无机材料学报 ›› 2022, Vol. 37 ›› Issue (10): 1051-1057.DOI: 10.15541/jim20220185 CSTR: 32189.14.10.15541/jim20220185

收稿日期:2022-04-03

修回日期:2022-05-15

出版日期:2022-10-20

网络出版日期:2022-05-27

通讯作者:

顾学红, 教授. E-mail: xhgu@njtech.edu.cn作者简介:吕庆洋(1997-), 男, 硕士研究生. E-mail: 201961204185@njtech.edu.cn

基金资助:

LÜ Qingyang( ), ZHANG Yuting, GU Xuehong(

), ZHANG Yuting, GU Xuehong( )

)

Received:2022-04-03

Revised:2022-05-15

Published:2022-10-20

Online:2022-05-27

Contact:

GU Xuehong, professor. E-mail: xhgu@njtech.edu.cnAbout author:LÜ Qingyang (1997-), male, Master candidate. E-mail: 201961204185@njtech.edu.cn

Supported by:摘要:

TiO2膜具有亲水性强和热化学稳定性好等优点而用于超滤分离, 但是TiO2膜以管式膜为主, 渗透通量低且制备周期长。为了提高TiO2膜的渗透通量, 并缩短膜的制备周期, 本工作以钛酸四丁酯为前驱体, 采用超声辅助溶胶-凝胶法制备高通量的中空纤维负载型TiO2超滤膜。系统考察了硝酸与钛酸四丁酯的摩尔比(酸钛比)、超声时间和煅烧温度对TiO2溶胶粒径及膜截留性能的影响。结果表明:当酸钛比为0.25时, 溶胶的平均粒径为3252 nm, 采用超声处理30 s后, 平均粒径减小至1817 nm。采用超声后的溶胶循环涂膜并在350 ℃煅烧两次后可得到完整无缺陷的中空纤维TiO2超滤膜, 膜层平均厚度为1 μm, 膜的纯水渗透通量为145 L·m-2·h-1·bar-1(1 bar=0.1 MPa), 葡聚糖截留分子量为2586 Da, 对应的平均孔径为2.5 nm。

中图分类号:

吕庆洋, 张玉亭, 顾学红. 超声辅助溶胶-凝胶法制备中空纤维TiO2超滤膜[J]. 无机材料学报, 2022, 37(10): 1051-1057.

LÜ Qingyang, ZHANG Yuting, GU Xuehong. Fabrication of Hollow Fiber Supported TiO2 Ultrafiltration Membranes via Ultrasound-assisted Sol-Gel Method[J]. Journal of Inorganic Materials, 2022, 37(10): 1051-1057.

