无机材料学报 ›› 2021, Vol. 36 ›› Issue (10): 1031-1038.DOI: 10.15541/jim20200690 CSTR: 32189.14.10.15541/jim20200690

汤嘉伟1( ), 王永邦1,2, 马成1, 杨海潇1, 王际童1, 乔文明1(

), 王永邦1,2, 马成1, 杨海潇1, 王际童1, 乔文明1( ), 凌立成1

), 凌立成1

收稿日期:2020-12-01

修回日期:2021-02-22

出版日期:2021-10-20

网络出版日期:2021-03-12

通讯作者:

乔文明, 教授. E-mail: qiaowm@ecust.edu.cn

作者简介:汤嘉伟(1996-), 男, 硕士研究生. E-mail: 15216726632@163.com

基金资助:

TANG Jiawei1( ), WANG Yongbang1,2, MA Cheng1, YANG Haixiao1, WANG Jitong1, QIAO Wenming1(

), WANG Yongbang1,2, MA Cheng1, YANG Haixiao1, WANG Jitong1, QIAO Wenming1( ), LING Licheng1

), LING Licheng1

Received:2020-12-01

Revised:2021-02-22

Published:2021-10-20

Online:2021-03-12

Contact:

QIAO Wenming, professor. E-mail: qiaowm@ecust.edu.cn

About author:TANG Jiawei (1996-), male, Master candidate. E-mail: 15216726632@163.com

Supported by:摘要:

以1-甲基萘热溴化/脱溴聚合沥青为前驱体, 中孔二氧化硅SBA-15为模板, 采用液相浸渍法合成有序中孔炭。通过不同测试手段对中孔炭的微观结构和电化学性能进行了研究。当模板剂和沥青质量比为1:1, 升温速率为 1 ℃·min-1, 碳化温度为900 ℃时, 所制备的中孔炭性能最优, 具有高度有序的二维六方孔道结构, 比表面积为675 m2·g-1, 孔容为1 cm3·g-1, 孔径集中在3.84 nm左右。该中孔炭用于Li-S电池的正极载体材料表现出良好的电化学性能, 在0.2C(1C=1675 mA·g-1)电流密度下经300次循环后放电比容量和容量保持率分别为688 mAh·g-1和67.1%, 在3C电流密度下比容量可达556 mAh·g-1。

中图分类号:

汤嘉伟, 王永邦, 马成, 杨海潇, 王际童, 乔文明, 凌立成. 甲基萘沥青基有序中孔炭的制备及电化学性能[J]. 无机材料学报, 2021, 36(10): 1031-1038.

TANG Jiawei, WANG Yongbang, MA Cheng, YANG Haixiao, WANG Jitong, QIAO Wenming, LING Licheng. Methylnaphthalene Pitch-based Ordered Mesoporous Carbon: Synthesis and Electrochemical Properties[J]. Journal of Inorganic Materials, 2021, 36(10): 1031-1038.

