Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (12): 1289-1294.DOI: 10.15541/jim20220320

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Wangguo1( ), LIU Dianguang1(

), LIU Dianguang1( ), WANG Kewei2, MA Baisheng2, LIU Jinling3

), WANG Kewei2, MA Baisheng2, LIU Jinling3

Received:2022-06-07

Revised:2022-08-09

Published:2022-12-20

Online:2022-08-26

Contact:

LIU Dianguang, associate professor. E-mail: dianguang@swjtu.edu.cnAbout author:LI Wangguo (1997-), male, Master candidate. E-mail: 1648155341@qq.com

Supported by:CLC Number:

LI Wangguo, LIU Dianguang, WANG Kewei, MA Baisheng, LIU Jinling. High Entropy Oxide Ceramics (MgCoNiCuZn)O: Flash Sintering Synthesis and Properties[J]. Journal of Inorganic Materials, 2022, 37(12): 1289-1294.

| Label | E/(V·cm-1) | J/(mA·mm-2) | Tf/℃ | t | Te/℃ |

|---|---|---|---|---|---|

| F1 | 50 | 150 | 300 | 60 s | 990 |

| F2 | 50 | 200 | 300 | 60 s | 1060 |

| F3 | 50 | 250 | 300 | 60 s | 1100 |

| F4 | 50 | 300 | 300 | 60 s | 1130 |

| C1 | - | - | 990 | 2 h | - |

| C2 | - | - | 1060 | 2 h | - |

| C3 | - | - | 1100 | 2 h | - |

| C4 | - | - | 1130 | 2 h | - |

Table 1 Experimental parameters of flash sintering and conventional sintering

| Label | E/(V·cm-1) | J/(mA·mm-2) | Tf/℃ | t | Te/℃ |

|---|---|---|---|---|---|

