无机材料学报 ›› 2024, Vol. 39 ›› Issue (6): 662-670.DOI: 10.15541/jim20230557 CSTR: 32189.14.10.15541/jim20230557

所属专题: 【结构材料】陶瓷基复合材料(202506)

收稿日期:2023-12-04

修回日期:2024-01-19

出版日期:2024-06-20

网络出版日期:2024-01-22

通讯作者:

傅正义, 教授. E-mail: zyfu@whut.edu.cn;作者简介:孙海洋(1999-), 男, 硕士研究生. E-mail: sunhaiyang@whut.edu.cn

基金资助:

SUN Haiyang( ), JI Wei(

), JI Wei( ), WANG Weimin, FU Zhengyi(

), WANG Weimin, FU Zhengyi( )

)

Received:2023-12-04

Revised:2024-01-19

Published:2024-06-20

Online:2024-01-22

Contact:

FU Zhengyi, professor. E-mail: zyfu@whut.edu.cn;About author:SUN Haiyang (1999-), male, Master candidate. E-mail: sunhaiyang@whut.edu.cn

Supported by:摘要:

高性能结构材料部件在航空航天、交通汽车、电子信息、冶金等领域具有重要的应用价值, 得到了广泛研究。增强结构材料部件整体性能的方法主要包括材料本征性能提升和结构复合设计优化, 但提高单一结构材料的本征力学性能的研究已接近极限。本研究旨在提出周期序构结构材料的理念, 并采用一体化烧结制备出整体性能更好的结构复合材料, 从而探索高性能结构复合材料发展的新范式。通过周期序构化的设计, 构建了兼具陶瓷高硬度和金属强韧性的TiB-Ti功能单元, 设计制备了不同周期序构模式的TiB-Ti高性能结构复合材料。在此基础上, 对这些结构进行了力学性能研究, 并通过分析其断裂模式来探究不同序构模式对材料整体性能的影响。结果表明, 周期序构化可以通过改变材料宏观断裂模式和应力分散特性来提高材料的整体性能。这一研究新范式对其他结构复合材料的结构设计和性能突破具有指导和借鉴意义。对周期序构模式的复杂化探索, 对周期序构结构材料的应用场景探索和其他性能测试研究也将是未来需要重点关注的问题。

中图分类号:

孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670.

SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units[J]. Journal of Inorganic Materials, 2024, 39(6): 662-670.

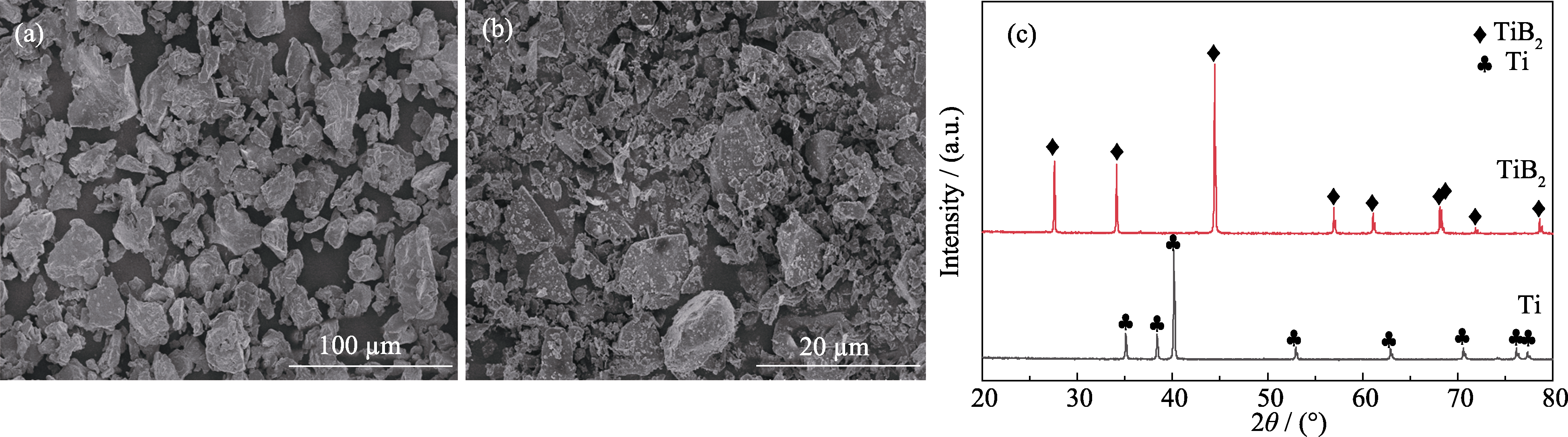

图1 原料的形貌和相组成

Fig. 1 Morphologies and phase compositions of raw materials (a, b) Microstructures of (a) Ti powder and (b) TiB2powder; (c) XRD patterns of Ti and TiB2powders