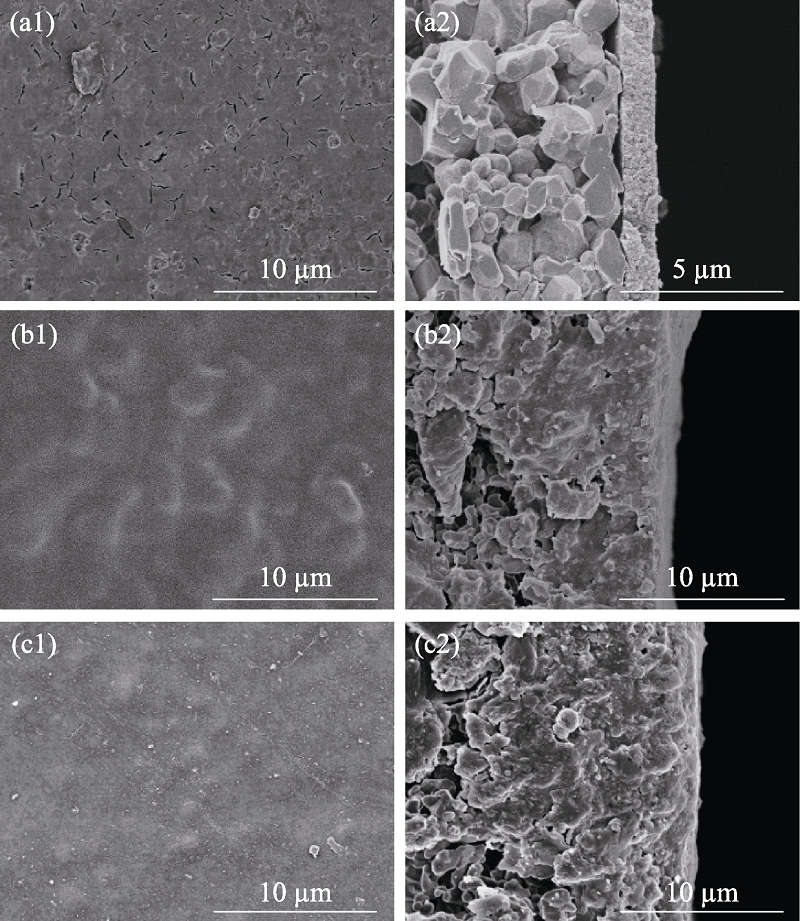

图2 不同酸钛比制备的TiO2膜表面和断面SEM照片

Fig. 2 Surface and cross-section SEM images of TiO2 membranes prepared with different acid/titanium ratios (a1, a2) CM0.25-0-350; (b1, b2) CM0.5-0-350; (c1, c2) CM0.75-0-350

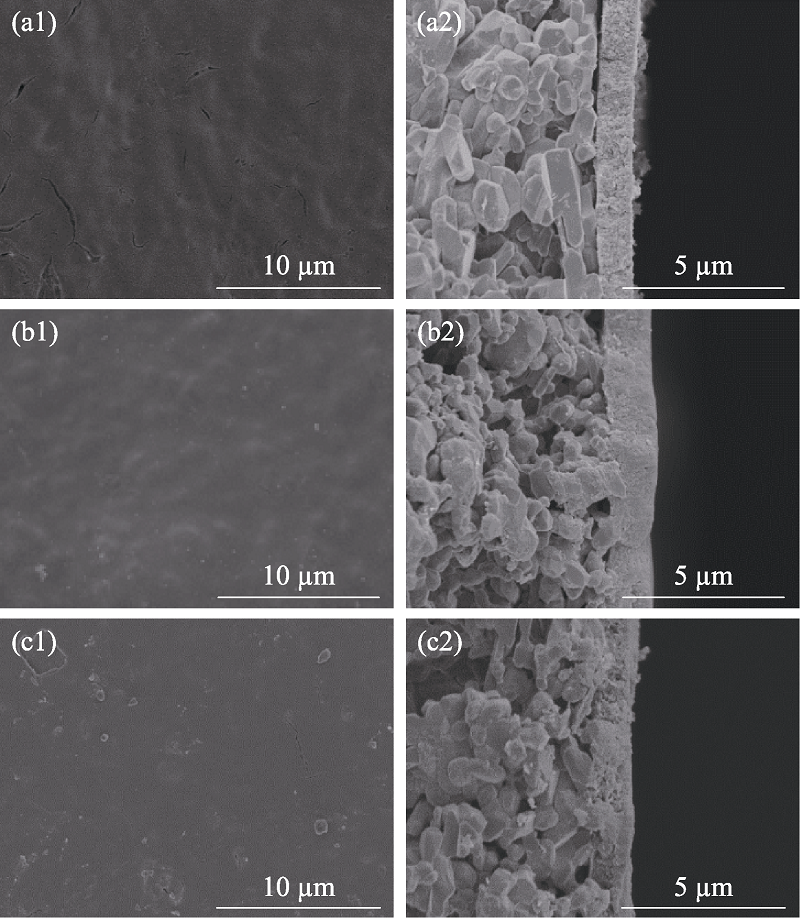

图4 不同超声时间制备的TiO2膜表面及断面SEM照片

Fig. 4 Surface and cross-section SEM images of TiO2 membranes prepared by sonication for different periods (a1, a2) UM0.25-15-350; (b1, b2) UM0.25-30-350; (c1, c2) UM0.25-45-350

