Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (5): 531-538.DOI: 10.15541/jim20230587

Special Issue: 【信息功能】透明与闪烁陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LÜ Zhaoyang1,2( ), XU Yong1,2, YANG Jiuyan1,2, TU Guangsheng1,2, TU Bingtian1,2, WANG Hao1,2(

), XU Yong1,2, YANG Jiuyan1,2, TU Guangsheng1,2, TU Bingtian1,2, WANG Hao1,2( )

)

Received:2023-12-21

Revised:2024-01-20

Published:2024-05-20

Online:2024-02-22

Contact:

WANG Hao, professor. E-mail: shswangh@whut.edu.cnAbout author:LÜ Zhaoyang (1999-), male, Master candidate. E-mail: lvzhaoyang2021@163.com

Supported by:CLC Number:

LÜ Zhaoyang, XU Yong, YANG Jiuyan, TU Guangsheng, TU Bingtian, WANG Hao. Effect of MgF2 Additive on Preparation and Optical Properties of MgAl1.9Ga0.1O4 Transparent Ceramics[J]. Journal of Inorganic Materials, 2024, 39(5): 531-538.

Fig. 1 Sintering trajectories of MAGS-0.1 ceramics with 0.1%, 0.2% and 0.5% MgF2 and the unaided MAGS-0.1 ceramics Colorful figure is available on website

Fig. 2 Variations of the shrinkage and shrinkage rate of MAGS-0.1 ceramic green bodies containing 0 and 0.2% MgF2 as a function of temperature (a) Shrinkage curves; (b) Shrinkage rate curves

Fig. 3 TG-DSC curves of MAGS-0.1 powder containing 10% MgF2 and XRD patterns of MAGS-0.1 powder containing 10% MgF2 after heating and holding at different temperatures (a) TG-DSC curves of MAGS-0.1 powder containing 10% MgF2 heated at 10 ℃/min; (b) XRD patterns of MAGS-0.1 powder containing 10% MgF2 after heating and holding at 1150, 1250, 1350 and 1450 ℃ for 5 min followed by quenching; (c) Enlarged XRD patterns of the (220) crystal face in (b)