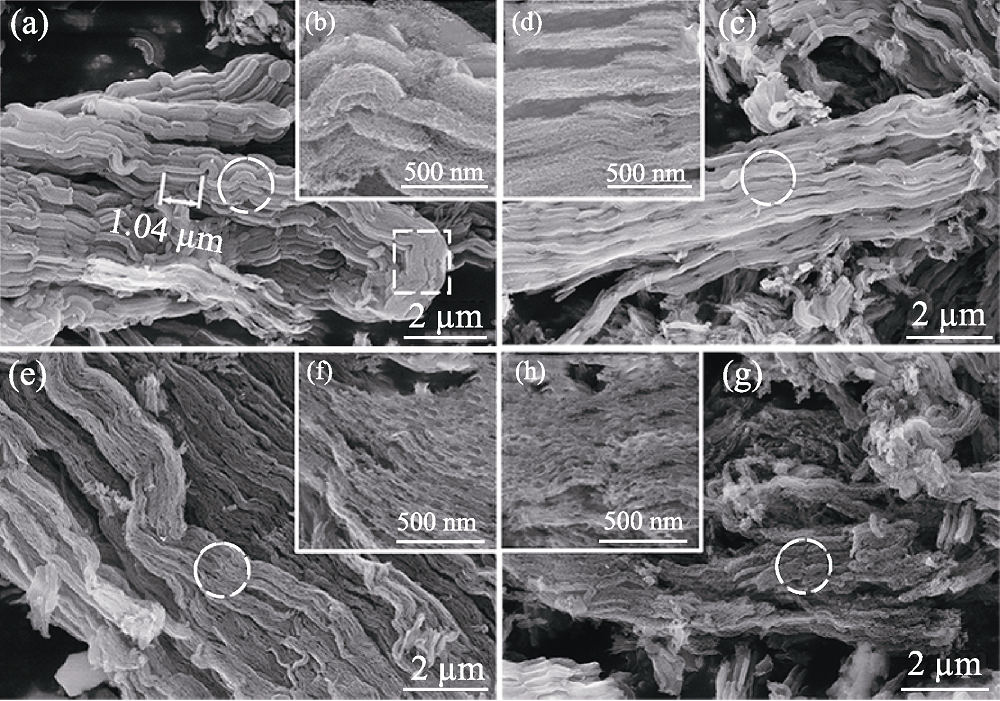

图1 模板剂和沥青质量比为(a, b)0.6、(c, d)0.8、(e, f)1.0和(g, h)1.2时所制中孔炭的SEM照片

Fig. 1 SEM images of mesoporous carbon obtained at template/pitch mass ratios of (a, b) 0.6, (c, d) 0.8, (e, f) 1.0, and (g, h) 1.2

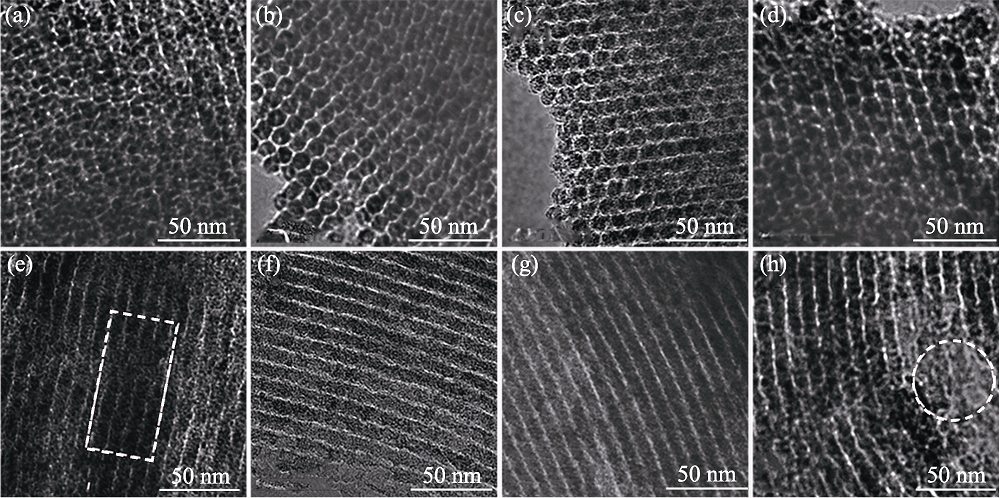

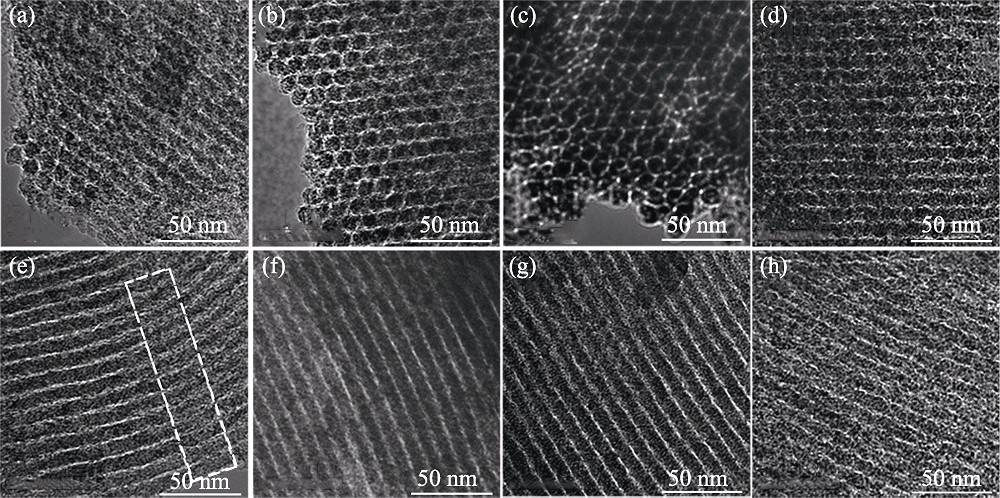

图2 模板剂和沥青质量比为(a, e)0.6、(b, f)0.8、(c, g)1.0和(d, h)1.2时所制中孔炭沿(a~d) [100]和(e~h) [001]晶向的TEM照片

Fig. 2 TEM images of mesoporous carbon along (a-d) [100] and (e-h) [001] orientations obtained at template/pitch mass ratios of (a, e) 0.6, (b, f) 0.8, (c, g) 1.0 and (d, h) 1.2