| F1 | 50 | 150 | 300 | 60 s | 990 |

| F2 | 50 | 200 | 300 | 60 s | 1060 |

| F3 | 50 | 250 | 300 | 60 s | 1100 |

| F4 | 50 | 300 | 300 | 60 s | 1130 |

| C1 | - | - | 990 | 2 h | - |

| C2 | - | - | 1060 | 2 h | - |

| C3 | - | - | 1100 | 2 h | - |

| C4 | - | - | 1130 | 2 h | - |

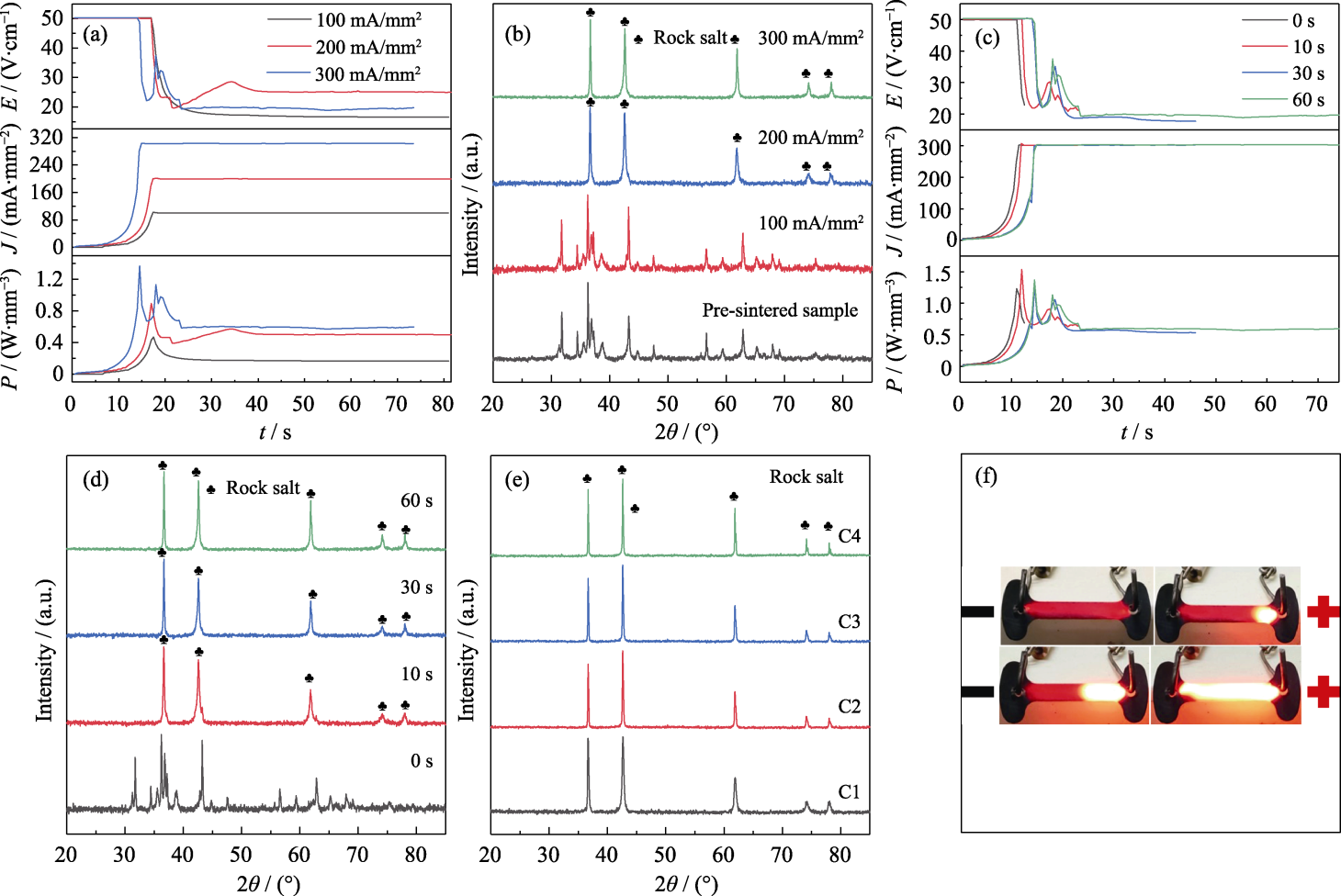

Fig. 1 Flash sintering curves, XRD patterns of samples and pictures of flash sintered sample in the stable stage Flash sintering curves (a) and XRD patterns at room temperature (b) of samples flash sintered at electric field strength of 50 V/cm, holding time of 60 s, and current densities of 100, 200 and 300 mA/mm2, respectively; Flash sintering curves (c) and XRD patterns at room temperature (d) of samples flash sintered at electric field strength of 50 V/cm, current density of 300 mA/mm2, holding time of 0, 10, 30, 60 s; (e) XRD patterns of conventional sintered samples C1-C4; (f) Photos of flash sintered samples in the stable stage; The holding time referrs to the time during the stable stage of flash sintering; Colorful figures are available on website

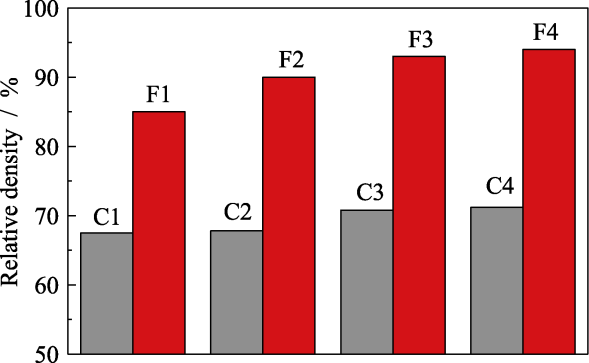

Fig. 2 Densities of samples flash sintered at different current densities at 300 ℃ with holding time of 60 s, and of samples conventionally sintered at the corresponding temperatures

