceramics. Progress in Materials Science, 2020, 111: 100651. |

| [6] | KHANRA A K, GODKHINDI M M. Effect of Ni additives on pressureless sintering of SHS ZrB2. Advances in Applied Ceramics, 2005, 104(6): 273. |

| [7] | WANG H, CHEN D, WANG C A, et al. Preparation and characterization of high-toughness ZrB2/Mo composites by hot-pressing process. International Journal of Refractory Metals and Hard Materials, 2009, 27(6): 1024. |

| [8] | GUO S Q. Densification of ZrB2-based composites and their mechanical and physical properties: a review. Journal of the European Ceramic Society, 2009, 29(6): 995. |

| [9] | GUO S. Densification, microstructure, elastic and mechanical properties of reactive hot-pressed ZrB2-ZrC-Zr cermets. Journal of the European Ceramic Society, 2014, 34(3): 621. |

| [10] | MISHRA S K, PATHAK L C. Effect of carbon and titanium carbide on sintering behaviour of zirconium diboride. Journal of Alloys and Compounds, 2008, 465(1/2): 547. |

| [11] | REZAIE A, FAHRENHOLTZ W G, HILMAS G E. Effect of hot pressing time and temperature on the microstructure and mechanical properties of ZrB2-SiC. Journal of Materials Science, 2007, 42(8): 2735. |

| [12] | SHA J J, LI J, WANG S H, et al. Toughening effect of short carbon fibers in the ZrB2-ZrSi2 ceramic composites. Materials and Design, 2015, 75: 160. |

| [13] | ASL M S, NAYEBI B, AHMADI Z, et al. Effects of carbon additives on the properties of ZrB2-based composites: a review. Ceramics International, 2018, 44(7): 7334. |

| [14] | ASL M S, FARAHBAKHSH I, NAYEBI B. Characteristics of multi-walled carbon nanotube toughened ZrB2-SiC ceramic composite prepared by hot pressing. Ceramics International, 2016, 42(1): 1950. |

| [15] | MONTEVERDE F, BELLOSI A. Efficacy of HfN as sintering aid in the manufacture of ultrahigh-temperature metal diborides- matrix ceramics. Journal of Materials Research, 2004, 19(12): 3576. |

| [16] | MONTEVERDE F, BELLOSI A. Effect of the addition of silicon nitride on sintering behaviour and microstructure of zirconium diboride. Scripta Materialia, 2002, 46(3): 223. |

| [17] | MONTEVERDE F, BELLOSI A. Beneficial effects of AlN as sintering aid on microstructure and mechanical properties of hot-pressed ZrB2. Advanced Engineering Materials, 2003, 5(7): 508. |

| [18] | SILVESTRONI L, SCITI D. Densification of ZrB2-TaSi2 and HfB2-TaSi2 ultra-high-temperature ceramic composites: densification of ZrB2-TaSi2 and HfB2-TaSi2 ceramic composites. Journal of the American Ceramic Society, 2011, 94(6): 1920. |

| [19] | SILVESTRONI L, KLEEBE H J, LAUTERBACH S, et al. Transmission electron microscopy on Zr- and Hf-borides with MoSi2 addition: densification mechanisms. Journal of Materials Research, 2010, 25(5): 828. |

| [20] | SCITI D, SILVESTRONI L, CELOTTI G, et al. Sintering and mechanical properties of ZrB2-TaSi2 and HfB2-TaSi2 ceramic composites. Journal of the American Ceramic Society, 2008, 91(10): 3285. |

| [21] | LAVRENKO V O, PANASYUK A D, GRIGOREV O M, et al. High-temperature (to 1600 ℃) oxidation of ZrB2-MoSi2 ceramics in air. Powder Metallurgy and Metal Ceramics, 2012, 51(1): 102. |

| [22] | MUSA C, LICHERI R, ORRÙ R, et al. Synthesis, sintering, and oxidative behavior of HfB2-HfSi2 ceramics. Industrial and Engineering Chemistry Research, 2014, 53(22): 9101. |