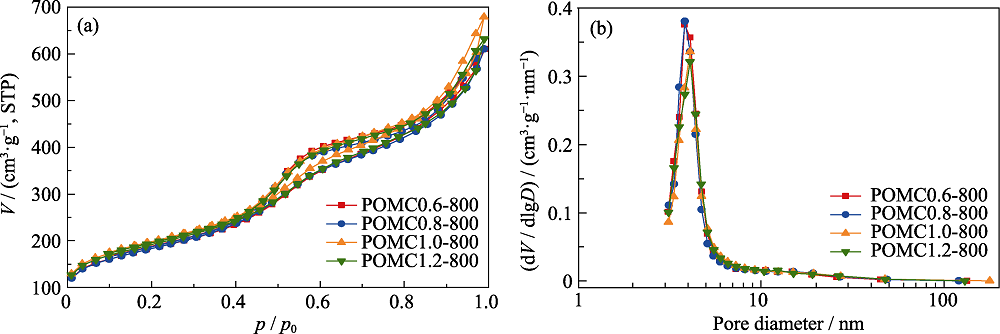

图3 不同SBA-15添加量时中孔炭的(a)氮气吸脱附等温线及(b)BJH孔径分布图

Fig. 3 (a) N2 adsorption-desorption isotherms and (b) BJH pore size distributions of mesoporous carbon obtained from various addition amounts of SBA-15

| Sample | SBET/(m2·g-1) | Vtotal/(cm3·g-1) | Davea/nm | d100b/nm | a0c/nm | Wall thicknessd/nm |

|---|---|---|---|---|---|---|

| SBA-15e | 488 | 1.24 | 8.31 | 10.23 | 11.81 | 3.50 |

| POMC0.6-800 | 654 | 0.94 | 3.84 | 9.71 | 11.21 | 7.37 |

| POMC0.8-800 | 653 | 0.94 | 3.85 | 9.71 | 11.21 | 7.36 |

| POMC1.0-800 | 703 | 1.05 | 4.11 | 9.48 | 10.95 | 6.84 |

| POMC1.2-800 | 684 | 0.98 | 4.10 | 8.73 | 10.08 | 5.98 |

| POMC1.0-800-F | 681 | 0.93 | 3.85 | 8.72 | 10.07 | 6.22 |

| POMC1.0-700 | 749 | 1.16 | 4.12 | 9.46 | 10.92 | 6.80 |

| POMC1.0-900 | 675 | 1.00 | 3.84 | 9.28 | 10.72 | 6.88 |

| POMC1.0-1000 | 676 | 0.95 | 3.85 | 8.71 | 10.06 | 6.21 |

表1 在不同工艺条件下所制备中孔炭的孔结构参数

Table 1 Porous structural parameters of mesoporous carbon obtained under different process conditions

| Sample | SBET/(m2·g-1) | Vtotal/(cm3·g-1) | Davea/nm | d100b/nm | a0c/nm | Wall thicknessd/nm |