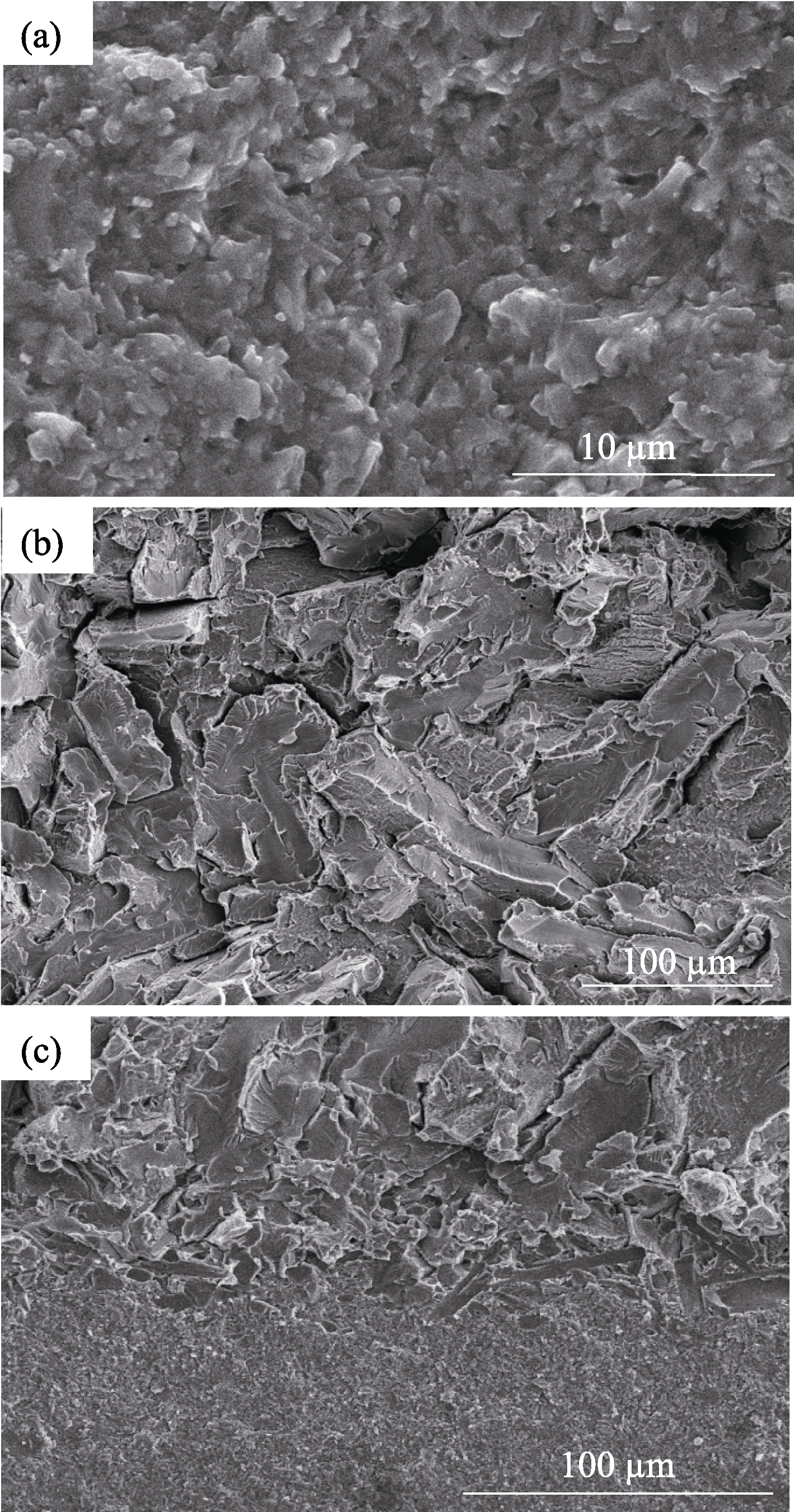

图4 SPS制备的TiB-Ti复合材料的断口微观形貌

Fig. 4 Fractural microstructures of TiB-Ti composites prepared by SPS (a) TiB fracture surface; (b) Ti fracture surface; (c) Two-phase interface fracture