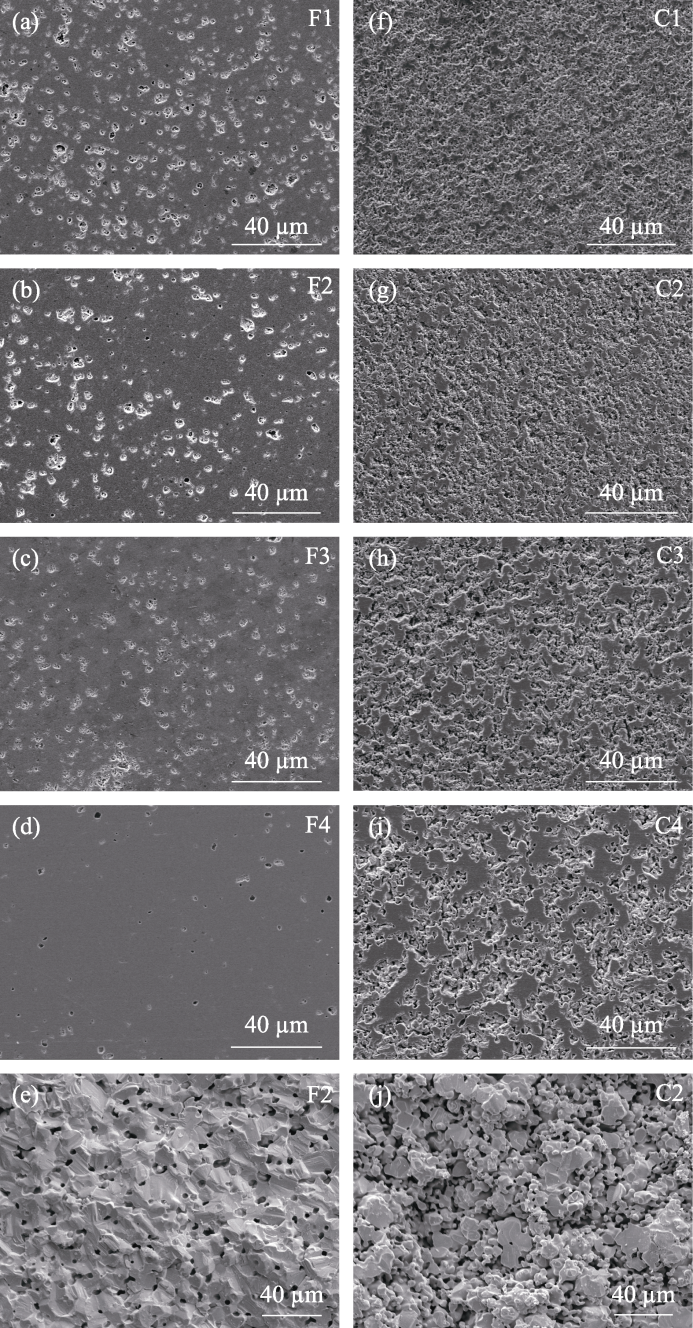

Fig. 3 Comparison of microstructures of flash sintered samples with different current densities and conventional sintered samples at corresponding temperatures (a-e) Microstructures of flash sintered samples; (f-j) Microstructures of conventional sintered samples

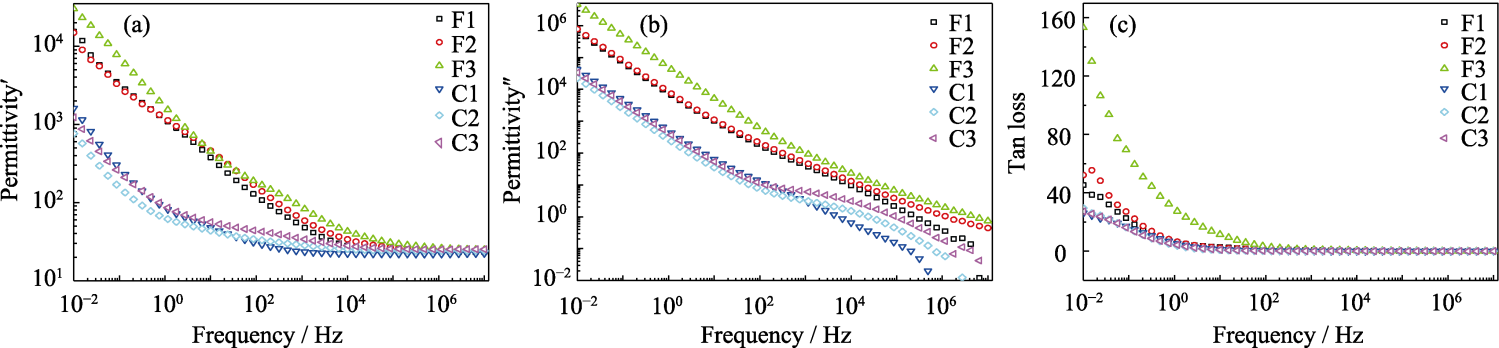

Fig. 5 Real (a) and imaginary (b) parts of the dielectric constants, and tangent loss of flash sintered samples at different current densities and conventional sintered samples at the corresponding temperatures (c)

| [1] |

XIANG H, XING Y, DAI F, et al. High-entropy ceramics: present status, challenges, and a look forward. Journal of Advanced Ceramics, 2021, 10: 385-441.