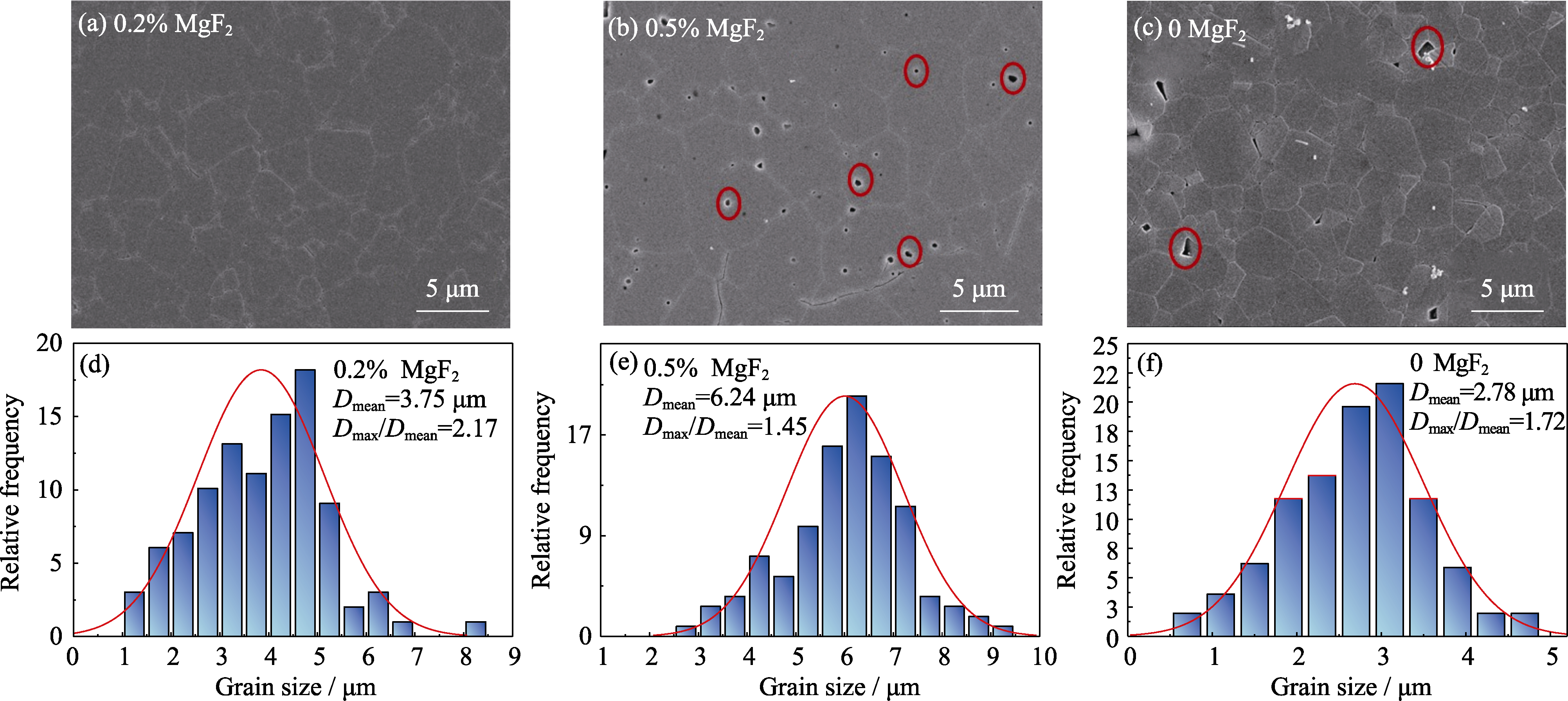

Fig. 6 Surface SEM images and grain size distributions of MAGS-0.1 ceramics with different additive contents after pressureless presintering and chemical etching (a, d) Sample with 0.2% MgF2; (b, e) Sample with 0.5% MgF2; (c, f) Sample without additive

Fig. 7 Surface SEM images and grain size distributions of MAGS-0.1 ceramics after HIP sintering and chemical etching (a, c) Sample with 0.2% MgF2; (b, d) Sample without additive