| [23] | SAJDAK M, KORNAUS K, ZIENTARA D, et al. Processing, microstructure and mechanical properties of TiB2-MoSi2-C ceramics. Crystals, 2024, 14(3): 212. |

| [24] | GROHSMEYER R J, SILVESTRONI L, HILMAS G E, et al. ZrB2-MoSi2 ceramics: a comprehensive overview of microstructure and properties relationships. Part I: processing and microstructure. Journal of the European Ceramic Society, 2019, 39(6): 1939. |

| [25] | NIIHARA K. A fracture mechanics analysis of indentation- induced Palmqvist crack in ceramics. Journal of Materials Science Letters, 1983, 2(5): 221. |

| [26] | ZU Y, CHEN G, FU X, et al. Effects of liquid phases on densification of TiO2-doped Al2O3-ZrO2 composite ceramics. Ceramics International, 2014, 40(3): 3989. |

| [27] | MELÉNDEZ-MARTÍNEZ J J, DOMÍNGUEZ-RODRÍGUEZ A, MONTEVERDE F, et al. Characterisation and high temperature mechanical properties of zirconium boride-based materials. Journal of the European Ceramic Society, 2002, 22(14/15): 2543. |

| [28] | SUN X, HAN W, HU P, et al. Microstructure and mechanical properties of ZrB2-Nb composite. International Journal of Refractory Metals and Hard Materials, 2010, 28(3): 472. |

| [29] | GUO S Q, KAGAWA Y, NISHIMURA T. Mechanical behavior of two-step hot-pressed ZrB2-based composites with ZrSi2. Journal of the European Ceramic Society, 2009, 29(4): 787. |

| [30] | ORLOVSKAYA N, STADELMANN R, LUGOVY M, et al. Mechanical properties of ZrB2-SiC ceramic composites: room temperature instantaneous behaviour. Advances in Applied Ceramics, 2013, 112(1): 9. |

| [31] | LI W, ZHANG X, HONG C, et al. Microstructure and mechanical properties of zirconia-toughened ZrB2-MoSi2 composites prepared by hot-pressing. Scripta Materialia, 2009, 60(2): 100. |

| [32] | ASL M S, KAKROUDI M G, NOORI S. Hardness and toughness of hot pressed ZrB2-SiC composites consolidated under relatively low pressure. Journal of Alloys and Compounds, 2015, 619: 481. |

| [33] | GUI K, HU P, HONG W, et al. Microstructure, mechanical properties and thermal shock resistance of ZrB2-SiC-Cfcomposite with inhibited degradation of carbon fibers. Journal of Alloys and Compounds, 2017, 706: 16. |

| [34] | YANG Y, QIAN Y H, XU J J, et al. Effects of TaSi2 addition on room temperature mechanical properties of ZrB2-20SiC composites. Ceramics International, 2018, 44(14): 16150. |

| [35] | MONTEVERDE F. Hot pressing of hafnium diboride aided by different sinter additives. Journal of Materials Science, 2008, 43(3): 1002. |

| [36] | LANG Q, LI N, LIU X, et al. Regulating Mg/Fe interfacial compound formation by in-situ alloying with Gd and Y. Journal of Magnesium and Alloys, 2024, 12(12): 5179. |

| [37] | SONG G, LI T, ZHANG Z, et al. Investigation of unequal thickness Mg/steel butt-welded plate by hybrid laser-tungsten inert gas welding with a Ni interlayer. Journal of Manufacturing Processes, 2017, 30: 299. |

| [38] | HU D L, GU H, ZOU J, et al. Core-rim structure, bi-solubility and a hierarchical phase relationship in hot-pressed ZrB2-SiC-MC ceramics (M=Nb, Hf, Ta, W). Journal of Materiomics, 2021, 7(1): 69. |

| [39] | ZHU S, LI J, XING J, et al. Cathodoluminescence characteristics of a novel core-rim structure in Bi-doped (Sr,Ba)TiO3 ceramics. Ceramics International, 2019, 45(6): 8027. |

| [40] | ENGSTRÖM I, LÖNNBERG B. Thermal expansion studies of the group IV-VII transition-metal disilicides. Journal of Applied Physics, 1988, 63(9): 4476. |