|---|---|---|---|---|---|---|

| SBA-15e | 488 | 1.24 | 8.31 | 10.23 | 11.81 | 3.50 |

| POMC0.6-800 | 654 | 0.94 | 3.84 | 9.71 | 11.21 | 7.37 |

| POMC0.8-800 | 653 | 0.94 | 3.85 | 9.71 | 11.21 | 7.36 |

| POMC1.0-800 | 703 | 1.05 | 4.11 | 9.48 | 10.95 | 6.84 |

| POMC1.2-800 | 684 | 0.98 | 4.10 | 8.73 | 10.08 | 5.98 |

| POMC1.0-800-F | 681 | 0.93 | 3.85 | 8.72 | 10.07 | 6.22 |

| POMC1.0-700 | 749 | 1.16 | 4.12 | 9.46 | 10.92 | 6.80 |

| POMC1.0-900 | 675 | 1.00 | 3.84 | 9.28 | 10.72 | 6.88 |

| POMC1.0-1000 | 676 | 0.95 | 3.85 | 8.71 | 10.06 | 6.21 |

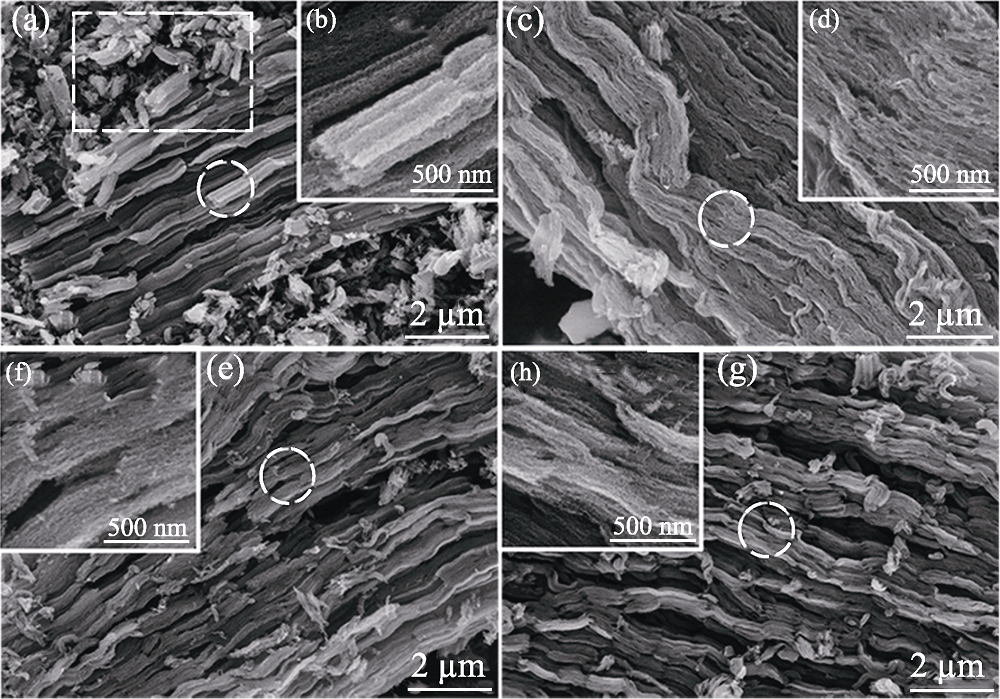

图7 碳化温度为(a, b)700、(c, d)800、(e, f)900和(g, h)1000 ℃时所制中孔炭的SEM照片

Fig. 7 SEM images of mesoporous carbon obtained under carbonization temperatures of (a, b) 700, (c, d) 800, (e, f) 900 and (g, h) 1000 ℃

图8 碳化温度为(a, e) 700、(b, f) 800、(c, g) 900和(d, h) 1000 ℃时所制中孔炭的TEM照片

Fig. 8 TEM images of mesoporous carbon obtained under carbonization temperatures of (a, e) 700, (b, f) 800, (c, g) 900 and (d, h) 1000 ℃

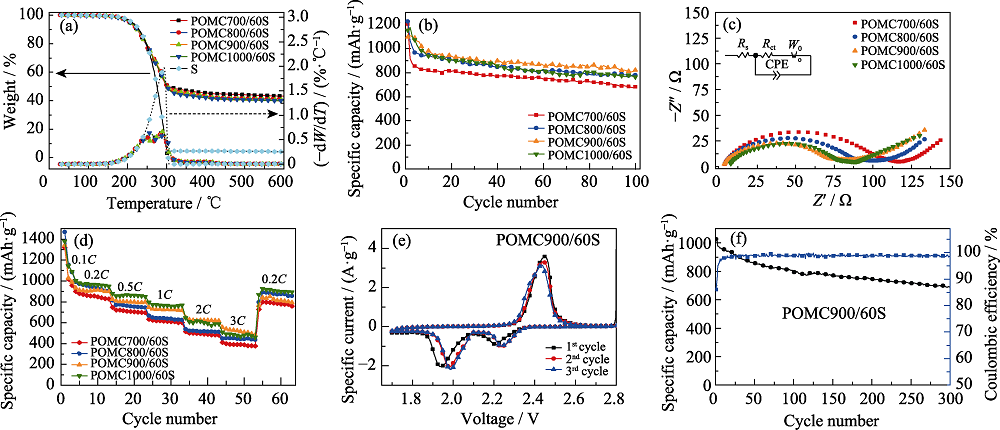

图9 POMCt/60S的(a)热失重曲线、(b)0.2C下的循环性能、(c)交流阻抗谱和(d)倍率性能, POMC900/60S的(e)CV曲线和(f)0.2C下的长循环稳定性

Fig. 9 (a) TG and DTG curves, (b) cycling performance at 0.2C rate, (c) EIS spectra and (d) rate performance of sample POMCt/60S, (e) CV curves and (f) long cycling performance at 0.2C rate of sample POMC900/60S

| Elemental analysis/wt% | SPa/℃ | CYb/wt% | Solubility/wt% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | Br(diff.) | H/C | TS | TI-THFS | THFI-QS | QI | ||

| 93.65 | 4.63 | 1.72 | 0.59 | 278 | 56.3 | 89.8 | 6.9 | 3.3 | 0 |

表S1 甲基萘沥青T290的一般物性参数

Table S1 General physical properties of methylnaphthalene pitch T290

| Elemental analysis/wt% | SPa/℃ | CYb/wt% | Solubility/wt% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | Br(diff.) | H/C | TS | TI-THFS | THFI-QS | QI | ||