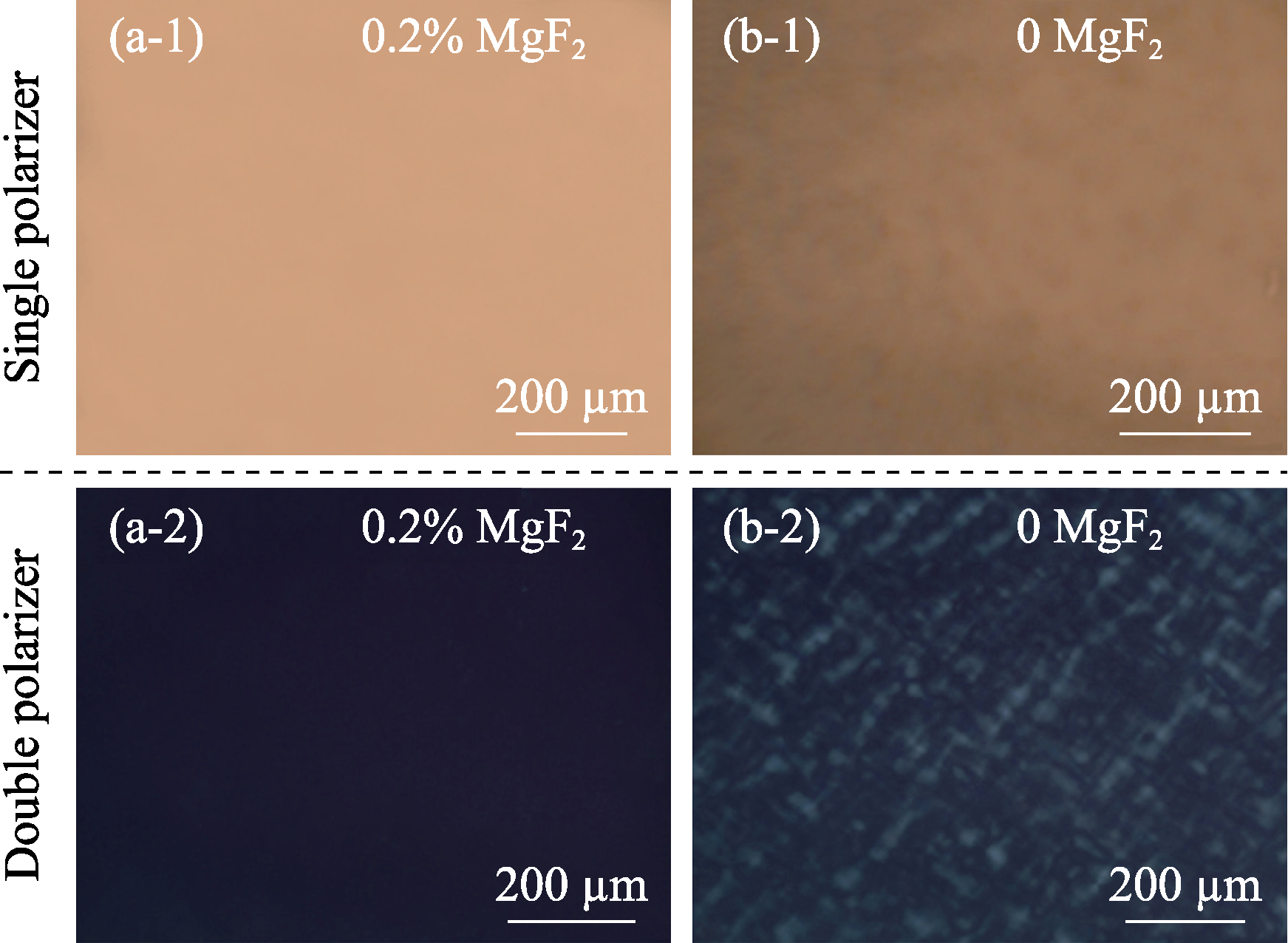

Fig. 9 Optical polarized transmission micrographs of transparent ceramics without additive and with 0.2% MgF2 (a) Sample with 0.2% MgF2; (b) Sample without additive

Fig. 10 Optical properties of samples with different additive contents and sizes Inset: Appearance image of a sample containing 0.2% MgF2 with ϕ108.8 mm×9.36 mm

| [1] | RUBAT D M, KLEEBE H J, MÜLLER M M, et al. Fifty years of research and development coming to fruition; unraveling the complex interactions during processing of transparent magnesium aluminate (MgAl2O4) spinel. Journal of the American Ceramic Society, 2013, 96(11): 3341. |

| [2] | WAETZIG K, KRELL A. The effect of composition on the optical properties and hardness of transparent Al-rich MgO·nAl2O3 spinel ceramics. Journal of the American Ceramic Society, 2016, 99(3): 946. |

| [3] | SANGHERA J, BAYYA S, VILLALOBOS G, et al. Transparent ceramics for high-energy laser systems. Optical Materials, 2011, 33(3): 511. |

| [4] | PAPPAS J M, DONG X. Porosity characterization of additively manufactured transparent MgAl2O4 spinel by laser direct deposition. Ceramics International, 2020, 46(5): 6745. |

| [5] | TU B T, TU G S, WANG H, et al. Highly transparent MgAl0.5Ga1.5O4 ceramic for overcoming the trade-off between infrared transmittance and mechanical properties. Scripta Materialia, 2022, 216: 114756. |

| [6] | YANG J Y, WANG H, TU B T, et al. Preparation and optical properties of highly transparent MgAl1.9Ga0.1O4 ceramics via aqueous gel-casting method. Journal of the European Ceramic Society, 2023, 43(10): 4506. |