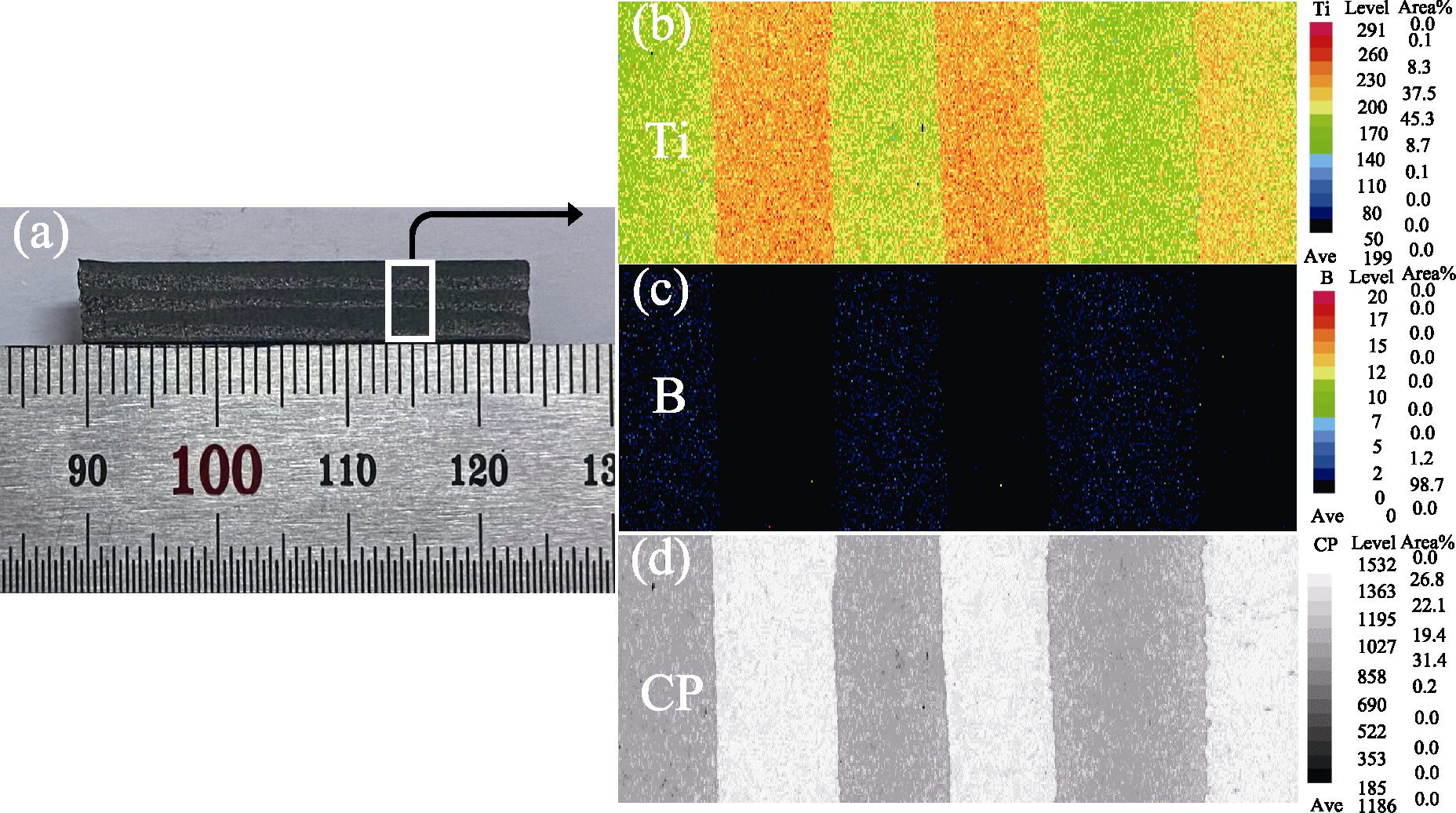

图5 EPMA测试的TiB-Ti周期序构复合材料ababab截面上元素的分布图

Fig. 5 Distribution of elements on ababab section of TiB-Ti periodic ordered composite tested by EPMA (a) Sample selection photo; (b) Ti element distribution; (c) B element distribution; (d) Backscattered electron (BSE) image