DOI URL |

| [2] |

ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015, 6: 8485.

DOI PMID |

| [3] |

WANG Q, SARKAR A, LI Z, et al. High entropy oxides as anode material for Li-ion battery applications: a practical approach. Electrochemistry Communications, 2019, 100: 121-125.

DOI URL |

| [4] |

BĖRARDAN D, FRANGER S, DRAGOE D, et al. Colossal dielectric constant in high entropy oxides. Physica Status Solidi (RRL)- Rapid Research Letters, 2016, 10: 328-333.

DOI URL |

| [5] |

BĖRARDAN D, FRANGER S, MEENA A K, et al. Room temperature lithium superionic conductivity in high entropy oxides. Journal of Materials Chemistry A, 2016, 4: 9536-9541.

DOI URL |

| [6] |

QIU N, CHEN H, YANG Z, et al. A high entropy oxide (Mg0.2Co0.2Ni0.2Cu0.2Zn0.2O) with superior lithium storage performance. Journal of Alloys and Compounds, 2019, 777: 767-774.

DOI URL |

| [7] |

CHEN J, LIU W, LIU J, et al. Stability and compressibility of cation-doped high-entropy oxide MgCoNiCuZnO5. The Journal of Physical Chemistry C, 2019, 123: 17735-17744.

DOI URL |

| [8] | BRAUN J L, ROST C M, LIM M, et al. Charge-induced disorder controls the thermal conductivity of entropy-stabilized oxides. Adv. Mater., 2018, 30: e1805004. |

| [9] | HONG W, CHEN F, SHEN Q, et al. Microstructural evolution and mechanical properties of (Mg,Co,Ni,Cu,Zn)O high-entropy ceramics. Journal of the American Ceramic Society, 2019, 102: 2228-2237. |

| [10] |

CHEN H, LIN W, ZHANG Z, et al. Mechanochemical synthesis of high entropy oxide materials under ambient conditions: dispersion of catalysts via entropy maximization. ACS Materials Letters, 2019, 1: 83-88.

DOI URL |

| [11] |

CHEN H, FU J, ZHANG P, et al. Entropy-stabilized metal oxide solid solutions as CO oxidation catalysts with high-temperature stability. Journal of Materials Chemistry A, 2018, 6: 11129-11133.

DOI URL |

| [12] |

DUPUY A D, WANG X, SCHOENUNG J M. Entropic phase transformation in nanocrystalline high entropy oxides. Materials Research Letters, 2018, 7: 60-67.

DOI URL |

| [13] | LIU J, SHAO G, LIU D, et al. Design and synthesis of chemically complex ceramics from the perspective of entropy. Materials Today Advances, 2020, 8: 1-12. |

| [14] |

LIU D, PENG X, LIU J, et al. Ultrafast synthesis of entropy- stabilized oxide at room temperature. Journal of the European Ceramic Society, 2020, 40: 2504-2508.

DOI URL |

| [15] |

YOON B, AVILA V, RAJ R, et al. Reactive flash sintering of the entropy-stabilized oxide Mg0.2Ni0.2Co0.2Cu0.2Zn0.2O. Scripta Materialia, 2020, 181: 48-52.

DOI URL |

| [16] |

KUMAR A, SHARMA G, AFTAB A, et al. Flash assisted synthesis and densification of five component high entropy oxide (Mg, Co, Cu, Ni, Zn)O at 350 ℃ in 3 min. Journal of the European Ceramic Society, 2020, 40: 3358-3362.

DOI URL |

| [17] |

SARKAR A, DJENADIC R, USHARANI N J, et al. Nanocrystalline multicomponent entropy stabilised transition metal oxides. Journal of the European Ceramic Society, 2017, 37: 747-754.