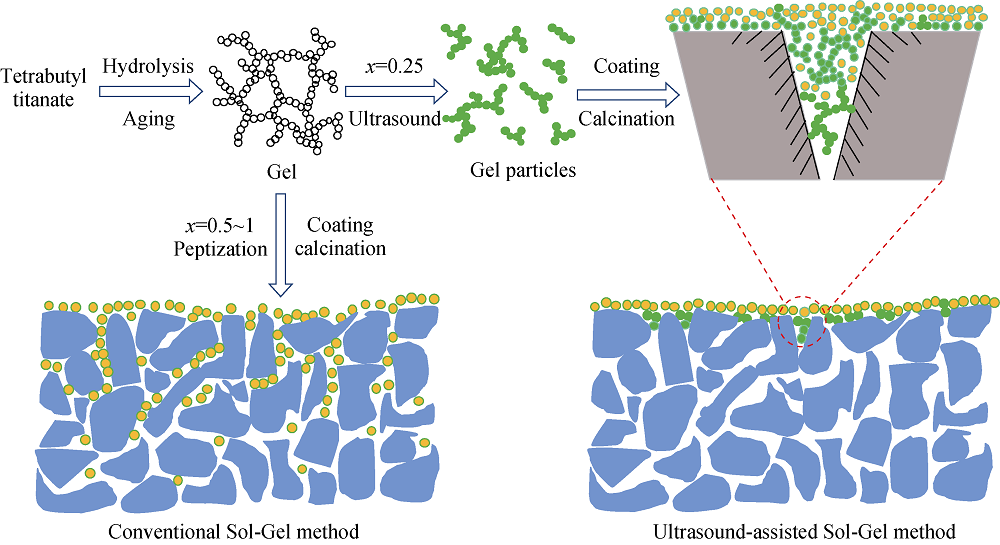

图5 采用常规和超声辅助溶胶-凝胶法制备的TiO2膜成膜机理图

Fig. 5 Schematic diagram of proposed formation mechanism of TiO2 membranes prepared by conventional and ultrasound-assisted Sol-Gel methods

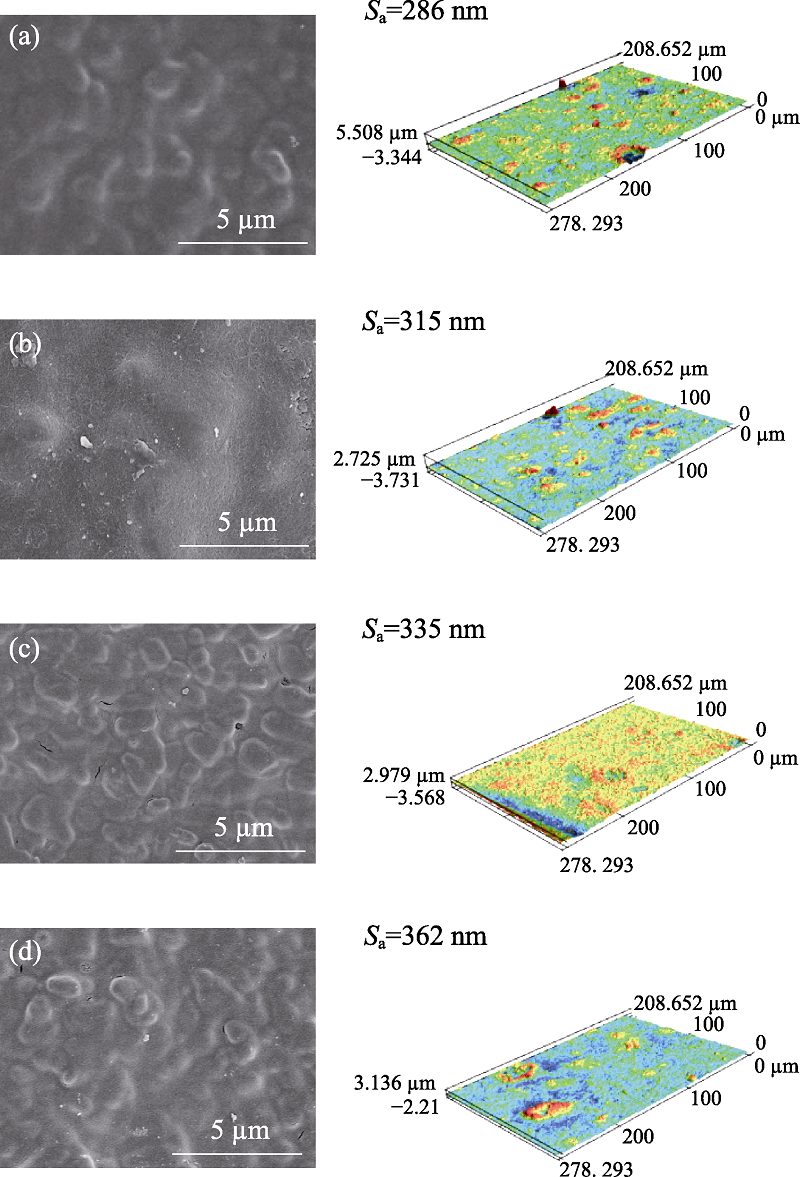

图7 不同温度煅烧得到的TiO2膜表面SEM照片及其3D形貌

Fig. 7 Surface SEM and 3D morphologies of TiO2 membranes calcined at different temperatures (a) UM0.25-30-350; (b) UM0.25-30-400; (c) UM0.25-30-450; (d) UM0.25-30-500