| [7] | MEIR S, KALABUKHOV S, FROUMIN N, et al. Synthesis and densification of transparent magnesium aluminate spinel by SPS processing. Journal of the American Ceramic Society, 2009, 92(2): 358. |

| [8] | ROZENBURG K, REIMANIS I E, KLEEBE H J, et al. Chemical interaction between LiF and MgAl2O4 spinel during sintering. Journal of the American Ceramic Society, 2007, 90(7): 2038. |

| [9] | GOLDSTEIN A, RAETHEL J, KATZ M, et al. Transparent MgAl2O4/LiF ceramics by hot-pressing: host-additive interaction mechanisms issue revisited. Journal of the European Ceramic Society, 2016, 36(7): 1731. |

| [10] | IKESUE A, AUNG Y L. Advanced spinel ceramics with highest VUV-vis transparency. Journal of the European Ceramic Society, 2020, 40(6): 2432. |

| [11] | NEČINA V, HOSTAŠA J, PABST W, et al. Magnesium fluoride (MgF2)-a novel sintering additive for the preparation of transparent YAG ceramics via SPS. Journal of the European Ceramic Society, 2022, 42(7): 3290. |

| [12] | XU Z Y, SUN D M, LI A X, et al. X-ray diffraction analysis of the oxidation of MgF2. Journal of the Chinese Ceramic Society, 2002, 30(4): 505. |

| [13] | LIU Y M, ZHAO Z Y, LI A X, et al. A Rietveld full-spectrum fitting study on the oxidation of MgF2. Journal of Anhui University Natural Science Edition, 2002, 26(4): 46. |

| [14] | ZHOU T Y, ZHANG L, WEI S, et al. MgO assisted densification of highly transparent YAG ceramics and their microstructural evolution. Journal of the European Ceramic Society, 2018, 38(2): 687. |

| [15] | MOHAMED N R. Sintering of Ceramics. Florida: CRC Press, 2007: 79-81. |

| [16] | TALIMIAN A, EL-MAGHRABY H F, MICHÁLKOVÁ M, et al. Sintering and grain growth behaviour of magnesium aluminate spinel: effect of lithium hydroxide addition. Journal of the European Ceramic Society, 2021, 41(11): 5634. |

| [17] | 宗潇. MgAlON透明陶瓷的设计、制备及组成—结构—性能关系研究. 武汉: 武汉理工大学博士学位论文, 2021. |

| [18] | BOULESTEIX R, MAITRE A, BAUMARD J F, et al. Mechanism of the liquid-phase sintering for Nd: YAG ceramics. Optical Materials, 2009, 31(5): 711. |

| [19] | LI W J, WANG H, TU B T, et al. Preparation and property of Mg0.9Al2.08O3.97N0.03 transparent ceramic with broad optical transmission range. Journal of Inorganic Materials, 2022, 37(9): 969. |

| [20] | IKESUE A, AUNG Y L. Anisotropic alumina ceramics with isotropic optical properties. Journal of Advanced Ceramics, 2023, 12(1): 72. |

| [21] | KLEIN C A. Flexural strength of infrared-transmitting window materials: bimodal Weibull statistical analysis. Optical En-gineering, 2011, 50(2): 1. |

| [22] | DENG B, JIANG D, GONG J. Is a three-parameter Weibull function really necessary for the characterization of the statistical variation of the strength of brittle ceramics. Journal of the European Ceramic Society, 2018, 38(4): 2234. |

| [23] | KHALILI A. Statistical properties of Weibull estimators. Journal of Materials Science 1991, 26: 6741. |

| [24] | TOKARIEV O, SCHNETTER L, BECK T, et al. Grain size effect on the mechanical properties of transparent spinel ceramics. Journal of the European Ceramic Society, 2013, 33(4): 749. |