| [41] | KEIHN F G, KEPLIN E J. High-temperature thermal expansion of certain group IV and group V diborides. Journal of the American Ceramic Society, 1967, 50(2): 81. |

| [1] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [2] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [3] | HE Zongbei, CHEN Fang, LIU Dianguang, LI Tongye, ZENG Qiang. Sintering Behavior of Simulating Core FCM Fuel via Hot Oscillatory Pressing [J]. Journal of Inorganic Materials, 2024, 39(5): 501-508. |

| [4] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [5] | Zhui WANG, Jian-Jun HAN, Jian-Qiang LI, Xiao-Yu LI, Jiang-Tao LI, Gang HE, Jun XIE. Plastic Sintering Behavior of Large-sized La2O3-TiO2-ZrO2 Amorphous Bulk [J]. Journal of Inorganic Materials, 2019, 34(4): 433-438. |

| [6] | NIE Lan-Jian, GU Zhen-An, WANG Yu-Fen, XIANG Zai-Kui, ZHANG Chen-Yang, RAO Chuan-Dong. SiO2 Soot Body at Vacuum Sintering Process: Densification and Transparency Mechanism [J]. Journal of Inorganic Materials, 2019, 34(10): 1060-1066. |

| [7] | GUO Sheng-Qiang, WANG Hao, TU Bing-Tian, WANG Bin, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Fabrication and Property of Fine-grained MgO·1.44Al2O3 Spinel Transparent Ceramic [J]. Journal of Inorganic Materials, 2019, 34(10): 1067-1071. |

| [8] | LI Ren-Yi, LI Xiao-Yu, LI Jian-Qiang, ZHAO Jian-Ling, MA Xiao-Guang, HE Gang, LI Jiang-Tao. Large-sized La2O3-TiO2-SiO2 Amorphous Oxide Fabricated by Hot Press Sintering [J]. Journal of Inorganic Materials, 2017, 32(8): 851-856. |

| [9] | YUAN Qin, SONG Yong-Cai. Effects of Al and O Content on Transformation from SiAlCO to Si(Al)C Fibers after High Temperature Treatment [J]. Journal of Inorganic Materials, 2016, 31(4): 393-400. |

| [10] | YUAN Qin, SONG Yong-Cai. Effect of SiCxOy Decomposition on Densification of SiCO(Al) Fibers during Sintering Process [J]. Journal of Inorganic Materials, 2016, 31(12): 1320-1326. |

| [11] | LI Hai-Tao, LI Qian, YAN Yan-Fu, XU Rong-Hui. Effect of ZnO-doping on Sinterability and Microwave Dielectric Property of Ca0.25(Li0.43Sm0.57)0.75TiO3 Ceramics [J]. Journal of Inorganic Materials, 2015, 30(4): 369-373. |

| [12] | LI Yan, CUI Hong, ZHANG Hua-Kun, JI A-Lin, JIE Yu-Jie. Densification Behavior of Thermal Gradient CVI of Large-scale C/C Composites [J]. Journal of Inorganic Materials, 2015, 30(2): 153-158. |

| [13] | DU Xian-Wu, ZHANG Zhi-Xiao, WANG Wei-Min, FU Zheng-Yi, WANG Hao. Effect of Particle Size on Densification and Mechanical Properties of Hot-pressed Boron Carbide [J]. Journal of Inorganic Materials, 2013, 28(10): 1062-1066. |

| [14] | ZHANG Guo-Jun, ZOU Ji, NI De-Wei, LIU Hai-Tao, KAN Yan-Mei. Boride Ceramics: Densification, Microstructure Tailoring and Properties Improvement [J]. Journal of Inorganic Materials, 2012, 27(3): 225-233. |

| [15] | LI Jian-Li, SU Zhe-An, ZHANG Ming-Yu, YANG Xin, HUANG Qi-Zhong. Mechanism of Densification of C/C Composites Fabricated with High Density Preform [J]. Journal of Inorganic Materials, 2011, 26(7): 711-714. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||