DOI URL |

| [18] |

PARK J, CHEN I W. In situ thermometry measuring temperature flashes exceeding 1,700 ℃ in 8mol% Y2O3-stablized zirconia under constant-voltage heating. Journal of the American Ceramic Society, 2013, 96: 697-700.

DOI URL |

| [19] |

CHAIM R. On the kinetics of liquid-assisted densification during flash sintering of ceramic nanoparticles. Scripta Materialia, 2019, 158: 88-90.

DOI URL |

| [20] |

REN K, HUANG S, CAO Y, et al. The densification behavior of flash sintered BaTiO3. Scripta Materialia, 2020, 186: 362-365.

DOI URL |

| [21] |

JHA S K, CHARALAMBOUS H, WANG H, et al. In-situ observation of oxygen mobility and abnormal lattice expansion in ceria during flash sintering. Ceramics International, 2018, 44: 15362-15369.

DOI URL |

| [22] |

RAJ R. Joule heating during flash-sintering. Journal of the European Ceramic Society, 2012, 32: 2293-2301.

DOI URL |

| [23] |

NARAYAN J. A new mechanism for field-assisted processing and flash sintering of materials. Scripta Materialia, 2013, 69: 107-111.

DOI URL |

| [24] |

ZHANG Y, NIE J, CHAN J M, et al. Probing the densification mechanisms during flash sintering of ZnO. Acta Materialia, 2017, 125: 465-475.

DOI URL |

| [25] |

JI W, PARKER B, FALCO S, et al. Ultra-fast firing: effect of heating rate on sintering of 3YSZ, with and without an electric field. Journal of the European Ceramic Society, 2017, 37: 2547-2551.

DOI URL |

| [26] |

REN K, WANG Q, LIAN Y, et al. Densification kinetics of flash sintered 3mol% Y2O3 stabilized zirconia. Journal of Alloys and Compounds, 2018, 747: 1073-1077.

DOI URL |

| [27] |

COLOGNA M, PRETTE A L G, RAJ R. Flash-sintering of cubic yttria-stabilized zirconia at 750 ℃ for possible use in SOFC manufacturing. Journal of the American Ceramic Society, 2011, 94: 316-319.

DOI URL |

| [28] |

PARK H S, RUDD R E, CAVALLO R M, et al. Grain-size- independent plastic flow at ultrahigh pressures and strain rates. Physical Review Letters, 2015, 114: 065502.

DOI URL |

| [29] |

LI J, FAN J, YUAN Y, et al. Effect of oscillatory pressure on the sintering behavior of ZrO2 ceramic. Ceramics International, 2020, 46: 13240-13243.

DOI URL |

| [30] |

LIU D, ZHANG X, FAN J, et al. Sintering behavior and mechanical properties of alumina ceramics exposed to oscillatory pressure at different sintering stages. Ceramics International, 2021, 47: 23682-23685.

DOI URL |

| [31] |

REN K, XIA J, WANG Y. Grain growth kinetics of 3mol% yttria- stabilized zirconia during flash sintering. Journal of the European Ceramic Society, 2019, 39: 1366-1373.

DOI URL |

| [32] |

ZHAO R, HAN D, LU S, et al. Position-sensitive electric property of flash-sintered 3Y-TZP ceramics based on DC bias assisted impedance analysis. Ceramics International, 2022, 48: 2882-2885.

DOI URL |

| [33] |

YAO S, LIU D, LIU J, et al. Ultrafast preparation of Al2O3-ZrO2 multiphase ceramics with eutectic morphology via flash sintering. Ceramics International, 2021, 47: 31555-31560.

DOI URL |

| [34] |

HOMES C C, VOGT T, SHAPIRO S M, et al. Optical response of high-dielectric-constant perovskite-related oxide. Science, 2001, 293: 673-676.

PMID |

| [35] | 许静. 有机改性SiC晶须/PVDF复合薄膜的制备及介电性能研究. 西安: 西安建筑科技大学硕士学位论文, 2018. |

| [36] |

LIU D, WANG K, ZHAO K, et al. Creep behavior of zirconia ceramics under a strong DC field. Scripta Materialia, 2022, 214: 114654.