| [1] | YE Junhao, ZHOU Zhenzhen, HU Chen, WANG Yanbin, JING Yanqiu, LI Tingsong, CHENG Ziqiu, WU Junlin, IVANOV Maxim, HRENIAK Dariusz, LI Jiang. Yb:Sc2O3 Transparent Ceramics Fabricated from Co-precipitated Nano-powders: Microstructure and Optical Property [J]. Journal of Inorganic Materials, 2025, 40(2): 215-224. |

| [2] | GU Junyi, FAN Wugang, ZHANG Zhaoquan, YAO Qin, ZHAN Hongquan. Structure and Optical Property of Pr2O3 Powder Prepared by Reduction [J]. Journal of Inorganic Materials, 2023, 38(7): 771-777. |

| [3] | LI Yue, ZHANG Xuliang, JING Fangli, HU Zhanggui, WU Yicheng. Growth and Property of Ce3+-doped La2CaB10O19 Crystal [J]. Journal of Inorganic Materials, 2023, 38(5): 583-588. |

| [4] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [5] | WANG Dewen, WANG Junping, YUAN Houcheng, LIU Zhang, ZHOU Jin, DENG Jiajie, WANG Xin, WU Benhua, ZHANG Jian, WANG Shiwei. Metre-scale Y3Al5O12 (YAG) Transparent Ceramics by Vacuum Reactive Sintering [J]. Journal of Inorganic Materials, 2023, 38(12): 1483-1484. |

| [6] | LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range [J]. Journal of Inorganic Materials, 2022, 37(9): 969-975. |

| [7] | MU Licheng, YANG Jinping, WANG Junping, ZHAO Jin, LIU Mengwei, WANG Dewen, ZHANG Jian. Preparation of YAG Transparent Ceramics by Epoxy Resin Modified Spontaneous Coagulation Casting [J]. Journal of Inorganic Materials, 2022, 37(9): 941-946. |

| [8] | LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 911-917. |

| [9] | XIAO Shulin, DAI Zhonghua, LI Dingyan, ZHANG Fanbo, YANG Lihong, REN Xiaobing. Electrical and Optical Property of Lanthanum Oxide Doped Potassium Sodium Niobate Ceramics [J]. Journal of Inorganic Materials, 2022, 37(5): 520-526. |

| [10] | JING Yanqiu, LIU Qiang, SU Sha, LI Xiaoying, LIU Ziyu, WANG Jingya, LI Jiang. Fabrication of Highly Transparent Co:MgAl2O4 Ceramic Saturable Absorber for Passive Q-switching in 1.5 μm [J]. Journal of Inorganic Materials, 2021, 36(8): 877-882. |

| [11] | ZENG Jianjun, ZHANG Kuibao, CHEN Daimeng, GUO Haiyan, DENG Ting, LIU Kui. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7 High-entropy Transparent Ceramics by Vacuum Sintering [J]. Journal of Inorganic Materials, 2021, 36(4): 418-424. |

| [12] | LIU Ziyu, TOCI Guido, PIRRI Angela, PATRIZI Barbara, FENG Yagang, CHEN Xiaopu, HU Dianjun, TIAN Feng, WU Lexiang, VANNINI Matteo, LI Jiang. Fabrication and Optical Property of Nd:Lu2O3 Transparent Ceramics for Solid-state Laser Applications [J]. Journal of Inorganic Materials, 2021, 36(2): 210-216. |

| [13] | HUANG Xinyou, LIU Yumin, LIU Yang, LI Xiaoying, FENG Yagang, CHEN Xiaopu, CHEN Penghui, LIU Xin, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Yb:YAG Transparent Ceramics Using Alcohol-water Co-precipitation Method [J]. Journal of Inorganic Materials, 2021, 36(2): 217-224. |

| [14] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| [15] | ZHAO Changjiang,MA Chao,LIU Juncheng,LIU Zhigang,CHEN Yan. Sputtering Power on the Microstructure and Properties of MgF2 Thin Films Prepared with Magnetron Sputtering [J]. Journal of Inorganic Materials, 2020, 35(9): 1064-1070. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||