| Membrane | Membrane configuration | Calcination temperature/℃ | Pore size / nm | Thickness/ μm | Coating number | Water flux/ (L·m-2·h-1·bar-1) | MWCO/ Da | Ref. |

|---|---|---|---|---|---|---|---|---|

| P25-TiO2 | Tube | 400 | 3.6 | 2 | 4 | 128 | 5600 | [ |

| MXene-TiO2 | Tube | 400 | 6.5 | 5 | 1 | 90 | 22000 | [ |

| P123-TiO2 | Tube | 400 | 6.1 | 2 | 3 | 7.16 | 19000 | [ |

| CM0.5-0-350 | Hollow fiber | 350 | 4.4 | 5 | 3 | 142 | 9078 | This work |

| UM0.25-30-350 | Hollow fiber | 350 | 2.5 | 1 | 2 | 145 | 2586 | This work |

表1 常规及超声辅助的溶胶-凝胶法与文献中制备的TiO2膜的性能比较

Table 1 Comparison between TiO2 membranes prepared by conventional and ultrasound-assisted sol-gel method

| Membrane | Membrane configuration | Calcination temperature/℃ | Pore size / nm | Thickness/ μm | Coating number | Water flux/ (L·m-2·h-1·bar-1) | MWCO/ Da | Ref. |

|---|---|---|---|---|---|---|---|---|

| P25-TiO2 | Tube | 400 | 3.6 | 2 | 4 | 128 | 5600 | [ |

| MXene-TiO2 | Tube | 400 | 6.5 | 5 | 1 | 90 | 22000 | [ |

| P123-TiO2 | Tube | 400 | 6.1 | 2 | 3 | 7.16 | 19000 | [ |

| CM0.5-0-350 | Hollow fiber | 350 | 4.4 | 5 | 3 | 142 | 9078 | This work |

| UM0.25-30-350 | Hollow fiber | 350 | 2.5 | 1 | 2 | 145 | 2586 | This work |

| [1] |

ZHU B, HU Y X, KENNEDY S, et al. Dual function filtration and catalytic breakdown of organic pollutants in wastewater using ozonation with titania and alumina membranes. Journal of Membrane Science, 2011, 378(1/2): 61-72.

DOI URL |

| [2] | ALVENTOSA E, BARREDO S, ALCAINA M L, et al. Ultrafiltration technology with a ceramic membrane for reactive dye removal: optimization of membrane performance. Journal of Hazard Mater., 2012(209/210): 492-500. |

| [3] |

KOVACS I, VEREB G, KERTESZ S, et al. Fouling mitigation and cleanability of TiO2 photocatalyst-modified PVDF membranes during ultrafiltration of model oily wastewater with different salt contents. Environmental Science and Pollution Research, 2018, 25(35): 34912-34921.

DOI URL |

| [4] |

GASCHI P S, GASCHI P S, BARROS S T, et al. Pretreatment with ceramic membrane microfiltration in the clarification process of sugarcane juice by ultrafiltration. Acta Scientiarum Technology, 2014, 36(2): 303-306.

DOI URL |

| [5] | LEHMAN S G, LIU L. Application of ceramic membranes with pre-ozonation for treatment of secondary wastewater effluent. Water Reseach, 2009, 43(7): 2020-2028. |

| [6] |

KUZNIATSOVA T, MOTTERN M L, SHQAU K, et al. Micro-structural optimization of supported γ-alumina membranes. Journal of Membrane Science, 2008, 316(1/2): 80-88.

DOI URL |

| [7] |

GESTEL T V, KRUIDHOF H, BLANK D H A, et al. ZrO2 and TiO2 membranes for nanofiltration and pervaporation Part 1. Preparation and characterization of a corrosion-resistant ZrO2 nanofiltration membrane with a MWCO<300. Journal of Membrane Science, 2006, 284(1/2): 128-136.