| Parameter | TiB | Ti |

|---|---|---|

| Density/(g·cm-3) | 4.56 | 4.50 |

| E/GPa | 370 | 110 |

| KIC/(MPa·m1/2) | 6.1 | 29.3 |

| Bending strength/MPa | 489.95 | 238.32 |

| Compressive strength/MPa | 1035.43 | 1596.26 |

| Hardness/GPa | 20.0 | 1.7 |

表1 TiB陶瓷和Ti金属材料的力学参数

Table1 Mechanical properties of TiB ceramic and Ti metal materials

| Parameter | TiB | Ti |

|---|---|---|

| Density/(g·cm-3) | 4.56 | 4.50 |

| E/GPa | 370 | 110 |

| KIC/(MPa·m1/2) | 6.1 | 29.3 |

| Bending strength/MPa | 489.95 | 238.32 |

| Compressive strength/MPa | 1035.43 | 1596.26 |

| Hardness/GPa | 20.0 | 1.7 |

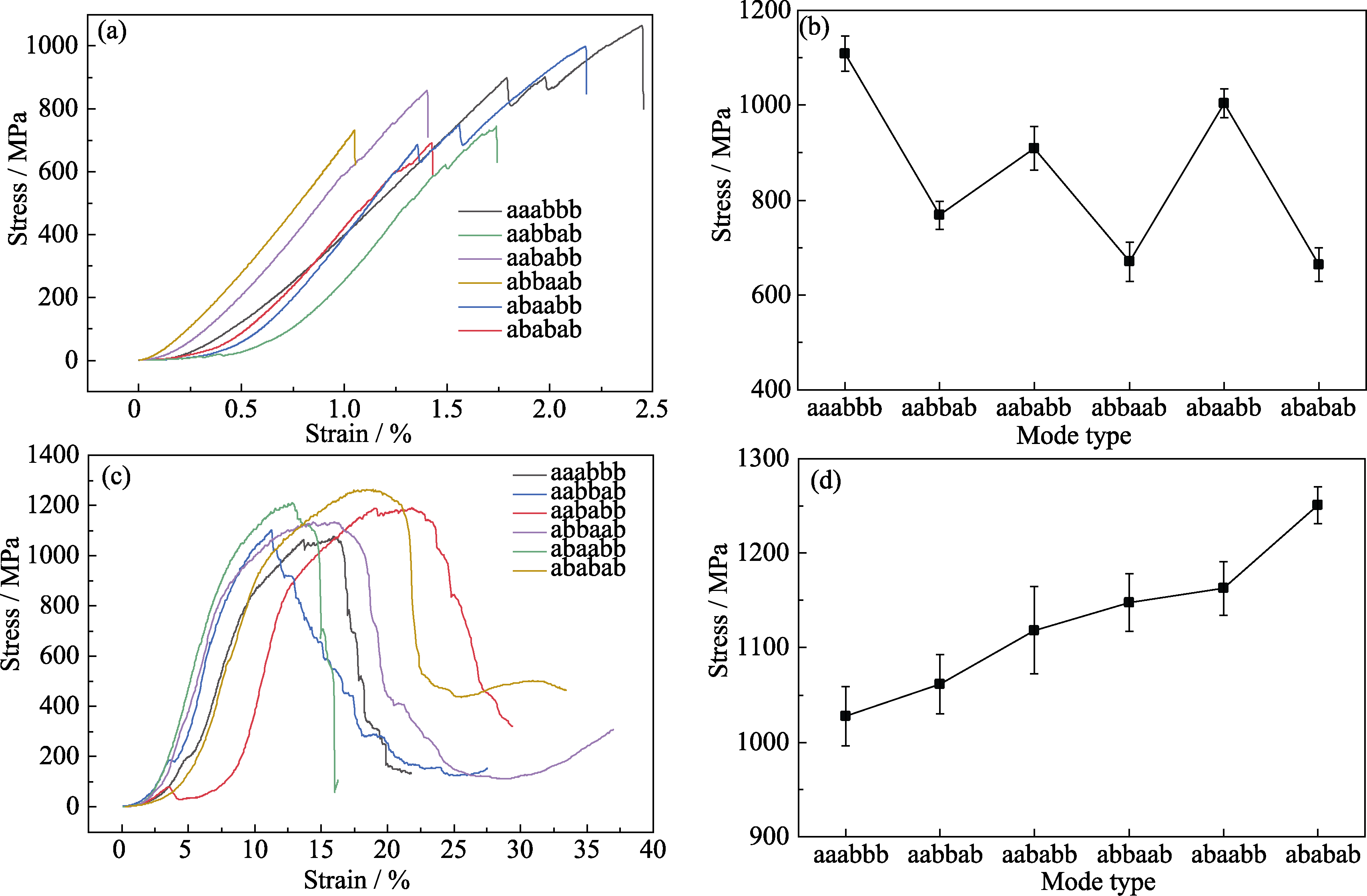

图7 六种TiB-Ti周期序构复合材料的力学性能

Fig. 7 Mechanical properties of six TiB-Ti periodic ordered composites (a) Bending strength stress-strain curves; (b) Bending strength line chart; (c) Compressive strength stress-strain curves; (d) Compressive strength line chart; Colorful figures are available on website