DOI URL |

| [37] |

MA B, ZHU Y, WANG K, et al. Microstructure and dielectric property of flash sintered SiO2-coated BaTiO3 ceramics. Scripta Materialia, 2019, 170: 1-5.

DOI URL |

| [1] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [2] | LI Junsheng, ZENG Liang, LIU Rongjun, WANG Yanfei, WAN Fan, LI Duan. Functional Strontium Tantalum Oxynitride Ceramics: Efficient Synthesis, Densification and Dielectric Performance [J]. Journal of Inorganic Materials, 2023, 38(8): 885-892. |

| [3] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [4] | LIU Jinling, LIU Dianguang, REN Ke, WANG Yiguang. Research Progress on the Flash Sintering Mechanism of Oxide Ceramics and Its Application [J]. Journal of Inorganic Materials, 2022, 37(5): 473-480. |

| [5] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [6] | SONG Jian-Min, DAI Xiu-Hong, LIANG Jie-Tong, ZHAO Lei, ZHOU Yang, GE Da-Yong, MENG Xu-Dong, LIU Bao-Ting. Resistive Switching Effect and Dielectric Property of Epitaxial BiFeO3 Thin Films by Off-axis Magnetron Sputtering [J]. Journal of Inorganic Materials, 2018, 33(9): 1017-1021. |

| [7] | GU Hui. Correlation of Intergranular Amorphous Structures on Multi-levelled Phase Relationship in Sialon Ceramics: Retrospect and Prospect [J]. Journal of Inorganic Materials, 2018, 33(2): 147-152. |

| [8] | WANG Lu, KONG Wen-Jie, LUO Hang, ZHOU Xue-Fan, ZHOU Ke-Chao, ZHANG Dou. Dielectric and Energy Storage Property of Dielectric Nanocomposites with BaTiO3 Nanofibers [J]. Journal of Inorganic Materials, 2018, 33(10): 1059-1064. |

| [9] | ZHENG Jia-Jun, ZHANG Hong-Yan, PAN Meng, LI Biao, ZHANG Qiu, KONG Qing-Lan, LIU Zhi-Ping, LI Rui-Feng. Synthesis of Monolith Hierachical ZSM-5 Zeolite Composed of Nanocrystals by Vapor-phase Transformation Method [J]. Journal of Inorganic Materials, 2015, 30(11): 1161-1166. |

| [10] | XIE Hui, YUAN Shu-Juan, KANG Bao-Juan, LU Bo, CAO Shi-Xun, ZHANG Jin-Cang. Giant Magnetodielectric Effect and Magnetic Properties of Ho0.5Pr0.5FeO3 Ceramics [J]. Journal of Inorganic Materials, 2014, 29(1): 77-80. |

| [11] | LIU Hao, SHEN Chun-Ying, LU Zheng-Dong, QIU Tai. Microwave Dielectric Properties of the (1-x)(Mg0.9Co0.1)TiO3-x(Ca0.61La0.26)TiO3 Ceramics [J]. Journal of Inorganic Materials, 2011, 26(6): 664-668. |

| [12] | ZHAO Li, SHEN Chun-Ying, QIU Tai. Studieson the (1- x)Mg0.7Zn0.3TiO3-xCa0.61La0.26TiO3Microwave Dielectric Ceramics System [J]. Journal of Inorganic Materials, 2011, 26(2): 219-224. |

| [13] | QIN Wen-Feng,XIONG Jie,LI Yan-Rong. Structure and Properties of BST/BZT/BST Multilayer Film [J]. Journal of Inorganic Materials, 2010, 25(3): 247-250. |

| [14] | LU Zheng-Dong,SHEN Chun-Ying,LI Liang,YANG Jian,QIU Tai. Study on the (1-x)(Mg0.7Zn0.3)TiO3-x(Ca0.61Nd0.26)TiO3 Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2010, 25(3): 332-336. |

| [15] | CHU Rui-Qing, HAO Ji-Gong, XU Zhi-Jun, ZANG Guo-Zhong. Preparation and Characterization of (K0.5Na0.5)0.94-2xLi0.06SrxNb0.98Sb0.02O3 Lead-free Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2010, 25(11): 1164-1168. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||