| 93.65 | 4.63 | 1.72 | 0.59 | 278 | 56.3 | 89.8 | 6.9 | 3.3 | 0 |

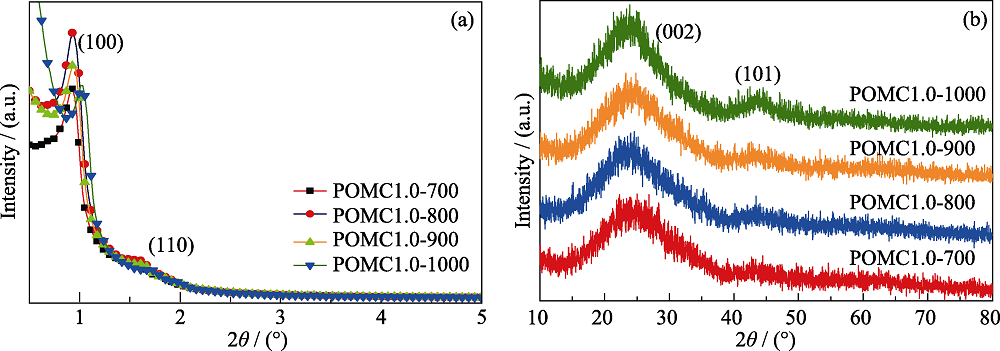

图S3 不同碳化温度所制中孔炭的(a)小角和(b)广角XRD谱图

Fig. S3 XRD patterns of mesoporous carbon prepared under various carbonization temperatures in the (a) low-angle and (b) wide-angle regions

| Pitch | Aliphatic carbons/% | Aromatic carbons/% | fa | |||

|---|---|---|---|---|---|---|

| CH3a | CH2b | Cchainc | Car1d | Car2e | ||

| T290 | 2.31 | 3.09 | 7.83 | 59.49 | 27.28 | 0.87 |

表S2 甲基萘沥青T290的脂肪碳和芳香碳的分布

Table S2 Distributions of aliphatic and aromatic carbons in methylnaphthalene pitch T290

| Pitch | Aliphatic carbons/% | Aromatic carbons/% | fa | |||

|---|---|---|---|---|---|---|

| CH3a | CH2b | Cchainc | Car1d | Car2e | ||

| T290 | 2.31 | 3.09 | 7.83 | 59.49 | 27.28 | 0.87 |

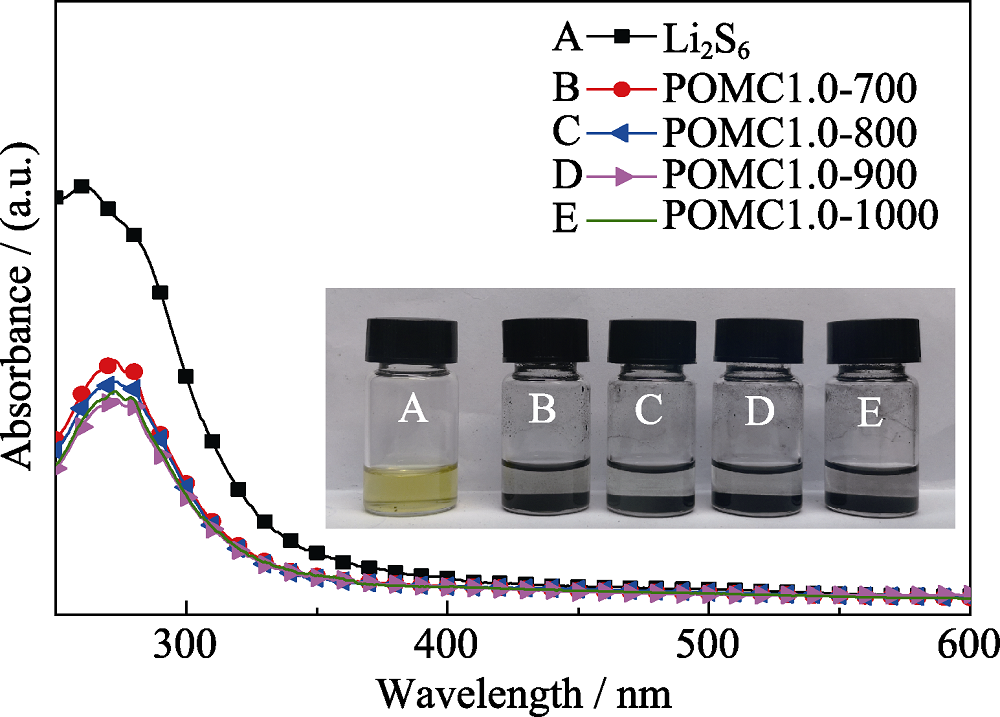

图S6 加入不同碳化温度所制中孔炭前后Li2S6溶液的紫外-可见吸收光谱图(插图为加入中孔炭2 h后的照片)