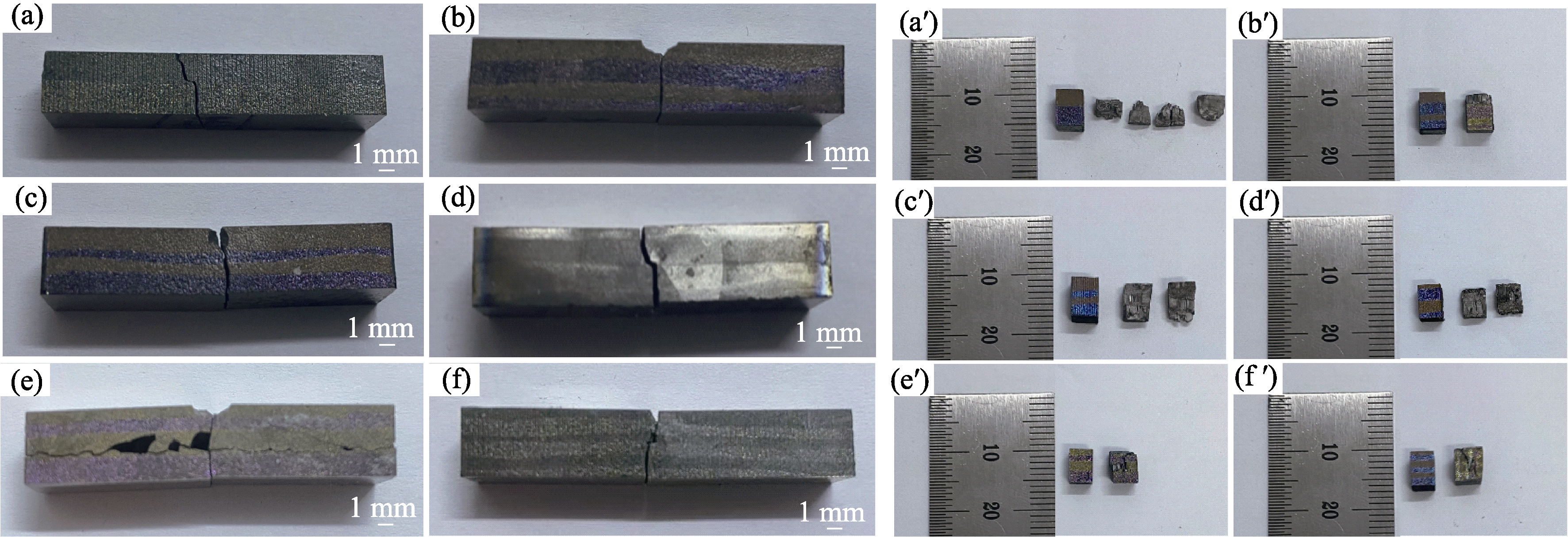

图8 六种TiB-Ti周期序构复合材料的三点抗弯试样宏观裂纹形貌(a~f)和压缩试样破坏形貌(a'~f')

Fig. 8 Macro-cracked morphologies (a-f) and fracture appearances (a'-f') of six TiB-Ti periodic ordered composite bending samples and compressed samples (a, a') aaabbb; (b, b') aabbab; (c, c') aababb; (d, d') abbaab; (e, e') abaabb; (f, f') ababab