DOI URL |

| [8] |

YACOU C, SMART S, COSTA J C D D. Mesoporous TiO2 based membranes for water desalination and brine processing. Separation and Purification Technology, 2015, 147: 166-171.

DOI URL |

| [9] |

CHOI H, STATHATOS E, DIONYSIOU D D. Sol-Gel preparation of mesoporous photocatalytic TiO2 films and TiO2-Al2O3 composite membranes for environmental applications. Applied Catalysis B: Environmental, 2006, 63: 60-67.

DOI URL |

| [10] |

DOBRAK A, VERRECHT B, DUNGEN H V D, et al. Solvent flux behavior and rejection characteristics of hydrophilic and hydrophobic mesoporous and microporous TiO2 and ZrO2 membranes. Journal of Membrane Science, 2010, 346(2): 344-352.

DOI URL |

| [11] |

GESTEL T V, SEBOLD D, HAULER F, et al. Potentialities of microporous membranes for H2/CO2 separation in future fossil fuel power plants: evaluation of SiO2, ZrO2, Y2O3-ZrO2and TiO2-ZrO2Sol-Gel membranes. Journal of Membrane Science, 2010, 359(1/2): 64-79.

DOI URL |

| [12] |

LI D, WANG H, JING W H, et al. Fabrication of mesoporous TiO2 membranes by a nanoparticle-modified polymeric sol process. Journal of Colloid and Interface Science, 2014, 433: 43-48.

DOI URL |

| [13] | KIM Y S, YANG S M. Preparation of continuous mesoporous silica thin film on a porous tube. Advanced Materials, 2002, 14(15): 1079-1081. |

| [14] |

TSURU T, NARITA M, SHINAGAWA R, et al. Nanoporous titania membranes for permeation and filtration of organic solutions. Desalination, 2008, 233(1/2/3): 1-9.

DOI URL |

| [15] |

XU Z, SUN Y Q, ZHUANG Y X, et al. Assembly of 2D MXene nanosheets and TiO2 nanoparticles for fabricating mesoporous TiO2-MXene membranes. Journal of Membrane Science, 2018, 564: 35-43.

DOI URL |

| [16] |

CABRERA M C C, WALKER G S, GRANT D M. Effect of processing parameters on the particle size and stabilisation of titania sols. Journal of Materials Science, 2005, 40: 3709-3714.

DOI URL |

| [17] |

CAI Y Y, WANG Y, CHEN X F, et al. Modified colloidal Sol-Gel process for fabrication of titania nanofiltration membranes with organic additives. Journal of Membrane Science, 2015, 476: 432-441.

DOI URL |

| [18] |

GESTEL T V, VANDECASTEELE C, BUEKENHOUDT A, et al. Corrosion properties of alumina and titania NF membranes. Journal of Membrane Science, 2003, 214(1): 21-29.

DOI URL |

| [19] |

JING W H, HUANG W, XING W H, et al. Fabrication of supported mesoporous TiO2 membranes:matching the assembled and interparticle pores for an improved ultrafiltration performance. Applied Materials and Interfaces, 2009, 1(7): 1607-1612.

DOI URL |

| [20] |

QIU M H, FAN S, CAI Y Y, et al. Co-sintering synthesis of bi-layer titania ultrafiltration membranes with intermediate layer of sol-coated nanofibers. Journal of Membrane Science, 2010, 365(1/2): 225-231.

DOI URL |

| [21] |

WU L Q, HUANG P, XU N P, et al. Effects of sol properties and calcination on the performance of titania tubular membranes. Journal of Membrane Science, 2000, 173: 263-273.

DOI URL |

| [22] |

WANG P, CHUNG T S. A new-generation asymmetric multi-bore hollow fiber membrane for sustainable water production via vacuum membrane distillation. Environmental Science and Technology, 2013, 47(12): 6272-6278.

DOI URL |

| [23] |

SHI Z Z, ZHANG Y T, CAI C, et al. Preparation and characterization of α-Al2O3 hollow fiber membranes with four- channel configuration. Ceramics International, 2015, 41(1): 1333-1339.

DOI URL |

| [24] |

CAI C, ZHANG Y T, ZHANG C, et al. Microstructure modulation of α-Al2O3hollow fiber membranes with four-channel geometric configuration. Asia-Pacific Journal of Chemical Engineering, 2016, 11(6): 949-957.