Fig. S6 UV-Vis absorption spectra of the Li2S6 solution before and after adding POMC prepared under various carbonization temperatures (inset: digital image of pure Li2S6 solution and Li2S6 solutions after adding POMC for 2 h)

| Carbon-based sulfur host | Precursor | Sulfur content /wt% | Initial capacity /(mAh·g-1) | Retention | Rate performance /(mAh·g-1) | Ref. |

|---|---|---|---|---|---|---|

| Hierarchical structure ordered mesoporous carbon | Phenolic resin | 60 | 1138 at 0.1C | ~70% after 80 cycles | 761 at 2.7C | [ |

| Core-shell structure ordered meso@microporous carbon | Sucrose | 60 | 1037 at 0.5C | ~81% after 200 cycles | 605 at 2C | [ |

| Hierarchical microporous-mesoporous carbon | Phenolic resin | 60 | 939 at 0.3C | ~78% after 150 cycles | 561 at 2C | [ |

| Mesoporous hollow carbon | Petroleum pitch | 70 | 1071 at 0.5C | ~91% after 100 cycles | 450 at 3C | [ |

| Ordered mesoporous carbon | Methylnaphthalene pitch | 60 | 1095 at 0.2C | ~78% after 100 cycles | 651 at 2C, 556 at 3C | This work |

表S3 甲基萘沥青基中孔炭与同类用于锂硫电池的碳基载体材料的电化学性能对比

Table S3 Comparison of electrochemical performance of POMC with similar carbon hosts for Li-S batteries

| Carbon-based sulfur host | Precursor | Sulfur content /wt% | Initial capacity /(mAh·g-1) | Retention | Rate performance /(mAh·g-1) | Ref. |

|---|---|---|---|---|---|---|

| Hierarchical structure ordered mesoporous carbon | Phenolic resin | 60 | 1138 at 0.1C | ~70% after 80 cycles | 761 at 2.7C | [ |

| Core-shell structure ordered meso@microporous carbon | Sucrose | 60 | 1037 at 0.5C | ~81% after 200 cycles | 605 at 2C | [ |

| Hierarchical microporous-mesoporous carbon | Phenolic resin | 60 | 939 at 0.3C | ~78% after 150 cycles | 561 at 2C | [ |

| Mesoporous hollow carbon | Petroleum pitch | 70 | 1071 at 0.5C | ~91% after 100 cycles | 450 at 3C | [ |

| Ordered mesoporous carbon | Methylnaphthalene pitch | 60 | 1095 at 0.2C | ~78% after 100 cycles | 651 at 2C, 556 at 3C | This work |

| [1] |

WU Z X, ZHAO D Y. Ordered mesoporous materials as adsorbents. Chem. Commun., 2011, 47(12):3332-3338.

DOI URL |

| [2] |

XU X T, TAN H B, WANG Z M, et al. Extraordinary capacitive deionization performance of highly-ordered mesoporous carbon nano-polyhedra for brackish water desalination. Environ. Sci.: Nano, 2019, 6(3):981-989.

DOI URL |

| [3] |

NAUSHAD M, AHAMAD T, ALMASWARI B M, et al. Nickel ferrite bearing nitrogen-doped mesoporous carbon as efficient adsorbent for the removal of highly toxic metal ion from aqueous medium. Chem. Eng. J., 2017, 330:1351-1360.

DOI URL |

| [4] |

RAFIEE M, KARIMI B, SHIRMOHAMMADI H. Graphitized nitrogen-doped ordered mesoporous carbon derived from ionic liquid; catalytic performance toward ORR. Electrocatalysis, 2018, 9(5):632-639.

DOI URL |

| [5] |

WANG Y, ZHANG J S, WANG X C, et al. Boron- and fluorine-containing mesoporous carbon nitride polymers: metal- free catalysts for cyclohexane oxidation. Angew. Chem. Int. Ed., 2010, 49(19):3356-3359.

DOI URL |

| [6] |

GUO B K, WANG X Q, FULVIO P F, et al. Soft-templated mesoporous carbon-carbon nanotube composites for high performance lithium-ion batteries. Adv. Mater., 2011, 23(40):4661-4666.

DOI URL |

| [7] |

LIN T Q, CHEN I, LIU F X, et al. Nitrogen-doped mesoporous carbon of extraordinary capacitance for electrochemical energy storage. Science, 2015, 350(6267):1508-1513.

DOI URL |

| [8] |

SCHUSTER J, HE G, MANDLMEIER B, et al. Spherical ordered mesoporous carbon nanoparticles with high porosity for lithium- sulfur batteries. Angew. Chem. Int. Ed., 2012, 51(15):3591-3595.

DOI URL |

| [9] |

WU M B, AI P P, TAN M H, et al. Synthesis of starch-derived mesoporous carbon for electric double layer capacitor. Chem. Eng. J., 2014, 245:166-172.

DOI URL |

| [10] |

ZHI J, ZHAO W, LIU X Y, et al. Highly conductive ordered mesoporous carbon based electrodes decorated by 3D graphene and 1D silver nanowire for flexible supercapacitor. Adv. Funct. Mater., 2014, 24(14):2013-2019.