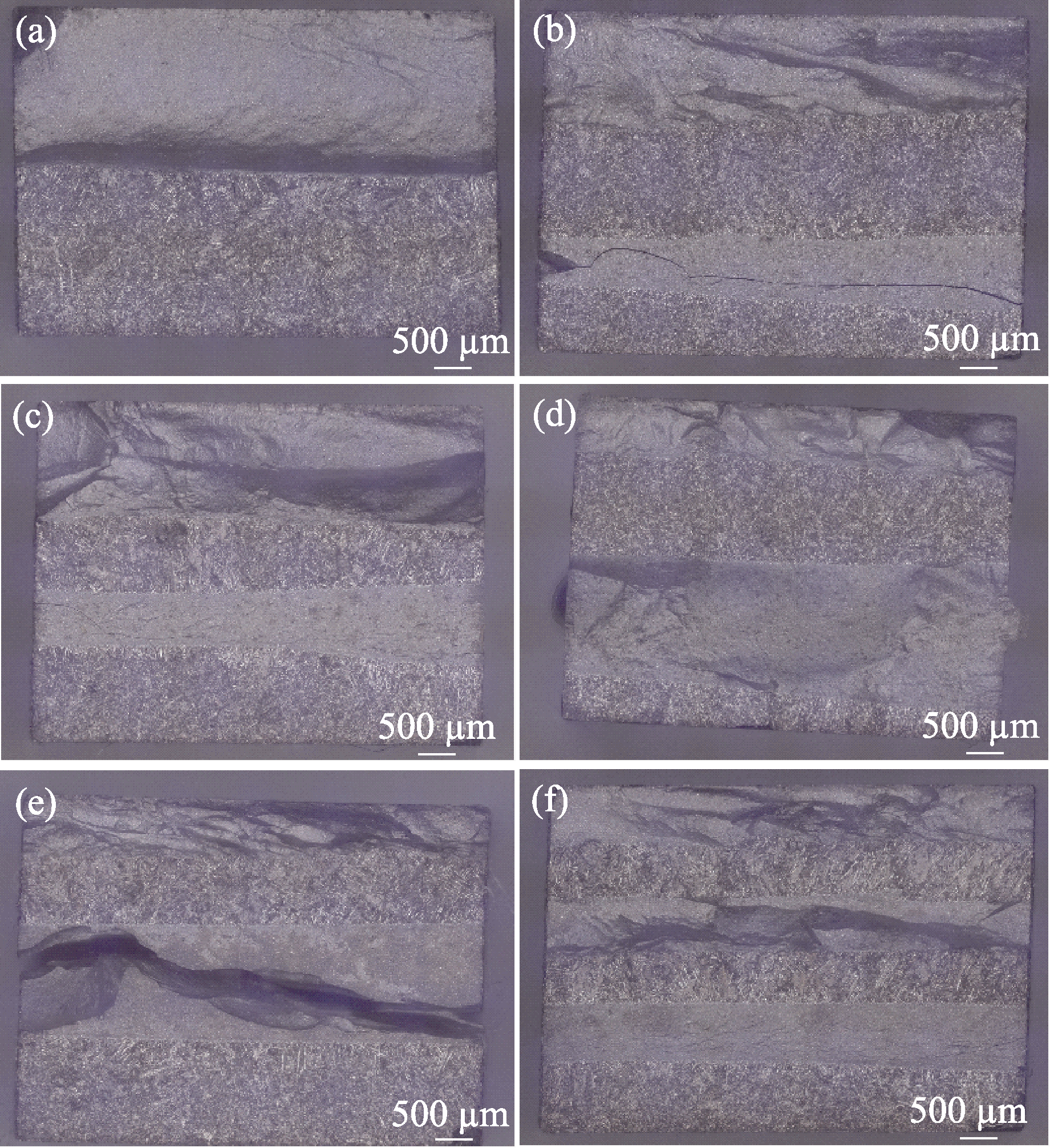

图9 六种TiB-Ti周期序构复合材料的三点抗弯试样宏观断口形貌

Fig. 9 Macro fracture morphologies of six TiB-Ti periodic ordered composite bending samples (a) aaabbb; (b) aabbab; (c) aababb; (d) abbaab; (e) abaabb; (f) ababab