DOI URL |

| [25] |

DING X B, FAN Y Q, XU N P. A new route for the fabrication of TiO2 ultrafiltration membranes with suspension derived from a wet chemical synthesis. Journal of Membrane Science, 2006, 270(1/2): 179-186.

DOI URL |

| [26] |

WHU J A, BALTZIS B C, SIRKAR K K. Nanofiltration studies of larger organic microsolutes in methanol solutions. Journal of Membrane Science, 2000, 170: 159-172.

DOI URL |

| [27] |

ALVES A K, BERUTTI F A, BERGMANN C P. The effects of pH on the preparation of alumina by Sol-Gel process. Particulate Science and Technology, 2005, 23(4): 351-360.

DOI URL |

| [28] |

TSURU T, OGAWA K, KANEZASHI M, et al. Permeation characteristics of electrolytes and neutral solutes through titania nanofiltration membranes at high temperatures. Langmuir, 2010, 26(13): 10897-10905.

DOI PMID |

| [29] |

SKLUZACEK J M, ISABEL T M, MARC A A. Influence of membrane support structure on the efficiency of an iron-modified silica nanofiltration membrane. Journal of Porous Materials, 2007, 15(3): 303-309.

DOI URL |

| [30] |

ZASPALIS V T, PRAAG W V, KEIZER K, et al. Synthesis and characterization of primary alumina, titania and binary membranes. Journal of Materials Science, 1992, 27: 1023-1035.

DOI URL |

| [1] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [2] | 袁利萍, 吴袁泊, 俞佳静, 张世琰, 孙铱, 胡云楚, 范友华. 磷钼酸插层水滑石复合CNFs气凝胶的制备及其隔热保温性能[J]. 无机材料学报, 2025, 40(4): 415-424. |

| [3] | 马彬彬, 钟婉菱, 韩涧, 陈椋煜, 孙婧婧, 雷彩霞. ZIF-8/TiO2复合介观晶体的制备及光催化活性[J]. 无机材料学报, 2024, 39(8): 937-944. |

| [4] | 叶梓滨, 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江. 阳极支撑型锥管串接式直接碳固体氧化物燃料电池组的制备及性能[J]. 无机材料学报, 2024, 39(7): 819-827. |

| [5] | 沈斌, 张旭, 熊怀, 李海元, 谢兴龙. 溶胶-凝胶SiO2减反膜的制备与光学性能研究[J]. 无机材料学报, 2024, 39(5): 525-530. |

| [6] | 孔剑锋, 黄杰成, 刘兆林, 林存生, 王治宇. 基于DPEPA聚合物凝胶电解质的准固态钠离子电池[J]. 无机材料学报, 2024, 39(12): 1331-1338. |

| [7] | 戴乐, 刘洋, 高轩, 王书豪, 宋雅婷, 唐明猛, 刘丽莎, 汪尧进. 浓度梯度掺杂实现BiFeO3薄膜自极化[J]. 无机材料学报, 2024, 39(1): 99-106. |

| [8] | 郭宇翔, 黄立强, 王刚, 王宏志. 双锂盐凝胶复合电解质的制备及其在锂金属电池中的应用[J]. 无机材料学报, 2023, 38(7): 785-792. |

| [9] | 张祥松, 刘业通, 王永瑛, 武子瑞, 刘振中, 李毅, 杨娟. 自组装制备PtIr合金气凝胶及其高效电催化氨氧化性能[J]. 无机材料学报, 2023, 38(5): 511-520. |

| [10] | 刘文龙, 赵瑾, 刘娟, 毛小建, 章健, 王士维. 微波干燥自发凝固成型氧化铝湿坯[J]. 无机材料学报, 2023, 38(4): 461-468. |

| [11] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [12] | 贾玉娜, 曹旭, 焦秀玲, 陈代荣. 无机酸铝体系氧化铝连续纤维的制备技术研究[J]. 无机材料学报, 2023, 38(11): 1257-1264. |

| [13] | 贾鑫, 李晋宇, 丁世豪, 申倩倩, 贾虎生, 薛晋波. Pd纳米颗粒协同氧空位增强TiO2光催化CO2还原性能[J]. 无机材料学报, 2023, 38(11): 1301-1308. |

| [14] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [15] | 王晓俊, 许文, 刘润路, 潘辉, 朱申敏. 水凝胶负载的纳米银/氮化碳光催化剂的制备及性能研究[J]. 无机材料学报, 2022, 37(7): 731-740. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||