DOI URL |

| [11] |

HADOUN H, SADAOUI Z, SOUAMI N, et al. Characterization of mesoporous carbon prepared from date stems by H3PO4 chemical activation. Appl. Surf. Sci., 2013, 280:1-7.

DOI URL |

| [12] |

ZHU H W, JING Y K, PAL M, et al. Mesoporous TiO2@N-doped carbon composite nanospheres synthesized by the direct carbonization of surfactants after Sol-Gel process for superior lithium storage. Nanoscale, 2017, 9(4):1539-1546.

DOI URL |

| [13] |

HEROU S, RIBADENEYRA M C, MADHU R, et al. Ordered mesoporous carbons from lignin: a new class of biobased electrodes for supercapacitors. Green Chem., 2019, 21(3):550-559.

DOI URL |

| [14] |

BRANDIELE R, PICELLI L, PILOT R, et al. Nitrogen and sulfur doped mesoporous carbons, prepared from templating silica, as interesting material for supercapacitors. ChemistrySelect, 2017, 2(24):7082-7090.

DOI URL |

| [15] |

XU B, PENG L, WANG G Q, et al. Easy synthesis of mesoporous carbon using nano-CaCO3 as template. Carbon, 2010, 48(8):2377-2380.

DOI URL |

| [16] |

BENZIGAR M R, TALAPANENI S N, JOSEPH S, et al. Recent advances in functionalized micro and mesoporous carbon materials: synthesis and applications. Chem. Soc. Rev., 2018, 47(8):2680-2721.

DOI URL |

| [17] |

EFTEKHARI A, FAN Z Y. Ordered mesoporous carbon and its applications for electrochemical energy storage and conversion. Mater. Chem. Front., 2017, 1(6):1001-1027.

DOI URL |

| [18] |

HONG Z Q, LI J X, ZHANG F. Synthesis of magnetically graphitic mesoporous carbon from hard templates and its application in the adsorption treatment of traditional Chinese medicine wastewater. Acta Phys.-Chim. Sin., 2013, 29(3):590-596.

DOI URL |

| [19] |

MA T Y, LIU L, YUAN Z Y. Direct synthesis of ordered mesoporous carbons. Chem. Soc. Rev., 2013, 42(9):3977-4003.

DOI URL |

| [20] |

CAO L, KRUK M. A family of ordered mesoporous carbons derived from mesophase pitch using ordered mesoporous silicas as templates. Adsorption, 2010, 16(4):465-472.

DOI URL |

| [21] |

ZHANG X L, ZHONG C H, LIN Q L, et al. Facile fabrication of graphitic mesoporous carbon with ultrathin walls from petroleum asphalt. J. Anal. Appl. Pyrol., 2017, 126:154-157.

DOI URL |

| [22] |

ENTERRIA M, FIGUEIREDO J L. Nanostructured mesoporous carbons: tuning texture and surface chemistry. Carbon, 2016, 108:79-102.

DOI URL |

| [23] |

GAO Q, QU F Y, ZHENG W T, et al. A simple method to synthesize graphitic mesoporous carbon materials with different structures. J. Porous Mat., 2013, 20(4):983-988.

DOI URL |

| [24] |

PENG X M, HU F P, DAI H L, et al. Study of the adsorption mechanisms of ciprofloxacin antibiotics onto graphitic ordered meso- porous carbons. J. Taiwan Inst. Chem. E., 2016, 65:472-481.

DOI URL |

| [25] | XIE R L, ZONG Z M, LIU F J, et al. Nitrogen-doped porous carbon foams prepared from mesophase pitch through graphitic carbon nitride nanosheet templates. RSC Adv., 2015, 5(57):45718-45724. |

| [26] | GE C Z. Synthesis, Structure and Properties of High Performance Synthetic Pitch and Mesophase Pitch. Shanghai: PhD dissertation of East China University of Science and Technology, 2016. |

| [27] | SUN F G, WHANG J T, LONG D H, et al. A high-rate lithium-sulfur battery assisted by nitrogen-enriched mesoporous carbons decorated with ultrafine La2O3 nanoparticles. J. Mater. Chem. A, 2013, 1(42):13283-13289. |

| [28] |

HSIEH P Y, WIDEGREN J A, SLIFKA A J, et al. Direct measurement of trace polycyclic aromatic hydrocarbons in diesel fuel with 1H and 13C NMR spectroscopy: effect of PAH content on fuel lubricity. Energ. Fuel, 2015, 29(7):4289-4297.

DOI URL |

| [29] |

GE C, YANG H, MIYAWAKI J, et al. Synthesis and characterization of high-softening-point methylene-bridged pitches by visible light irradiation assisted free-radical bromination. Carbon, 2015, 95:780-788.