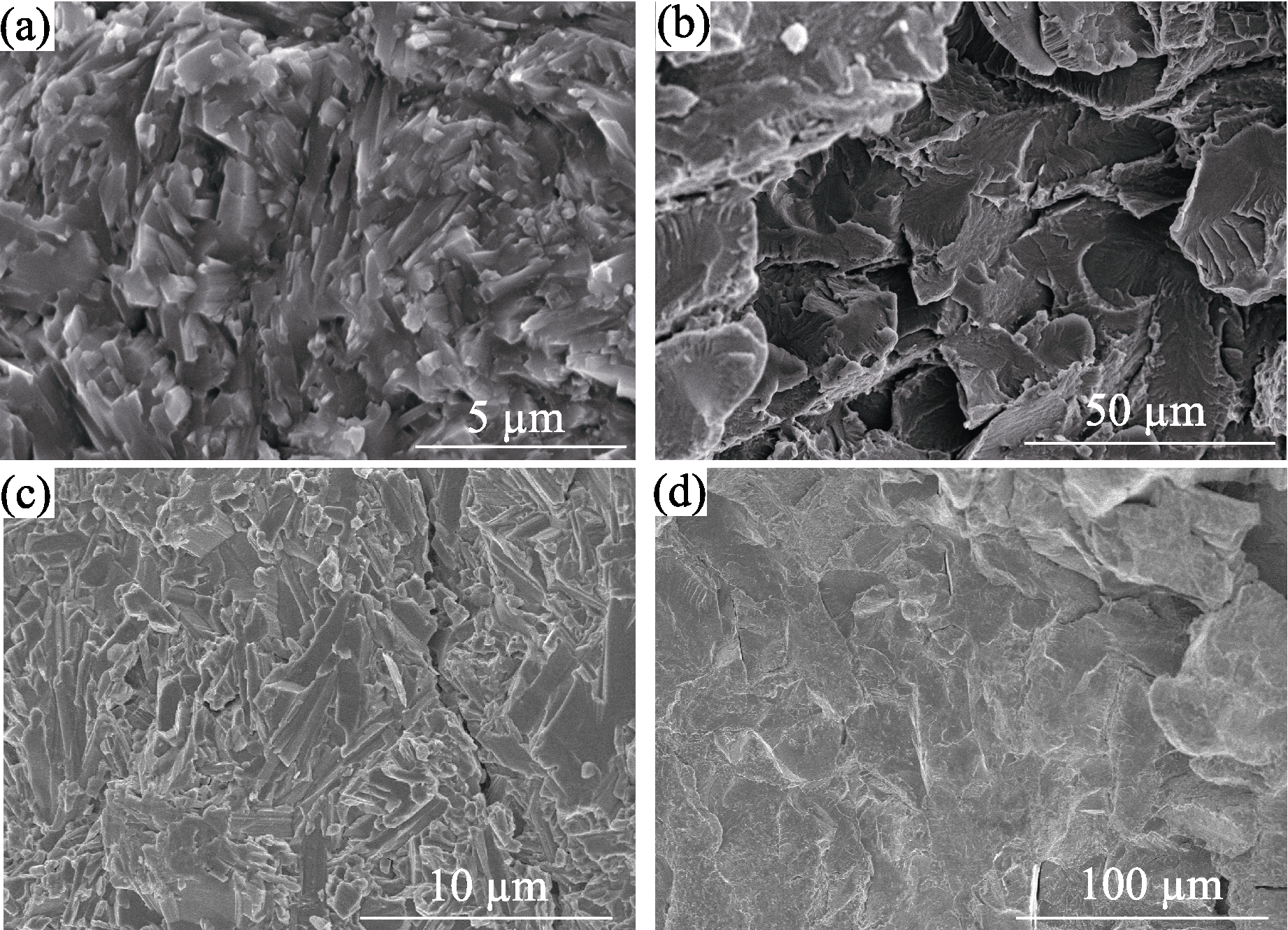

图11 TiB-Ti周期序构复合材料的抗弯微观断口形貌(a, b)和压缩显微断口形貌(c, d)

Fig. 11 Microscopic fracture morphologies of TiB-Ti periodic ordered composite bending samples (a, b) and compressed samples (c, d) (a, c) TiB layer; (b, d) Ti layer

| [1] | OYA T, TIESLER N, KAWANISHI S, et al. Experimental and numerical analysis of multilayered steel sheets upon bending. Journal of Materials Processing Technology, 2010, 210(14): 1926. |

| [2] | GO Y H, CHO J, JEONG C Y, et al. Stress distribution of bulk metallic glass/metal laminate composites during uni-axial fracture. Materials Science and Engineering A, 2007, 460/461: 377. |

| [3] | AGHDAM M M, KAMALIKHAH A. Micromechanical analysis of layered systems of MMCs subjected to bending-effects of thermal residual stresses. Composite Structures, 2004, 66(1-4):563. |

| [4] | KUO, D H; KRIVEN, W M. Fracture of multilayer oxide composites. Materials Science and Engineering: A, 1998, 241(1):241. |

| [5] | LUO W, YAN S, ZHOU J. Ceramic-based dielectric metamaterials. Interdisciplinary Materials, 2022, 1(1):11. |

| [6] | LUO J. Computing grain boundary “phase” diagrams. Interdisciplinary Materials, 2023, 2(1):137. |

| [7] | EAST D, GIBSON M A, LIANG D, et al. Production and mechanical properties of roll bonded bulk metallic glass/aluminum laminates. Metallurgical and Materials Transaction A, 2013, 44(5): 2010. |

| [8] | CARREÑO F, CHAO J, POZUELO M, et al. Microstructure and fracture properties of an ultrahigh carbon steel-mild steel laminated composite. Scripta Materialia, 2003, 48(8):1135. |

| [9] | SYN C K, LESUER D R, SHERBY O D. Enhancing tensile ductility of a particulate-reinforced aluminum metal matrix composite by lamination with Mg-9%Li alloy. Materials Science and Engineering, 1996, 206(2):201. |

| [10] | OHASHI Y, WOLFENSTINE J, KOCH J, et al. Fracture behavior of a laminated steel-brass composite in bend tests. Materials Science and Engineering, 1992, 151(1):37. |