DOI URL |

| [30] |

CHEN S R, ZHAI Y P, XU G L, et al. Ordered mesoporous carbon/sulfur nanocomposite of high performances as cathode for lithium-sulfur battery. Electrochimica Acta, 2011, 56(26):9549-9555.

DOI URL |

| [31] |

LI Z, JIANG Y, YUAN L X, et al. A highly ordered meso@microporous carbon-supported sulfur@smaller sulfur core-shell structured cathode for Li-S batteries. ACS Nano, 2014, 8(9):9295-9303.

DOI URL |

| [32] |

LI D, HAN F, WANG S, et al. High sulfur loading cathodes fabricated using peapodlike, large pore volume mesoporous carbon for lithium-sulfur battery. ACS Appl. Mater. Inter., 2013, 5(6):2208-2213.

DOI URL |

| [33] |

NIU S Z, WU S D, LU W, et al. A one-step hard-templating method for the preparation of a hierarchical microporous- mesoporous carbon for lithium-sulfur batteries. New Carbon Mater., 2017, 32(4):289-296.

DOI URL |

| [34] |

JAYAPRAKASH N, SHEN J, MOGANTY S S, et al. Porous hollow carbon@sulfur composites for high-power lithium-sulfur batteries. Angew. Chem. Int. Ed., 2011, 50(26):5904-5908.

DOI URL |

| [1] | 王新玲, 周娜, 田亚文, 周明冉, 韩静茹, 申远升, 胡执一, 李昱. SnS2/ZIF-8衍生二维多孔氮掺杂碳纳米片复合材料的锂硫电池性能研究[J]. 无机材料学报, 2023, 38(8): 938-946. |

| [2] | 李婷婷, 张阳, 陈加航, 闵宇霖, 王久林. 锂硫电池S@pPAN正极用柔性黏结剂研究[J]. 无机材料学报, 2022, 37(2): 182-188. |

| [3] | 李高然, 李红阳, 曾海波. 硼基材料在锂硫电池中的研究进展[J]. 无机材料学报, 2022, 37(2): 152-162. |

| [4] | 张文君, 赵雪莹, 吕江维, 曲有鹏. 中空有序介孔有机硅的研究进展: 制备及在肿瘤治疗中的应用[J]. 无机材料学报, 2022, 37(11): 1192-1202. |

| [5] | 金高尧, 何海传, 吴杰, 张梦源, 李亚娟, 刘又年. 锂硫电池正极用钴掺杂空心多孔碳载体材料[J]. 无机材料学报, 2021, 36(2): 203-209. |

| [6] | 蒋浩,吴淏,侯成义,李耀刚,肖茹,张青红,王宏志. 切割方向对桦木衍生的取向微通道生物质炭锂硫电池隔膜性能的影响[J]. 无机材料学报, 2020, 35(6): 717-723. |

| [7] | 王佳宁, 靳俊, 温兆银. α-MoC1-x纳米晶富集碳球修饰隔膜对锂硫电池性能的影响[J]. 无机材料学报, 2020, 35(5): 532-540. |

| [8] | 李亚东, 李伟平, 王琴, 郑道光, 王建新. 碳纤维支撑柔性碳硫复合电极的制备、物性及电池性能研究[J]. 无机材料学报, 2019, 34(4): 373-378. |

| [9] | 王宇晖, 靳 俊, 郭战胜, 温兆银. 锂硫电池循环过程中变形演化的直接观测[J]. 无机材料学报, 2017, 32(3): 247-251. |

| [10] | 柴二亚, 潘俊安, 袁国龙, 程豪, 安峰, 谢淑红. 聚苯胺包覆蛋白石页岩/硫复合材料的制备及其电化学性能[J]. 无机材料学报, 2017, 32(11): 1165-1170. |

| [11] | 杨书廷, 闫 崇, 曹朝霞, 史梦姣, 李艳蕾, 尹艳红. 以荷叶制备多级孔碳硫复合正极材料及性能研究[J]. 无机材料学报, 2016, 31(2): 135-140. |

| [12] | 马国强, 温兆银, 王清松, 靳 俊, 吴相伟, 张敬超. CeO2纳米晶的添加对锂硫电池电化学性能的影响[J]. 无机材料学报, 2015, 30(9): 913-918. |

| [13] | 陈飞彪, 王英男, 吴伯荣, 熊云奎, 廖维林, 吴 锋, 孙 喆. 锂硫电池石墨烯/硫复合正极材料的制备及其电化学性能[J]. 无机材料学报, 2014, 29(6): 627-632. |

| [14] | 胡菁菁, 李国然, 高学平. 锂/硫电池的研究现状、问题及挑战[J]. 无机材料学报, 2013, 28(11): 1181-1186. |

| [15] | 陈 龙, 刘景东, 张诗群. 负载ZnS的介孔炭复合硫正极材料的制备及性能研究[J]. 无机材料学报, 2013, 28(10): 1127-1131. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||