| [11] | SMITH D J, ZUO Y Q, PARTRIDGE P G, et al. Bend stiffness and strength of laminates composed of titanium alloy and titanium metal matrix composite. Materials Science and Technology, 1997, 13(1):35. |

| [12] | LIU B X, HUANG L J, GENG L, et al. Fabrication and superior ductility of laminated Ti-(TiBw/Ti) composites by diffusion welding. Journal of Alloys and Compounds, 2014, 602: 187. |

| [13] | LIU B X, HUANG L J, GENG L, et al. Gradient grain distribution and enhanced properties of novel laminated TiTiBw/Ti composites by reaction hot-pressing. Materials Science and Engineering: A, 2014, 595: 257. |

| [14] | LIU B X, HUANG LJ, GENG L, et al. Microstructure and tensile behavior of novel laminated Ti-TiBw/Ti composites by reaction hot pressing. Materials Science and Engineering A, 2013, 583: 182. |

| [15] | GUPTA N, MUKHOPADHYAY A, PAVANI K, et al. Spark plasma sintering of novel ZrB2-SiC-TiSi2 composites with better mechanical properties. Materials Science and Engineering: A, 2012, 534: 111. |

| [16] | MALIK P, KADOLI R. Thermo-elastic response of SUS316-Al2O3 functionally graded beams under various heat loads. International Journal of Mechanical Sciences, 2017, 128: 206. |

| [17] | KHOA N D, THIEM H T, DUC N D. Nonlinear buckling and postbuckling of imperfect piezoelectric S-FGM circular cylindrical shells with metal-ceramic-metal layers in thermal environment using Reddy’s third-order shear deformation shell theory. Mechanics of Advanced Materials and Structures, 2019, 26(3):248. |

| [18] | FENG H B, JIA D C, ZHOU Y. Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites. Composites Part A: Applied Science and Manufacturing, 2005, 36(5):558. |

| [19] | 神祥博, 张朝晖, 王富耻, 等. 放电等离子烧结法制备 TiB 陶瓷刀具材料的显微结构和力学性能. 模具制造, 2010, 10(12):92. |

| [20] | NAMBU S, MICHIUCHI M, INOUE J, et al. Effect of interfacial bonding strengthon tensile ductility of multilayered steel composites. Composites Science and Technology, 2009, 69(11/12): 1936. |

| [21] | WADGAONKAR S C, PARAMESWARAN V. Structure of near-tip stress field and variation of stress intensity factor for a crack in a transversely graded material. Journal of Applied Mechanics, 2009, 76(1):011014. |

| [22] | KIDANE A, ADDIS A. Quasi-static and dynamic fracture initiation toughness of Ti/TiB layered functionally graded material under thermo-mechanical loading. Engineering Fracture Mechanics, 2010, 77(3):479. |

| [23] | LIU B X, HUANG L J, GENG L, et al. Fracture behaviors and micro-structural failure mechanisms of laminated Ti-TiBw/Ti composites. Material Science and Engineering: A, 2014; 611: 290. |

| [24] | HAN Y F, DUAN H Q, LU W J, et al. Fabrication and characterization of laminated Ti-(TiB+La2O3)/Ti composite. Progress in Natural Science: Materials International, 2015, 25(5):453. |

| [25] | LIU B X, HUANG L J, GENG L. Elastic and plastic behaviors of laminated Ti-TiBw/Ti composites. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2015, 30(3):596. |

| [26] | KOSEKI T, INOUE J, NAMBU S. Development of multilayer steels for improved combinations of high strength and high ductility. Materials Transactions, 2014, 55(2):227. |

| [27] | STEIF P S. Bimaterial interface instabilities in plastic solids. International Journal of Solids and Structures, 1986, 22(2):195. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [3] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [4] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [5] | 杨舒琪, 杨存国, 牛慧祝, 石唯一, 舒珂维. GeP3/科琴黑复合材料作为钠离子电池高性能负极材料[J]. 无机材料学报, 2025, 40(3): 329-336. |

| [6] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [7] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [8] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [9] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [10] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [11] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [12] | 王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38. |

| [13] | 全文心, 余艺平, 方冰, 李伟, 王松. 管状C/SiC复合材料高温空气氧化行为与宏细观建模研究[J]. 无机材料学报, 2024, 39(8): 920-928. |

| [14] | 何思哲, 王俊舟, 张勇, 费嘉维, 吴爱民, 陈意峰, 李强, 周晟, 黄昊. 高频低损耗的Fe/亚微米FeNi软磁复合材料[J]. 无机材料学报, 2024, 39(8): 871-878. |

| [15] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||